Connection structure between shoe insole and shoe outsole

A technology for connecting structure and shoe outsole, which is applied to shoe soles, footwear, insoles, etc., can solve the problems of insole and shoe outsole cannot be selected, the sole cannot be disassembled and assembled at will, and the choice of consumers is limited, etc. The effect of expansion selectivity, simple structure and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

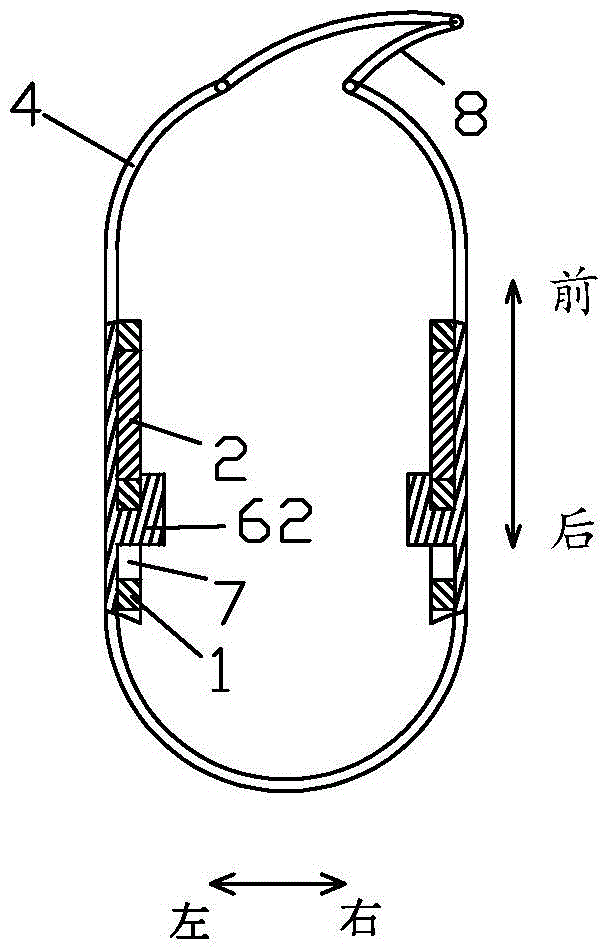

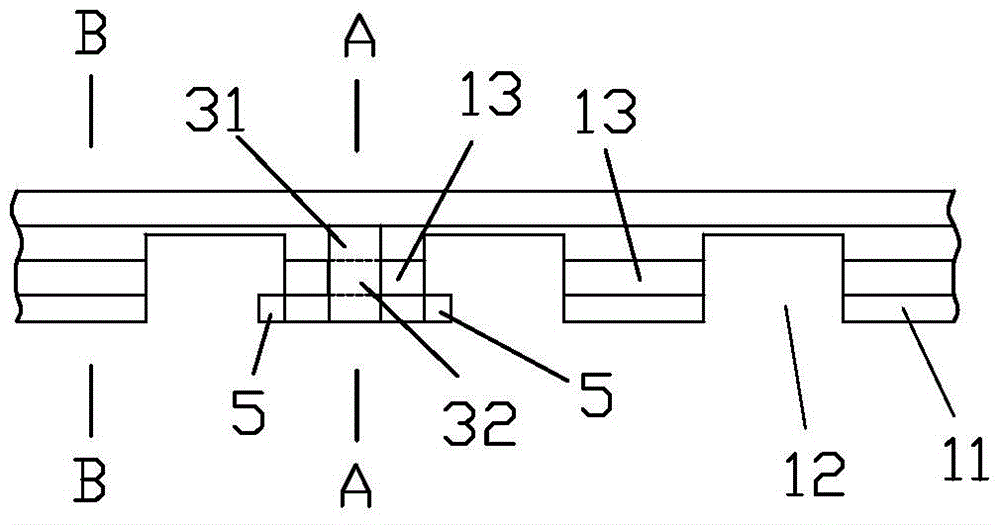

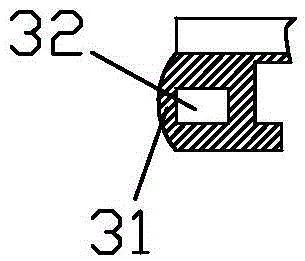

[0038] The accommodating groove 3 is formed with a rib 31 along the groove edge of the arch of the foot, and the rib 31 cooperates with the accommodating groove to form a rib hole 32, and the rib hole 32 can accommodate the shoe edge buckle 4 to pass through. Then constitute the limiting structure, see for details figure 1 , figure 2 shown.

[0039] When assembling, the shoe edge buckle 4 needs to pass through the rib hole 32. For the convenience of assembly, preferably, the shoe edge buckle 4 is formed by connecting a plurality of short shoe edge buckles 41, adjacent short The interface position of the shoe side buckle 41 is provided with cooperating locking teeth 42, and the locking teeth 42 can be pulled into the rib hole 32, and the rib hole 32 restricts the mutual matching locking teeth 42 from separating from each other. When connected on the shoe edge buckle 4, this structure is particularly suitable for sandals. Easy and fast installation, see Figure 8 .

Embodiment 2

[0041] The limiting structure includes a screw hole (not shown) arranged on the sole and a bolt (not shown) matching the screw hole. When some soles such as high-heeled shoes are relatively thick, bolt connection can be used as The limit structure, the use of bolts will not affect the wearing comfort, and the bolts themselves can also be used as decorative embellishments for high-heeled shoes, the connection is also reliable, and the assembly is quick.

[0042] The limit structure is varied, not only can be the rib hole as described in embodiment 1, and the bolt structure described in embodiment 2, but also can be provided with tongue on the shoe side buckle, arch of foot The sole of the part is provided with a button hole 7, and the tongue 6 cooperates with the button hole 7 to make the shoe edge buckle 4 close to the outer peripheral edge of the sole to form the position-limiting structure.

[0043] more specific,

Embodiment 3

[0045] The tongue 6 is an oblique tongue 61 arranged obliquely relative to the shoe edge buckle 4 , and the buttonhole 7 is an oblique buttonhole matching the oblique tongue 61 . Specific reference Figure 10As shown, the slanted tongue 61 is like a hook. When the slanted tongue 61 is inserted into the corresponding slanted button hole, it will cooperate to form a state of hooking each other, so that the plane between the insole 1 and the outsole 2 The front, back, left, and right directions of the machine can be positioned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com