Patents

Literature

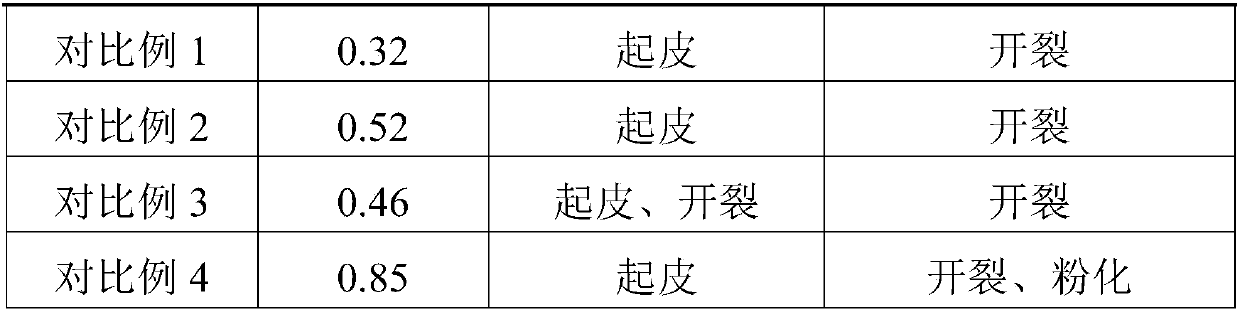

39results about How to "Avoid cracking and peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

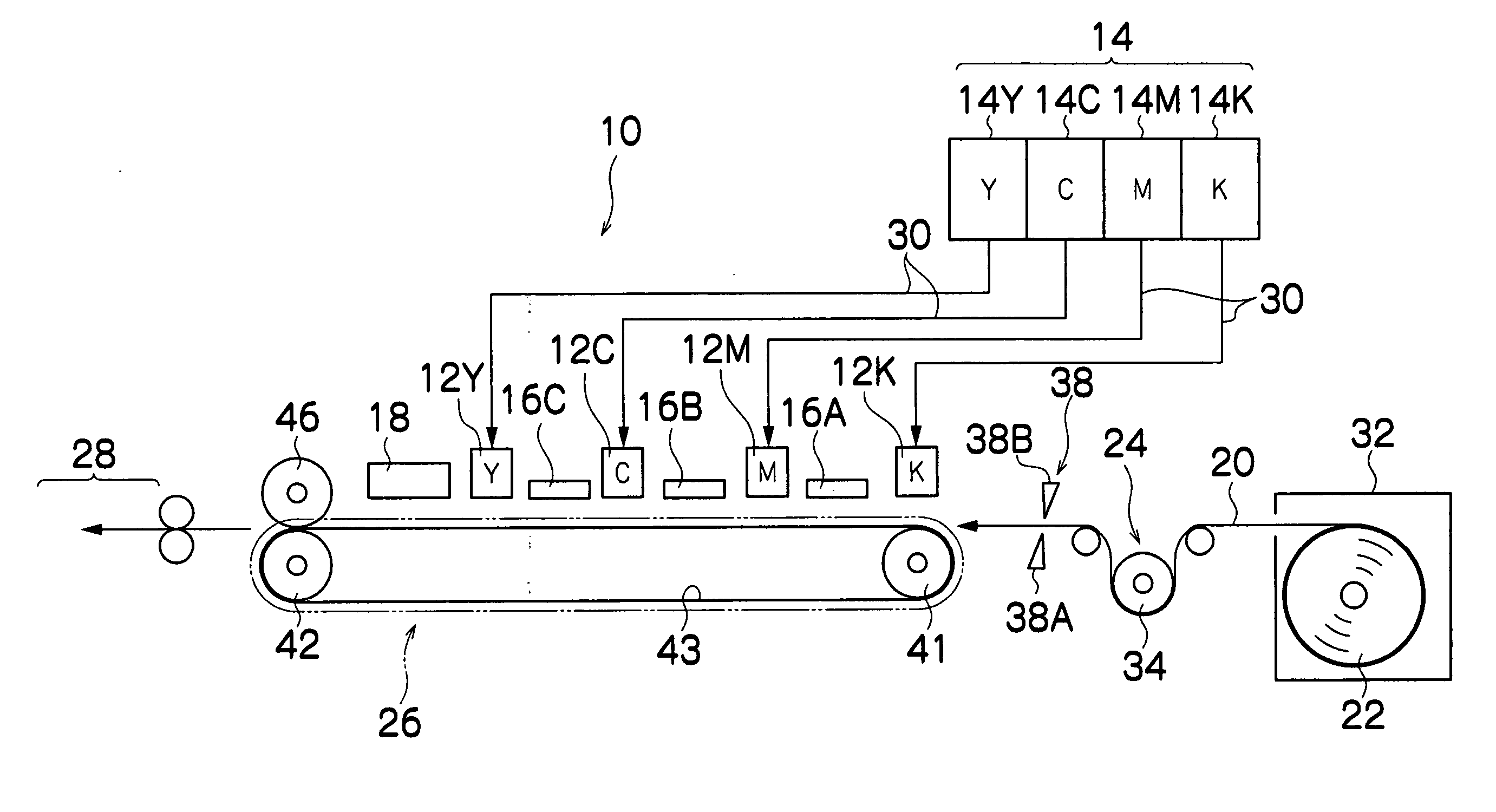

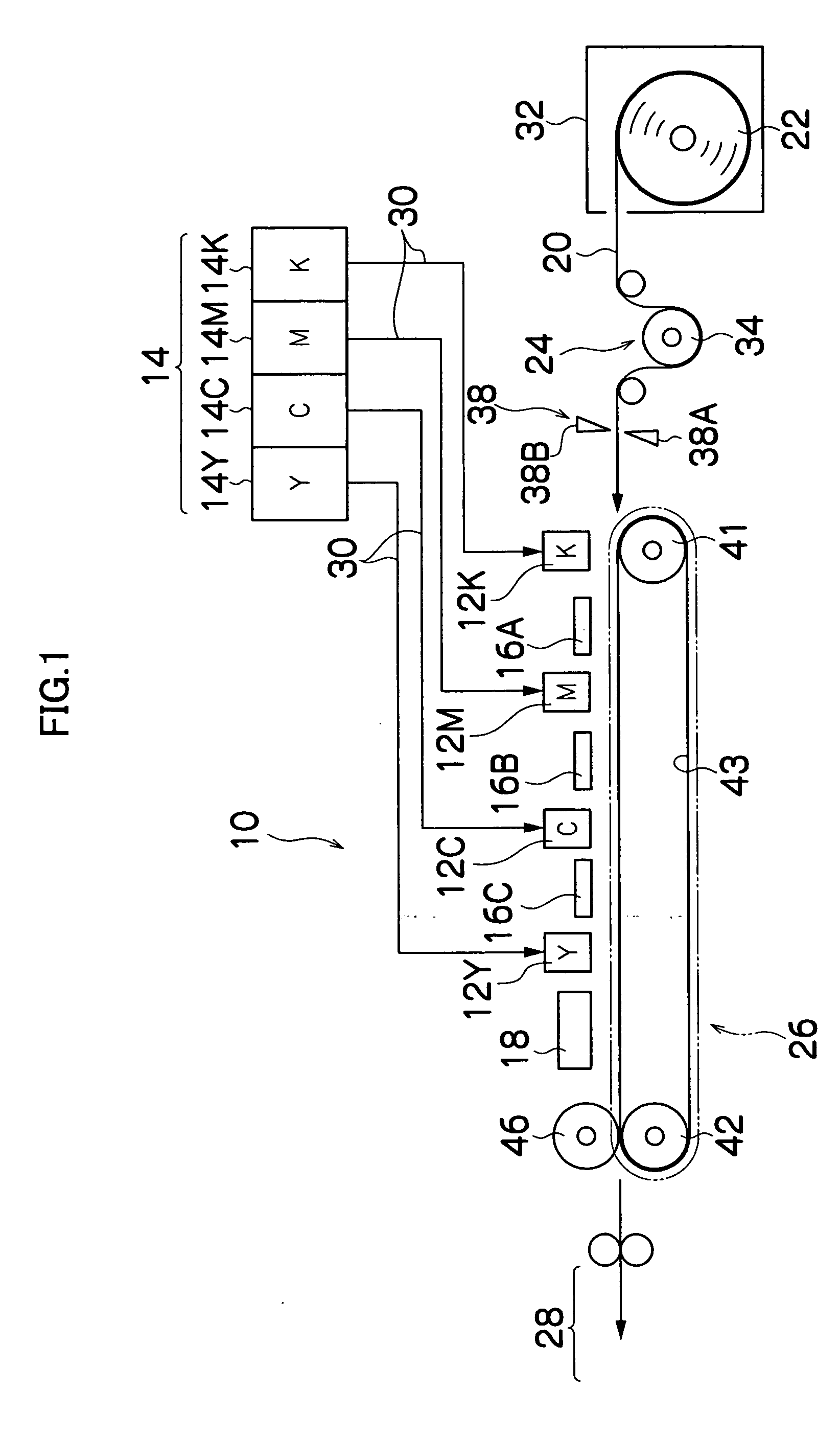

Image forming apparatus and method

InactiveUS20050190248A1Avoid cracking and peelingImage deterioration is causedInking apparatusOther printing apparatusUltraviolet lightsImaging equipment

