Method for packaging micro electromechanical systems microphone

a micro electromechanical system and microphone technology, applied in the field of methods, can solve the problems of difficult manufacturing of ecms, inability to manufacture ecms with surface mount technology, and conventional method takes a lot of time on packaging mems microphones, so as to save production time and cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

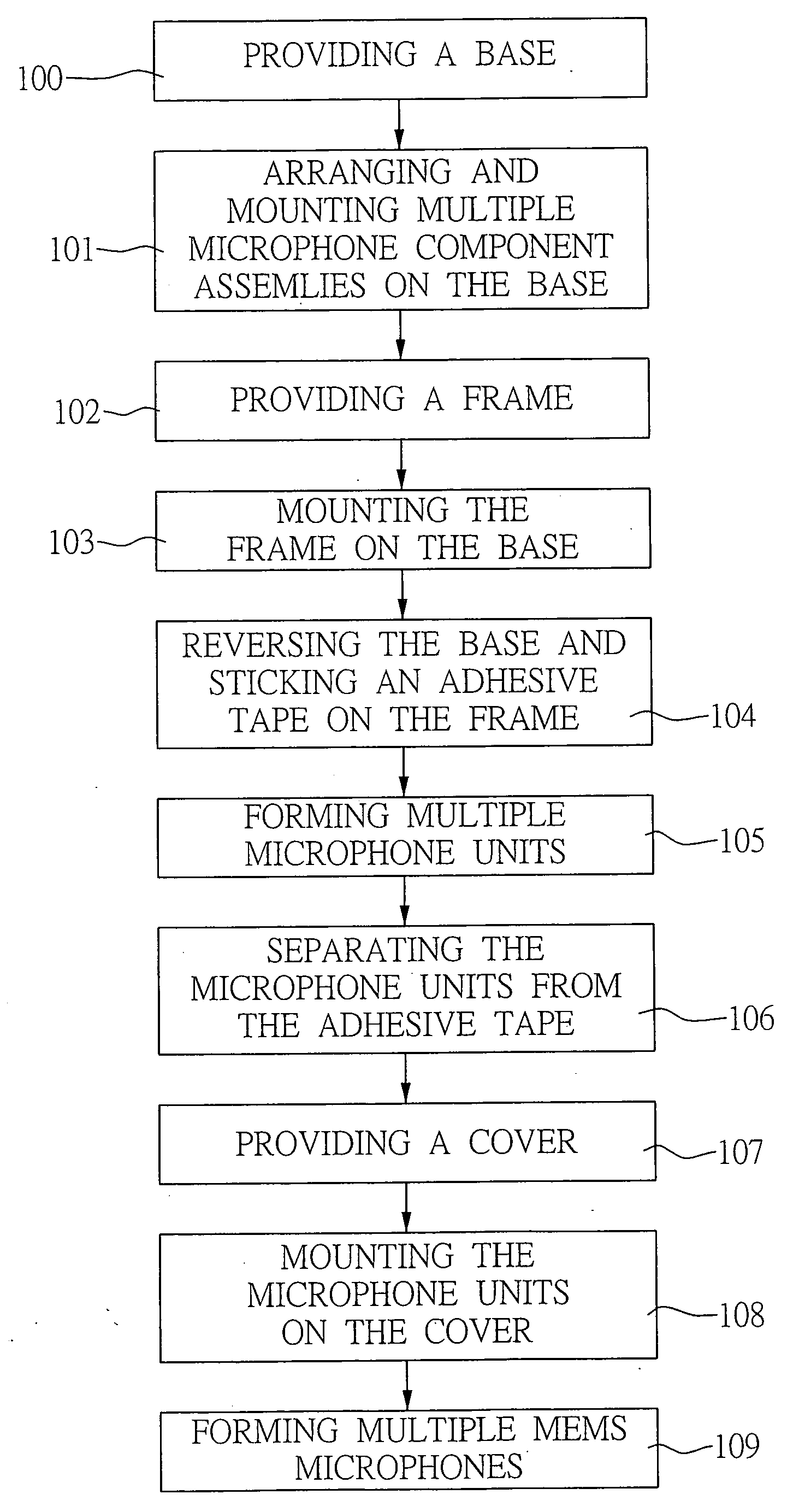

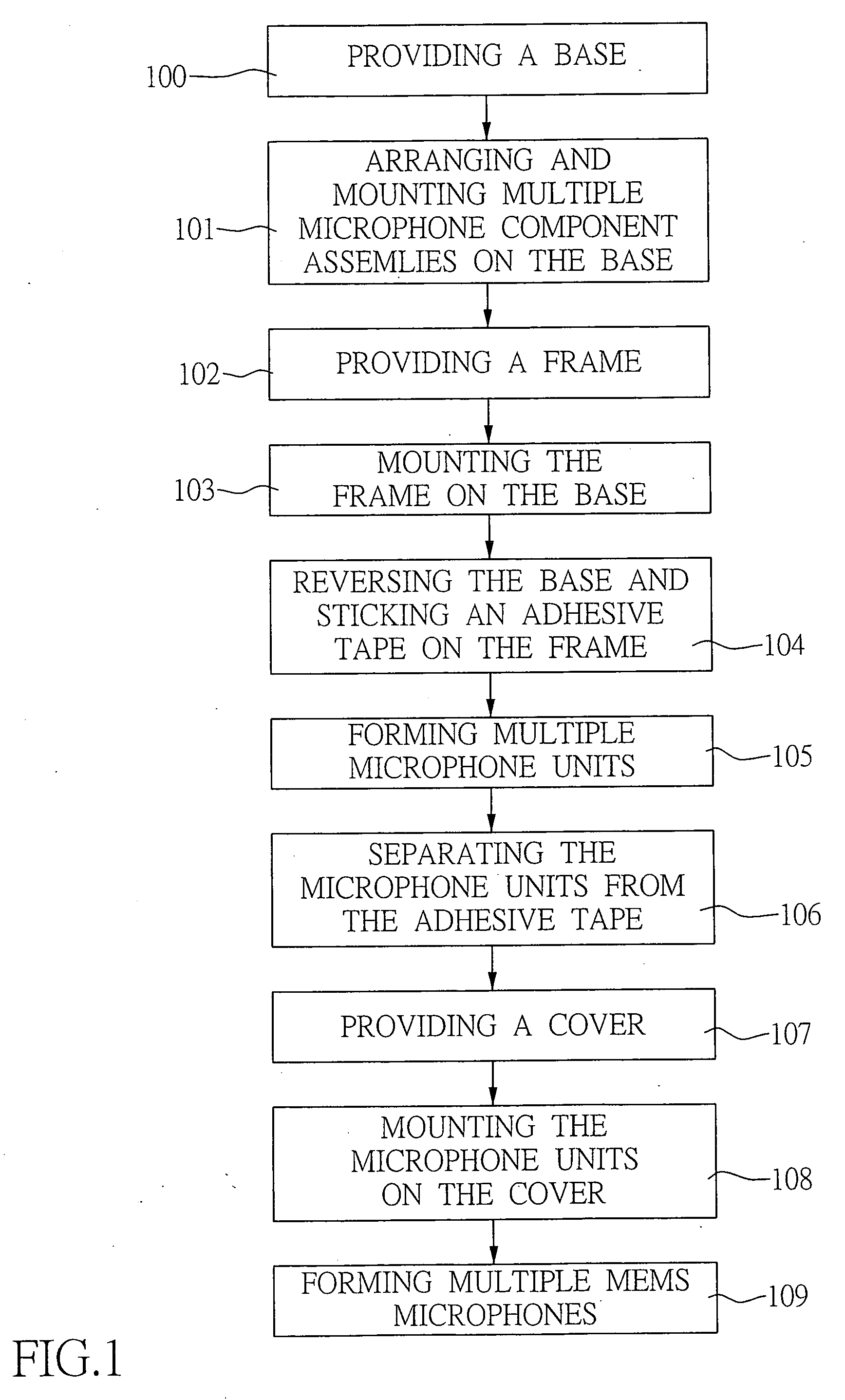

[0023]With reference to FIG. 1, a method for packaging micro electromechanical systems (MEMS) microphone in accordance with the present invention comprises steps of providing a base (100), arranging and mounting multiple microphone component assemblies on the base (101), providing a frame (102), mounting the frame on the base (103), optionally reversing the base and adhering a adhesive tape to the frame (104), forming multiple microphone units (105), optionally separating the microphone units from the adhesive tape (106), providing a cover (107), mounting the microphone units on the cover (108) and forming multiple MEMS microphones (109).

