Ceramic material for 3D printing and preparation method thereof

A ceramic material and 3D printing technology, applied in the field of composite materials, can solve the problems of few varieties and dependence on imports, and achieve the effects of low cost, good matching, and small powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

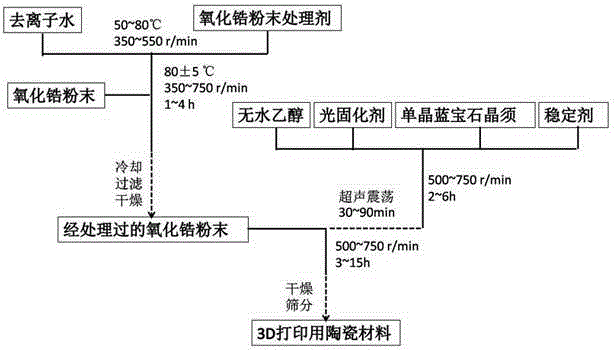

Method used

Image

Examples

Embodiment 1

[0039] (1) Add 20 parts by weight of sodium pyrophosphate into 100% deionized water in a heating device at 50~80°C, and stir at a speed of 350~750r / min until the sodium pyrophosphate is fully dissolved.

[0040] (2) Add 80 parts by weight of zirconia powder to the above solution, stir at 350~750r / min at a constant temperature of 80±5°C for 1 hour, after fully reacting, cool, filter, and dry to obtain treated zirconia powder.

[0041] (3) 2 parts by weight of Y 2 o 3 , 5 parts by weight of acrylate and polyurethane resin (1:1) and 1 part by weight of single crystal sapphire whiskers were added to 200 parts by weight of absolute ethanol according to the formula, and stirred rapidly at room temperature at 500~750r / min for 2~6h .. (4) Shake the above mixture for 30~90min under ultrasonic.

[0042] (5) Add the treated zirconia powder into the above mixture, and stir at 500~750r / min for 3~15h.

[0043] (6) Dry the above mixed powder at 80-120°C and sieve to obtain the ceramic ma...

Embodiment 2

[0045] (1) Add 20 parts by weight of sodium tripolyphosphate to 200 parts by weight of deionized water in a heating device at 50-80°C, and stir at a speed of 350-750 r / min until sodium tripolyphosphate is fully dissolved.

[0046] (2) Add 90 parts by weight of zirconia powder to the above solution, stir at 350~750r / min at a constant temperature of 80±5°C for 2h, after fully reacting, cool, filter, and dry to obtain treated zirconia powder.

[0047] (3) 1 part by weight of Y 2 o 3 , 3 parts by weight of acrylate and polyurethane resin (1:1) and 3 parts by weight of single crystal sapphire whiskers were added to 200 parts by weight of absolute ethanol according to the formula, and stirred rapidly at room temperature at 500~750r / min for 2~6h ..

[0048] (4) Shake the above mixture for 30~90min under ultrasonic.

[0049] (5) Add the treated zirconia powder into the above mixture, and stir at 500~750r / min for 3~15h.

[0050] (6) Dry the above mixed powder at 80-120°C and sieve ...

Embodiment 3

[0052] (1) In a heating device at 50-80°C, add 25 parts by weight of oxalic acid into 300°C deionized water, and stir at a speed of 350-750r / min until the oxalic acid is fully dissolved.

[0053] (2) Add 100 parts by weight of zirconia powder to the above solution, stir at 350~750r / min at a constant temperature of 80±5°C for 2h, after fully reacting, cool, filter, and dry to obtain treated zirconia powder.

[0054] (3) 5 parts by weight of CeO 2 , 5 parts by weight of acrylate and polyurethane resin (2:3) and 7 parts by weight of single crystal sapphire whiskers were added to 500 parts by weight of absolute ethanol according to the formula, and stirred rapidly at room temperature at 500~750r / min for 2~6h ..

[0055](4) Shake the above mixture for 30~90min under ultrasonic.

[0056] (5) Add the treated zirconia powder into the above mixture, and stir at 500~750r / min for 3~15h.

[0057] (6) Dry the above mixed powder at 80-120°C and sieve to obtain the ceramic material for 3D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com