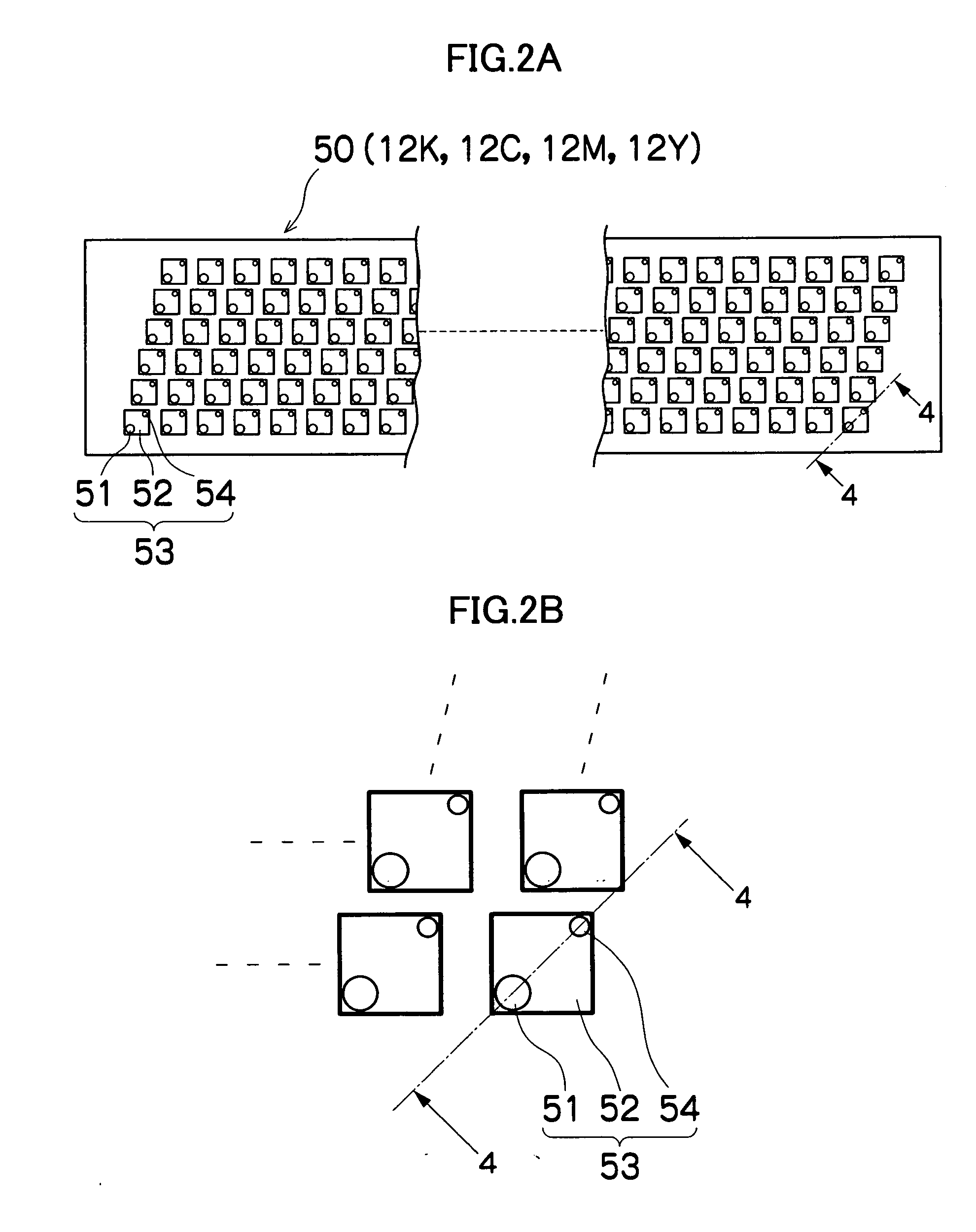

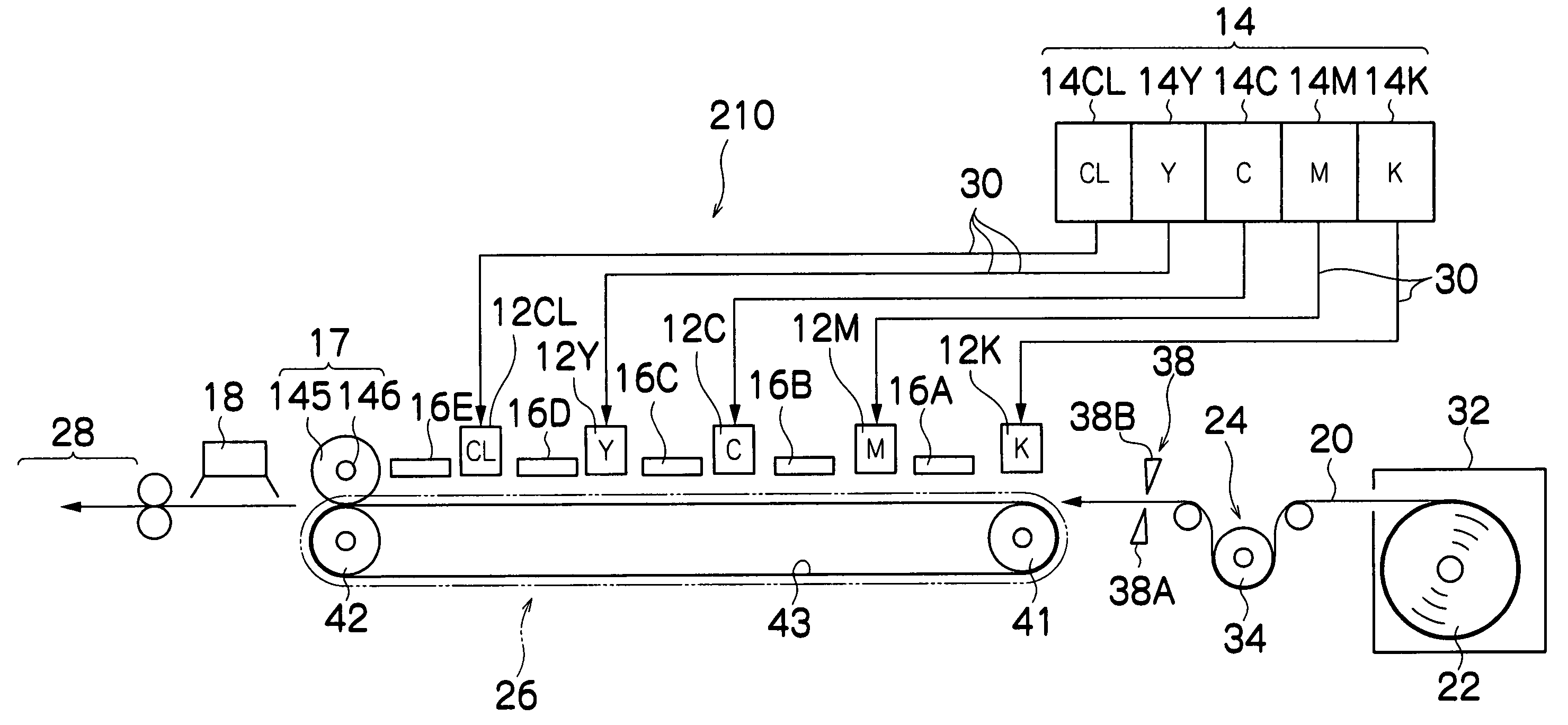

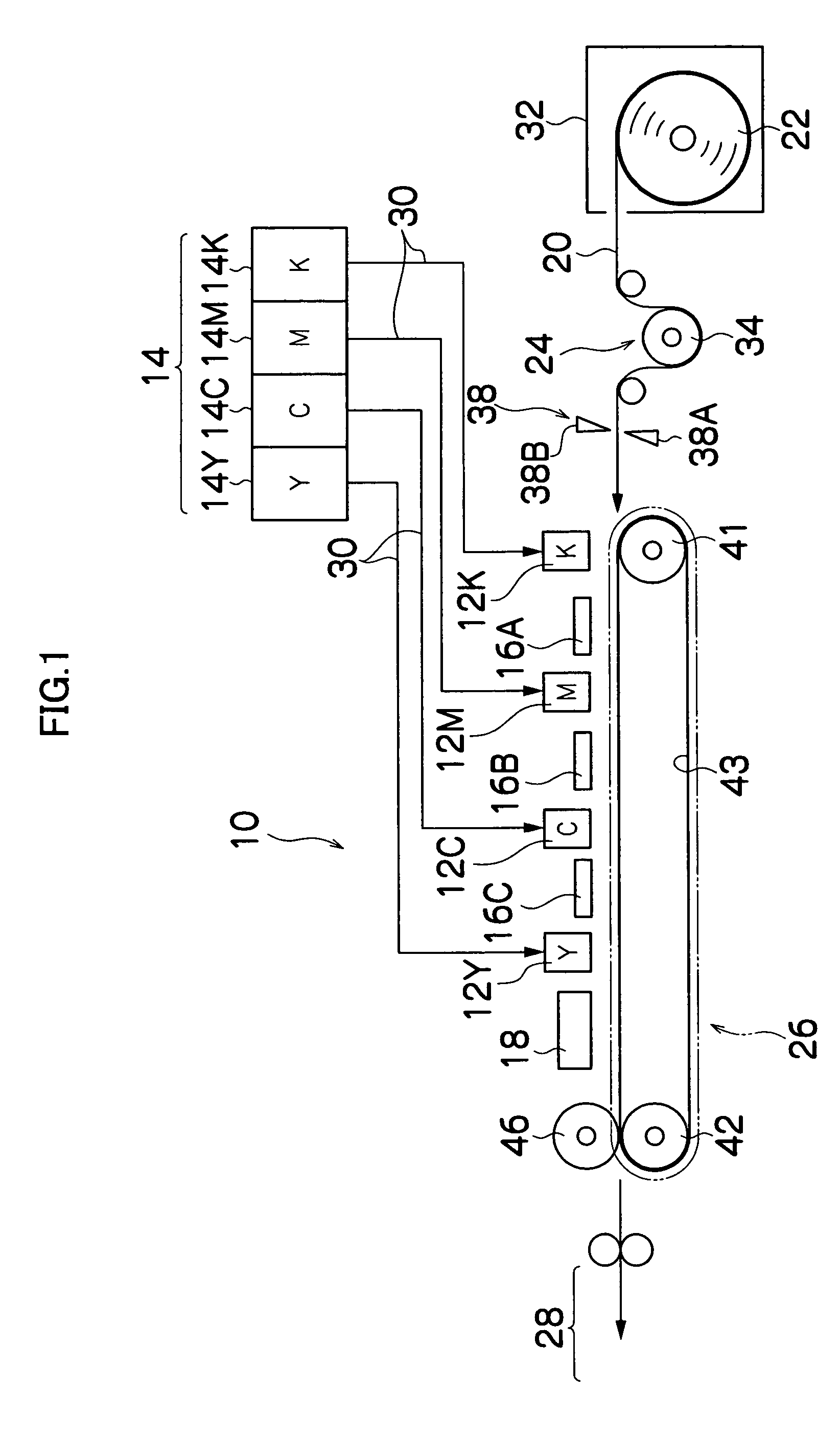

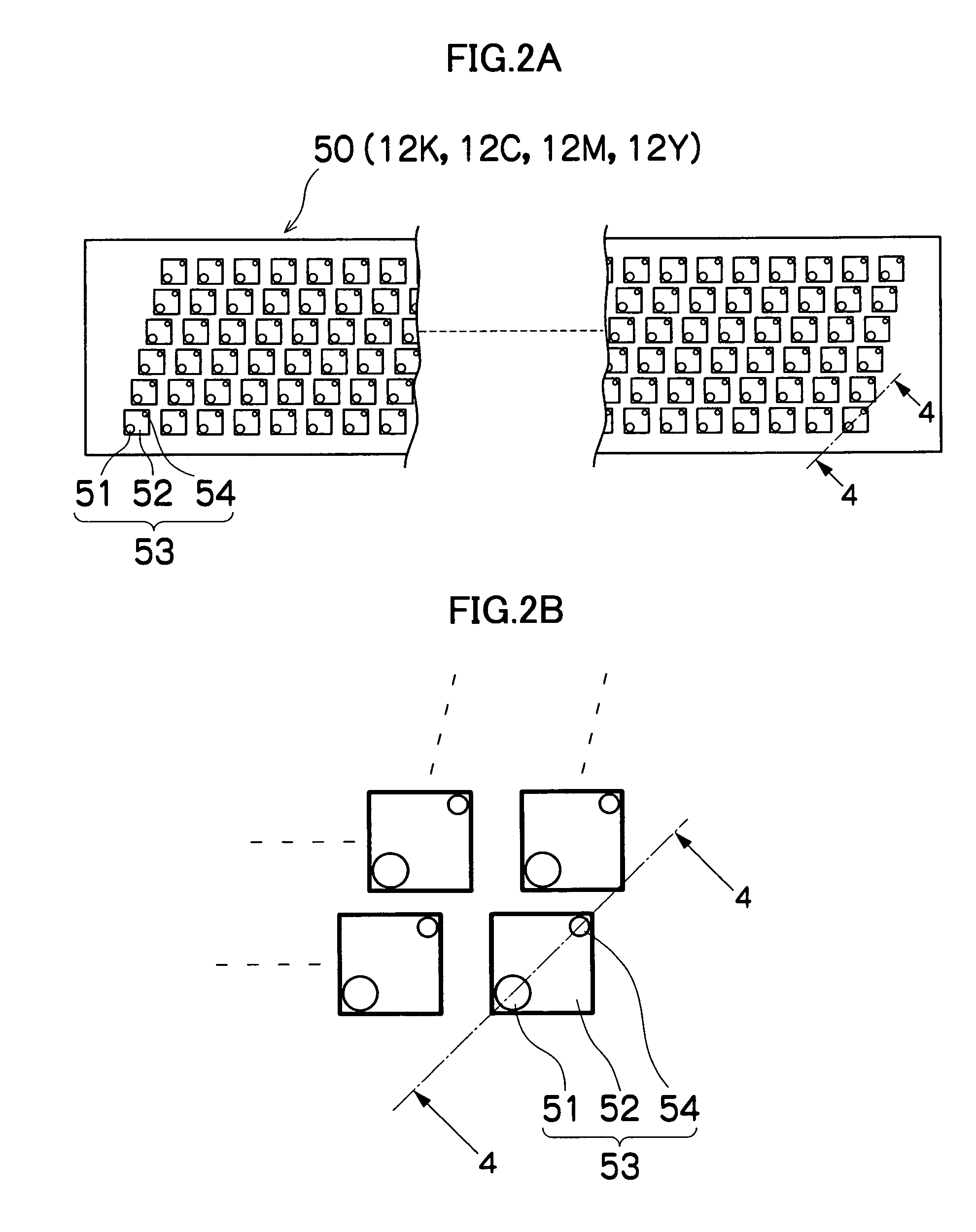

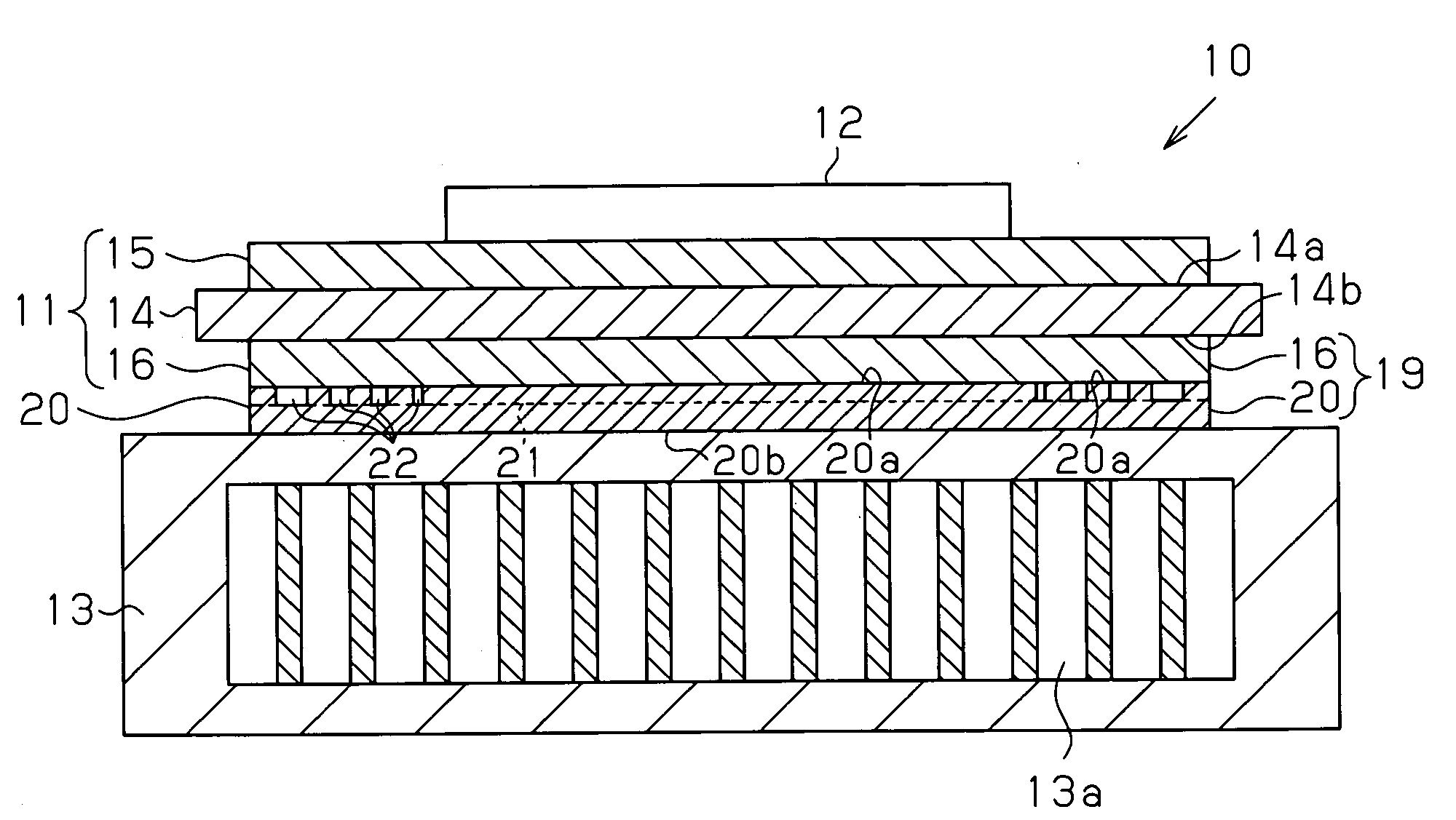

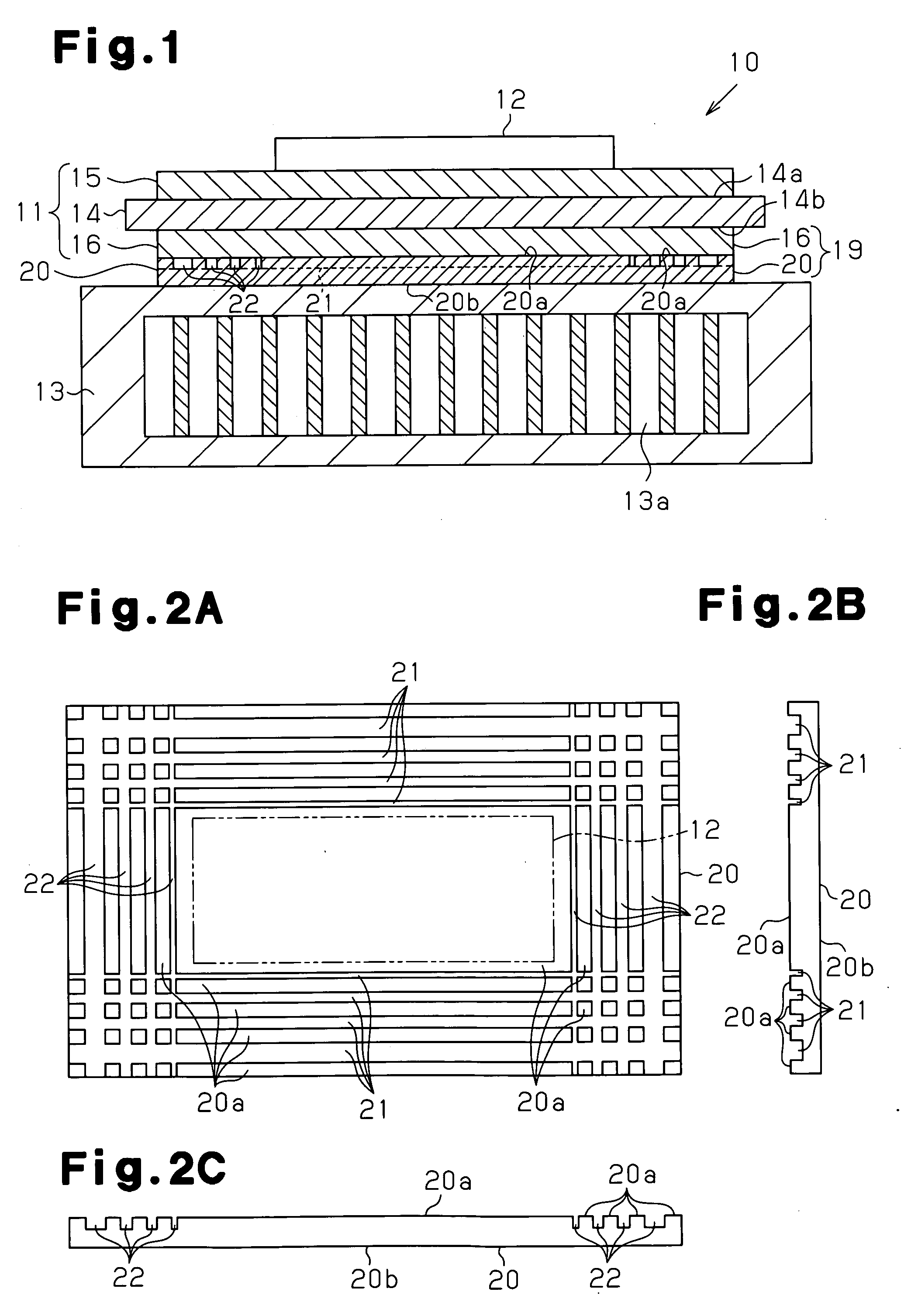

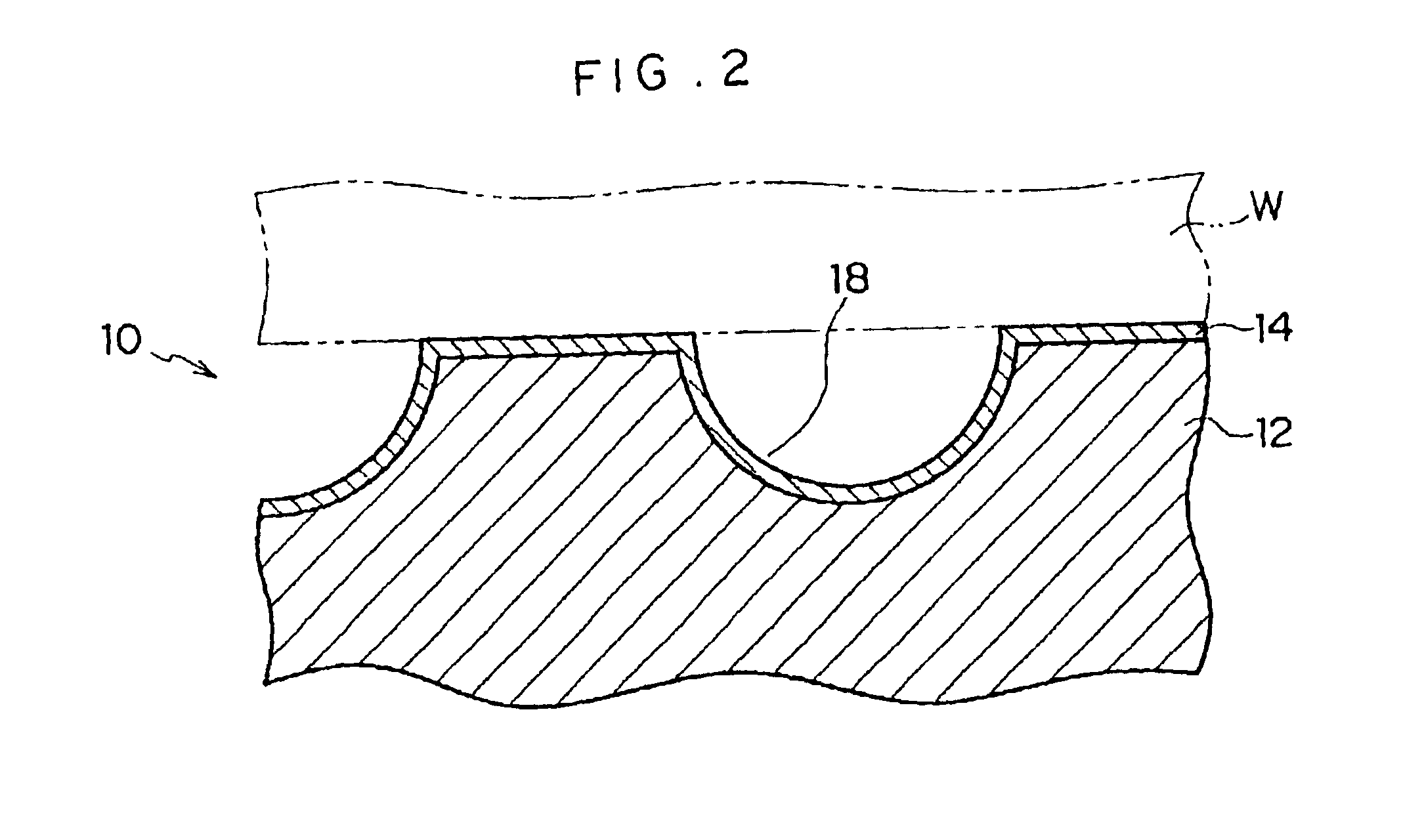

The image forming apparatus comprises: an ink discharge device comprising a plurality of full line type inkjet heads arranged separately for a plurality of inks of different colors, each of the inkjet heads having a nozzle row in which a plurality of nozzles for discharging droplets of the ink toward a surface of a recording medium are arranged through a length corresponding to a full width of the recording medium; an ink supply device which supplies ultraviolet curable inks of corresponding colors to the inkjet heads; a conveyance device which causes the inkjet heads and the recording medium to move relatively to each other by conveying at least one of the recording medium and the inkjet heads in a direction substantially perpendicular to a breadthways direction of the recording medium; a first curing device which irradiates ultraviolet light for causing the droplets of the ink, deposited on the surface of the recording medium by one of the inkjet heads on an upstream side in a direction of relative conveyance of the recording medium with respect to the inkjet heads, to semi-cure to a degree whereby the droplets of the ink discharged from the inkjet head on the upstream side do not mix on the surface of the recording medium with the droplets of the ink discharged by a next one of the inkjet heads situated on a downstream side in the direction of relative conveyance, the first curing device comprising an ultraviolet light source including a group of light emitting elements arranged in a linear form and disposed between the inkjet heads of the respective colors; and a second curing device which irradiates ultraviolet light for performing main curing of the droplets of the ink on the recording medium to a degree whereby image degradation does not occur upon subsequent handling of the cured droplets of the ink, the second curing device being disposed after one of the inkjet heads situated in a furthest downstream position of the inkjet heads.

Owner:FUJIFILM CORP

Image forming apparatus and method

InactiveUS7510277B2Avoid cracking and peelingImage deterioration is causedInking apparatusOther printing apparatusUltraviolet lightsImage formation

The image forming apparatus includes: an ink discharge device having a plurality of full line type inkjet heads, each of the inkjet heads having a nozzle row; an ink supply device; a first curing device which irradiates ultraviolet light for causing the droplets of the ink to semi-cure to a degree whereby the droplets of the ink discharged from the inkjet head on the upstream side do not mix with the droplets of the ink discharged by a next one of the inkjet heads situated on a downstream side in the direction of relative conveyance, the first curing device including an ultraviolet light source including a group of light emitting elements arranged in a linear form and disposed between the inkjet heads of the respective colors; and a second curing device which irradiates ultraviolet light for performing main curing of the droplets of the ink.

