An electronic component carrying belt molding machine and its use method

A technology for electronic components and carrier tapes, applied in the field of forming machines for electronic components carrier tapes, can solve the problems of low product quality and high production costs, and achieve the effects of improving production efficiency, ensuring quality stability, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

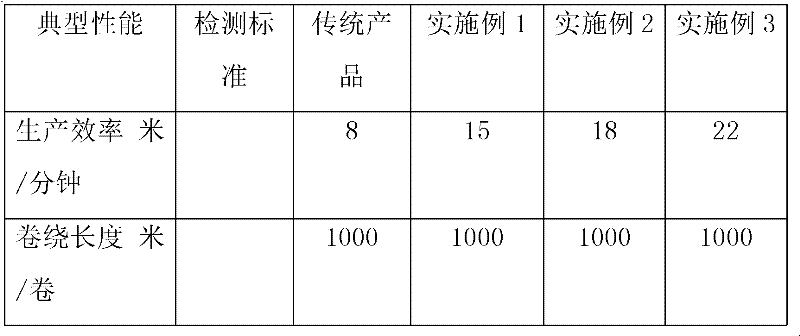

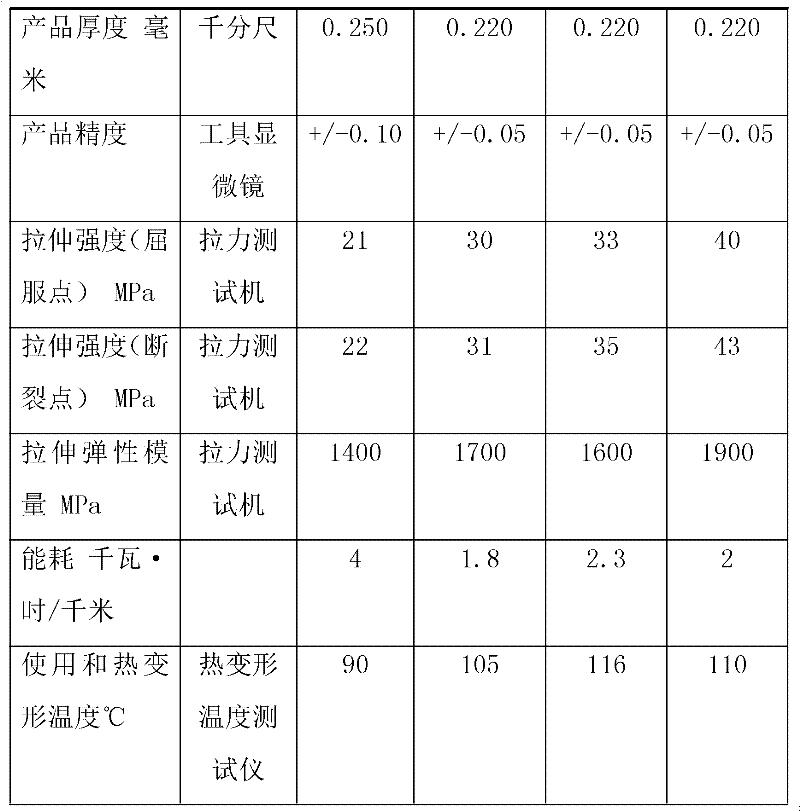

Embodiment 1

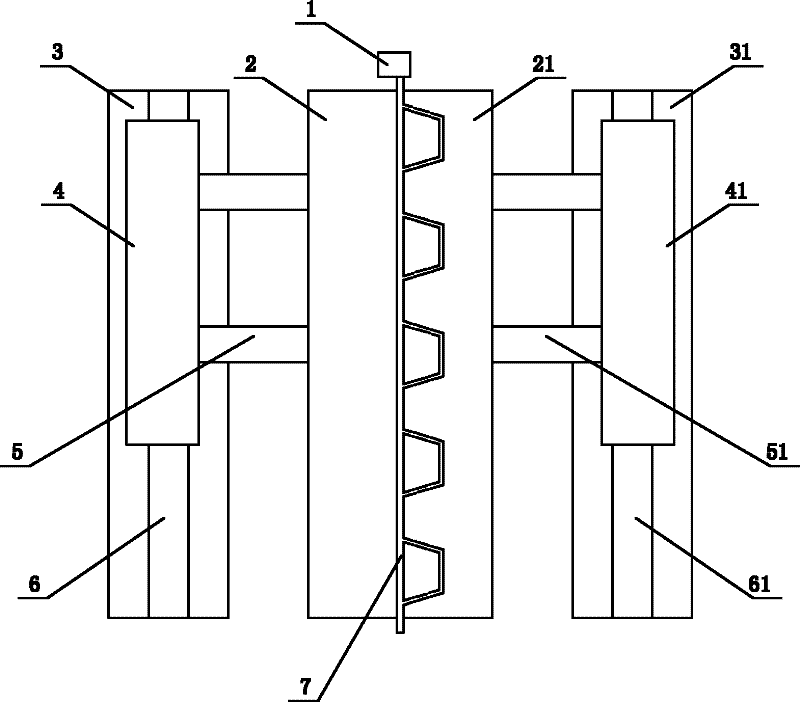

[0026] Such as figure 1 The shown one kind of forming machine for carrying tape of electronic components includes a film extrusion die head 1, a punch 2, a punch lateral movement mechanism 5, a punch longitudinal movement table 4, a punch base 3, a die 21, a die The lateral movement mechanism 51, the die longitudinal moving table 41 and the die base 31 correspond to the shapes of the punch 2 and the die 21, and the positions of the punch 2 and the die 21 correspond to the film extrusion die 1. The punch longitudinal moving platform 4 is installed on the punch base 3, and the punch longitudinal moving platform 4 moves up and down through the guide rail 6 installed on the punch base 3, and the punch 2 is installed on the punch longitudinal moving mechanism 5 through the punch on mobile station 4. The die longitudinal moving table 41 is installed on the die base 31, and the die longitudinal moving table 41 moves up and down through the guide rail 61 installed on the die base 31,...

Embodiment 2

[0040] The structure of the forming machine for carrying tape for electronic components is the same as that of Embodiment 1, and the temperature of the film fluid in step 1 of the method for using the forming machine for carrying tape for electronic components is between 231°C and 270°C. If the temperature of the production process is higher than 270°C, the plastic particles cannot form a film continuously, which will easily cause the carrier belt to break, and continuous production cannot be carried out, requiring intermittent shutdown. The flow velocity of the film fluid is 18 m / min, and the downward movement speed of the punch and die is consistent with the flow velocity of the film.

Embodiment 3

[0042] The structure of the forming machine for carrying tape for electronic components is the same as that of Embodiment 1, and in step 1 of the method for using the forming machine for carrying tape for electronic components, the polymer raw material is general-purpose polystyrene particles. The flow speed of the film fluid is 22 m / min, the downward movement speed of the punch and the die is consistent with the flow speed of the film, and the temperature is controlled between 190°C and 230°C. The products processed by the film fluid in the above temperature range are resistant The tensile strength performance is the best, the use and heat deformation temperature are the highest, and the tensile strength performance of the product produced at a temperature below 190°C is increased by 30%, and the use and heat deformation temperature is increased by 10%, compared with a temperature above 230°C and below 270°C The tensile strength of the products produced is increased by 20%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com