Graphite material at negative pole of lithium ion battery and preparation method thereof

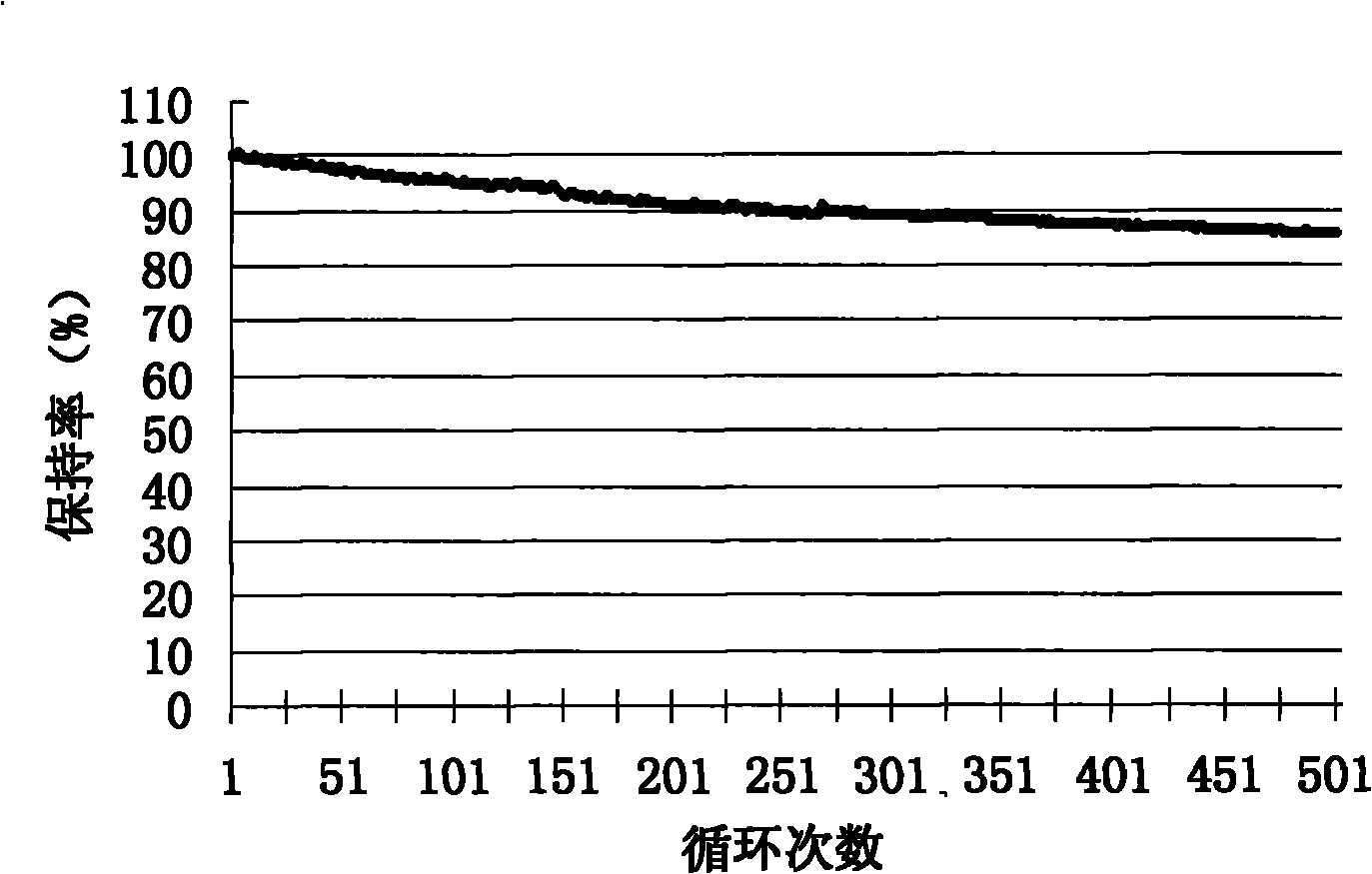

A lithium-ion battery and graphite material technology, which is applied in the field of lithium-ion battery negative electrode graphite material and its preparation, can solve the problems of unsatisfactory product yield, difficult to obtain ingredients, complicated preparation process, etc., achieve capacity play and good cycle, and process The effect of being simple and easy to operate and having a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

