Thick ti/tialn multilayer coating with high toughness and high hardness and preparation method thereof

A multi-layer coating, high hardness technology, applied in coating, metal material coating process, vacuum evaporation plating, etc. Internal stress increases and other problems, to achieve good oxidation resistance, easy control of the total thickness, and reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this example, the cemented carbide (WC-6wt.% Co, mass fraction) is ground and polished with SiC sandpaper, put into a solution mixed with acetone and ethanol at a volume ratio of 1:1, and ultrasonically cleaned for 15 minutes to Remove surface oil, oxide film and other dirt, load the pretreated substrate on the sample holder, put it into the ion plating vacuum chamber, close the chamber door, and evacuate to a vacuum degree of 5.0×10 -3 After Pa, argon gas was introduced to maintain the vacuum at 0.4 Pa, the negative bias voltage value of the substrate was 1000V, and the duty cycle was 60%, and the substrate was cleaned by ion bombardment for 10 minutes.

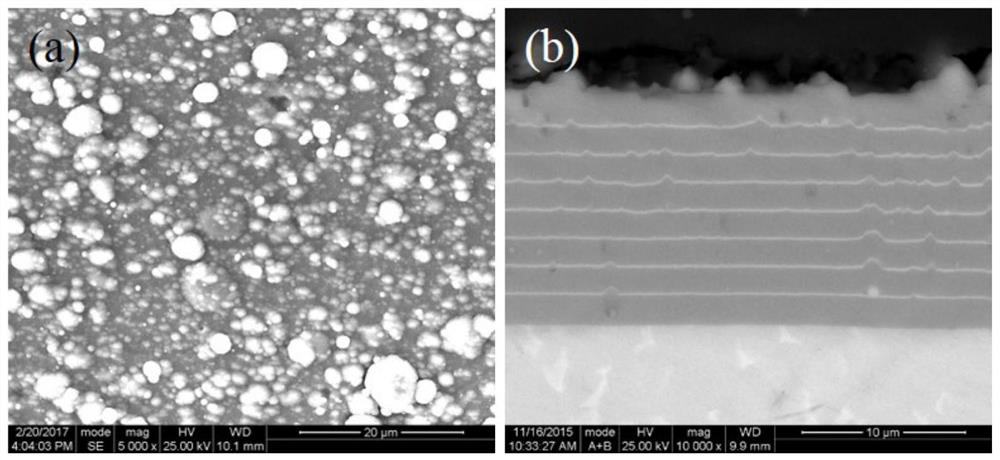

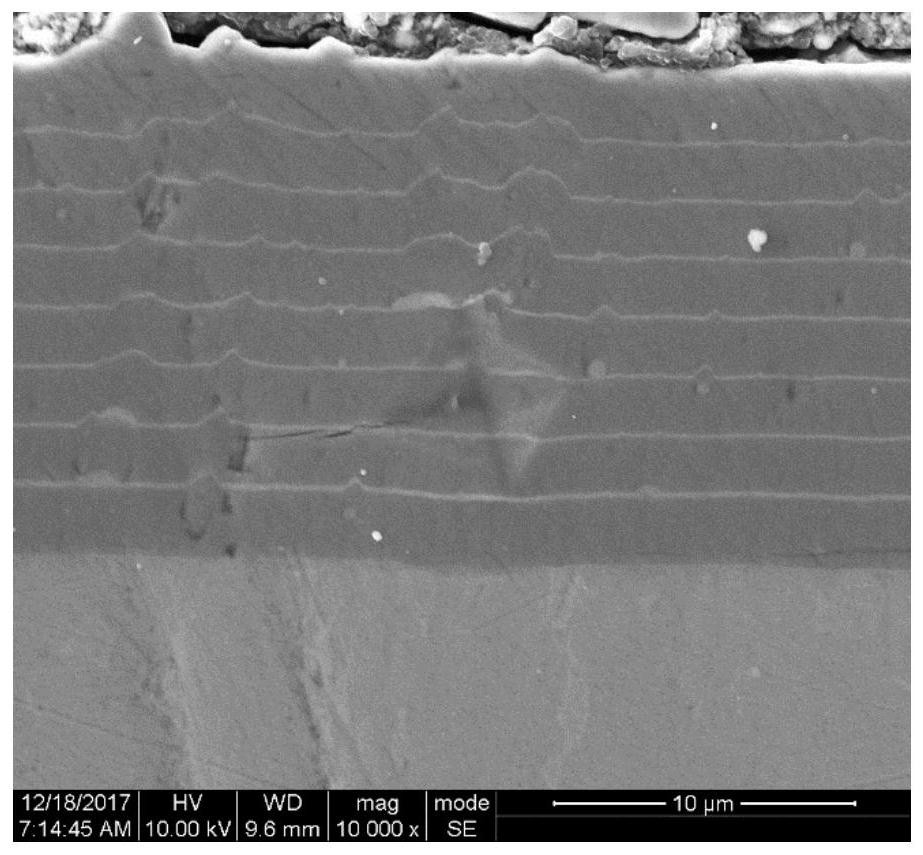

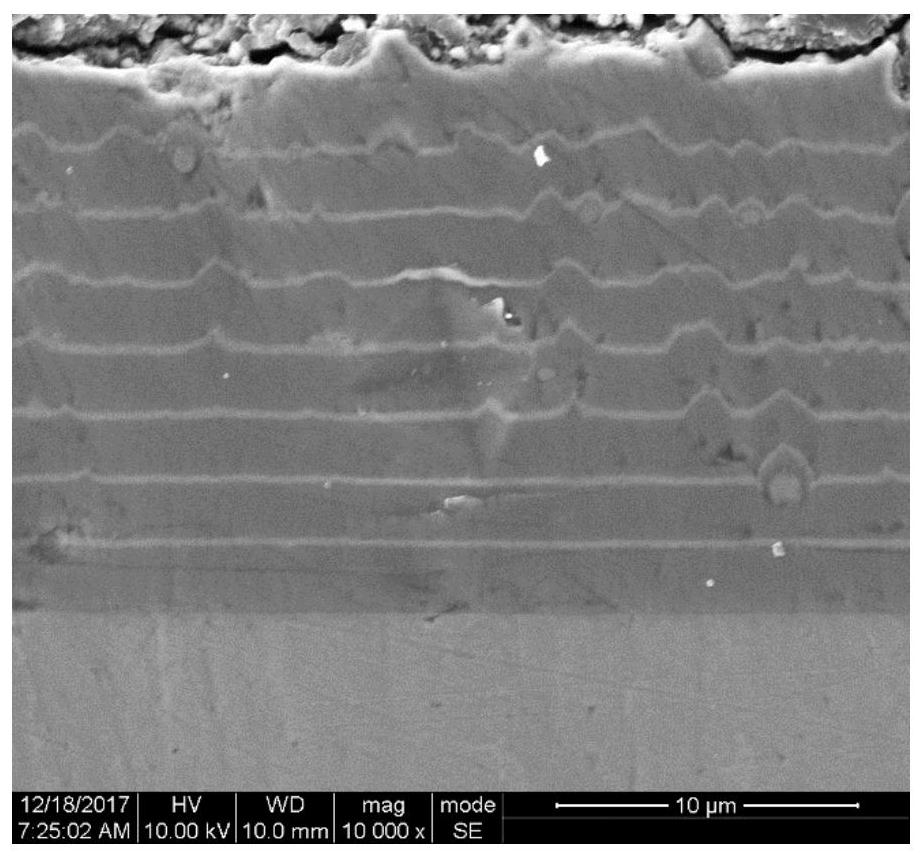

[0042] After cleaning, cut off the argon gas, feed nitrogen gas, maintain the vacuum pressure at 1.5Pa, control the substrate pulse negative bias value at 600V, turn on the Ti target current, and deposit for 3 minutes to form a TiN transition layer. Then alternate deposition of TiAlN sub-layer and Ti sub-layer: fir...

Embodiment 2

[0046] The difference from Example 1 is:

