Reaction chamber for forming tantalum deposition film on silicon substrate, and application thereof

A reaction chamber and silicon substrate technology, applied in the field of reaction chamber, can solve problems such as poor bombardment effect on the side wall of the tantalum ring, cracking and peeling, and excessive particles in the chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

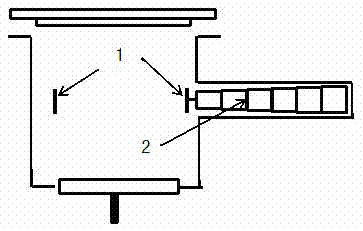

[0015] The invention provides a reaction chamber for a tantalum barrier process, the reaction chamber used for forming a tantalum deposition film on a silicon substrate can reduce the deposition of a tantalum film on a tantalum ring, prevent the film deposited on the tantalum ring from being too thick, and produce The problem of cracking and peeling of tantalum film.

[0016] The reaction chamber for forming a tantalum deposition film on a silicon substrate provided by the present invention will be further described in detail through the following examples, so as to better understand the content of the present invention, but the content of the examples does not limit the scope of the present invention. protected range.

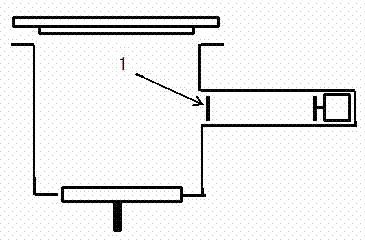

[0017] Such as figure 1 and figure 2 As shown, a cavity is provided on the chamber inner side wall of the reaction chamber body, and a fixed bracket 2 is arranged in the cavity, and the fixed bracket 2 has a telescopic part, and the fixed bracket 2 stretche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com