Single-component middle coating can be used for wet-on-wet and dry jet wet, and preparation method thereof

A dry-spray-wet, single-component technology, used in primers, coatings, polyurea/polyurethane coatings, etc., can solve problems such as increasing the difficulty of wet-to-wet paints, product use limitations, and affecting production effects, achieving savings Baking energy consumption, saving production time, and beneficial to construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

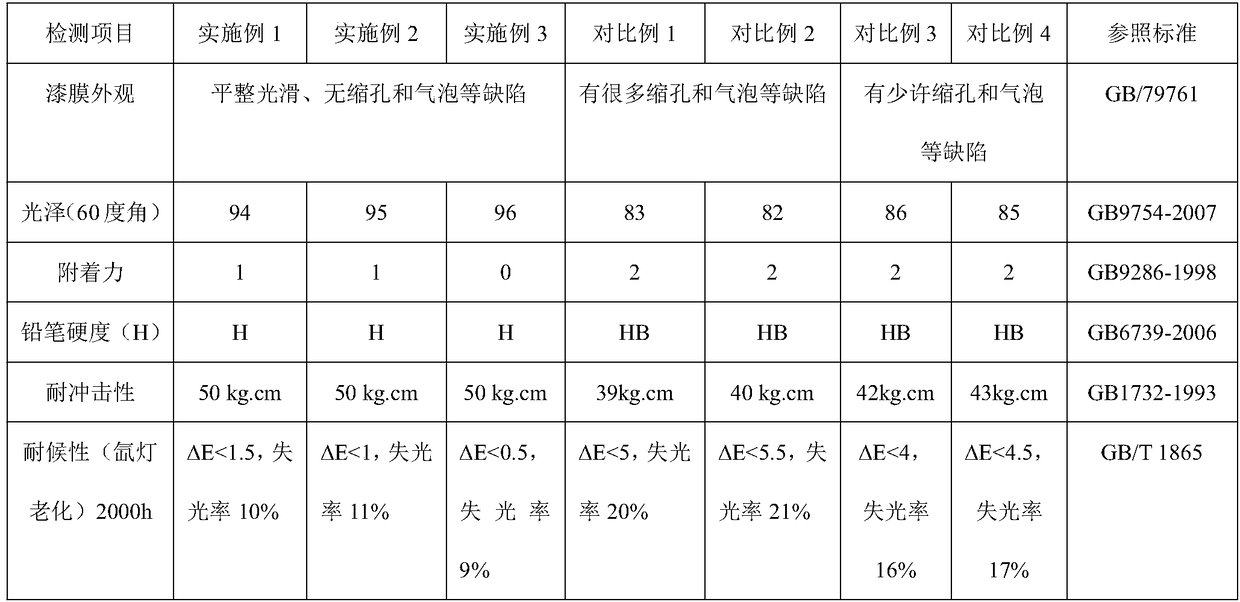

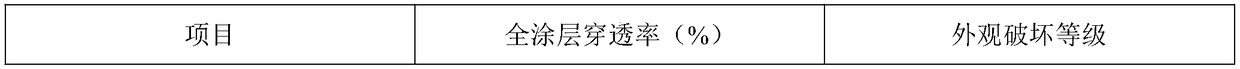

Examples

Embodiment 1

[0026] Embodiment 1, the present invention prepares wet-on-wet, dry-spray-wet one-component mid-coat primer

[0027] Example 1 of the present invention is a wet-on-wet, dry-spray-wet single-component intermediate coating primer, specifically comprising the following components in mass percentages: 35 kg of grinding component slurry, 25 kg of water-based acrylic polyol dispersion, and 25 kg of water-based polyurethane dispersion 10kg, water-based additive Tego 2704kg, amine neutralizer AMP-95 1.5kg, ethylene glycol butyl ether 1.5kg, wetting and leveling agent Afcona 35850.7kg, methyl etherified amino resin 8kg, thickener Hemings Dechem WT-105A 0.3kg and pure water 14kg.

[0028] The grinding component slurry specifically includes the following components in mass percent: 5 kg of superfine barium sulfate, 71.8 kg of titanium dioxide, 0.2 kg of carbon black, 3 kg of aqueous dispersant Tego 760W and 20 kg of pure water.

[0029]The preparation method of the above-mentioned wet-o...

Embodiment 2

[0033] Embodiment 2, the present invention prepares wet-on-wet, dry-spray-wet single-component midcoat primer

[0034] Embodiment 2 of the present invention 2 wet-on-wet, dry-spray-wet single-component midcoat primer, specifically including the following components in mass percentage: 45kg of grinding component slurry, 16kg of water-based acrylic polyol dispersion, and 16kg of water-based polyurethane dispersion. 10kg, Tego 270 3kg of water-based additives, 1.5kg of amine neutralizer AMP-95, 1.5kg of butyl glycol ether, 0.3kg of wetting and leveling agent Afcona 35850.3kg, 8kg of methyl etherified amino resin, thickener Hemmingsted Qian WT-105A 0.7kg and pure water 14kg.

[0035] The grinding component slurry specifically includes the following components by mass percentage: 15kg of ultrafine barium sulfate, 60.5kg of titanium dioxide, 0.5kg of carbon black, 4kg of aqueous dispersant Tego 760W and 20kg of pure water.

[0036] The preparation method of the above-mentioned wet-...

Embodiment 3

[0040] Embodiment 3, the present invention prepares wet-on-wet, dry-spray-wet single-component midcoat primer

[0041] Embodiment 3 of the present invention can be wet-on-wet, dry-spray-wet single-component midcoat primer, specifically including the following components in mass percentage: grinding component slurry 40kg, water-based acrylic polyol dispersion 20kg, water-based polyurethane dispersion 15kg, Tego 270 5kg of water-based additives, 1kg of amine neutralizer AMP-95, 2kg of butyl glycol ether, 0.5kg of wetting and leveling agent Afcona 3585, 4kg of methyl etherified amino resin, thickener Hemings Deqian WT-105A 0.5kg and pure water 12kg.

[0042] The grinding component slurry specifically includes the following components by mass percentage: 12 kg of ultrafine barium sulfate, 60 kg of titanium dioxide, 0.4 kg of carbon black, 5 kg of aqueous dispersant Tego 760W and 22.6 kg of pure water.

[0043] The preparation method of the above-mentioned wet-on-wet, dry-spray-we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com