[0047] When the TiAlN sub-layer is deposited, the nitrogen pressure is 1.6Pa, the substrate negative bias value is 520V, and the deposition time is 18min; when the Ti sub-layer is deposited, the argon working pressure is 0.35Pa, the substrate negative bias value is 120V, and the deposition time is controlled In 2.5 minutes; wherein, the thickness of the TiN transition layer is 0.1 μm, the thickness of each TiAlN sublayer is 1.7 μm, the thickness of each Ti sublayer is 0.2 μm, and the total number of layers is 16 layers. In the TiN transition layer, the atomic ratio Ti:N=1:1; in the TiAlN sublayer, the atomic ratio Ti:Al:N=1:1:2.

[0048] The Ti / TiAlN multilayer coating obtained in this example has a uniform distribution of the TiAlN sublayer and a dense structure, and the Ti / TiAlN multilayer coating is well bonded to the substrate through the transition layer. The hardness value of the Ti / TiAlN multilayer coating obtained in this exa...

Embodiment 3

[0050] The difference from Example 1 is:

[0051] When the TiAlN sub-layer is deposited, the nitrogen pressure is 1.7Pa, the substrate negative bias value is 500V, and the deposition time is 18min; when the Ti sub-layer is deposited, the argon working pressure is 0.4Pa, the substrate negative bias value is 150V, and the deposition time is controlled In 3.5 minutes; wherein, the thickness of the TiN transition layer is 0.1 μm, the thickness of each TiAlN sublayer is 1.7 μm, the thickness of each Ti sublayer is 0.3 μm, and the total number of layers is 16 layers. In the TiN transition layer, the atomic ratio Ti:N=1:1; in the TiAlN sublayer, the atomic ratio Ti:Al:N=1:1:2.

[0052] The Ti / TiAlN multilayer coating obtained in this example has a uniform distribution of the TiAlN sublayer and a dense structure, and the Ti / TiAlN multilayer coating is well bonded to the substrate through the transition layer. The hardness value of the Ti / TiAlN multilayer coating obtained in this exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com