Water-based epoxy protective coating system for nuclear power station concrete and preparation method of water-based epoxy protective coating system

A water-based epoxy and protective coating technology, applied in the field of coatings, can solve the problems of limited coating performance, poor impact resistance, and inconvenient construction, and achieve the effects of excellent anti-corrosion performance, low VOC emission, and excellent radiation protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

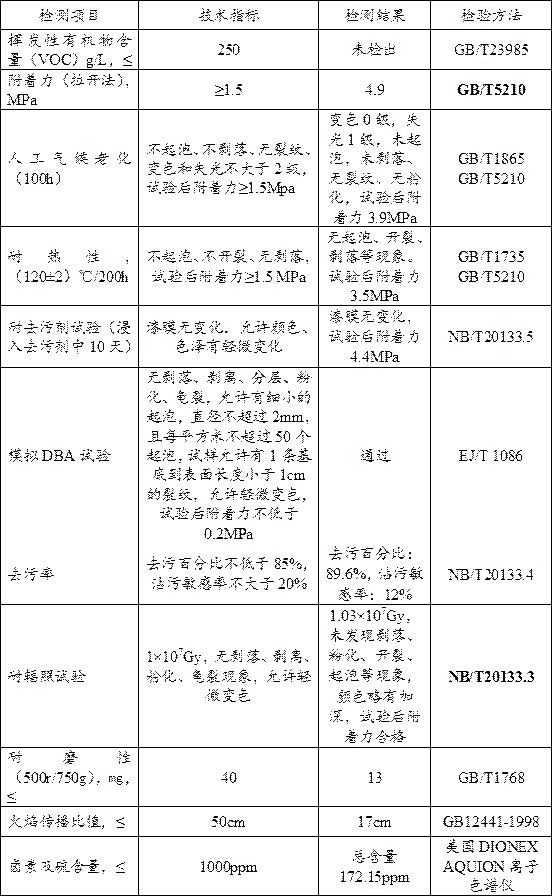

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but not limited thereto.

[0024] Unless otherwise specified, the raw materials used in the examples are commercially available industrial supplies, which can be purchased through commercial channels.

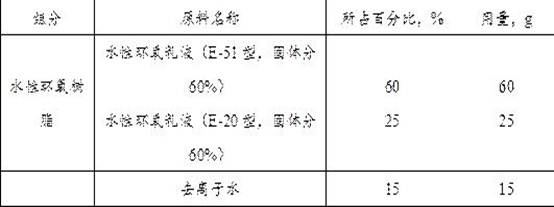

[0025] (1) Preparation of component A1

[0026] 1. Formula

[0027] Component A1 is composed of 40-100% water-based epoxy curing agent and deionized water as the balance. The above percentages are mass percentages. The specific formula is shown in Table 1.

[0028] Table 1 The formula of component A1

[0029] components raw material name Percentage, % Dosage, g Waterborne epoxy curing agent Huntsman Aradur3985 72.7 72.7 Deionized water 27.3 27.3

[0030] 2. Specific operation method

[0031] In the mixing container, add water-based epoxy curing agent and deionized water according to the formula of component Al in Table 1, stir at a medium speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com