Owner:FUJIFILM CORP

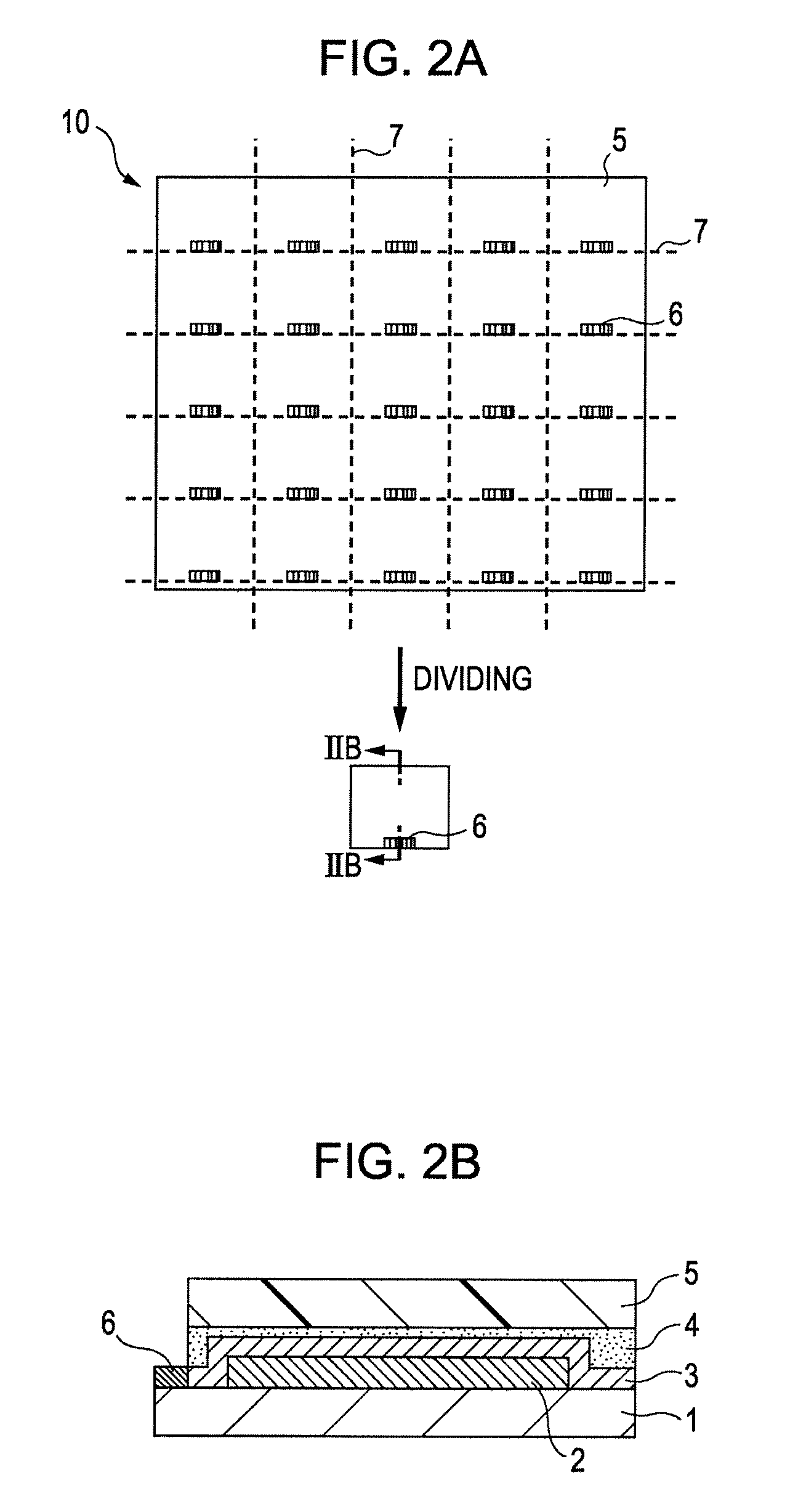

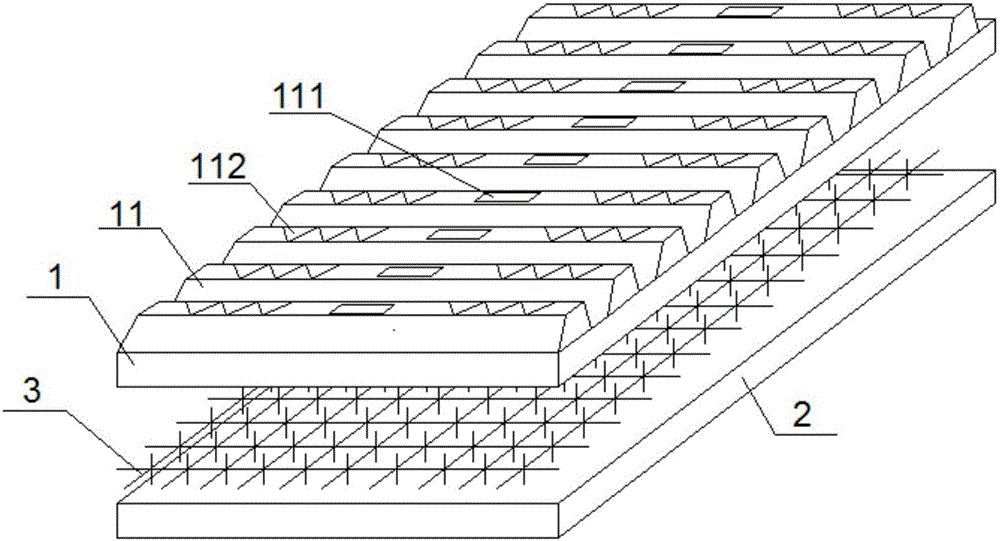

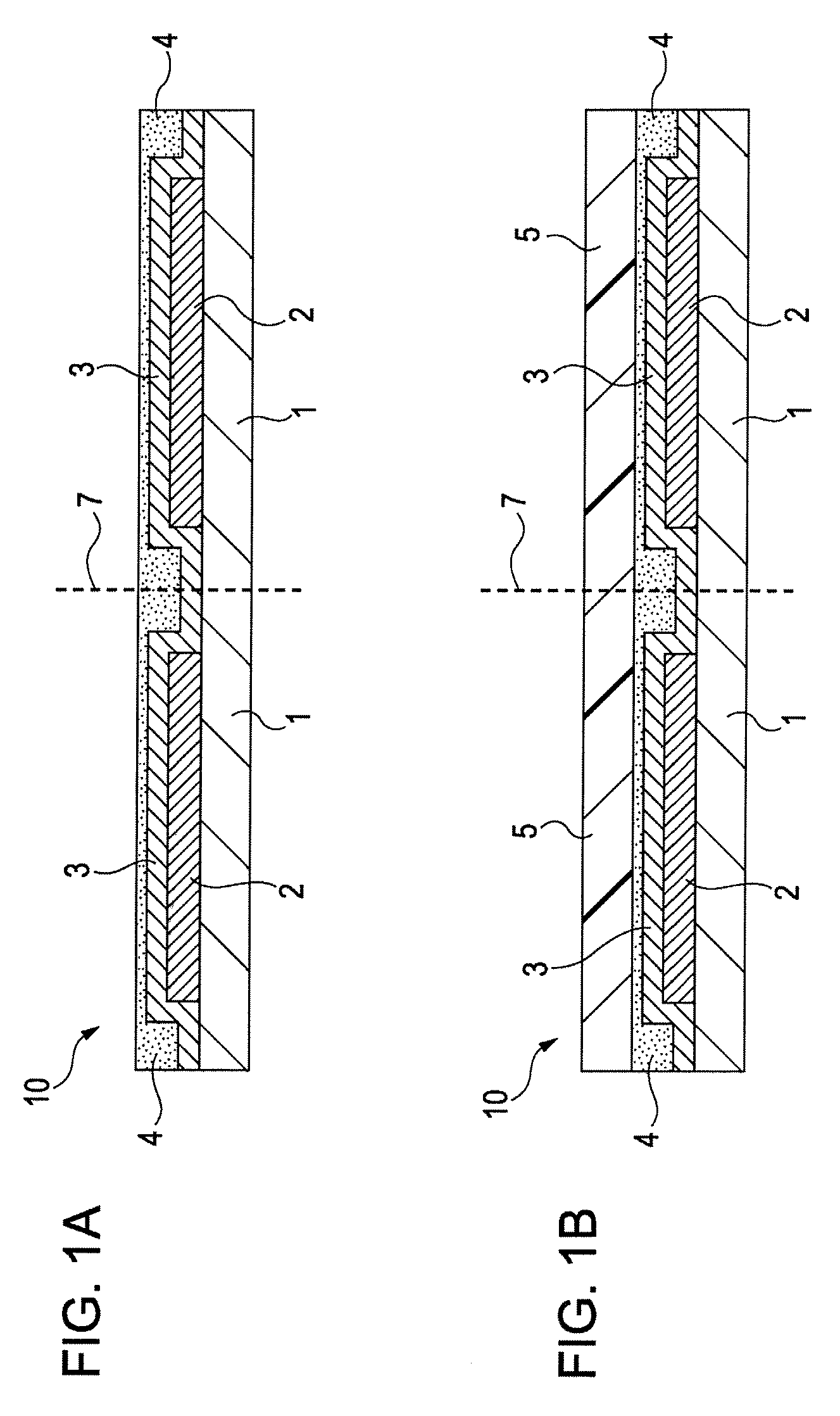

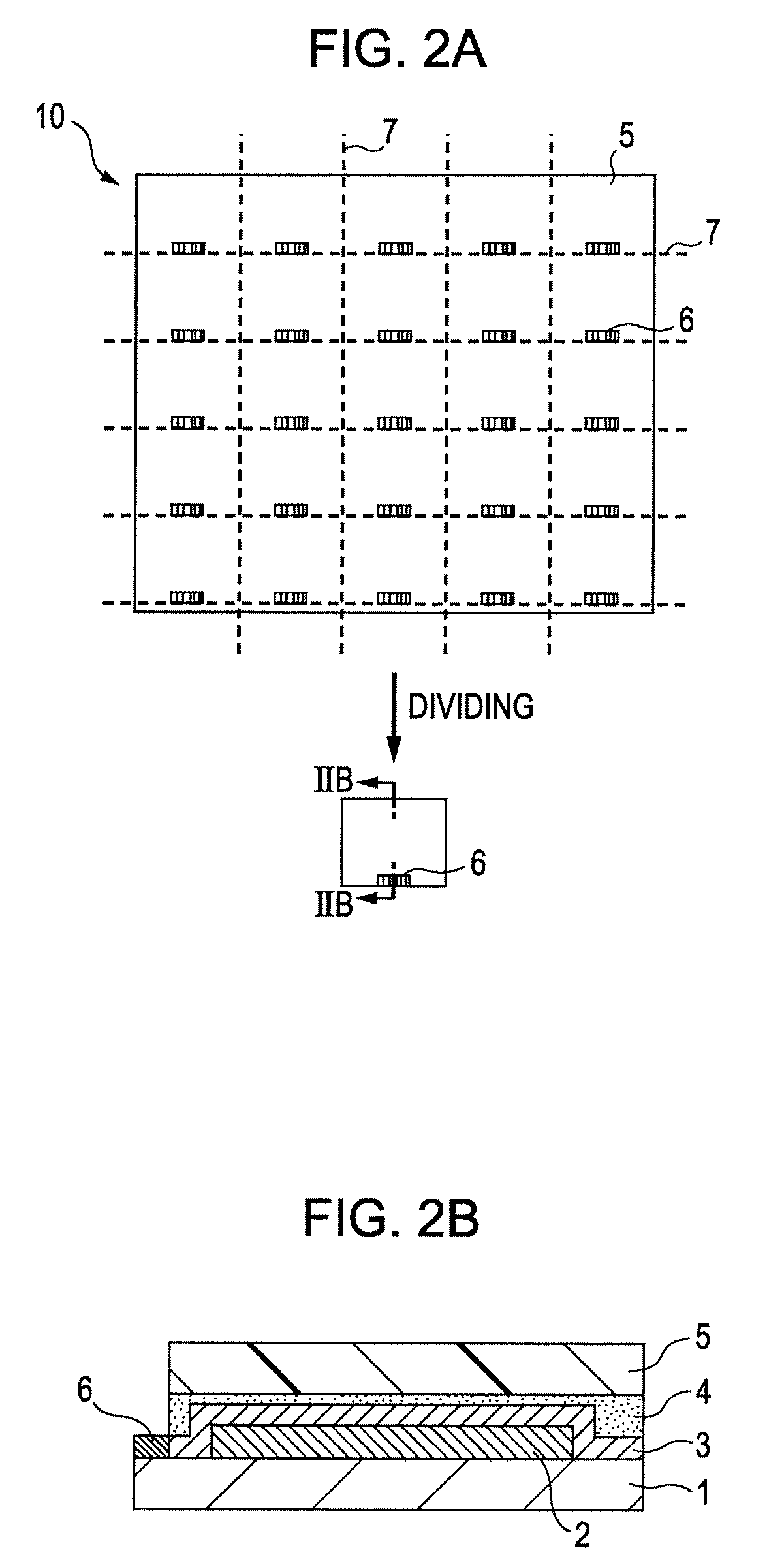

Method for manufacturing organic electroluminescence panel

ActiveUS20080220151A1Simple manufacturing processAvoid cracking and peelingSolid-state devicesCoatingsOrganic electroluminescenceChemistry

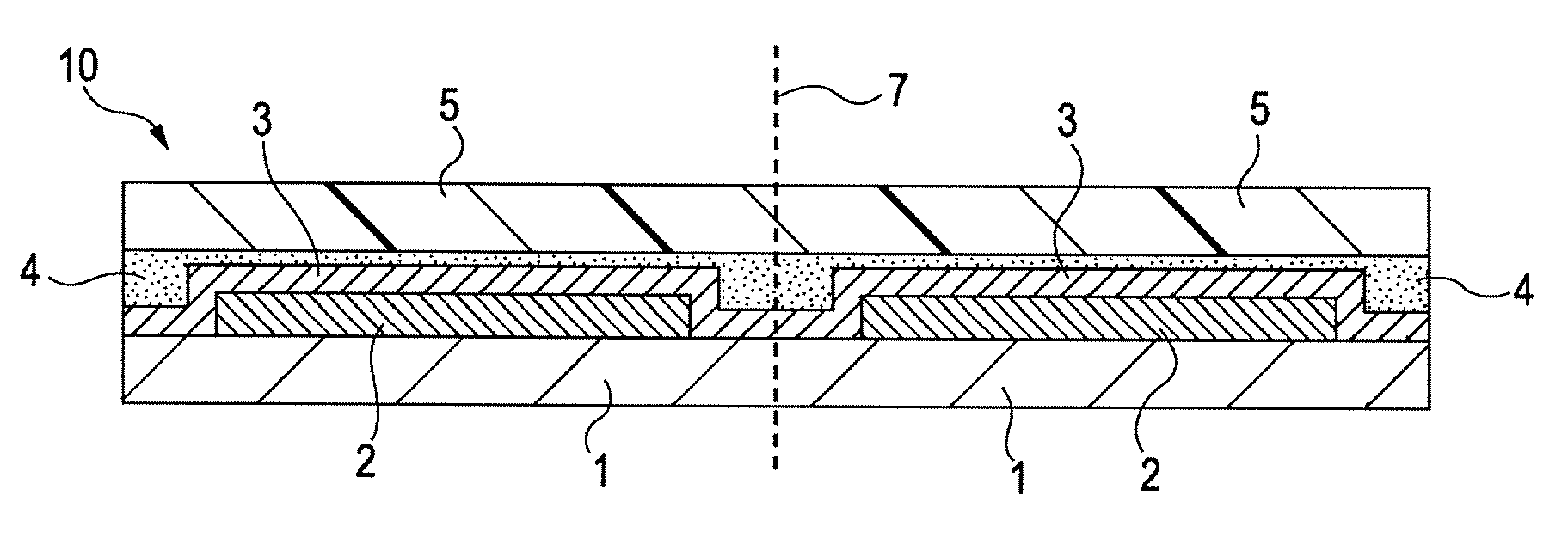

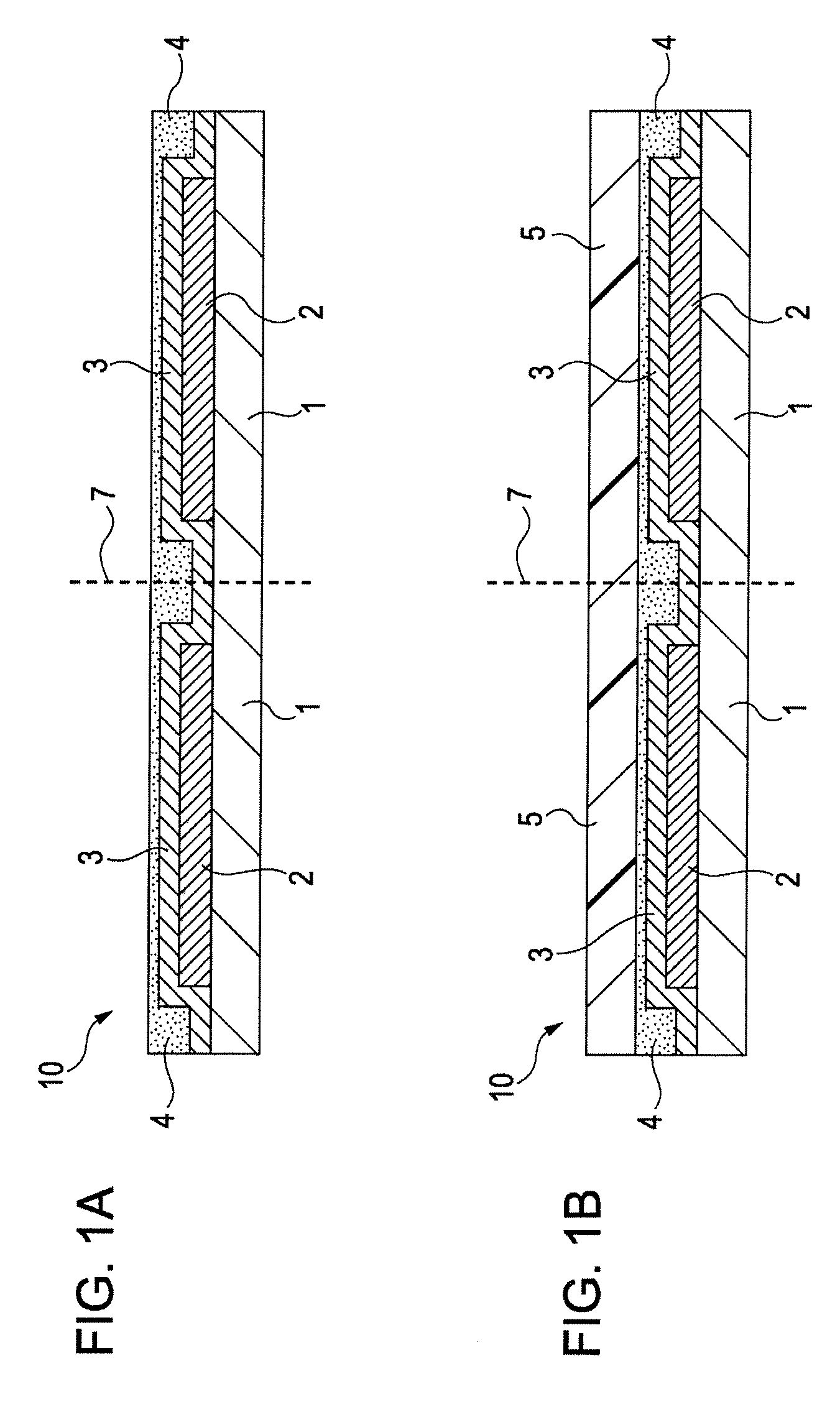

A substrate, an array of organic electroluminescence element groups disposed on the substrate, each organic electroluminescence element group formed of a plurality of organic electroluminescence elements, a protective layer disposed on the array of organic electroluminescence element groups, and a laminate member disposed on the protective layer were divided between the array of organic electroluminescence element groups into a plurality of organic electroluminescence panels.

