Titanium alloy thin-wall seamless lining straight cylinder section superplastic forming wall thickness uniformity control method

A superplastic forming and titanium alloy technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as failure to meet precision requirements, excessive wall thickness, and uneven distribution of wall thickness in the straight section of the lining, and achieve wall thickness Good control accuracy and stability, short forming time, and reduced mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

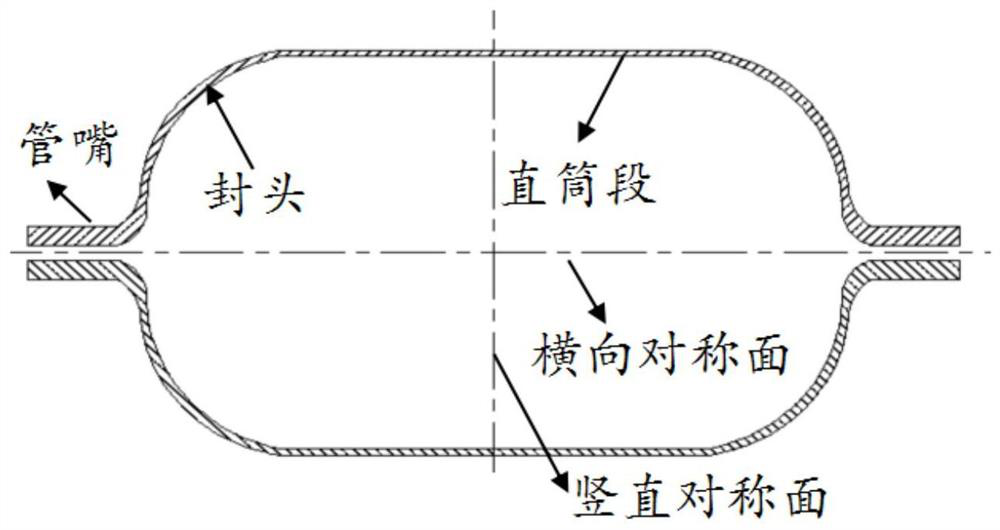

[0065] A specific example is given below. In this example, the cylindrical inner lining is TC4 titanium alloy, with a volume of 12L and a length of 408mm. , the head is ellipsoidal, the semi-major axis of the inner surface of the head is 118mm, the semi-minor axis is 76mm, the semi-major axis of the outer surface of the head is 119.5mm, the semi-minor axis is 80mm, the length of the nozzle is 14mm, and the outer surface of the nozzle is 14mm. The circle is φ38mm, the inner hole of the nozzle is φ16mm, and the thickness of the R corner is ~9mm. The specific process is as follows:

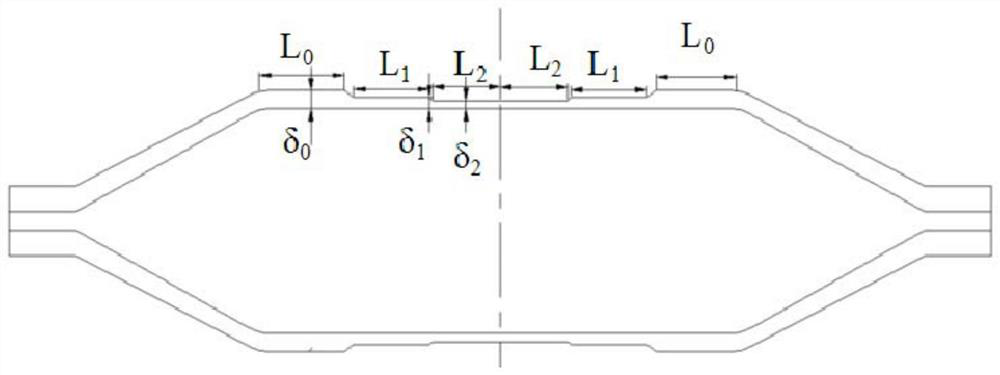

[0066] (1) Mold design and manufacture: design according to the requirements of the product's external dimensions, and design symmetrically distributed upper and lower molds. The material is high-temperature-resistant cast steel Ni7N. After the upper and lower molds are closed, the diameter of the straight section of the inner surface is:

[0067] D=0.998×(236mm+1.2mm+3mm)≈239.7mm (0.998 is the diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com