Fabricated-partition-wall connecting device and connecting method

A connecting device and assembly technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of poor sound insulation effect, affecting the aesthetics, integrity and interface peeling of the interior walls of the house.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described below in conjunction with specific embodiments.

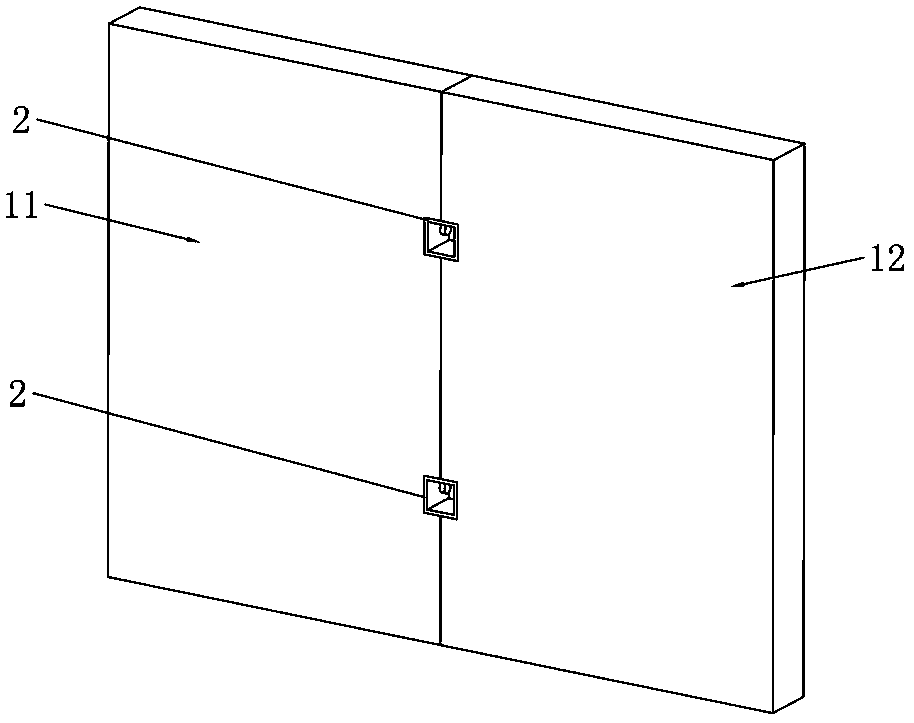

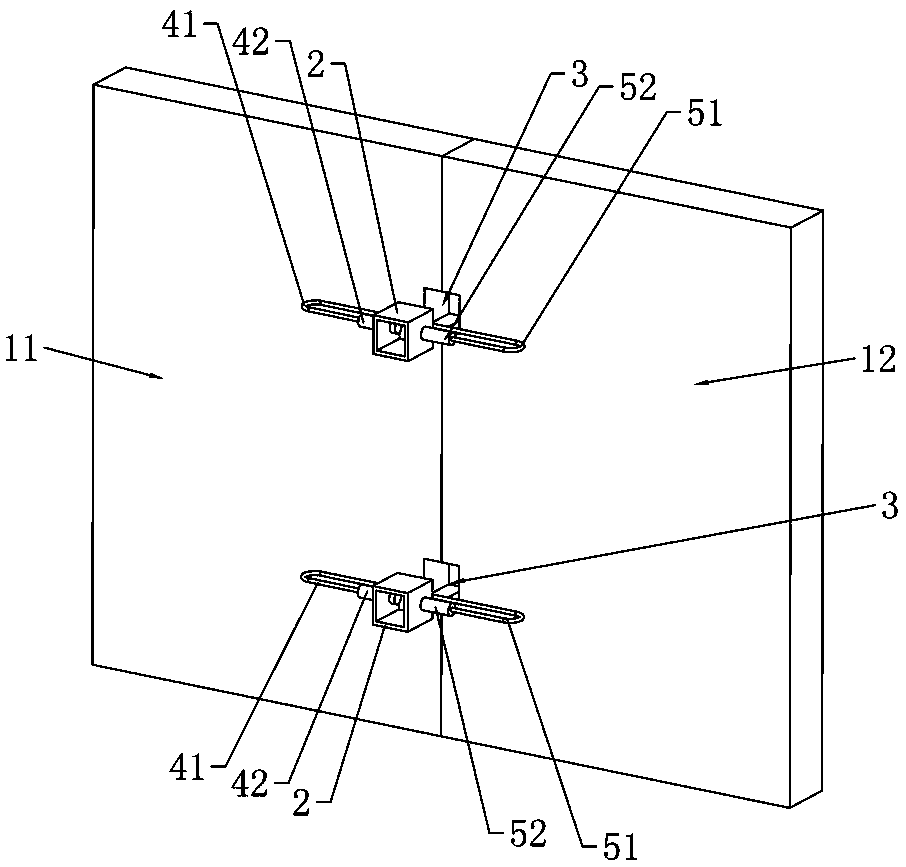

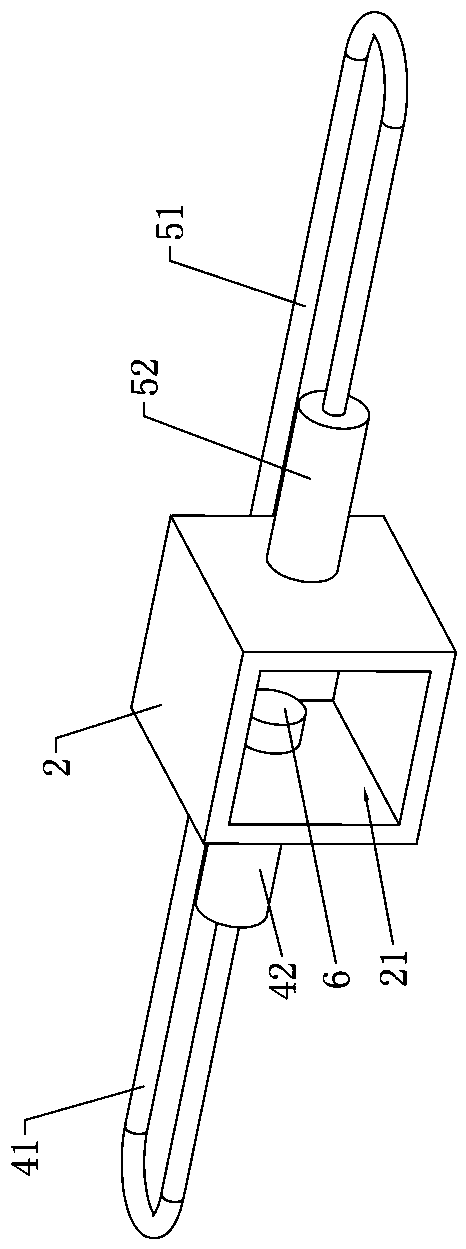

[0040] Such as Figure 1 to Figure 6 As shown, a prefabricated partition wall connection device, the prefabricated partition wall includes a left prefabricated panel 11 and a right prefabricated panel 12 respectively arranged vertically, the left prefabricated panel 11 is located at the left end of the right prefabricated panel 12 side, the right end surface of the left prefabricated plate 11 is in contact with the left end surface of the right prefabricated plate 12, the assembled partition wall connection device includes a steel connection box 2, and the interior of the steel connection box 2 is formed with a front opening The connection box chamber 21, the left side wall of the connection box chamber 21 is provided with a left bolt hole 22 completely penetrating to the left, and the right side wall of the connection box chamber 21 is provided with a right bolt hole completely pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com