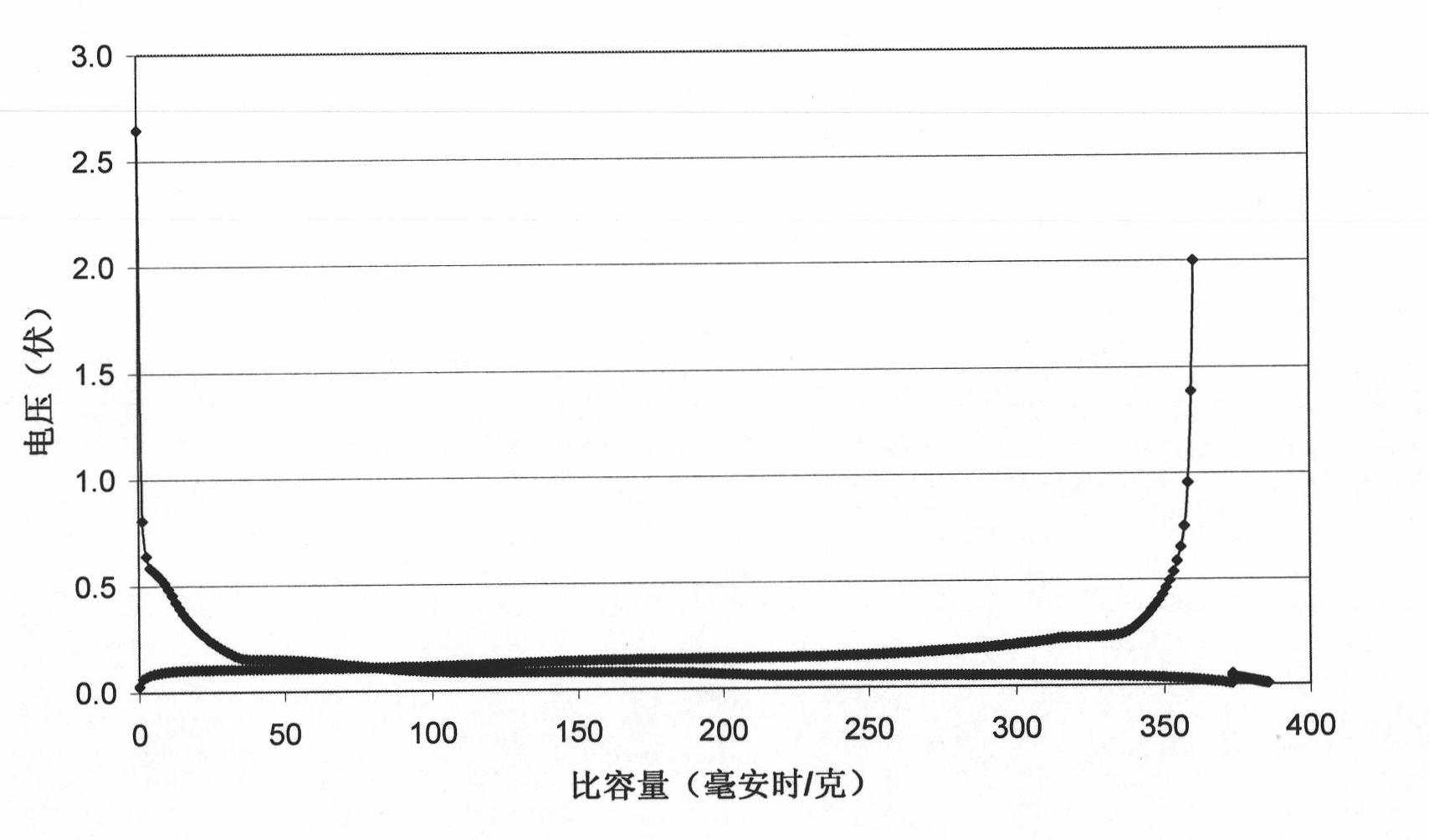

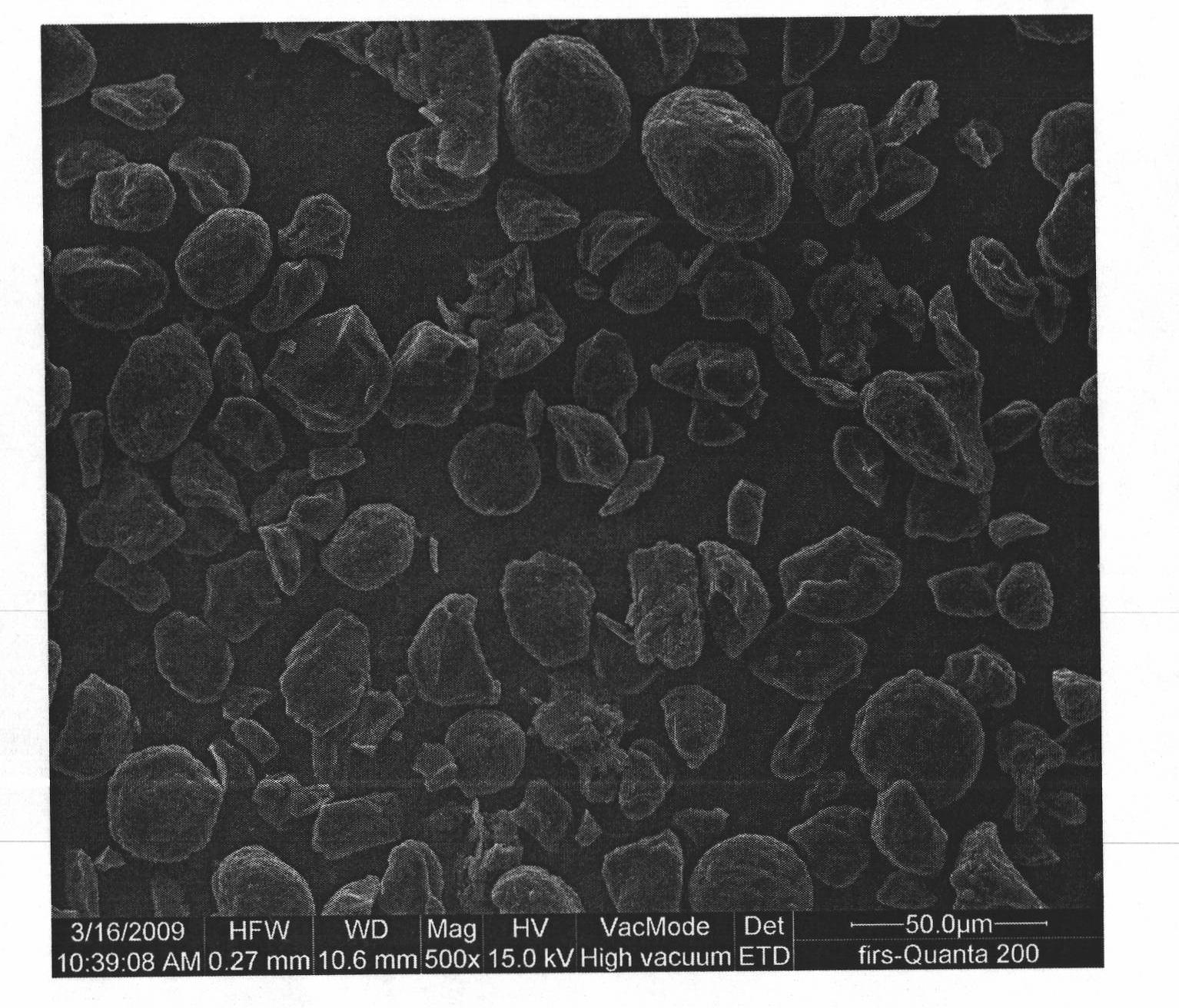

Embodiment 1

[0030] The raw material of mesophase carbon microspheres is crushed and classified in a crushing classifier to obtain a particle size D 50 = 25.6 μm powder, then carry out conventional graphitization high-temperature treatment (2500 ℃), obtain mesophase graphite, mix mesophase graphite and artificial graphite in a mass ratio of 70:30, and make lithium-ion battery negative electrode graphite material. The assembled button battery has a capacity of 353.6mAh / g and an initial efficiency of 91.6%.

Embodiment 2

[0032] The raw material of mesophase carbon microspheres is crushed and classified in a crushing classifier to obtain a particle size D 50 = 26.4 μm powder, then carry out conventional graphitization high-temperature treatment (2800 ℃), obtain mesophase graphite, mix mesophase graphite and artificial graphite in a mass ratio of 90:10, and make lithium-ion battery negative electrode graphite material. The assembled button battery has a capacity of 350.1mAh / g and an initial efficiency of 93.4%.

Embodiment 3

[0034] The raw material of mesophase carbon microspheres is crushed and classified in a crushing classifier to obtain a particle size D 50 = 16.7 μm powder, then carry out conventional graphitization high temperature treatment (2500 ℃), get mesophase graphite, mesophase graphite and artificial graphite are mixed uniformly by the mass ratio of 80:20, make lithium ion battery negative electrode graphite material. The assembled button cell has a capacity of 355.9mAh / g and an initial efficiency of 92.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com