Durable driving belt

A kind of transmission belt, durable technology, applied in the direction of transmission belt, belt/chain/gear, conjugated rayon, etc., can solve the problem of poor ventilation, wear resistance, heat and aging resistance of the pressing surface of the transmission belt, and the transmission belt is prone to peeling. and other problems, to achieve good adhesion, prolong service life, and improve ventilation and ventilation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

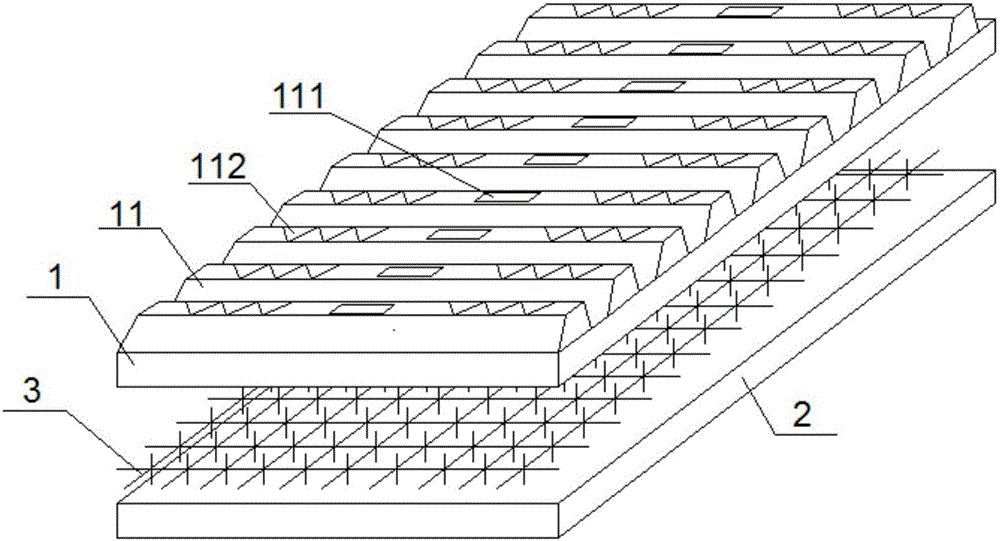

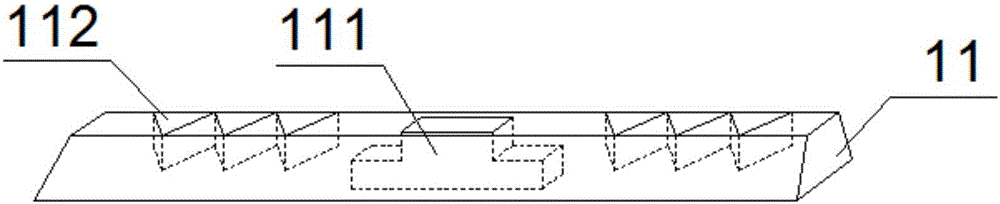

[0037] Such as Figure 1~3 As shown, the present invention provides a durable power transmission belt, which includes a compression rubber layer 1 that is crimped with a power transmission component, an adhesive rubber layer 2 bonded to the compression rubber layer 1, and a rubber layer 2 disposed on the compression rubber layer 1 and the reinforcing layer 3 between the bonding rubber layer 2,

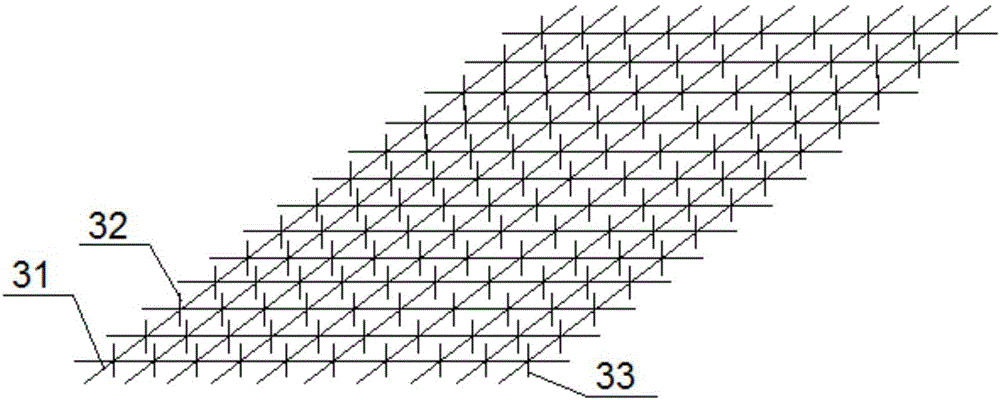

[0038] Wherein, the reinforcement layer 3 includes a composite fiber web 31 laying flat between the compression rubber layer 1 and the bonding rubber layer 2 , and a fiber web that can extend into the first surface of the composite fiber web 31 . A plurality of first bonding rods 32 inside the compressed rubber layer 1, a plurality of second bonding rods arranged on the second surface of the composite fiber web 31 and capable of extending into the inside of the bonding rubber layer 2 33 and the reinforcing cotton filled inside the grid of the composite fiber net 31, the reinforcing co...

Embodiment 2

[0055] Such as Figure 1~3 As shown, the present invention provides a durable power transmission belt, which includes a compression rubber layer 1 that is crimped with a power transmission component, an adhesive rubber layer 2 bonded to the compression rubber layer 1, and a rubber layer 2 disposed on the compression rubber layer 1 and the reinforcing layer 3 between the bonding rubber layer 2,

[0056] Wherein, the reinforcement layer 3 includes a composite fiber web 31 laying flat between the compression rubber layer 1 and the bonding rubber layer 2 , and a fiber web that can extend into the first surface of the composite fiber web 31 . A plurality of first bonding rods 32 inside the compressed rubber layer 1, a plurality of second bonding rods arranged on the second surface of the composite fiber web 31 and capable of extending into the inside of the bonding rubber layer 2 33 and the reinforcing cotton filled inside the grid of the composite fiber net 31, the reinforcing co...

Embodiment 3

[0073] Such as Figure 1~3 As shown, the present invention provides a durable power transmission belt, which includes a compression rubber layer 1 that is crimped with a power transmission component, an adhesive rubber layer 2 bonded to the compression rubber layer 1, and a rubber layer 2 disposed on the compression rubber layer 1 and the reinforcing layer 3 between the bonding rubber layer 2,

[0074] Wherein, the reinforcement layer 3 includes a composite fiber web 31 laying flat between the compression rubber layer 1 and the bonding rubber layer 2 , and a fiber web that can extend into the first surface of the composite fiber web 31 . A plurality of first bonding rods 32 inside the compressed rubber layer 1, a plurality of second bonding rods arranged on the second surface of the composite fiber web 31 and capable of extending into the inside of the bonding rubber layer 2 33 and the reinforcing cotton filled inside the grid of the composite fiber net 31, the reinforcing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com