Erectable net rack nodes

A prefabricated, joint technology, applied in the direction of architecture, building structure, etc., can solve the problems of difficult welding positioning of welding hollow ball joints, high processing precision requirements for bolt ball joints, and difficult construction, etc., to meet the needs of large-scale industrial production, The effect of shortening the construction period and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

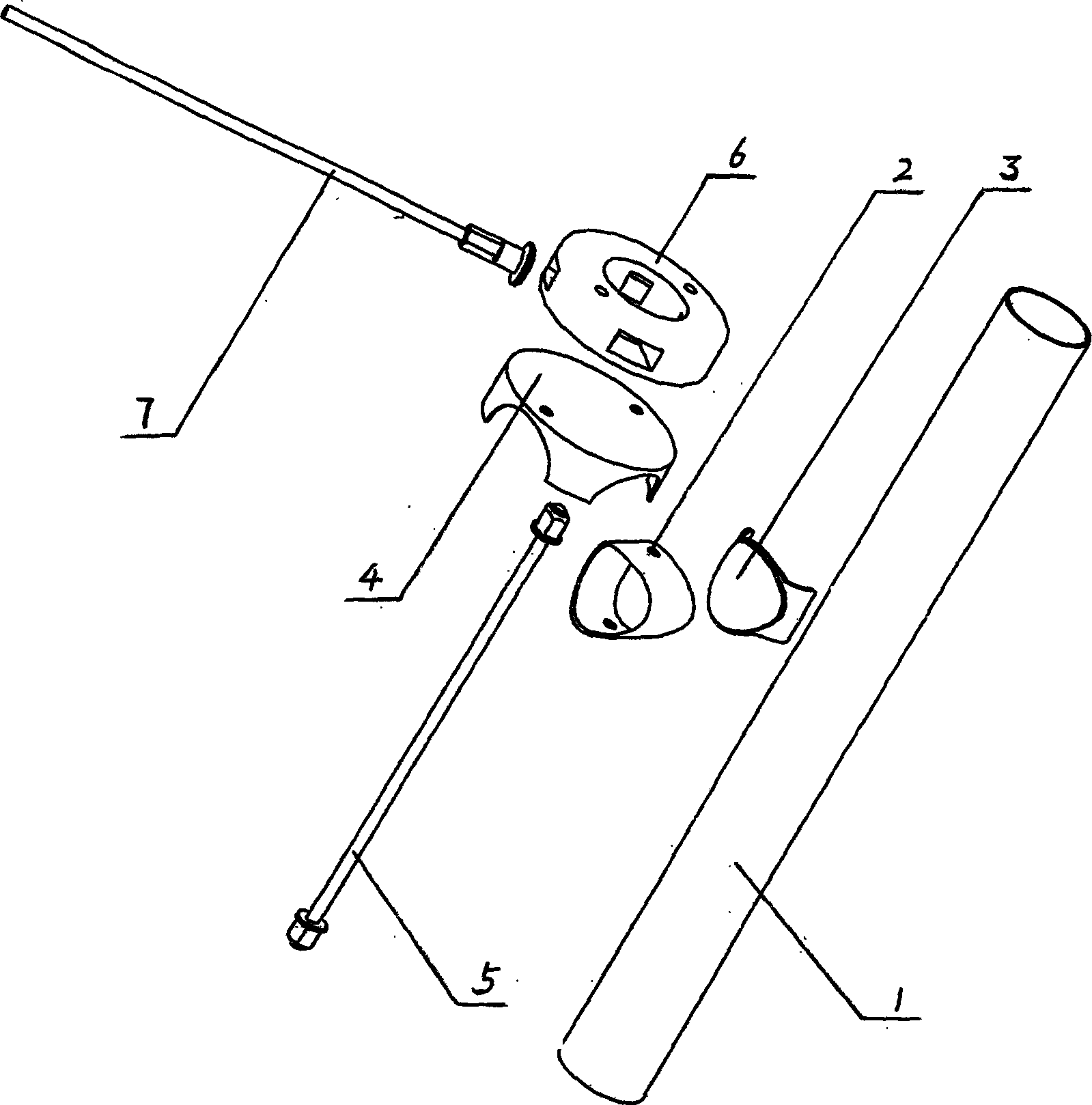

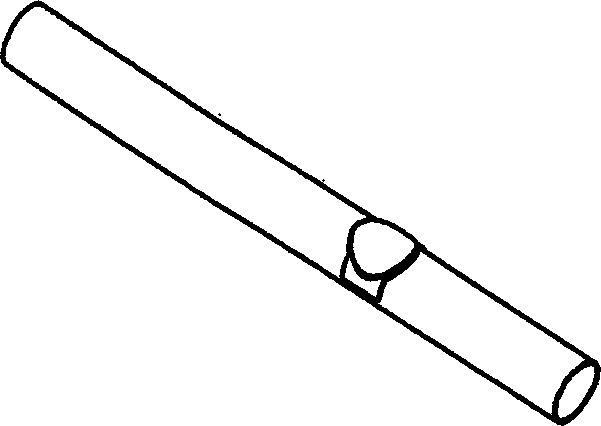

[0030] Such as figure 1 As shown, rod 1, spacer 2, spacer gasket 3, cover plate 4, fastening bolt 5, cable installation frame 6, cable 7.