Owner:CANON KK

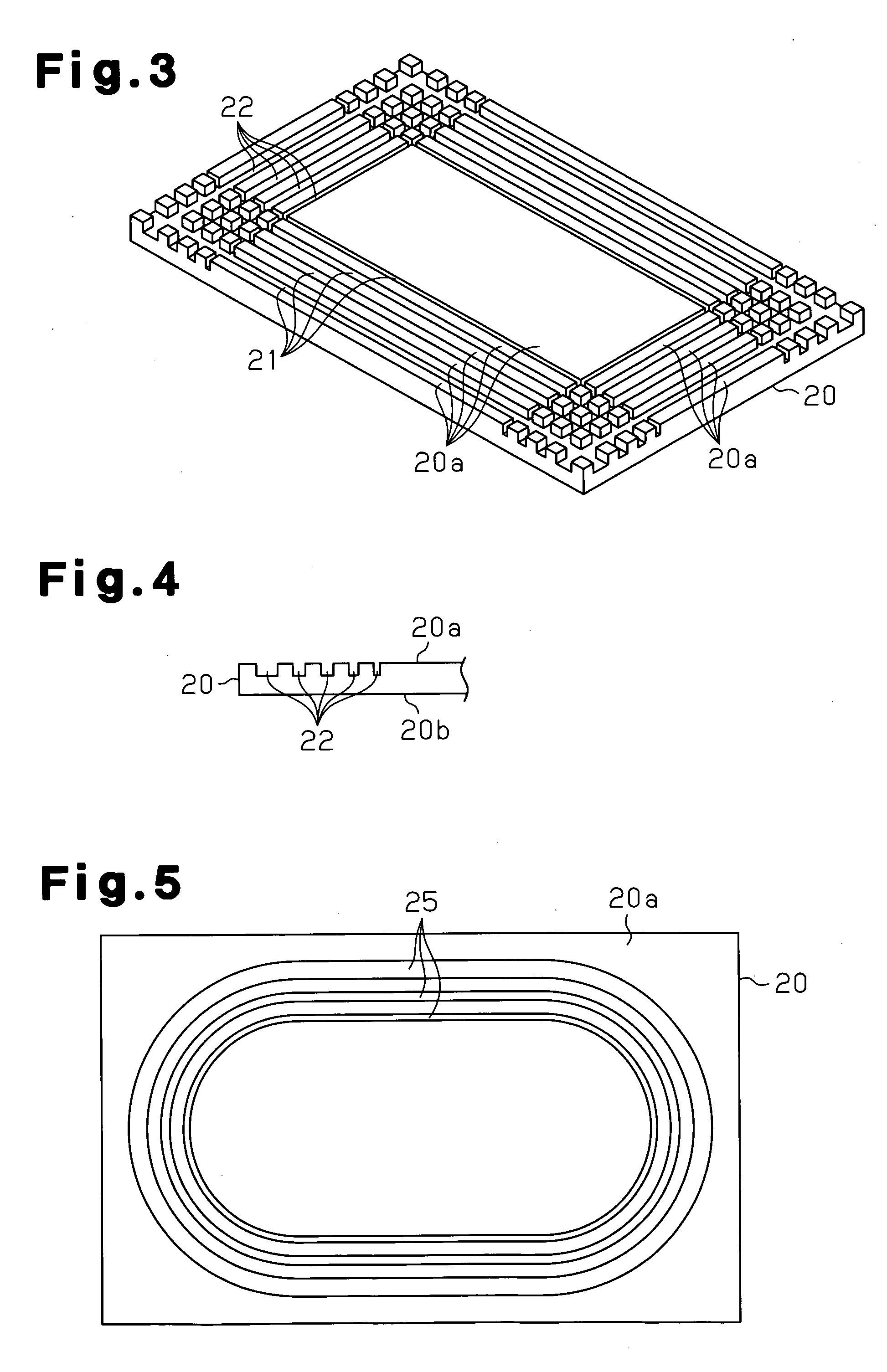

Semiconductor device

InactiveUS20080290499A1Improve cooling effectAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesCouplingCeramic substrate

A semiconductor device is disclosed that includes a ceramic substrate having first and second surfaces, a semiconductor element, a radiator, and an interposed portion located between the second surface and the radiator. The interposed portion has coupling regions that couple the second surface to the radiator, and non-coupling regions that do not couple the second surface to the radiator. Each non-coupling region is formed as an elongated groove. In the group of the non-coupling regions, the width of the outermost non-coupling region in the interposed portion is greater than the width of the innermost non-coupling region in the interposed portion. Regarding an adjacent pair of the non-coupling regions in the width direction, the width of the outer non-coupling region is greater than or equal to the width of the inner non-coupling region.

Owner:TOYOTA IND CORP +1

Traditional Chinese medicine sterilization hand cream

InactiveCN102908298AAvoid cracking and peelingRefreshing textureCosmetic preparationsToilet preparationsVegetable oilAdditive ingredient

The invention belongs to the field of cosmetics, and particularly relates to a traditional Chinese medicine sterilization hand cream which comprises the following components by weight percent: 20-25% of Chinese herbal medicinal ingredient, 10-20% of glycerol, 3-5% of vegetable oil, 0.1-0.3% of vitamin E, 0.5-0.8% of safflower seed oil, 0.2-0.5% of benzyl alcohol, 0.2-0.5% of cetearyl alcohol, 0.2-0.5% of collagen, 0.2-0.5% of squalane, 0.2-0.5% of honey, 0.5-2% of triethanolamine, 0.2-0.5% of shea butter, 0.2-0.5% of essence and the balance of medical Vaseline. The traditional Chinese medicine sterilization hand cream can be used for effectively supplementing water for hands, preventing peeling and cracking, protecting the dry hand skin, is fresh and cool in character, can rapidly permeate, and enables the skin to be smooth and nourished; and the hands can be instantaneously moisturized and smell perfect.

Owner:SHENYANG XINDA INFORMATION SCI & TECH

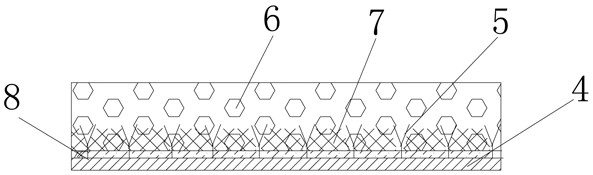

Sound-absorption coating composition

InactiveCN107760182AReduce weightAvoid cracking and peelingPolyurea/polyurethane coatingsReflecting/signal paintsWeather resistancePorous composite

The invention relates to the technical field of coating and in particular relates to a sound-absorption coating composition. The sound-absorption coating composition contains waterborne polyurethane emulsion, and titanium white and composite fibers which are dispersed in the waterborne polyurethane emulsion, wherein each composite fiber comprises a macroporous inner core and a mesoporous-containing outer wall. According to the sound-absorption coating composition provided by the invention, the composite fibers with different inner and outer pore structures are dispersed in the waterborne polyurethane emulsion so that the effect of reducing the whole mass of a coating layer can be realized and the transmission of sound waves can be stopped to realize a sound insulation effect; meanwhile, anetwork structure formed by the porous composite fibers has a certain buffering effect; an acting force of heat expansion of a sound-absorption coating layer can be effectively buffered and a condition that the sound-absorption coating layer is peeled and cracked is prevented; and the titanium white is added and has a reflection effect on incident light, so that the ageing of the sound-absorptioncoating layer is slowed down and the weather resistance is improved.

Owner:汪涛

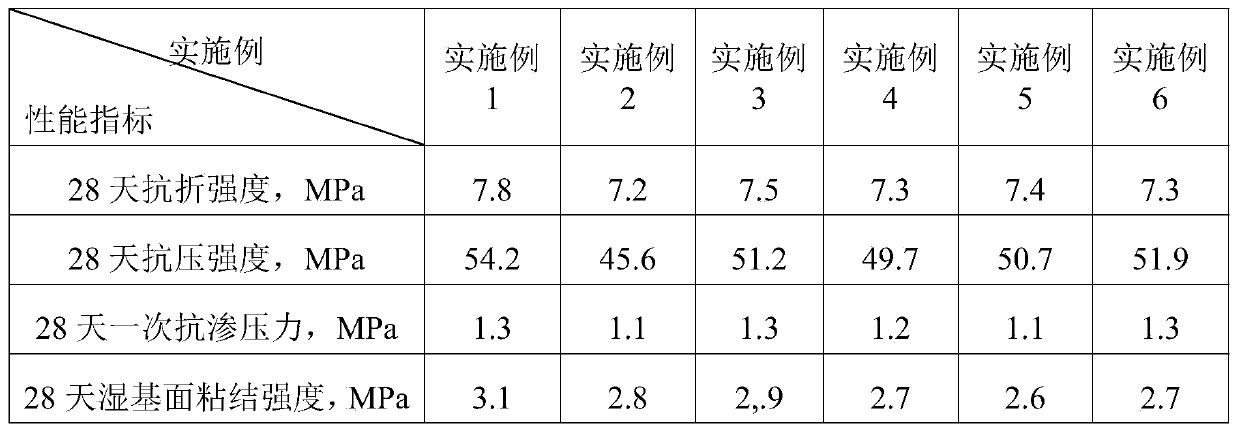

Cement-based capillary crystalline waterproof coating and preparation method thereof

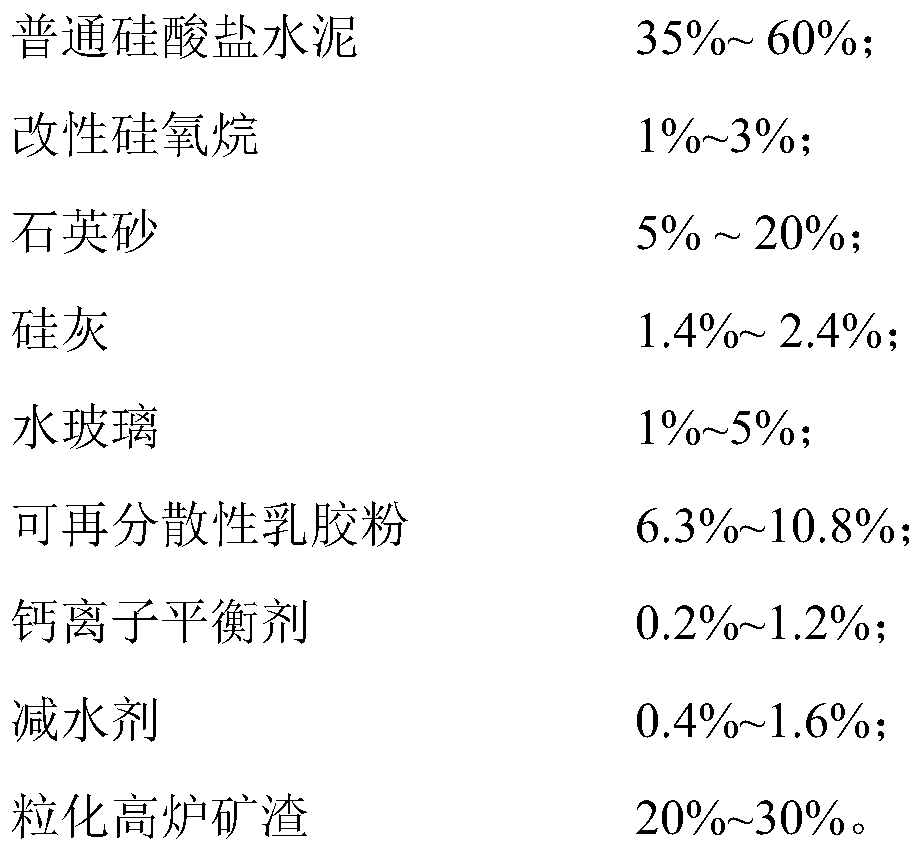

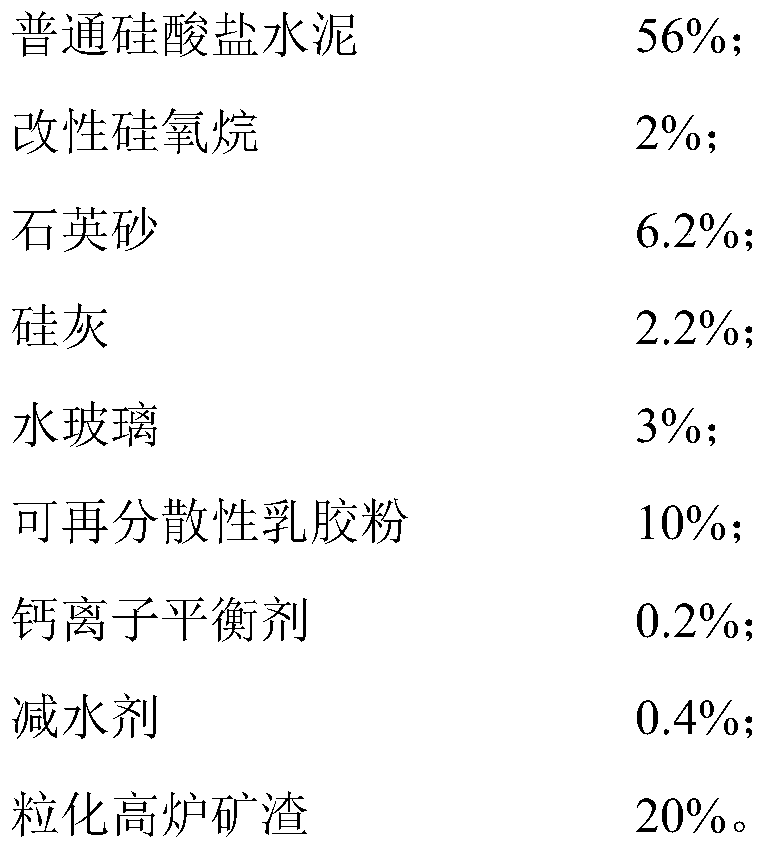

InactiveCN110922134AImprove impermeabilityImprove anti-seepage and waterproof effectSolid waste managementSilica fumeSiloxane

The invention discloses a cement-based capillary crystalline waterproof coating and a preparation method thereof, and belongs to the technical field of building waterproof materials. The cement-basedcapillary crystalline waterproof coating is composed of, by weight, 35%-60% of ordinary Portland cement; 1%-3% of a modified siloxane, 5%-20% of quartz sand, 1.4%-2.4% of silica fume, 1%-5% of water glass, 6.3%-10.8% of redispersible latex powder, 0.2%-1.2% of a calcium ion balancing agent, 0.4%-1.6% of a water reducing agent and 20%-30% of granulated blast furnace slag. By adopting the technicalscheme, the anti-permeability and waterproof performance, the bonding performance and the flexural and compressive strength of the obtained cement-based capillary crystalline waterproof coating can beeffectively improved, the anti-permeability and waterproof effects can be further improved when the cement-based capillary crystalline waterproof coating is applied to the surface of concrete, and therefore the service life of the concrete can be prolonged.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

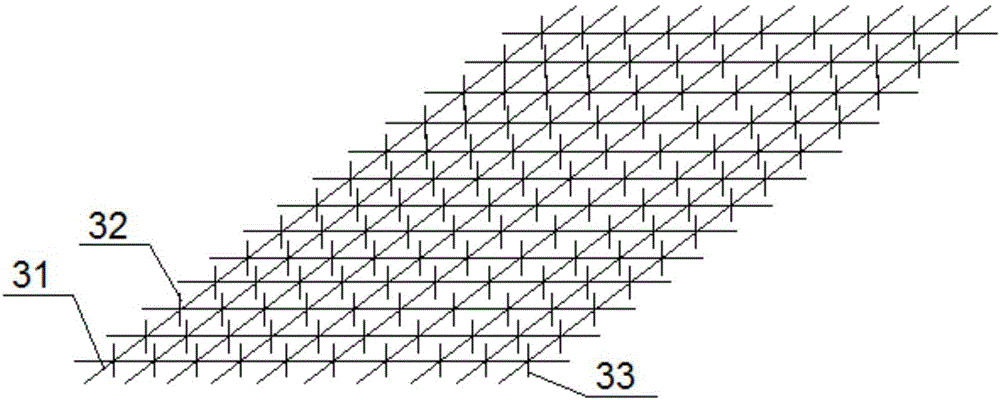

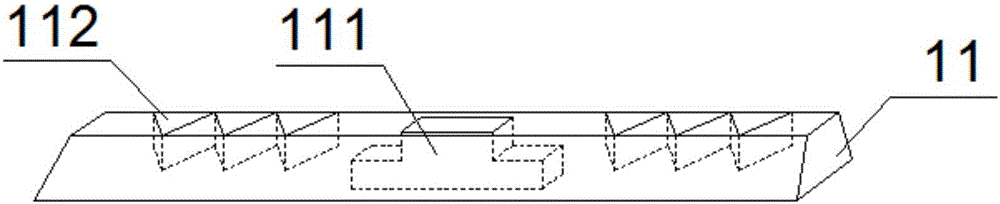

Durable driving belt

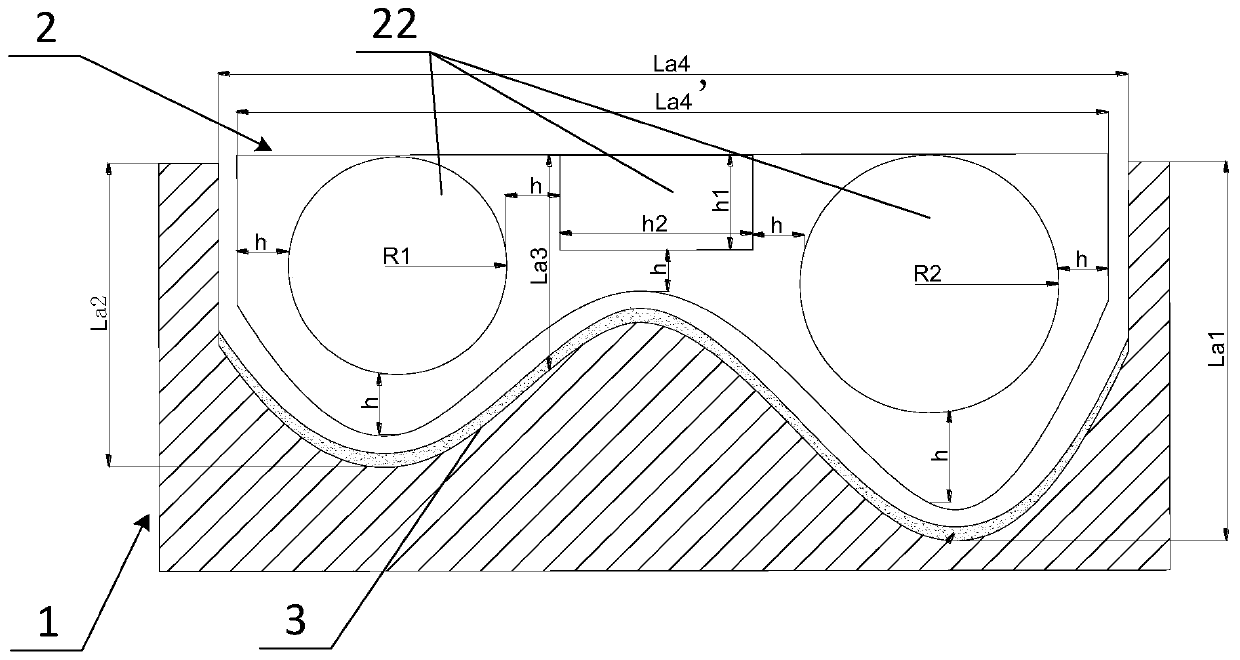

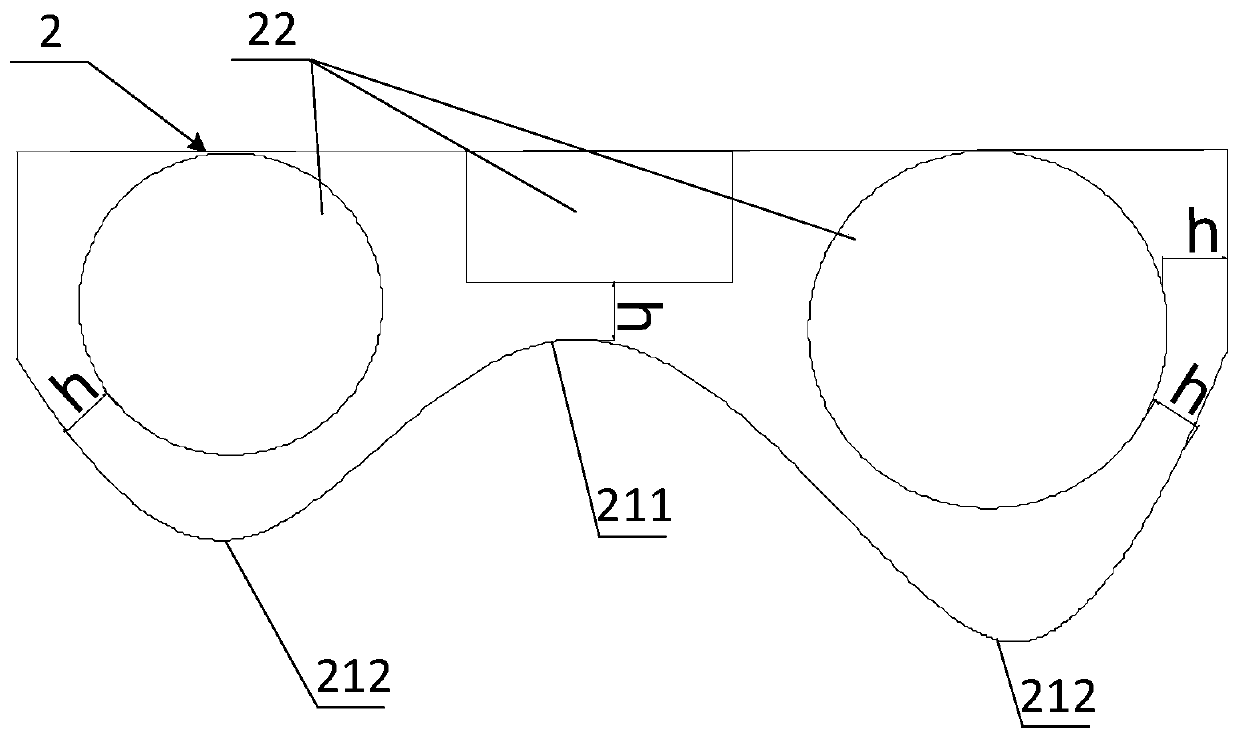

ActiveCN106641099AHigh mechanical strengthGuaranteed mechanical strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesHeat resistanceEngineering

The invention discloses a durable driving belt comprising a compressing rubber layer, a bonding rubber layer and a strengthening layer. The compressing rubber layer is connected with a power transmission assembly in a pressing mode, the bonding rubber layer bonds with the compressing rubber layer, and the strengthening layer is arranged between the compressing rubber layer and the bonding rubber layer, wherein the strengthening layer comprises composite fiber webs, first bonding rods, second bonding rods and strengthening cotton. The composite fiber webs are obtained by multiple fiber spinning solutions through the electrospinning technique. The first bonding rods and the second bonding rods are all obtained by smearing bonder on the outer portion of a plastic pipe. The driving belt has higher mechanical strength, flexibility is good, the abrasion resistance and heat resistance properties are excellent, the service life of the driving belt is greatly prolonged, and driving efficiency of the driving belt can be greatly improved.

