Combined mold and manufacturing method thereof

A technology of combining molds and manufacturing methods, applied in the field of molds, can solve the problems of cracking and spalling, low production efficiency, and high processing cost of metal male molds, and achieve the effects of improving service life, avoiding cracking and spalling, and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

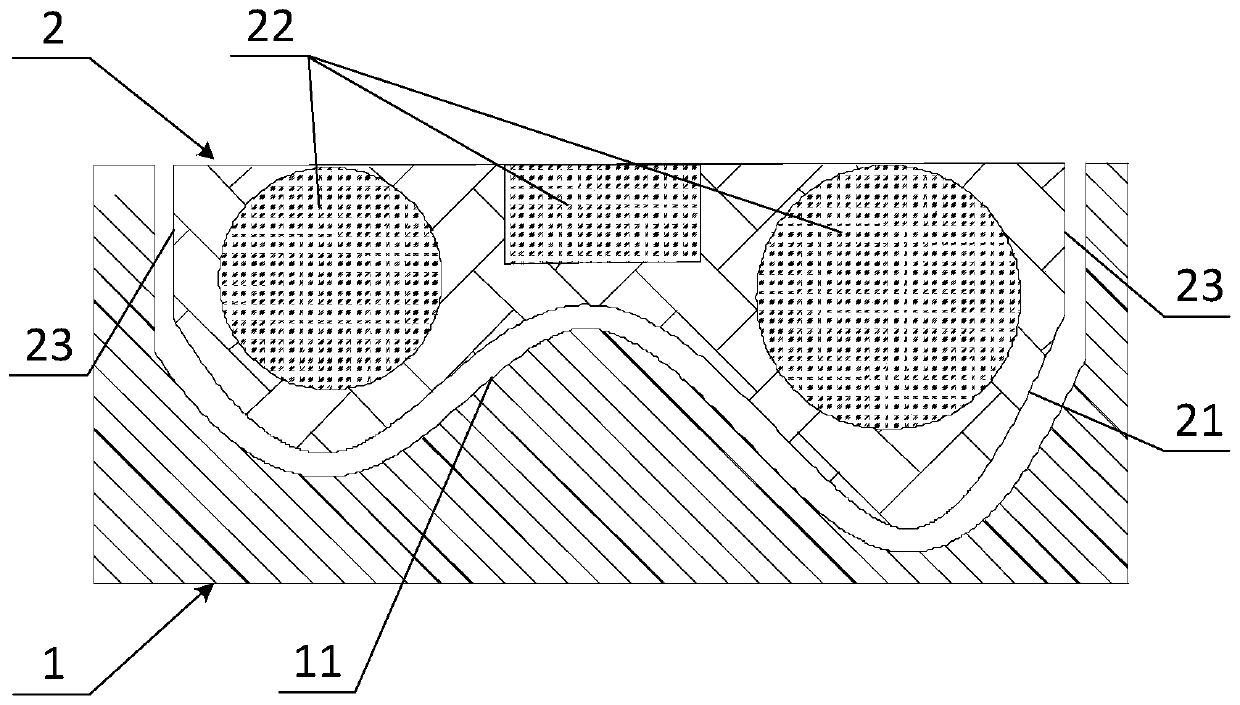

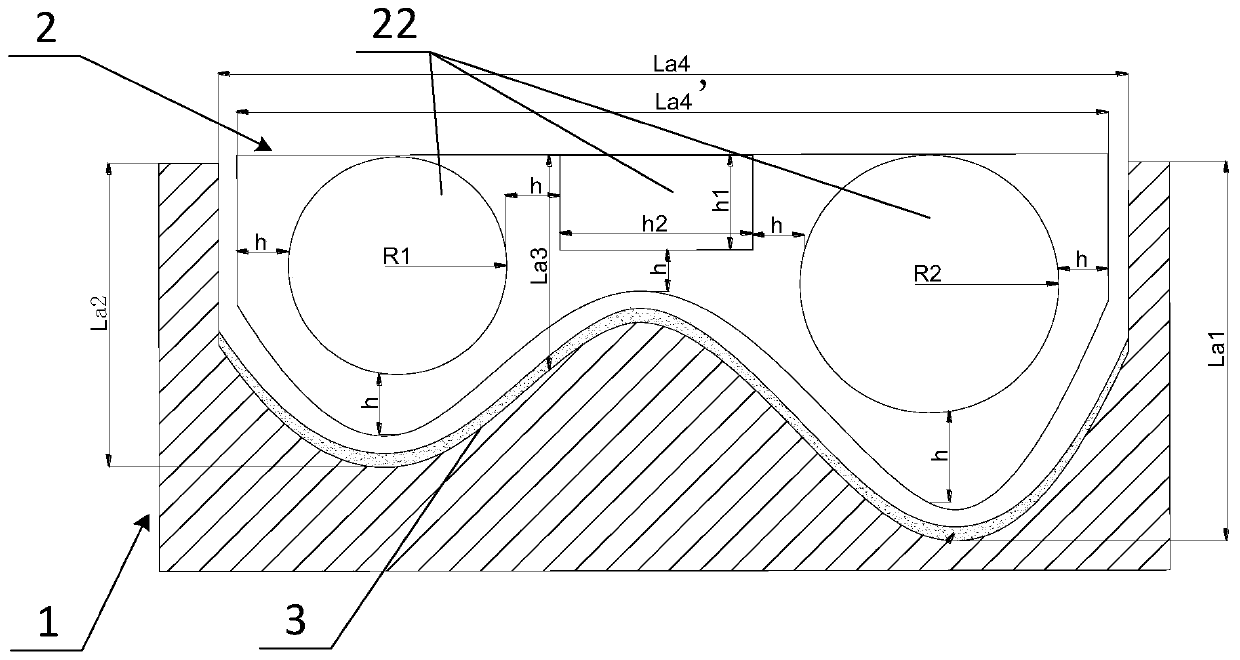

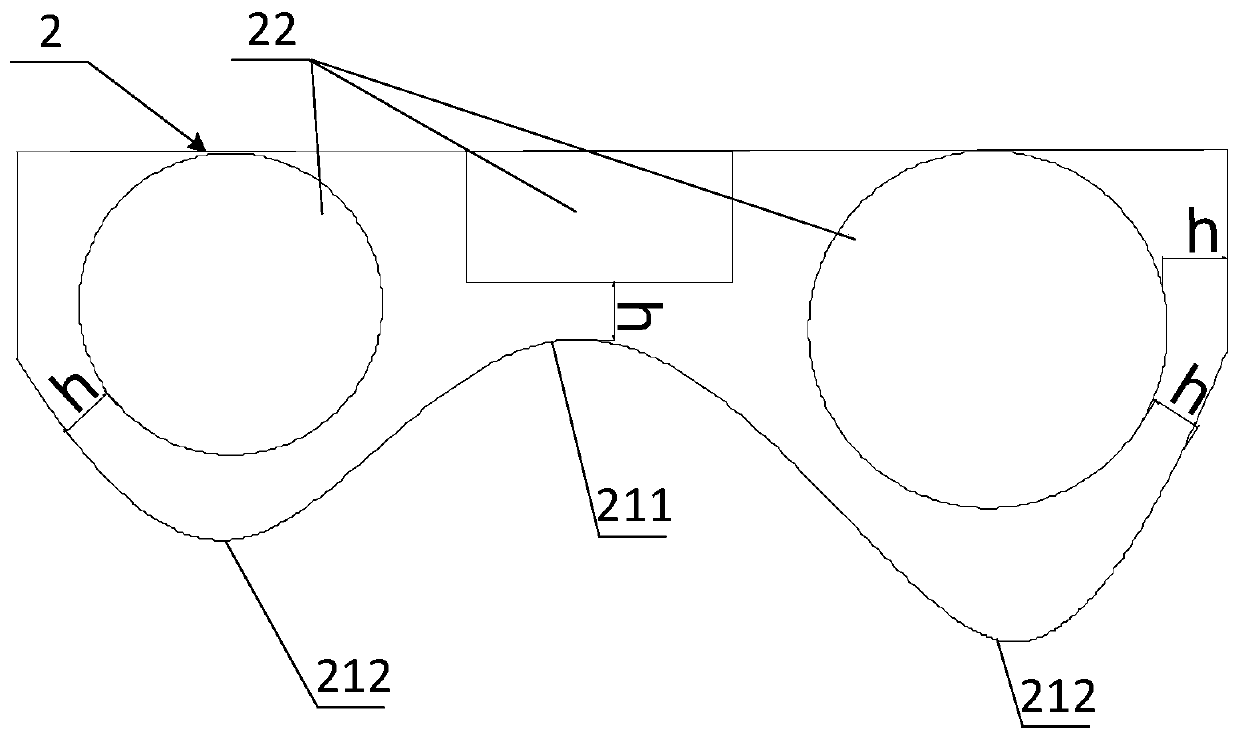

[0081] In step S1 of making the female mold, a metal female mold 1 is made according to the outer surface of the product 3, and the metal material can be aluminum, steel, etc.

[0082] Confirmation step S2 of metal embedded parts. In this embodiment, when the product wall thickness z is 2mm, the pressure F required for product molding is 0.6MPa, and the elastic modulus of the silica gel volume is K ΔT Is 721MPa, silica gel volume expansion coefficient α ΔT It is 5.6×〖10〗^(-4) / ℃, the empirical value of wall thickness C' is 5mm, and the temperature difference ΔT between the product curing temperature and room temperature is 120℃. First, use the following formula to calculate the expansion h of the silicone male mold 2 ΔT =1.486mm:

