Method for preparing high-purity arabinogalactan

A technology for arabinogalactan and an adsorbent, which is applied in the field of membrane separation technology for preparing high-purity arabinogalactan, can solve the problems of complicated regeneration and utilization, time-consuming, high purification cost, and saves production time and cost. The effect of eliminating column packing and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

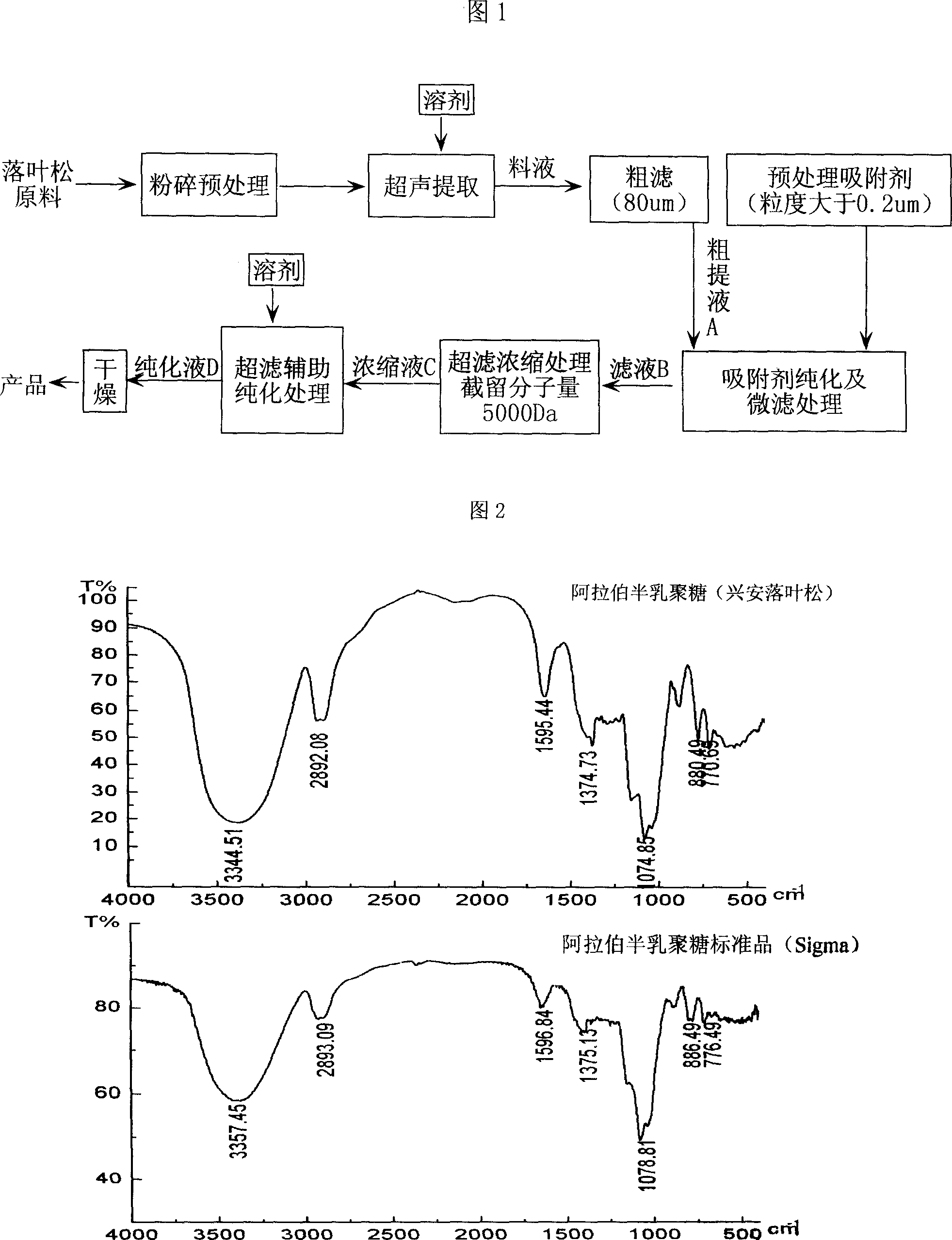

Image

Examples

example 1

[0021] Put 600 g of crushed Xing’an larch shavings with a particle size of 20 mesh or more into an ultrasonic extraction tank, add 30 L of water solvent at 50 °C, seal the extraction tank, set the extraction process temperature to 60 °C, time 60 min, and ultrasonic output frequency to 47 kHz. After the material is subjected to ultrasonic cavitation in the extraction tank, the ultrasonic generator is turned off, and the 80um modified fiber bundle membrane filter device is used to filter to obtain the crude extract A of arabinogalactan, and the solution is yellowish brown. In the crude Arabinogalactan extract A, according to the ratio of 22.32g / L, pretreated KH-862 medical activated carbon-assisted microfiltration clarification system was added for decolorization and purification to obtain filtrate B. Take 20L of filtrate B and concentrate it through a cellulose membrane with a cut-off molecular weight of 5000Da. During ultrafiltration, the inlet pressure was 0.6 MPa, the feedin...

example 2

[0023] Put 600 g of Xing’an larch wood powder with a particle size of 20-60 mesh into an ultrasonic extraction tank, add 30 L of water solvent at 35 °C, seal the extraction tank, set the extraction process temperature to 42 °C, time 150 min, and ultrasonic output frequency to 70 kHz. After the material is subjected to ultrasonic cavitation in the extraction tank, the ultrasonic generator is turned off to obtain the crude extract A of arabinogalactan. According to the ratio of 20.82g / L, add the pretreated KH-762 medical active carbon assisted microfiltration clarification system to the crude extract A for decolorization and purification, and the remaining operating parameters are the same as in Example 1. After the purified liquid D was dried, a beige powdery arabinogalactan was obtained, with a yield of 9.21% and a purity of 92.3% relative to the raw material (dry wood powder).

example 3

[0025] Put 600g of Xing’an larch wood powder with a particle size of 20-60 mesh into the extraction tank, add 30L of water solvent at 42°C, set the extraction process temperature at 60°C, time 60min, and ultrasonic output frequency at 67.8kHz. After the material is subjected to ultrasonic cavitation in the extraction tank, the ultrasonic generator is turned off to obtain the crude extract A of arabinogalactan. According to the ratio of 40.17g / L, a pretreated 100-200 mesh diatomaceous earth-assisted microfiltration clarification system was added to the crude extract A for decolorization and purification, and the rest of the operation process was the same as in Example 1. After freeze-drying the purified solution D, arabinogalactan was obtained in the form of yellow powder, with a yield of 12.91% and a purity of 82.7% relative to the raw material (dry wood powder).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com