Owner:日照新睿招商发展有限公司

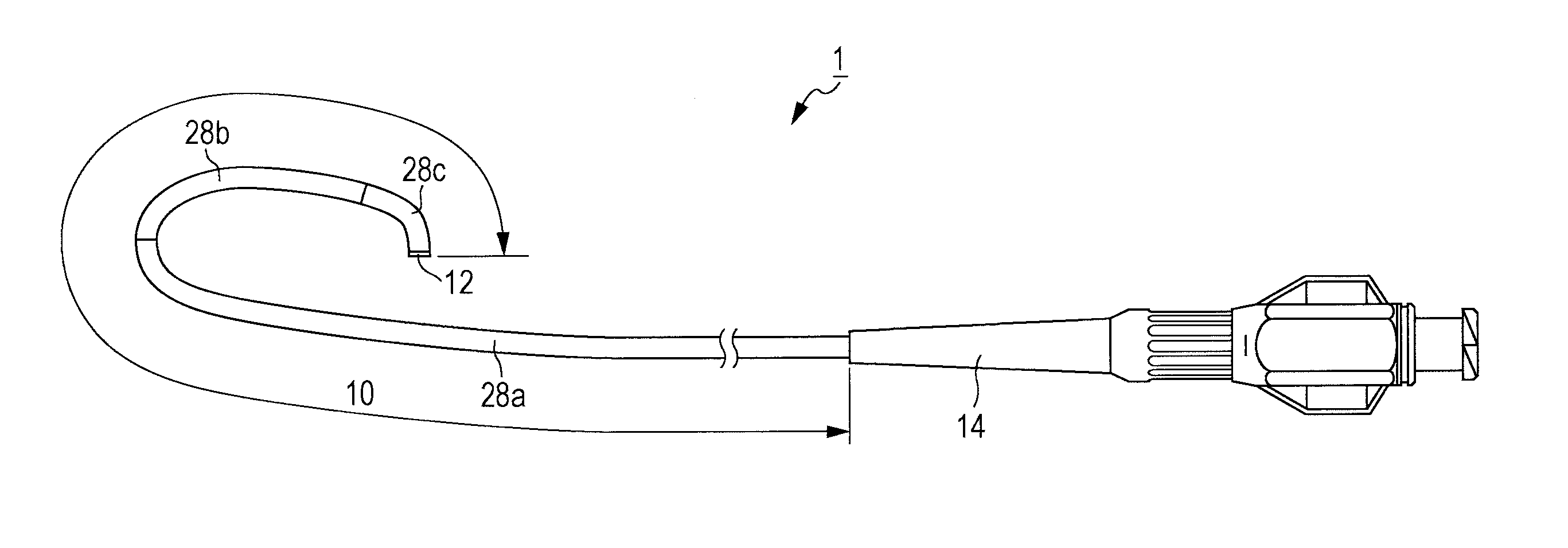

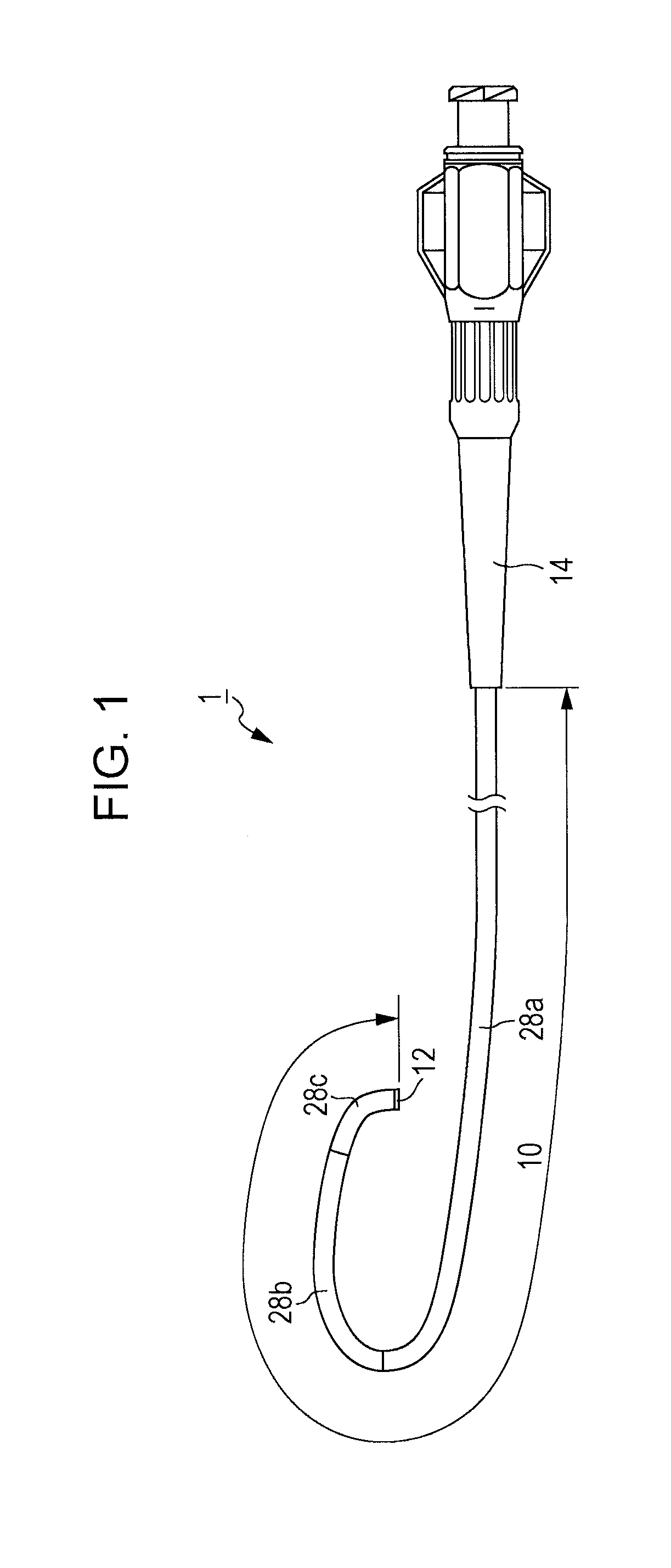

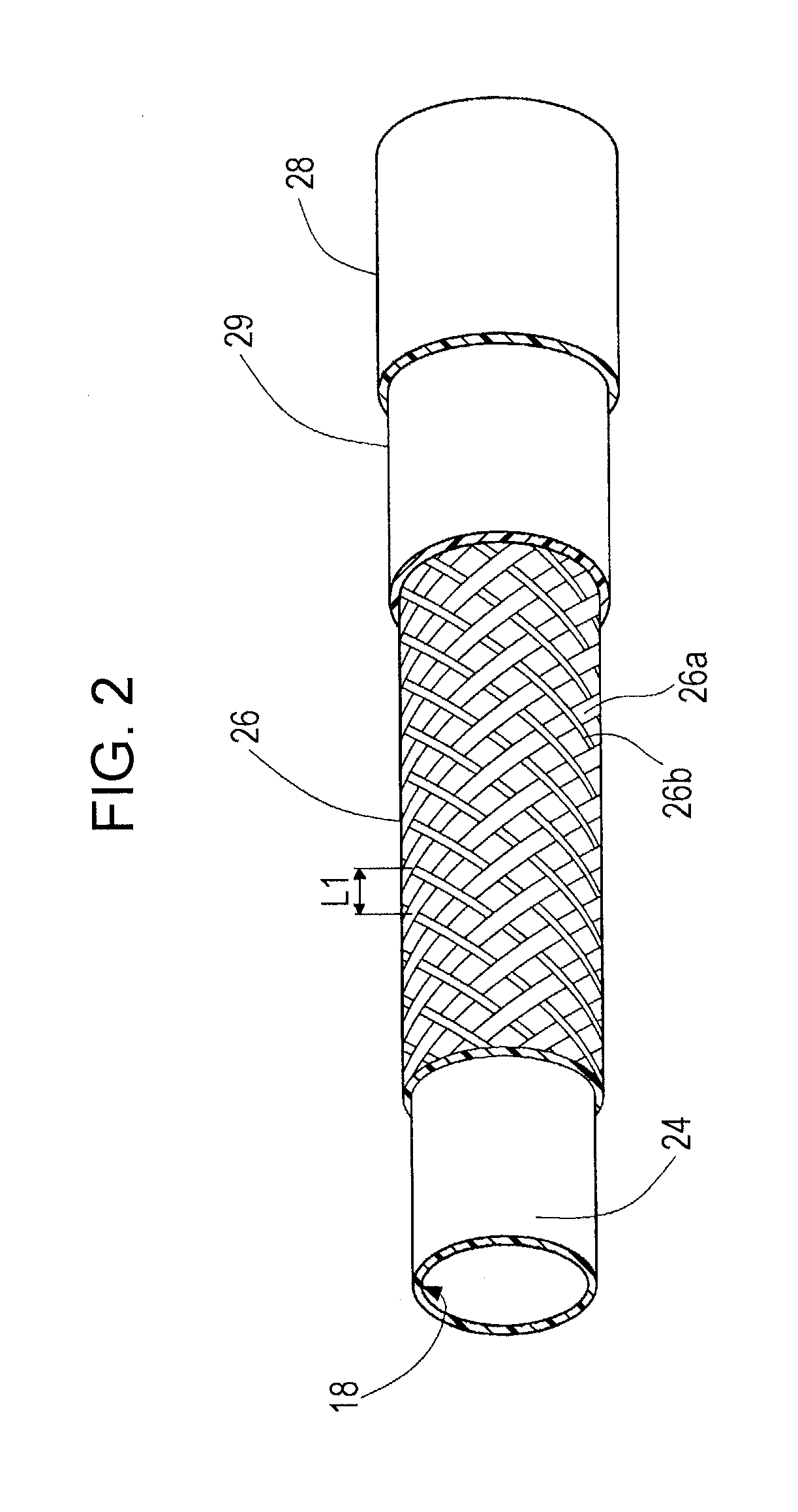

Catheter

InactiveUS20140236124A1Avoid cracking and peelingSuppress stressCatheterCoatingsCatheterBiomedical engineering

A catheter has an intermediate layer with a constant thickness in first and second adjacent portion, and the adhesive strength between the intermediate layer and an inner layer is uniform. When the catheter is curved, the movement of a braid caused by the curving of the catheter can be uniformly suppressed within the adjacent first and second portions. Even if, when the catheter is curved, a tensile stress towards a proximal end acts upon a first outer layer at the first portion and a tensile stress towards a distal end acts upon a second outer layer at the adjacent second portion, the first and second outer layers are caught by an uneven contour of the intermediate layer by an anchor effect, so that it is possible to prevent peeling of the first and second outer layers from the intermediate layer.

Owner:ASAHI INTECC CO LTD

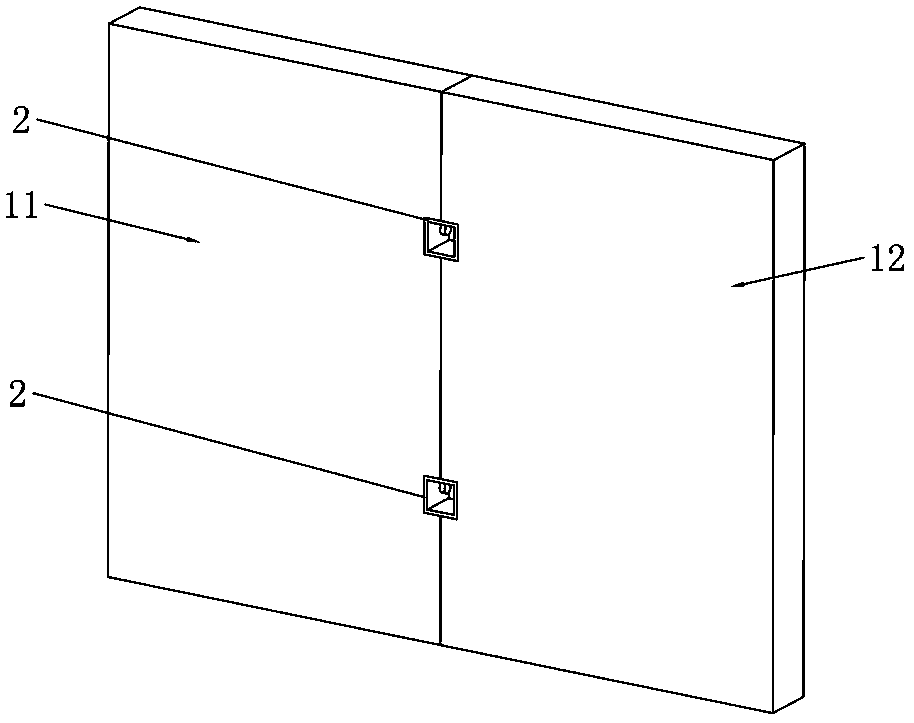

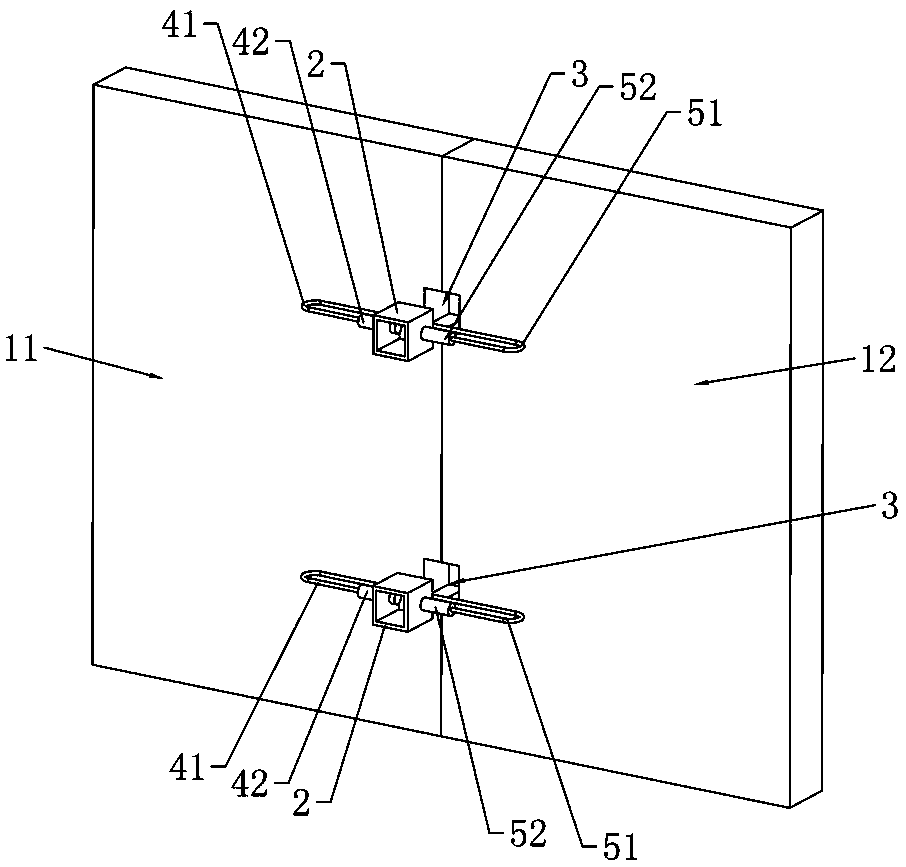

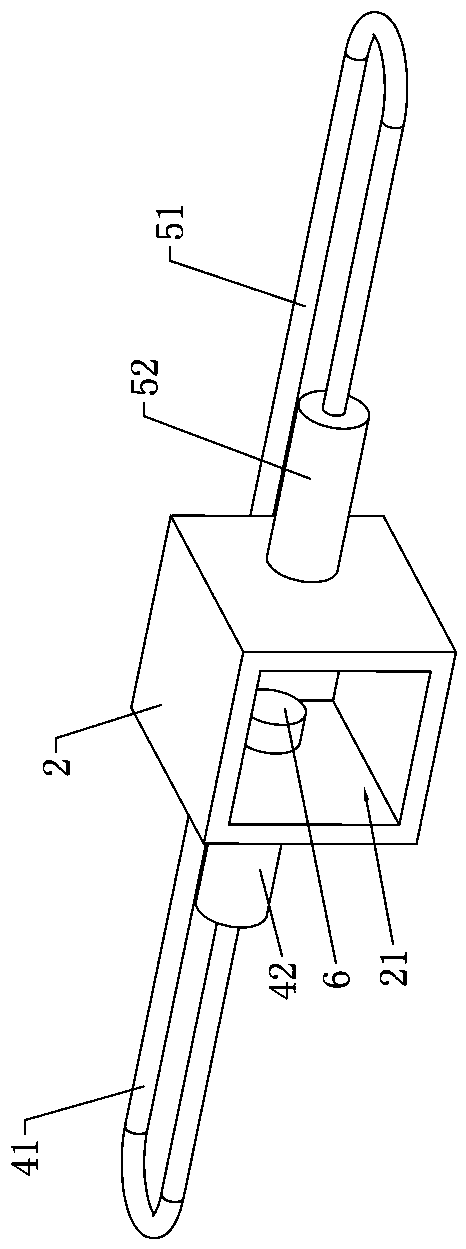

Fabricated-partition-wall connecting device and connecting method

Owner:广东华坤建设集团有限公司 +1

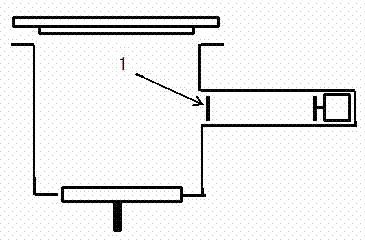

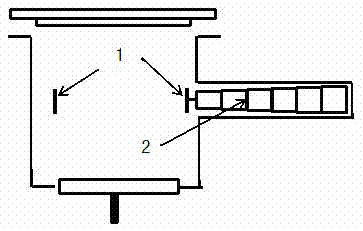

Reaction chamber for forming tantalum deposition film on silicon substrate, and application thereof

ActiveCN103031526AReduce depositionAvoid cracking and peelingVacuum evaporation coatingSemiconductor/solid-state device manufacturingSiliconTantalum

The invention provides a reaction chamber for forming a tantalum deposition film on a silicon substrate, and an application thereof. The reaction chamber comprises a reaction chamber body, wherein an empty cavity is arranged on the inner side wall of the cavity chamber of the reaction chamber body; a fixing bracket is arranged in the empty cavity and is provided with a telescopic component; the fixing bracket extends from the empty cavity under the driving of the telescopic component; and a tantalum ring is arranged at one end, capable of extending from the empty cavity, of the fixing bracket. According to the invention, the depositions of the tantalum film on the tantalum ring are reduced; and the problem of the cracking and the spalling of the tantalum film due to the condition that the film deposited on the tantalum ring is too thick is solved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

