Method for preparing aerogel through solvent plasticizing and foaming

An aerogel, to-be-foamed technology, used in aerogel preparation, chemical instruments and methods, molybdenum sulfide, etc., can solve the problems of unfavorable industrial application, unstable structure, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

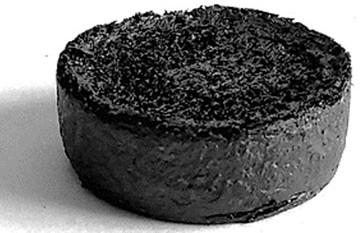

[0023] Mix the aqueous suspension of 5mg / ml Mxenes with sodium bicarbonate evenly (the mass ratio of Mxenes to sodium bicarbonate is 1:1), dry to form a film, and then place it in 10% hydrochloric acid to generate bubbles, and get Porous Mxenes airgel materials such as figure 1 , with a wall thickness of 195nm, an average pore size of 100μm, and a density of 11mg / cm 3 .

Embodiment 2

[0025] Mix the aqueous suspension of 5 mg / ml molybdenum disulfide and sodium bicarbonate uniformly (mass ratio 1:1), dry to form a film, and then place it in 10% hydrochloric acid to generate gas foaming, and get Porous molybdenum disulfide airgel materials, such as figure 2 , with a wall thickness of 105nm, an average pore size of 87μm, and a density of 15mg / cm 3 .

Embodiment 3

[0027] Mix 11mg / ml bacterial cellulose aqueous suspension with sodium carbonate uniformly (mass ratio 1:5), dry to form a film, and then place it in 15% hydrochloric acid to generate gas foaming, and obtain a porous membrane after 1min. cellulose airgel materials, such as image 3 , with a wall thickness of 360nm, an average pore size of 230μm, and a density of 35mg / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com