Filigree-simulating enamel dial plate and production method thereof

A production method and dial technology, applied in clocks and watches, special decorative structures, decorative art, etc., can solve the problems of low production efficiency of cloisonné enamel dials, restrictions on the application and development of watches and jewelry, and poor color gradient effects on enamel surfaces. Achieve bright and rich colors, avoid cracking and peeling of the glaze layer, prevent polishing from discoloration or deformation and peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

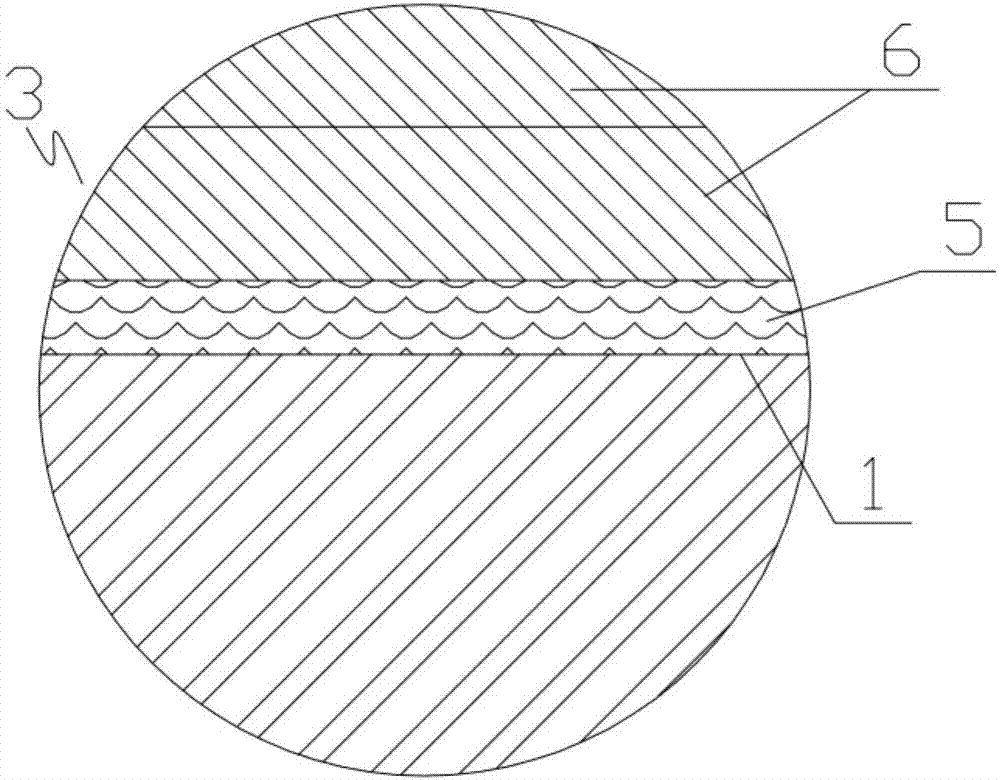

[0046] This embodiment 1 adopts a general-purpose quartz watch movement, and the production method of the imitation cloisonné enamel dial adapted to the general-purpose quartz watch movement is as follows:

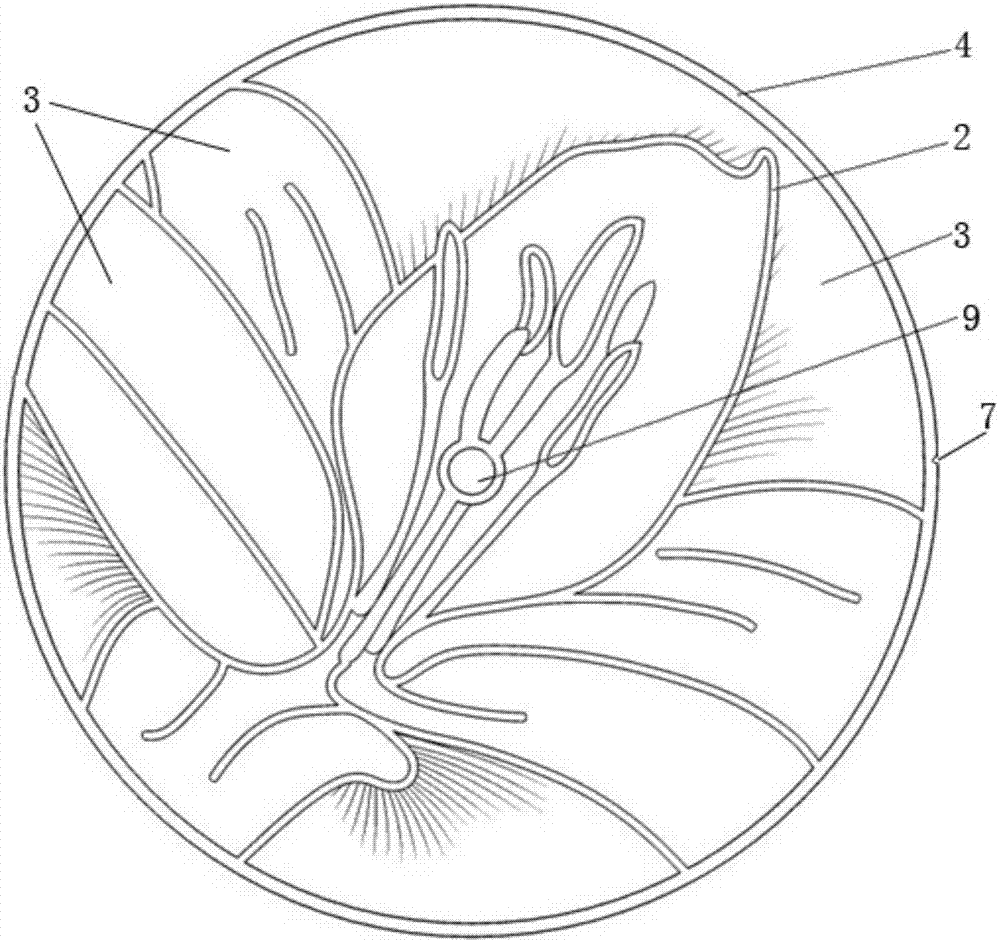

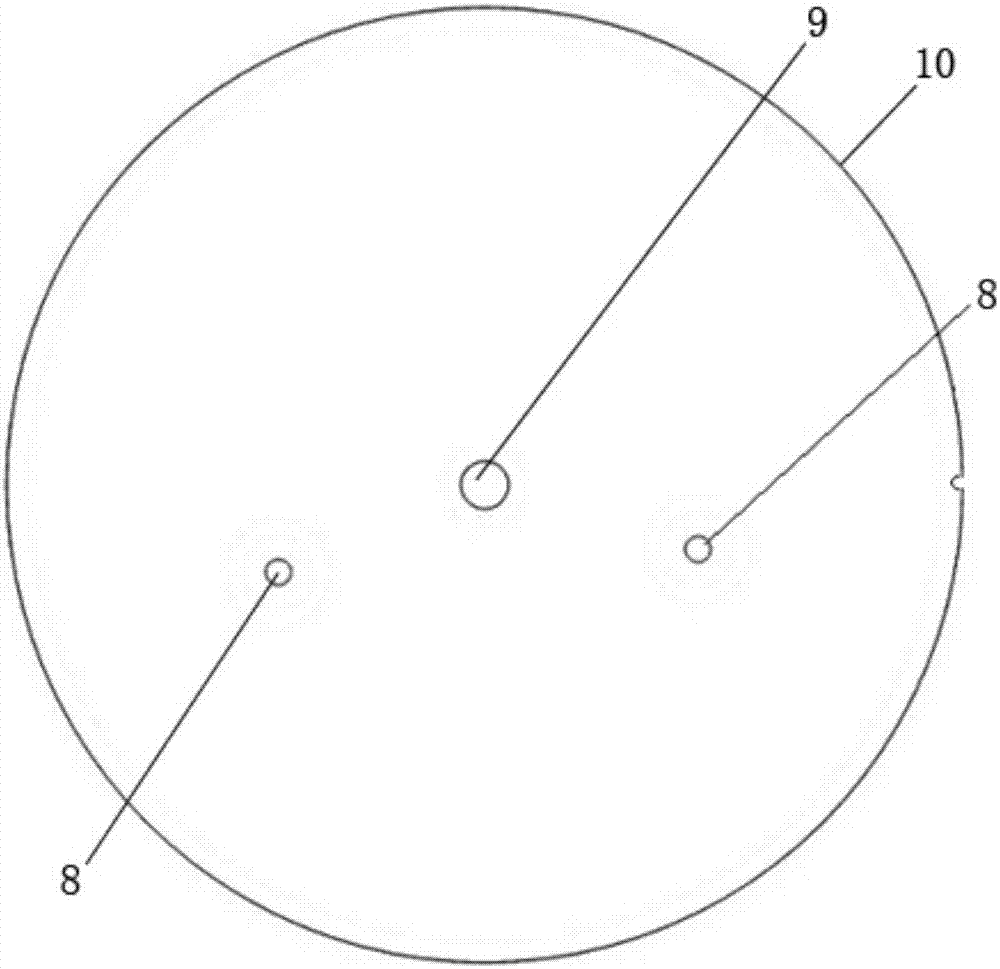

[0047] (1) Dial design: The shape of the dial is circular, the outer diameter of the dial is 33.0mm, and the thickness of the dial is 0.6mm. The position of the clip on the back of the dial corresponds to the position of the movement. The inner diameter of the center hole of the dial is 1.8mm, the outer diameter is 2.8mm, and the flatness tolerance between the bottom surface and the surface of the dial is controlled within 0.08mm. The metal wire on the surface of the dial forms a flower-shaped outline. The petals are transparent blue gradients, and the base outside the petals is transparent green. The thickness of the metal wire is 0.17mm and the height is 0.3mm. Determine the installation direction of the dial, and set a semicircular positioning line corresponding to the ...

Embodiment 2

[0057] Present embodiment 2 uses general-purpose mechanical watch movement, and the production method of the imitation cloisonné enamel dial that this general-purpose mechanical watch movement is adapted is as follows:

[0058] (1) Dial design: The shape of the dial is circular, the outer diameter of the dial is 38.0mm, and the thickness of the dial is 0.65mm. The position of the clip on the back of the dial corresponds to the position of the movement. The inner diameter of the center hole of the dial is 1.85mm and the outer diameter is 2.85mm, and the flatness tolerance between the bottom surface and the surface of the dial is controlled within 0.1mm. The metal wire on the surface of the dial forms a chrysanthemum-shaped outline, the petals are transparent yellow gradient, the base outside the petals is transparent blue, the thickness of the metal wire is 0.20mm, and the height is 0.35mm. Determine the installation direction of the dial, and set a semicircular positioning lin...

Embodiment 3

[0068] Present embodiment 3 uses general-purpose quartz watch movement, and the production method of the imitation cloisonné enamel dial that this general-purpose quartz watch movement is adapted is as follows:

[0069](1) Dial design: the shape of the dial is square, the outer dimension of the dial is 26×26mm, the tolerance is controlled within 0.1mm, the thickness of the dial is 0.55mm, the position of the clip on the back of the dial corresponds to the position of the movement, and the position of the clip is The diameter is 0.6mm, the height is 2.8mm, the inner diameter of the center hole of the dial is 1.75mm, the outer diameter is 2.75mm, and the flatness tolerance between the bottom surface and the surface of the dial is controlled within 0.07mm. The metal wire on the surface of the dial forms a horse-shaped outline. The thickness of the metal wire is 0.15mm and the height is 0.25mm. Determine the installation direction of the dial, and set a semicircular positioning li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com