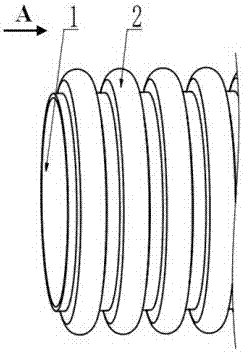

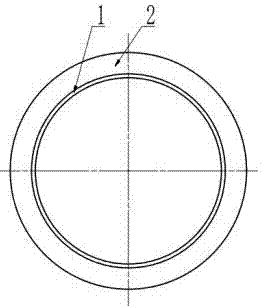

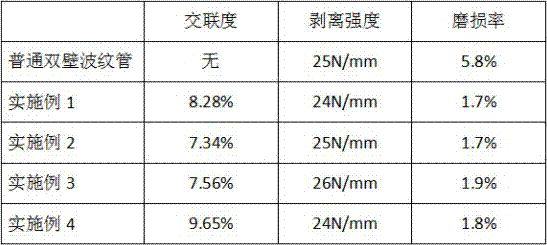

Double-wall corrugated pipe with wear-resistant inner wall and preparation method thereof

ActiveCN106977803AImprove liquidityImprove the lubrication effectRigid pipesPipe protection against damage/wearWear resistantSilanes

The invention discloses a double-wall corrugated pipe with a wear-resistant inner wall and a preparation method thereof. The double-wall corrugated pipe comprises a pipe inner wall base and a polyethylene corrugated pipe layer, the pipe inner wall base comprises, by weight, 50 to 80 parts of PE, 50 to 80 parts of POE, 10 to 50 parts of UHMWPE, 1 to 10 parts of silane, 0.1 to 0.5 parts of an initiator, 0.1 to 0.5 parts of an amine catalyst, 10 to 50 parts of a filler and 2 to 10 parts of a lubricant. After mortar swinging friction on the inner wall of the pipe 100000 times, the double-wall corrugated pipe with a wear-resistant inner wall has a wear rate reduced to 2% or less from 5% and improves wear resistance by 1 time or more. The double-wall corrugated pipe has physical and mechanical properties satisfying the national standard requirements, improves inner wall wear resistance, effectively prolongs a pipe service life and can be widely used in a sewage pipe network, drainage in residential quarters, rain and sewage diversion, industrial park wastewater discharge and drainage of large facilities.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Multilayer-structure celsian environment barrier coating as well as application and preparation method thereof

The invention relates to a high-temperature-resistant and corrosion-resistant coating, in particular to a multilayer-structure celsian environment barrier coating as well as application and a preparation method thereof, and aims to solve the problems that in the prior art, interlayer thermal expansion coefficients of silicon-based non-oxide ceramic environment barrier coating materials are not matched, so that the phenomena of through cracks, cracking and peeling are easily caused, and the problems of coating failure and base material oxidation are solved. The coating comprises a bonding layer, a combined middle layer and a surface layer, the bonding layer is a silicon layer covering the surface of a base body, the combined middle layer comprises a mullite layer covering the silicon layer and a mullite and strontium-doped barium feldspar mixed layer covering the mullite layer, and the surface layer is a strontium-doped barium feldspar layer covering the mullite and strontium-doped barium feldspar mixed layer; the thickness of the bonding layer is 90-120 microns, the thickness of the combined middle layer is 90-140 microns, the thickness of the surface layer is 120-160 microns, and the total thickness of the coating is greater than or equal to 300 microns. A matrix material used by the coating is a SiC matrix, a C / SiC composite material matrix or a SiC / SiC composite material matrix.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Method for fusing bioactive material on surface of artificial tooth pure titanium spiral-shafted implant

InactiveCN102626345APromotes early adhesionPromote proliferationDental implantsImpression capsFreeze-dryingSlurry

The invention discloses a method for fusing a bioactive material on the surface of an artificial tooth pure titanium spiral-shafted implant. The method comprises the following steps of: coating a layer of titanium slurry of 0.02-0.08 millimeter on the surface of the artificial tooth pure titanium spiral-shafted implant, sintering in vacuum after the titanium slurry becomes dry, and controlling the temperature at 1,000-1,500 DEG C; adding 20-30 percent of water into nano-scale artificial bone meal for bending into paste, filling titanium holes with a vacuum grouting method, and sintering at a low temperature; coating a layer of bone to form proteins, and performing freeze drying and refrigeration for later use; or before clinical use, wrapping with blood platelet-rich blood plasma. The method has the advantages of easiness, convenience, avoidance of the influence of high temperature on a material, reduction in hydroxyl denaturation and crystallinity degree, material crispness, cracking and stripping of a substrate, no need of special equipment, low cost, easiness for batch production, and the like.

Owner:NANNING YUEYANG TECH

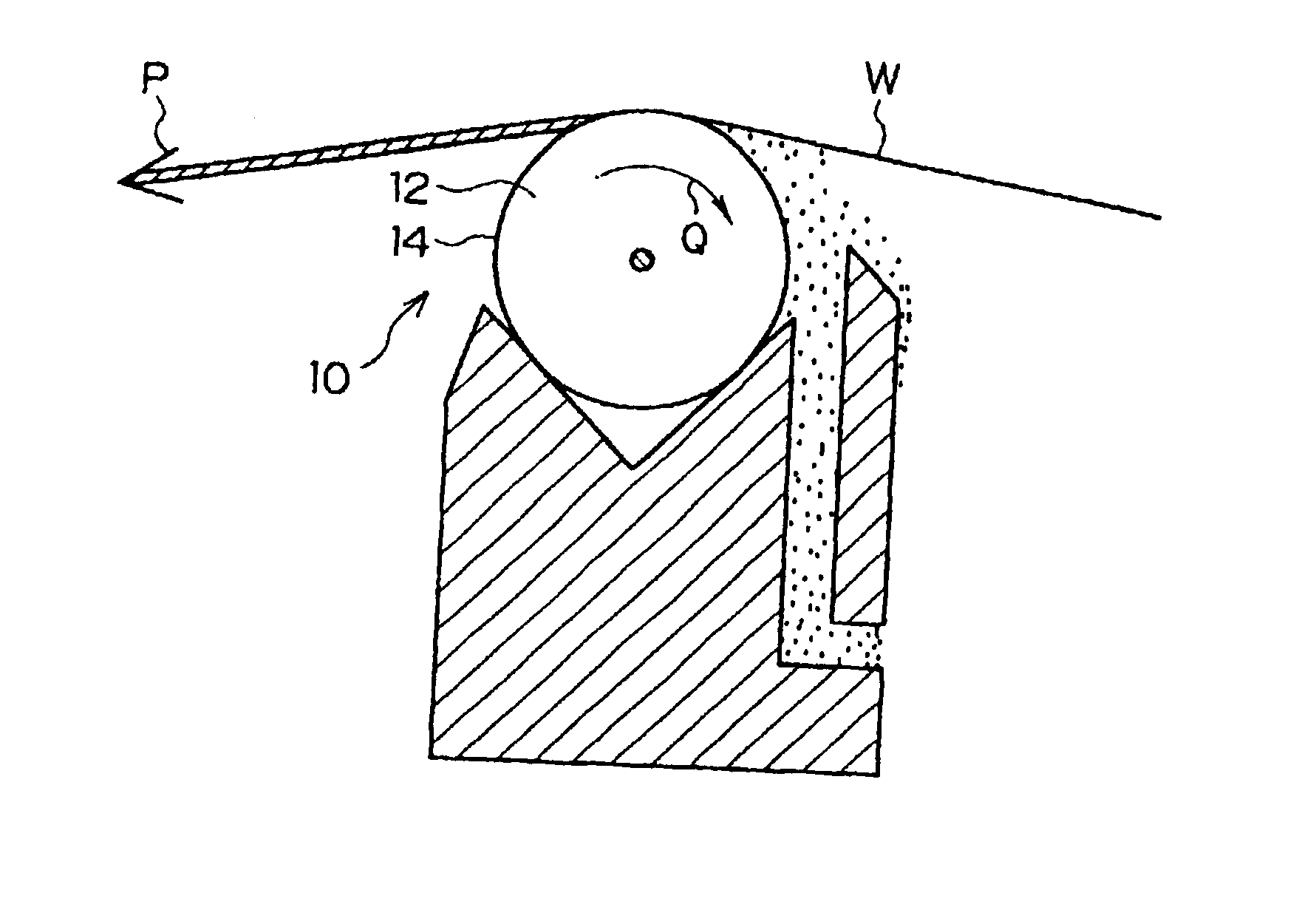

Rod for a coating device, and process for producing the same

InactiveUS6946031B2Improve adhesionUniform thicknessLiquid surface applicatorsVacuum evaporation coatingThermal expansionHardness

A rod for a coating device, used when a continuously-running body is coated with a coating solution, includes: a columnar base material; and an abrasion-resistant coating formed on a circumferential surface of the base material. When a friction coefficient between the coating and the body is represented by μ, a Vickers hardness of the coating is represented by Hv, a thermal expansion coefficient of the base material is represented by α1×10−6 / ° C., a thermal expansion coefficient of the coating is represented by α2×10−6 / ° C., and a film thickness of the coating is represented by t μm, μ and Hv satisfy a predetermined relational expression, and / or α1, α2 and t satisfy another predetermined relational expression. Specifically, Hv>1500×μ2+1200 and / or |α1−α2|<3 / (t−4)+7. The invention provides a process for producing a rod, for a coating device, on which an abrasion-resistant coating is formed on a base material to have a uniform thickness.

Owner:FUJIFILM CORP +1

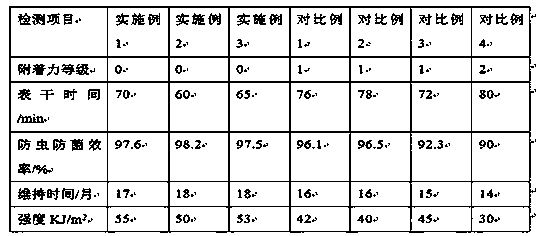

Antifreezing tree trunk whitening agent and preparation method thereof

PendingCN110229600AGood moisture absorptionLowering the freezing pointBiocideAntifouling/underwater paintsActive agentChemistry

The invention discloses an antifreezing tree trunk whitening agent and a preparation method thereof, and belongs to the technical field of tree whitening agents. An antifreezing active agent for preparation is chelated with calcium and magnesium ions in trees, so that the survival rate of the trees can be improved at a low temperature; hydrophobic C-C long chains on the main chain of a coating additive inhibit shrinkage and expansion of a coating film, and a good coating state is well kept; a surfactant is introduced into the coating film, and an insect-resistant active agent in the whiteningagent is released, so that insect-resistant and anti-microbial functions are synergistic; active substances with insect repelling and sterilizing functions in turmeric, Chinese prickly ash and the like are extracted by alcohol extraction, and insect-resistant and anti-bacterial effects on tree trunks are enhanced; a freezing-resistant active agent is used for reducing the freezing point and storing water inside the tree trunks, so that the tree trunks are prevented from cracking and spalling; and due to response of carbon dioxide generated by respiratory action of the tree trunks, viscosity ofthe coating film is improved, and the overall function of the tree trunk whitening agent is increased. According to the invention, the problems that a formed film of an existing tree trunk coating agent cracks and falls off easily and the insect-resistant and anti-bacterial effects are poor are solved.

Owner:戴小红

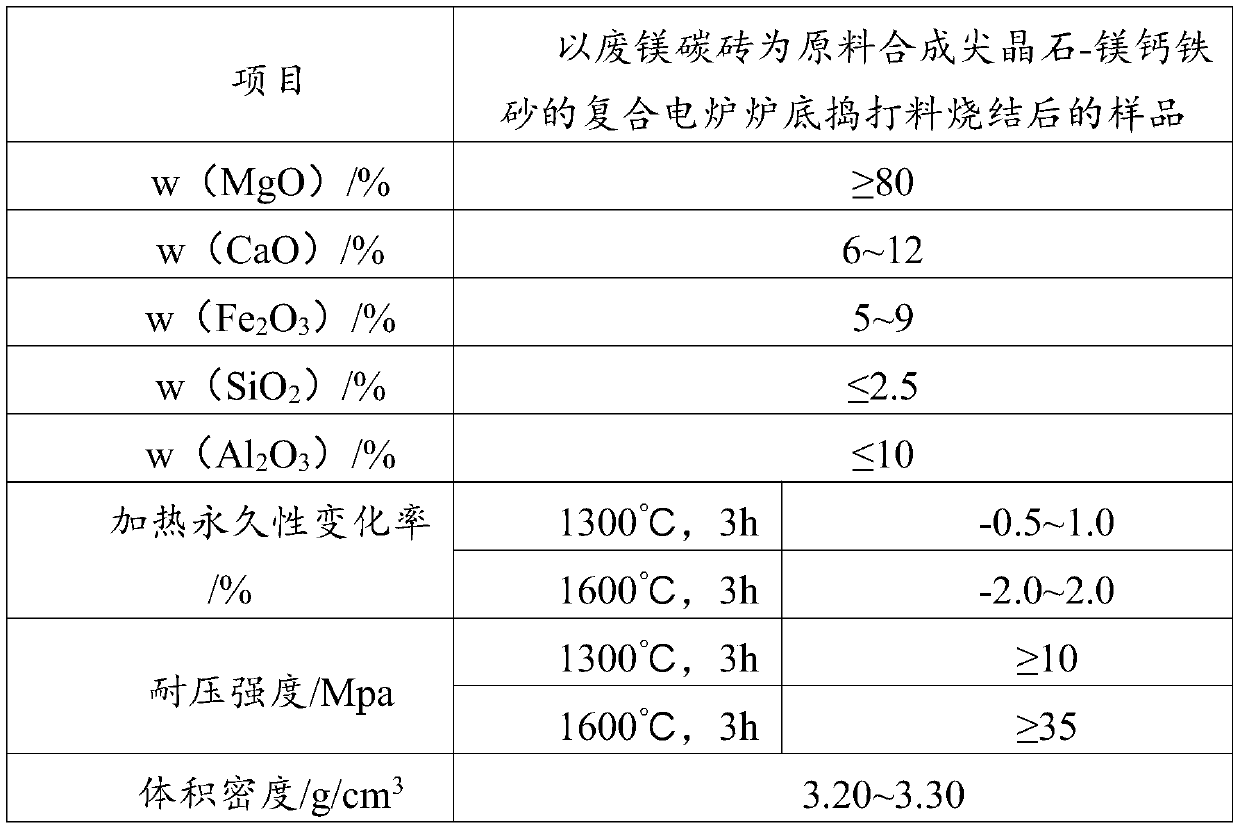

Composite electric furnace bottom ramming material for synthesizing spinel-magnesium-calcium-iron sand and preparation method thereof

The invention belongs to the field of refractory materials. The invention provides a composite electric furnace bottom ramming material for synthesizing spinel-magnesia-calcium-iron sand by taking waste magnesia-carbon bricks as raw materials. The composite electric furnace bottom ramming material comprises the following components in parts by weight: 92-109 parts of synthetic sand and 1-3 parts of a clay binding agent, in the raw materials for preparing the synthetic sand, the weight ratio of the magnesia carbon brick particles to the light calcined dolomite powder to the light calcined magnesium powder to the slaked lime powder to the iron oxide red is (50-55):(12-16):(20-25):(4-8):(4-6). The invention further provides a preparation method of the composite electric furnace bottom rammingmaterial. Spinel generated by adopting the method is crossed with periclase and dicalcium ferrite, so that the defect of high porosity of spinel is avoided, the thickness of a sintering layer at thebottom of the electric furnace is further reduced, and the phenomena of cracking and bleed-out of the bottom of the furnace are further reduced. The prepared composite electric furnace bottom rammingmaterial is good in comprehensive performance, excellent in high-temperature performance and long in service life.

Owner:北京利尔高温材料股份有限公司

Pure-traditional-Chinese-medicine hand cream with chapping-resistant and repairing effects

InactiveCN104523516ARepair chappedPromote absorptionCosmetic preparationsToilet preparationsVegetable oilAloe barberae

The invention discloses a pure-traditional-Chinese-medicine hand cream with the chapping-resistant and repairing effects. The pure-traditional-Chinese-medicine hand cream comprises the following components in parts by weight: 20-30 parts of pure-traditional-Chinese-medicine powder agent, 15-25 parts of glycerinum, 30-50 parts of vaseline and 1-2 parts of vegetable oil, wherein the pure-traditional-Chinese-medicine powder agent is prepared by cleaning coptis chinensis, ginseng and astragalus membranaceus, drying, crushing and mixing; and the vegetable oil is peppermint essential oil, aloe essential oil or lavender essential oil. The pure-traditional-Chinese-medicine hand cream disclosed by the invention has the advantages that water of the skin of the hand can be effectively supplemented, the desquamation and the chapping are prevented and simultaneously the good repairing effect for the hand chapping is achieved.

Owner:ZHENJIANG BIO INNOVA BIOTECH

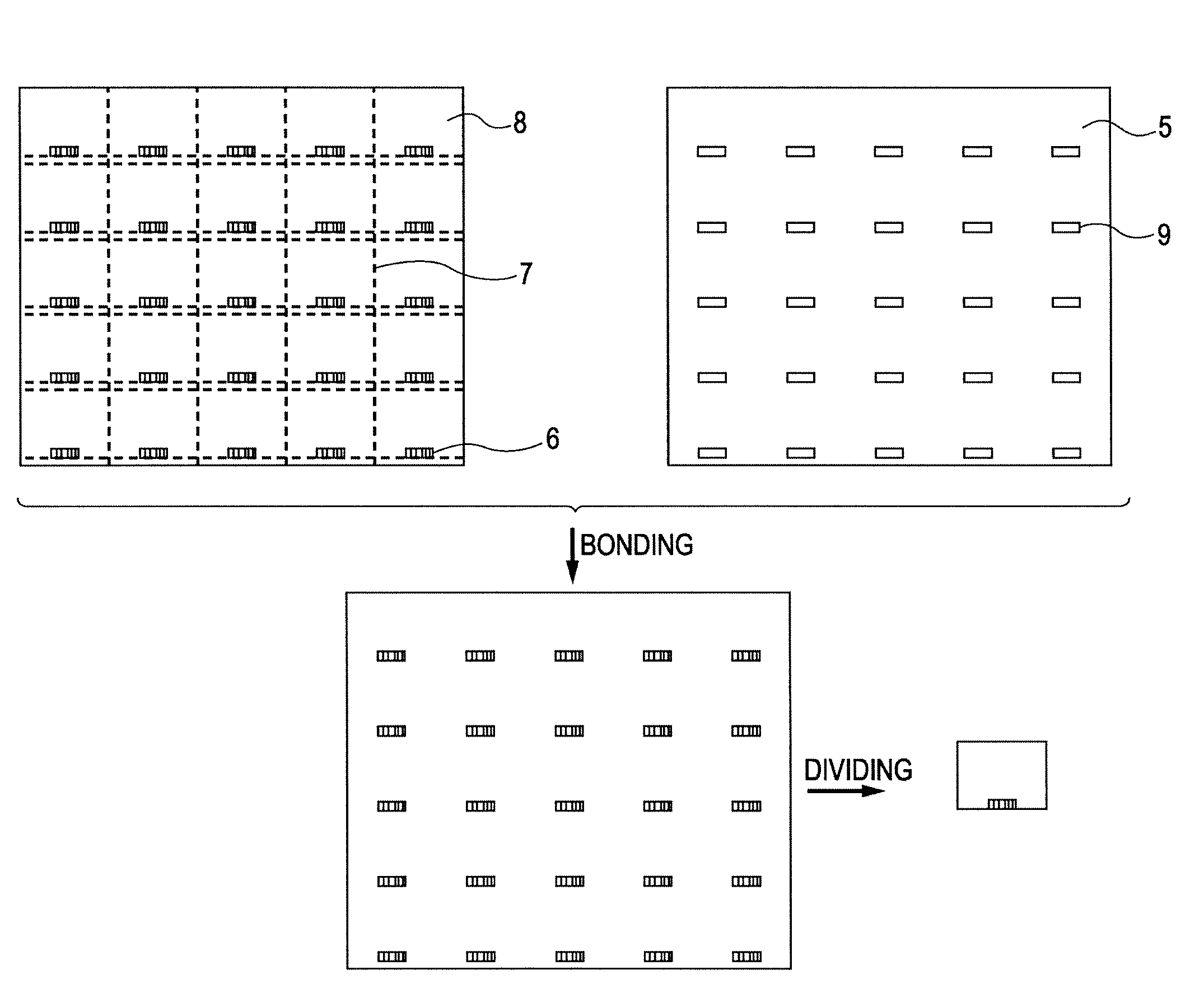

Method for manufacturing organic electroluminescence panel

ActiveUS8557067B2Simple manufacturing processAvoid cracking and peelingLamination ancillary operationsSolid-state devicesOrganic electroluminescenceChemistry

A substrate, an array of organic electroluminescence element groups disposed on the substrate, each organic electroluminescence element group formed of a plurality of organic electroluminescence elements, a protective layer disposed on the array of organic electroluminescence element groups, and a laminate member disposed on the protective layer were divided between the array of organic electroluminescence element groups into a plurality of organic electroluminescence panels.