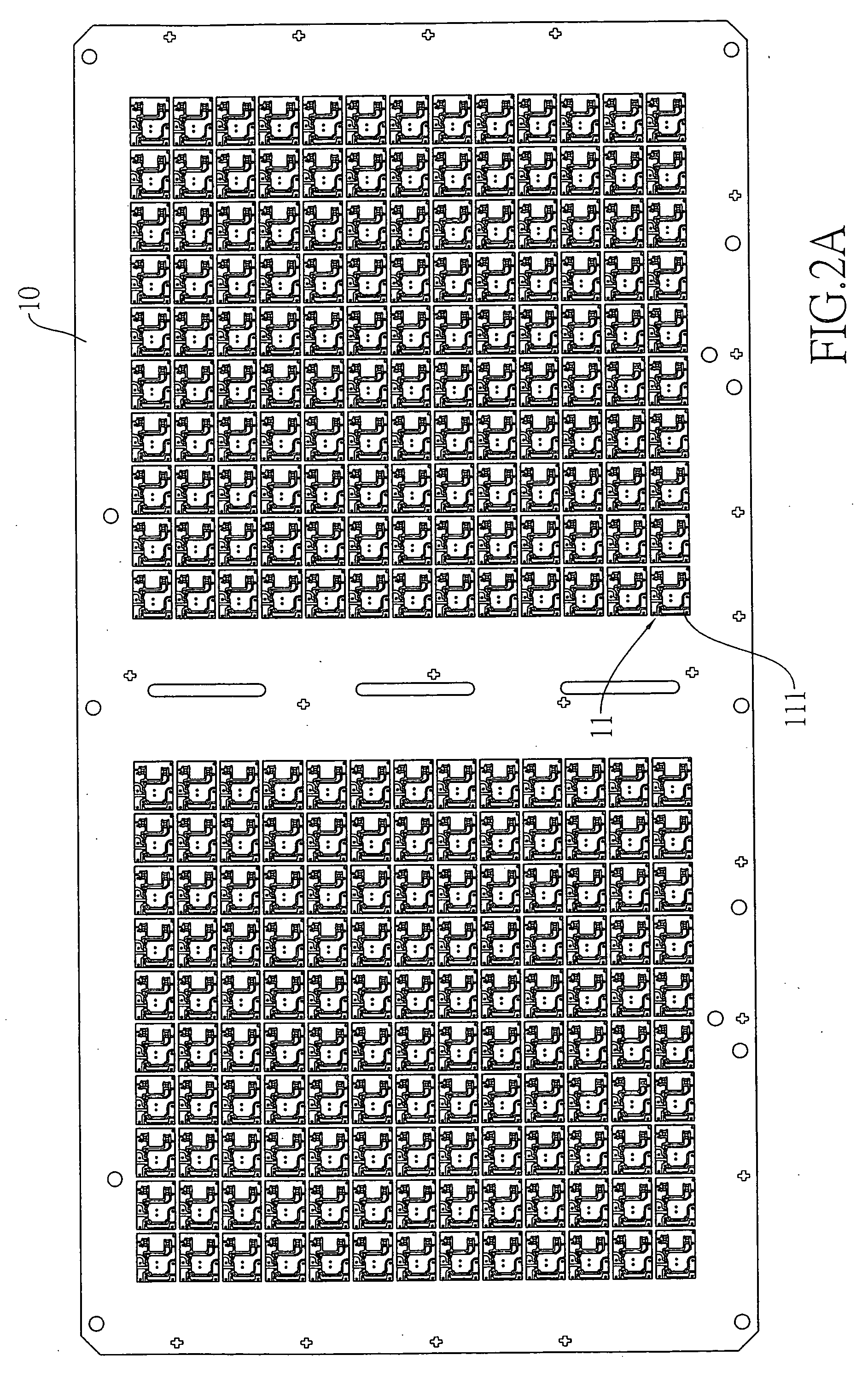

[0024]With further reference to FIGS. 2A, 2B and 3, in the step of providing a base (100), the base (10) has a top, a bottom, multiple circuit blocks (11), multiple circuit assemblies (111) and multiple contact assemblies (112). The circuit blocks (11) are defined on the base (10) and may be arranged in matrix. The circuit assemblies (111) are forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| heat resistance | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com