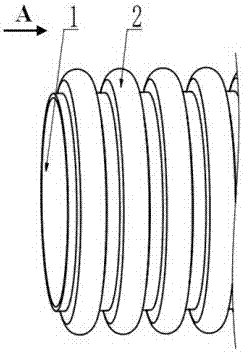

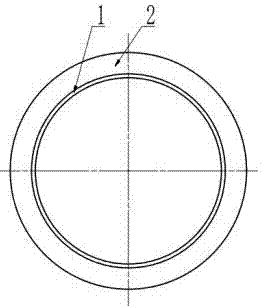

Double-wall corrugated pipe with wear-resistant inner wall and preparation method thereof

A double-wall corrugated pipe and corrugated pipe technology, applied in the field of pipe material preparation, can solve the problems of difficult compound formation of double-wall welding, poor fluidity, and inability to be processed by extrusion processing methods, so as to avoid peeling and cracking, simple production process, and easy processing good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

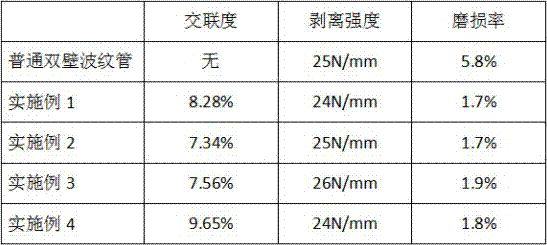

Embodiment 1

[0028] In this embodiment, smooth pipe inner wall matrix 1 is the following raw materials in parts by weight:

[0029] 50 parts of LLDPE, 50 parts of POE, 10 parts of UHMWPE, 4 parts of vinyltriethoxysilane, 0.2 parts of dibenzoyl peroxide, 0.2 parts of propylamine, 35 parts of wollastonite, 7 parts of calcium stearate; polyethylene The material of bellows layer 2 is PE100 grade.

[0030] The preparation process of the pipe is as follows:

[0031] 1) Dissolve the initiator dibenzoyl peroxide and amine catalyst propylamine in xylene solvent according to the amount of feed, and configure an initiator solution with a total concentration of 8%, and then mix the configured initiator solution, UHMWPE, vinyl Triethoxysilane was added to the high-speed mixer and mixed for 40 minutes. The speed of the high-speed mixer was 500rpm, and then LLDPE, filler wollastonite, and lubricant calcium stearate were added, and the material was mixed and discharged at a low speed of 80rpm, and then e...

Embodiment 2

[0034] In this embodiment, smooth pipe inner wall matrix 1 is the following raw materials in parts by weight:

[0035] 60 parts of LDPE, 60 parts of POE, 30 parts of UHMWPE, 8 parts of vinyltrimethylethoxysilane, 0.1 part of dicumyl peroxide, 0.1 part of t-butyl peroxy tert-butyl valerate, 0.1 part of ethylamine, 50 parts of calcium carbonate 5 parts of polyethylene wax; the material of polyethylene corrugated pipe layer 2 is PE80 grade material;

[0036] Its preparation process is the same as in Example 1, the total concentration of the initiator solution in step 1) is 10%, add in the high-speed mixer and mix for 30min, the speed of the high-speed mixer is 700rpm, and the mixing discharge speed is 90rpm. The temperature of the extruder is 150°C , the speed of the main engine is controlled so that the residence time of the material in the extruder is 4 minutes; the temperature of the extruder in step 2) is 180°C.

Embodiment 3

[0038] In this embodiment, smooth pipe inner wall matrix 1 is the following raw materials in parts by weight:

[0039] 20 parts of LDPE, 20 parts of HDPE, 40 parts of POE, 50 parts of UHMWPE, 4 parts of vinyltrimethoxysilane, 4 parts of vinyltrimethylethoxysilane, 0.3 parts of dicumyl peroxide, 0.3 parts of propylamine, talcum powder 20 parts, 8 parts of stearic acid; the material of polyethylene bellows layer 2 is PE100 grade.

[0040] Its preparation process is the same as in Example 1, the total concentration of the initiator solution in step 1) is 12%, add in the high-speed mixer and mix for 20min, the speed of the high-speed mixer is 600rpm, and the mixing discharge speed is 95rpm. The temperature of the extruder is 230°C , the speed of the main engine is controlled so that the residence time of the material in the extruder is 2 minutes; the temperature of the extruder in step 2) is 220°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com