Self-sealing composite structure coke tank

A composite structure, self-sealing technology, used in coke ovens, coke cooling, petroleum industry, etc., can solve problems such as falling off, large heat loss, easy cracking, etc., to solve easy burnout, reduce maintenance costs, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with accompanying drawing:

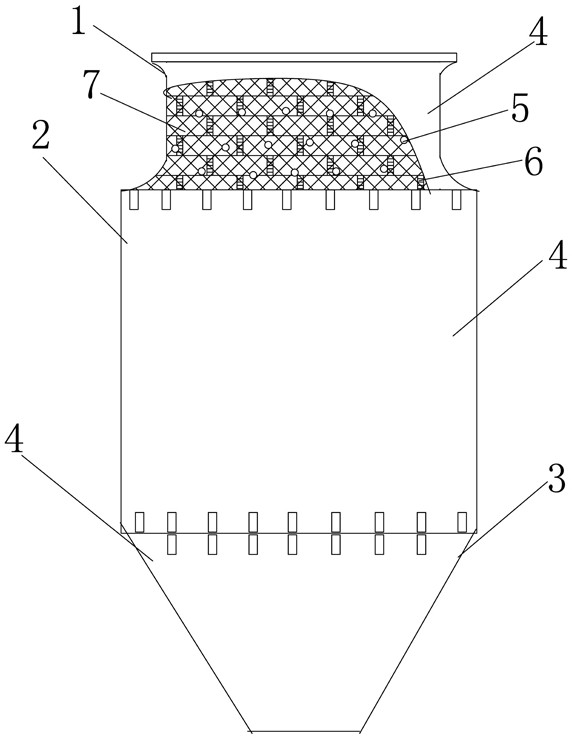

[0037] A coke tank with a self-sealing composite structure, which is mainly divided into a coke inlet section 1, a storage cylinder section 2, and a coke outlet section 3; each section is composed of a metal shell 4 and an anchor piece 5 on the inner wall of the metal shell 4 and castable material layer 6, which is that: the coke inlet section 1 and the storage cylinder section 2, as well as the storage cylinder section 3 and the coke outlet section 3 are all connected by a concave-convex structure or an up-and-down plug-in connection way to connect, even if the joint is not a straight seam;

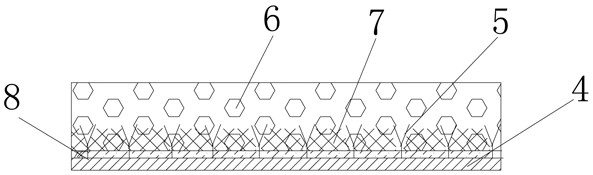

[0038] The structure of the coke inlet section 1: the metal mesh layer 7 is fixed on the anchor piece 5 and welded to the anchor piece 5; the castable layer 6 adopts a density of 1.6~1.9g / cm 3 Any value of lightweight refractory castable is enough, and its service temperature is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com