Owner:CANON KK

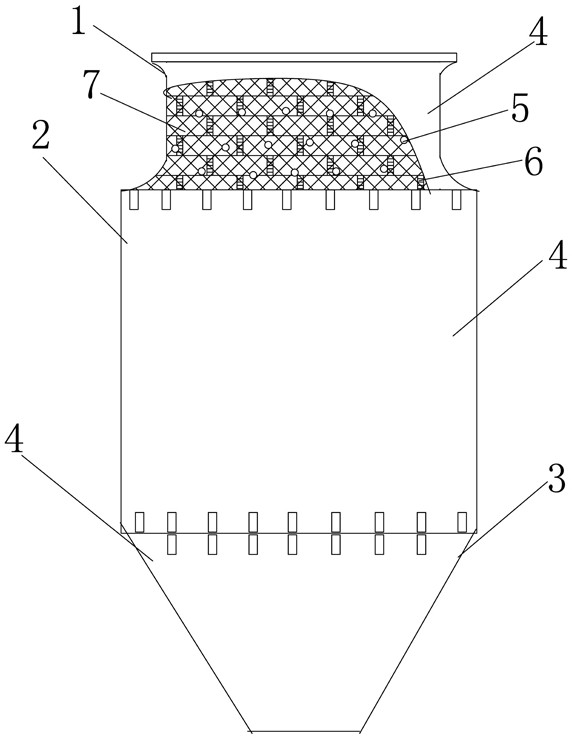

Self-sealing composite structure coke tank

PendingCN111662729AHigh strengthAvoid cracking and peelingCoke quenchingThermal insulationCokeRefractory

The invention relates to a self-sealing composite structure coke tank which is mainly divided into a coke inlet section, a storage cylinder section and a coke outlet section on the whole, each sectionis composed of a metal shell, an anchoring part on the inner wall of the metal shell and a castable layer, and the sections are connected in an embedded sealing mode. According to the coke inlet section structure, a metal net layer is fixed to an anchoring part and connected with the anchoring part; the castable layer is made of a light refractory castable with the density of 1.6-1.9 g / cm < 3 >;according to the storage cylinder section structure, a metal net layer is fixed to an anchoring part and connected with the anchoring part; a nano insulation board is adhered to the metal shell; the castable layer is made of a semi-heavy refractory castable with the density of 2.0-2.6 g / cm < 3 >; and the coke outlet section structure is the same as the material storage cylinder section structure.On the premise that the manufacturing cost is not increased, the service life of the coke tank lining plate can be prolonged, the replacement period is prolonged by at least 6 months compared with theoriginal replacement period, the maintenance cost can be reduced by at least 30%, and the temperature of the outer surface of the tank shell can be reduced by 50-100 DEG C.

Owner:武汉钢铁有限公司

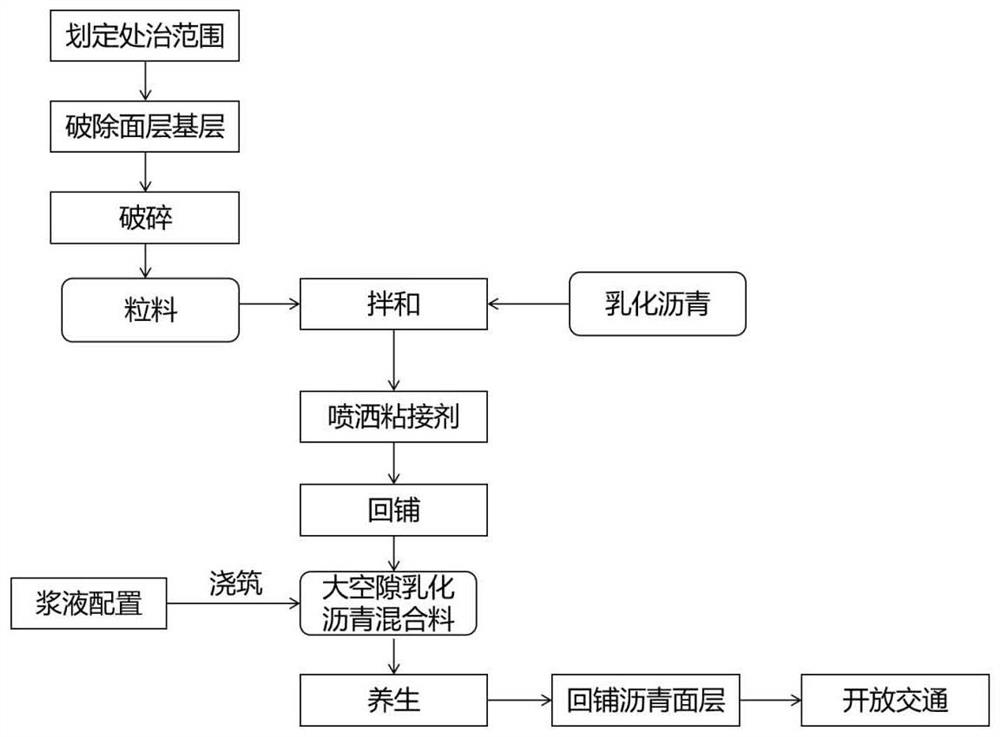

On-site rapid regeneration and repair method for damage for semi-rigid base of asphalt pavement

PendingCN113250031AEnable on-site recyclingTo achieve \"carbon neutralIn situ pavingsCement productionAggregate (composite)Adhesive

The invention discloses an on-site rapid regeneration and repair method for damage for a semi-rigid base of asphalt pavement. The method comprises the following steps: (1) determining a treatment range, breaking a whole surface layer and a whole base layer, and crushing the surface layer and the whole base layer through crushing equipment to produce backfill aggregates; 2) mixing the granules with emulsified asphalt; (3) spraying an interface adhesive to the excavation interface; (4) paving the mixed granules to the disease part, leveling and rolling to form a large-gap emulsified asphalt mixture; (5) pouring geopolymer or quick-hardening cement slurry into gaps of the backfill material; and (6), an asphalt surface layer is paved after the curing time is up, and traffic is opened. The repairing method is simple, rapid, small in traffic influence, energy-saving and environment-friendly, the semi-flexible composite material with the elastic modulus equivalent to that of an original pavement semi-rigid base layer is obtained through on-site recycling of an original pavement material, the semi-flexible composite material is bonded with the original pavement material through an interface chemical reaction, and the service life is prolonged.

Owner:YINGDA HEAT REGENERATION

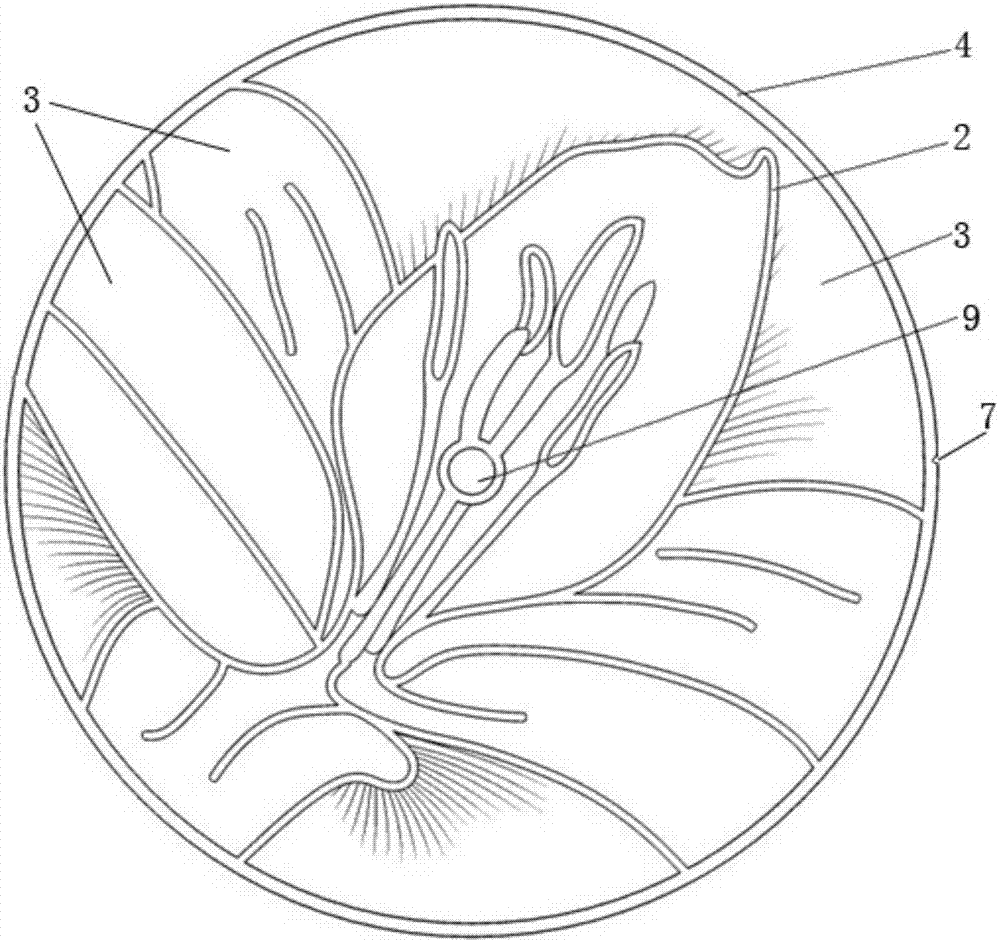

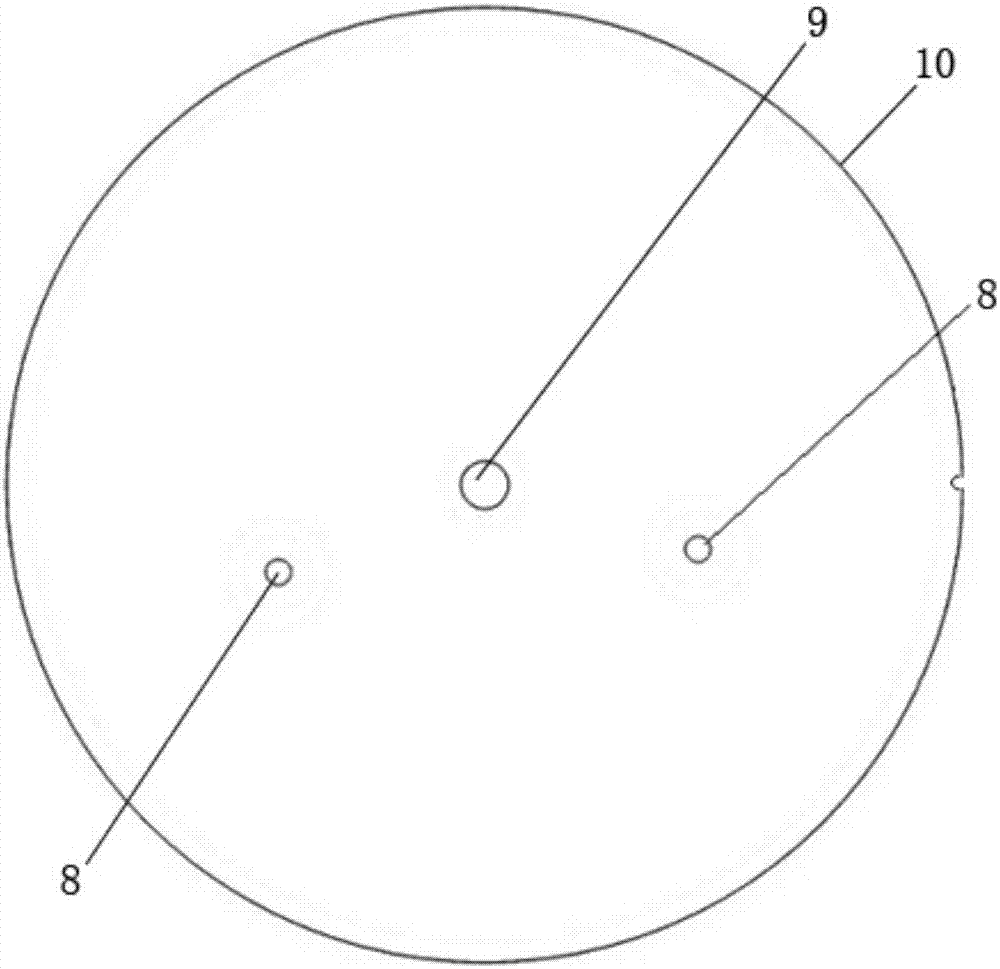

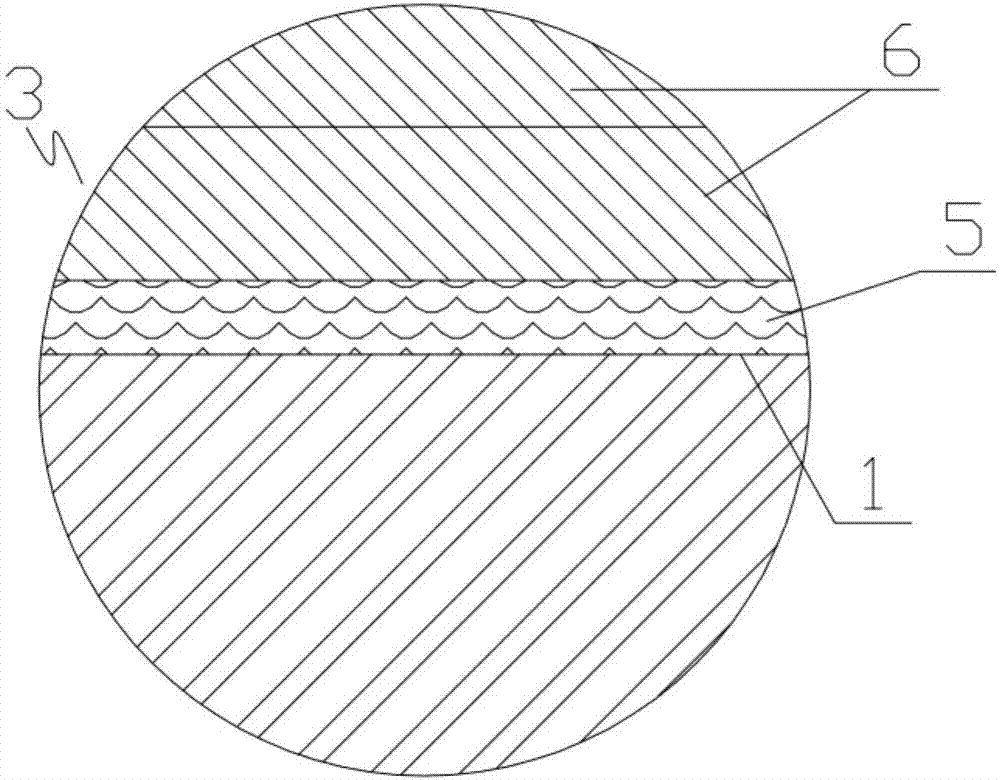

Filigree-simulating enamel dial plate and production method thereof

ActiveCN107379863AImprove aging resistanceSmall sticking pollutionSpecial ornamental structuresClockwork casesPunchingEngineering

The invention discloses a filigree-simulating enamel dial plate and a production method thereof. The filigree-simulating enamel dial plate comprises a dial plate body. The front face of the dial plate body is an enamel face. The enamel face comprises a base face, metal wires partitioned on the base face and having a filigree-simulating effect, cold enamel layers arranged in the partitioned areas in a filling manner and a frame surrounding the base face. The metal wires, the frame and the dial plate body are in a punching forming integrated structure relationship. According to the filigree-simulating enamel dial plate and the production method thereof, the filigree-simulating effect is good, the production efficiency is far higher than that of a traditional filigree technology, the production difficulty and the production cost of the enamel dial plate are lowered, and the product problems and the low defective rate caused by the traditional filigree technology are avoided. The production method is low in difficulty, good in stability, high in controllable degree, low in production risk, high in generation efficiency and capable of achieving batched production; and the produced filigree-simulating enamel dial plate has the attractiveness and the texture effect of a traditional filigree enamel dial plate and can meet the requirements of people.

