air flow cut-off device

A cut-off device and airflow technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of inability to reflect the working performance, easy failure of the valve core, and difficult repair, etc., to improve manufacturability and economic durability High performance, convenient for daily maintenance, convenient for production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

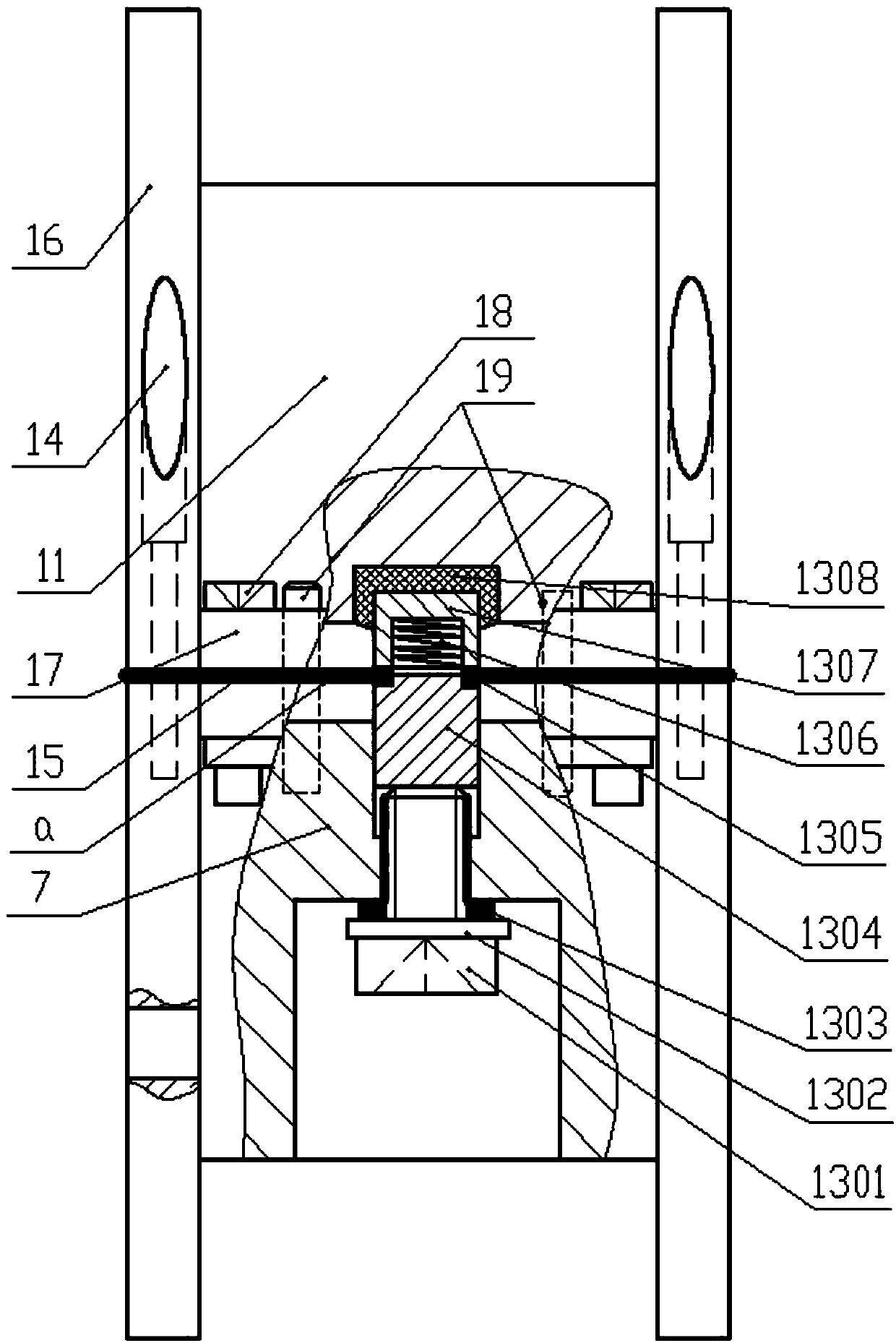

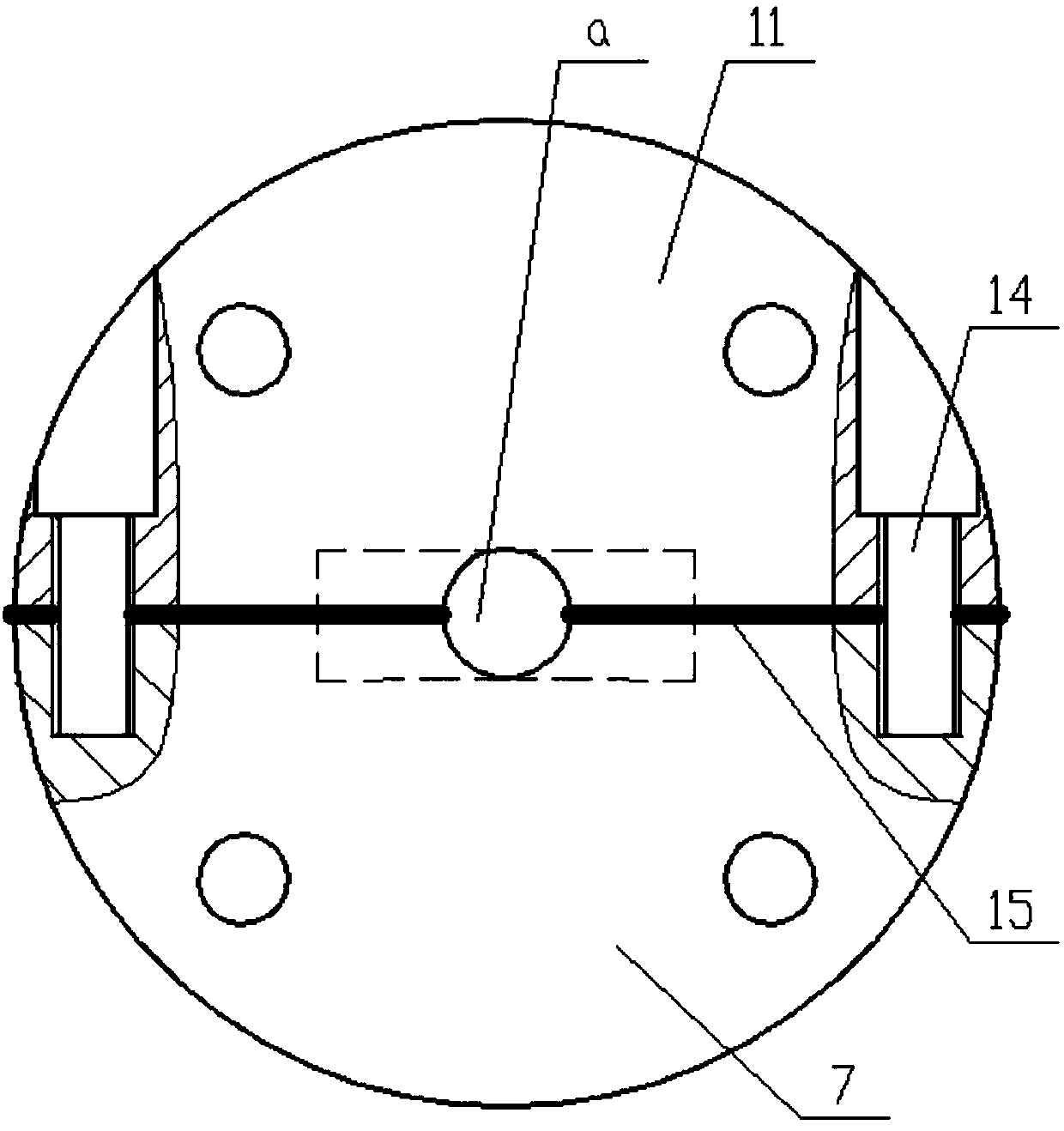

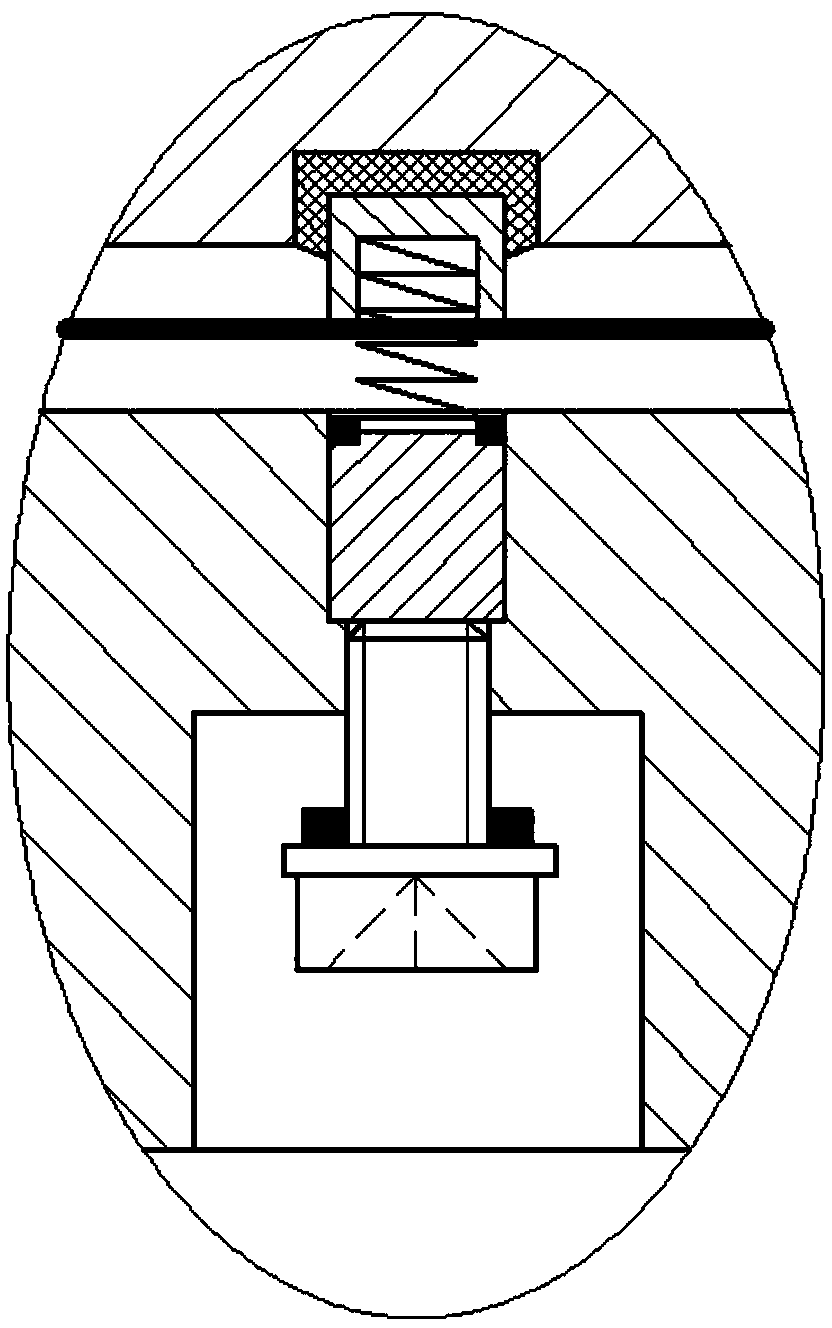

[0019] Such as figure 1 As shown in -2, an air flow cut-off device includes a shell, and the shell includes an upper shell 11 and a lower shell 7 with axial through grooves inside, and the upper shell 11 and the lower shell 7 are connected after being combined. The groove forms an air channel a arranged in the axial direction and open at both ends. The air channel a may be in the shape of any cavity channel, and the two ends of the air channel a are preferably made into round holes. After splicing, a complete flange plate 16 is also formed at both ends of the shell respectively, and each flange pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com