[0083] h ΔT =F / (K ΔT ×α ΔT ).

[0084] The following formula can be used to calculate the wall thickness h=27.144mm of the silicone male mold 2:

[0085] h=h ΔT / (α ΔT ×ΔT)+C',

[0086] Among them, ΔT is the temperature difference between p...

Embodiment 2

[0100] In step S1 of making the female mold, a metal female mold 1 is made according to the outer surface of the product 3, and the metal material can be aluminum, steel, etc.

[0101] Confirmation step S2 of metal embedded parts. In this embodiment, when the product wall thickness z is 2mm, the pressure F required for product molding is 1MPa, and the elastic modulus of the silica gel volume is K ΔT Is 721MPa, silica gel volume expansion coefficient α ΔT It is 5.6×〖10〗^(-4) / ℃, the empirical value of wall thickness C' is 5mm, and the temperature difference ΔT between the product curing temperature and room temperature is 120℃. First, use the following formula to calculate the expansion h of the silicone male mold 2 ΔT =1.486mm:

[0102] h ΔT =F / (K ΔT ×α ΔT ).

[0103] The following formula can be used to calculate the wall thickness h=23.144mm of the silicone male mold 2:

[0104] h=h ΔT / (α ΔT ×ΔT)+C',

[0105] Among them, ΔT is the temperature difference between pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com