Owner:GUANGZHOU PANYU POLYTECHNIC

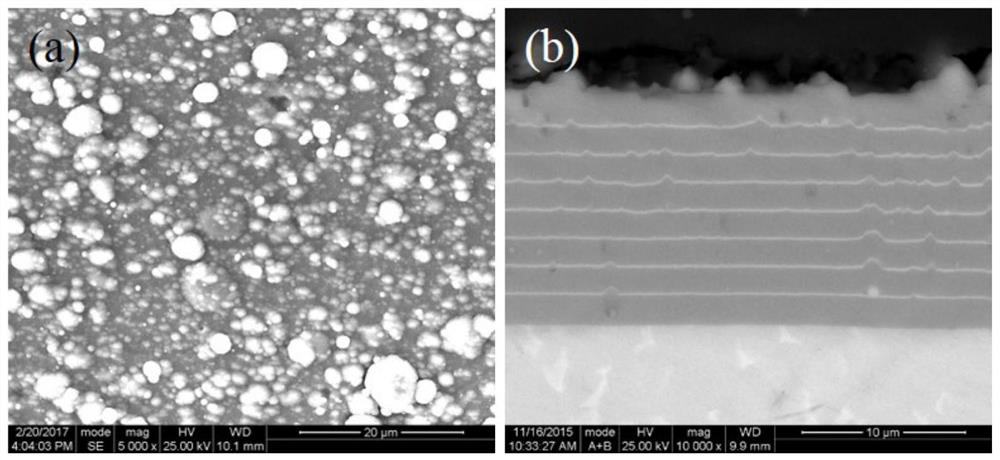

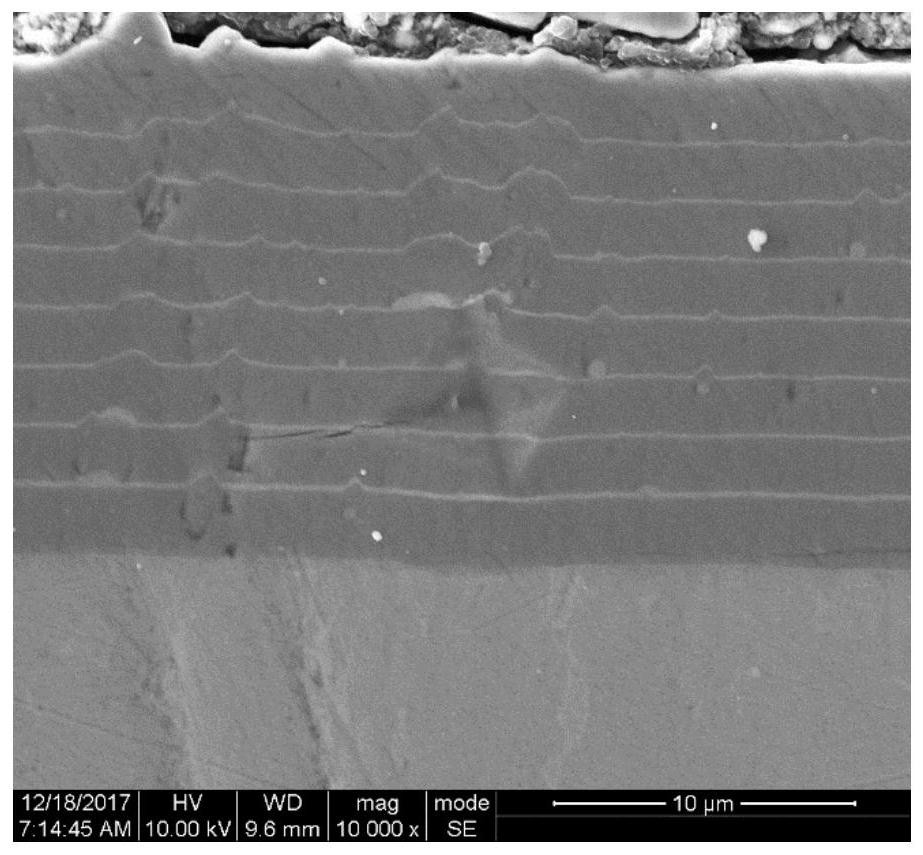

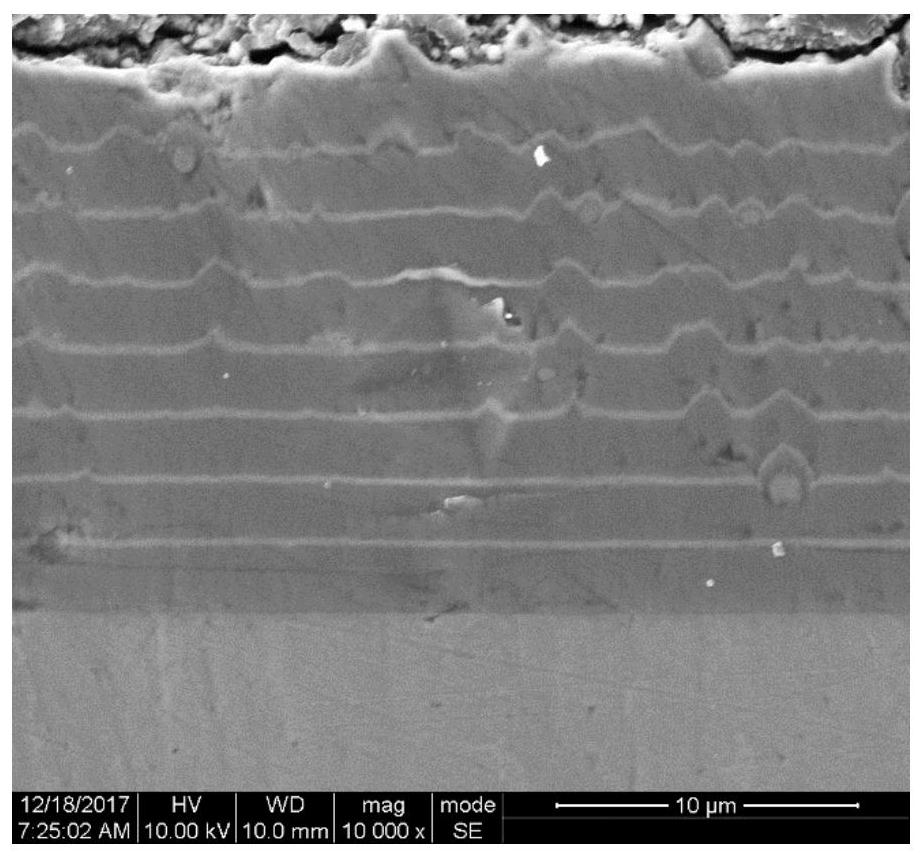

Thick ti/tialn multilayer coating with high toughness and high hardness and preparation method thereof

ActiveCN110004415BReduce internal stressPrevent cracking and peelingVacuum evaporation coatingSputtering coatingCemented carbideAlloy substrate

The invention relates to hard protective coatings, in particular to a thick Ti or TiAlN multilayer coating with high toughness and hardness and a preparation method thereof. The Ti or TiAlN multilayercoating deposits on the surface of a hard alloy substrate by using general arc ion plating equipment and selecting a Ti target and a TiAl target as cathode targets; the Ti or TiAlN multilayer coatingis a layered structure and comprises a TiN transition layer, multiple TiAlN sublayers and Ti sublayers; the first layer depositing on the substrate is the TiN transition layer, the second layer is the TiAlN sublayers, and then the Ti sublayers; the TiAlN sublayers and the Ti sublayers deposit in an alternating superposition mode, and the outermost layer is the TiAlN sublayers; The Ti or TiAlN multilayer coating has the characteristics of high thickness, good coating-substrate bonding strength, high hardness, high toughness and good oxidation resistance and the like.

Owner:HENAN INST OF SCI & TECH

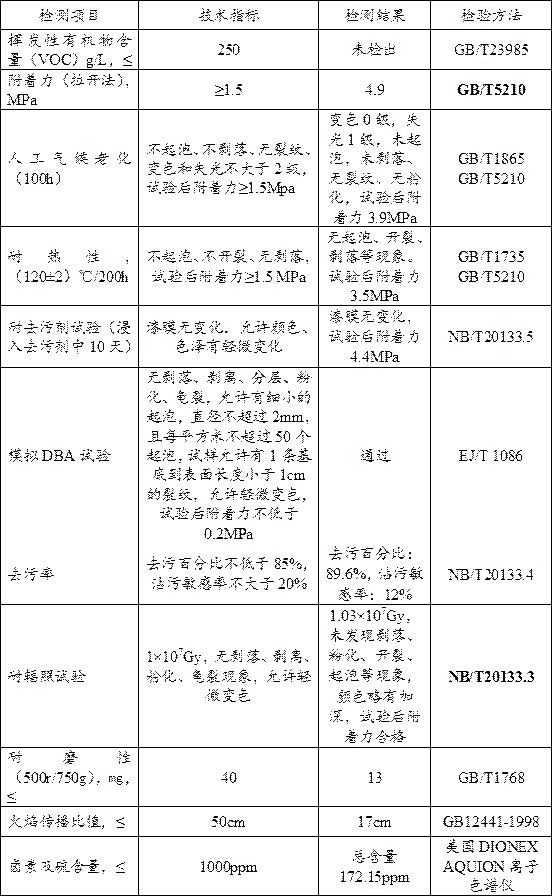

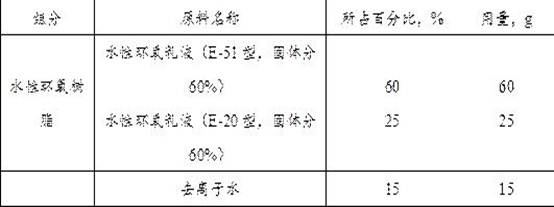

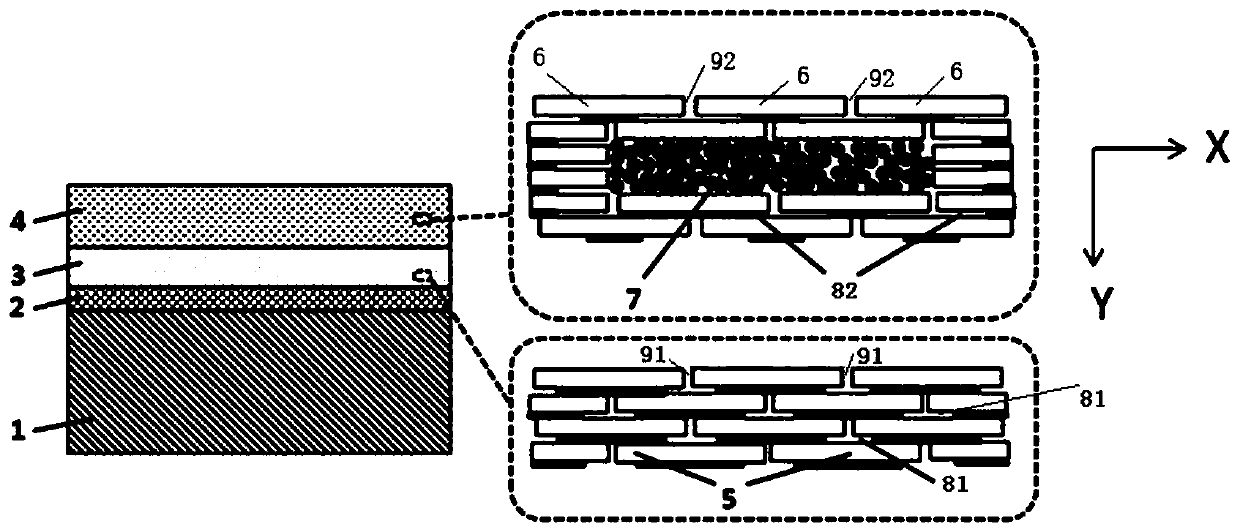

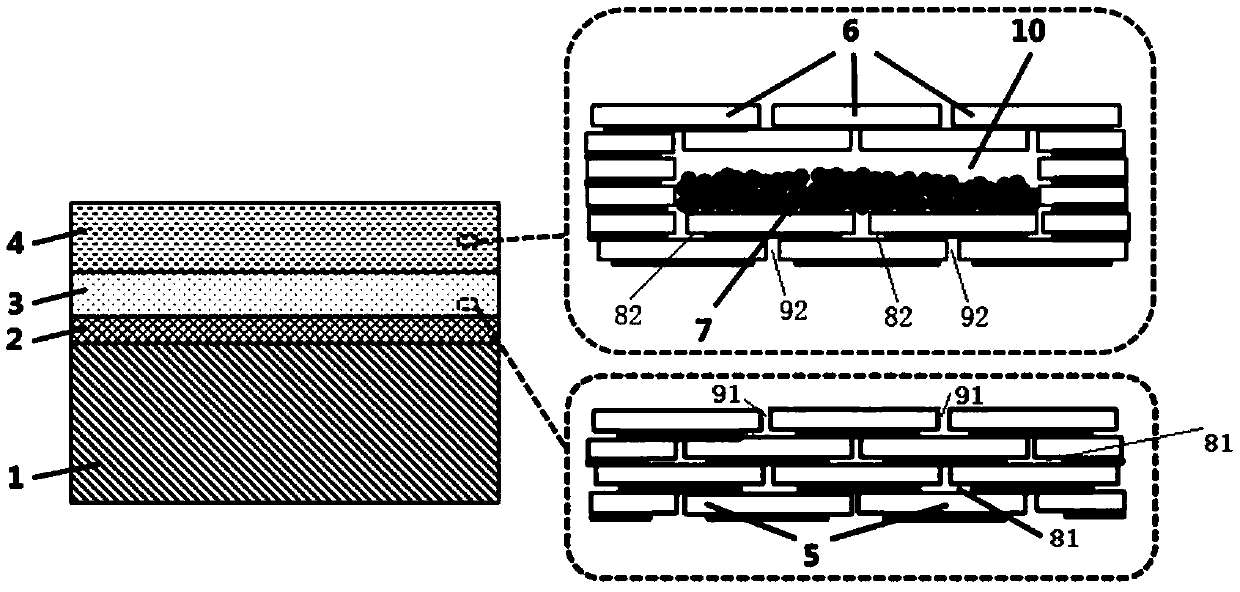

Water-based epoxy protective coating system for nuclear power station concrete and preparation method of water-based epoxy protective coating system

ActiveCN113637382AAnti-corrosionBoth radiation protectionAnti-corrosive paintsFilling pastesCoating systemNuclear power

The invention relates to a water-based epoxy protective coating system for nuclear power station concrete, the water-based epoxy protective coating system is composed of water-based epoxy repair mortar, water-based epoxy putty and water-based epoxy finish paint; the water-based epoxy repair mortar is composed of a component A1, a component B1 and a component C according to a mass ratio of (0.1-0.2): 0.15: 1; the water-based epoxy putty is composed of a component A2 and a component B2 in a mass ratio of (1.5-2): 1; the water-based epoxy finish paint is composed of a component A3 and a component B1 in a mass ratio of (3-5): 1; the component A1 comprises 40-100% of a waterborne epoxy curing agent and the balance of deionized water; the component B1 comprises 60-100% of water-borne epoxy resin and the balance of deionized water; and the component C consists of 20-60% of Portland cement, 40-80% of sand and 0.1-3% of an auxiliary agent. The invention also provides a preparation method of the water-based epoxy protective coating system for the nuclear power station concrete.

Owner:CHINA NAT OFFSHORE OIL CORP +3

High-viscosity oxidation-resistant heatproof waterproof sealant

InactiveCN108165215AHigh bond strengthHigh affinityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerOxidation resistant

The invention belongs to the technical field of waterproof materials and particularly relates to a high-viscosity oxidation-resistant heatproof waterproof sealant. The waterproof sealant comprises thefollowing components: a pure acrylic emulsion, ab acrylic emulsion, polyvinyl alcohol, hydroxyethyl cellulose, kaolin, titanium dioxide, nano calcium carbonate, polyurethane prepolymer, a polypropylene fiber, tetrahydronaphthalene, antioxidant, a defoamer, and a coalescing agent, wherein the polypropylene fiber is a staple fiber, the length specification of the fiber is 3-6 mm; the antioxidant ishindered phenol antioxidant; the defoamer is organosilicone defoamer; and the coalescing agent is propanediol butyl ether or propylene glycol methyl ether acetate. The waterproof sealant is excellentin adhesive property and sealing impermeability as well as heat resistance and oxidation resistance.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Insoles for treating chap in feet

InactiveCN105686209AAvoid cracking and peelingRefreshing textureOrganic active ingredientsInsolesMedicineGlycerol

The invention relates to a pair of insoles for treating chap in feet. A medicine pad, which is used for treating the chap in the corresponding foot, is arranged in the rear part of each of the insoles. The medicine pad consists of the following components: a urine ointment, glycerol and vitamin E, wherein the constituting proportion of the urine ointment to the glycerol to the vitamin E is at 3 to 5 to 2. The pair of insoles disclosed by the invention can be used for effectively preventing chap and peeling and for protecting chapped foot skin; and a medicine in the medicine pad is fresh in texture, soft and smooth, and is capable of rapidly penetrating and nourishing the skin.

Owner:杨素美

Sintering-resistant long-service-life thermal barrier coating of double-layer structure and preparation method of thermal barrier coating

InactiveCN109680239AAnti-sintering and long lifeRealization of anti-sintering and long lifeMolten spray coatingPressure inorganic powder coatingCeramic coatingNanoparticle

The invention discloses an sintering-resistant long-service-life thermal barrier coating of a double-layer structure and a preparation process of the thermal barrier coating. The thermal barrier coating comprises a toughening layer located inside and a heat insulating layer located outside. The heat insulating layer is formed by composite stacking of dense sheet layer units and loose nano-particlepiles, the thickness of the toughening layer accounts for 10%-50% of the total thickness of the thermal barrier coating of the double-layer structure, and the fracture toughness of a first thermal barrier coating material is larger than or equal to 2.5 MPa.m1 / 2. The thickness of the heat insulating layer accounts for 50%-90% of the total thickness of the double layers, and the heat conductivity of a second thermal barrier coating material and a third thermal barrier coating material does not exceed 2.5 W / m.K at the temperature of 1,000-1,600 DEG C. According to the thermal barrier coating ofthe double-layer structure, the purpose of sintering resistance of the ceramic coating in the high-temperature environment can be achieved, by means of the design of the toughening layer, the worsening influences of heat insulating holes on the service life are offset, and therefore collaborative design of sintering resistance and long service life of the thermal barrier coating of the novel structure is achieved.

Owner:XI AN JIAOTONG UNIV

Insulation layer formation method, member with insulation layer, resistance measurement method and junction rectifier

PendingUS20220251712A1Simple structureAvoid cracking and peelingTesting dielectric strengthVery high resistance measurementsElectrical resistance and conductanceInsulation layer

An insulation layer formation method comprises: a first step in which a surface treatment is applied to a base material to form thereon a high-resistance layer having high electric resistivity; a second step in which metal plating parts are formed on the base material that has undergone the first step in such a manner as to allow a high-resistance layer to be formed thereon; and a third process in which a high-resistance layer is formed on the base material that has undergone the second step.

Owner:NEXT INNOVATION

Combined mold and manufacturing method thereof

The invention provides a combined mold and a manufacturing method thereof. The combined mold comprises a metal female mold and a silica gel male mold, wherein a first molding surface arranged on the metal female mold is matched with a second molding surface arranged on the silica gel male mold, and meanwhile, when in a combined molding state, between the first molding surface and the second molding surface is provided with a product cavity which is used for processing products; the silica gel male mold is internally embedded with a plurality of metal embedded parts arranged in parallel, whichare used for reducing shrinkage and deformation of the silica gel male mold. According to the combined mold and the manufacturing method thereof, the metal embedded parts are arranged in the silica gel male mold to control the wall thickness of the silica gel male mold, and further control the amount of swelling and shrinkage and deformation, thus the stress of the silica gel male mold are controllable; in this way, during the extrusion and solidification of a performed piece, the performed piece can be ensured to be stressed uniformly, namely, the silica gel male mold conducts a balanced stress on the performed piece, thus avoiding cracking and flaking of the silica gel male mold so as to further improve the service life of the silica gel male mold as well as expanding the use scope of the silica gel male mold.

Owner:苏州华特时代碳纤维有限公司

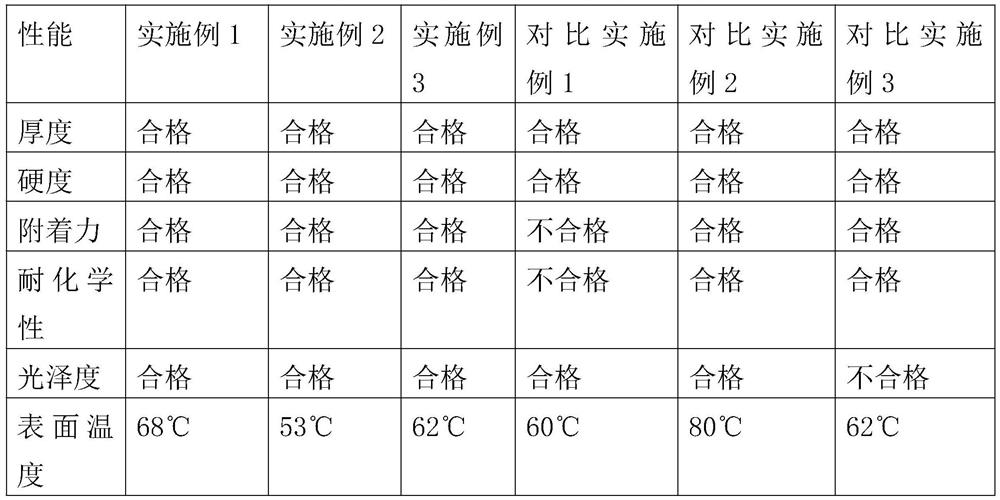

High-heat-dissipation ink and preparation method thereof

The invention discloses high-heat-dissipation ink which is prepared from the following raw materials in parts by weight: 30-50 parts of modified epoxy glue, 15-25 parts of a solvent, 10-20 parts of a curing agent, 10-20 parts of filler, 0.5-3 parts of a catalyst, 0.5-1 part of a dispersing agent, 2-7 parts of a defoaming agent and 0.1-2 parts of carbon nanotubes. The modified epoxy glue at least comprises epoxy resin, and the volume of the epoxy resin accounts for 20-50% of the volume of the modified epoxy glue. The solvent comprises one or more of propylene glycol methyl ether acetate, ethylene glycol monobutyl ether and propylene glycol diacetate. The filler at least comprises nano barium sulfate. Correspondingly, the invention also provides a preparation method of the high-thermal-conductivity ink. The high-heat-dissipation ink obtained through the proportion is obtained through mutual reaction of various raw materials and is high in adhesive force and chemical resistance, and by adding the filler, the wear resistance of the ink is improved on the premise that the optical performance of the ink is not affected.

Owner:FOSHAN ONMILLION NANO MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com