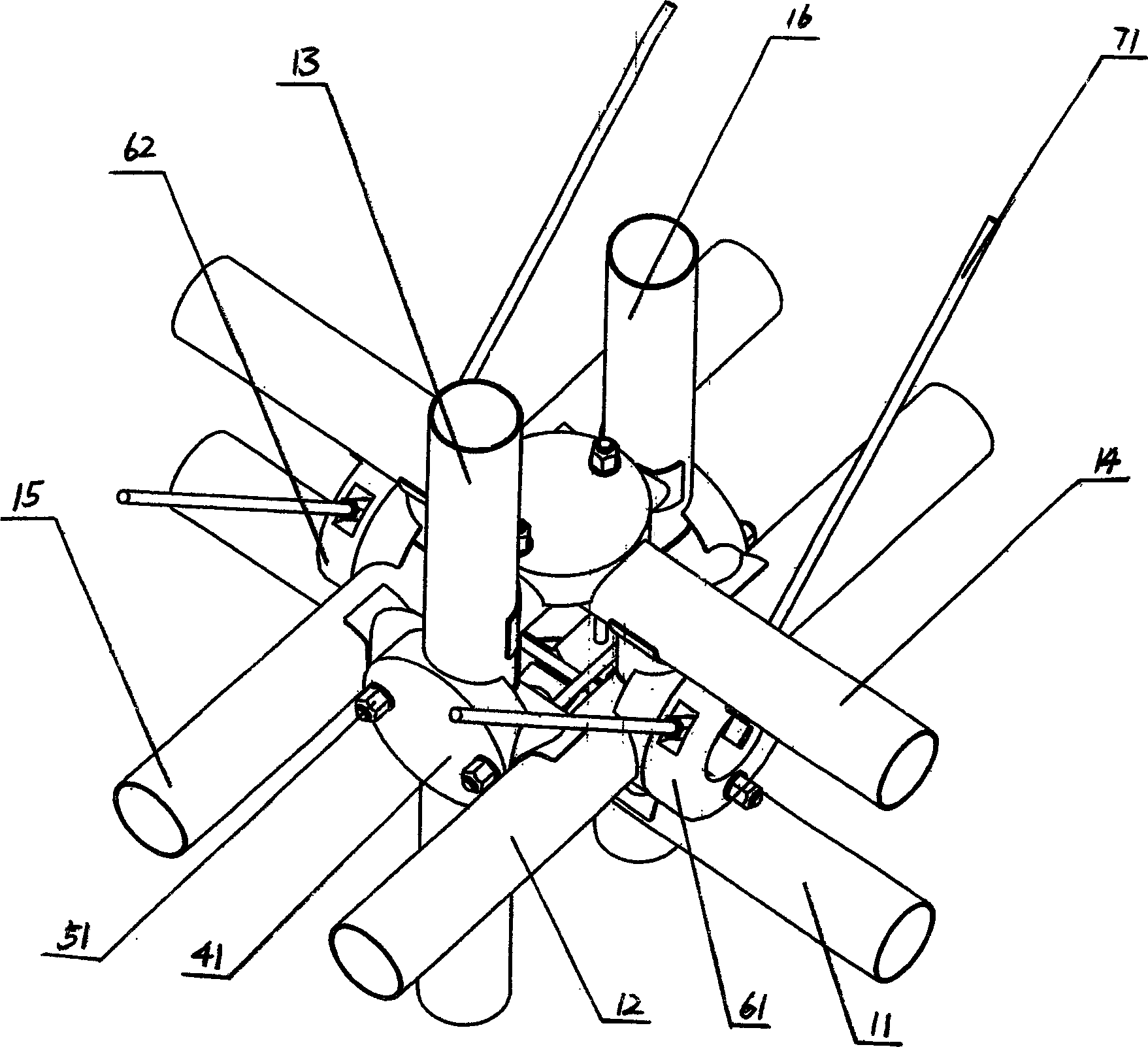

[0031] Such as figure 2 As shown, the first rod 11, the second rod 12, and the third rod 13 are vertically arranged in space through the first spacer and the second spacer respectively, and the fourth rod 14, the fifth rod 15, the The six rods 16 are arranged perpendicular to each other in space through the third spacer and the fourth spacer, and are connected to the first rod 11, the second rod 12, and the third rod 13 respectively through the fifth spacer and the sixth spacer. Arranged in parallel in space, the mutually parallel rods 13 and 16 are fixed by the fastening bolts 51 through the cover plate 41, and the mutually parallel rods 12 and 15 are fixed by the cable installation frame 61 and the cable installation frame 62 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com