High-heat-dissipation ink and preparation method thereof

A high heat dissipation and ink technology, applied in ink, household utensils, applications, etc., can solve problems affecting the optical performance of PCB boards, ink adhesion, ink peeling, etc., achieve good reactivity, prevent heat accumulation, and prevent peeling and cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

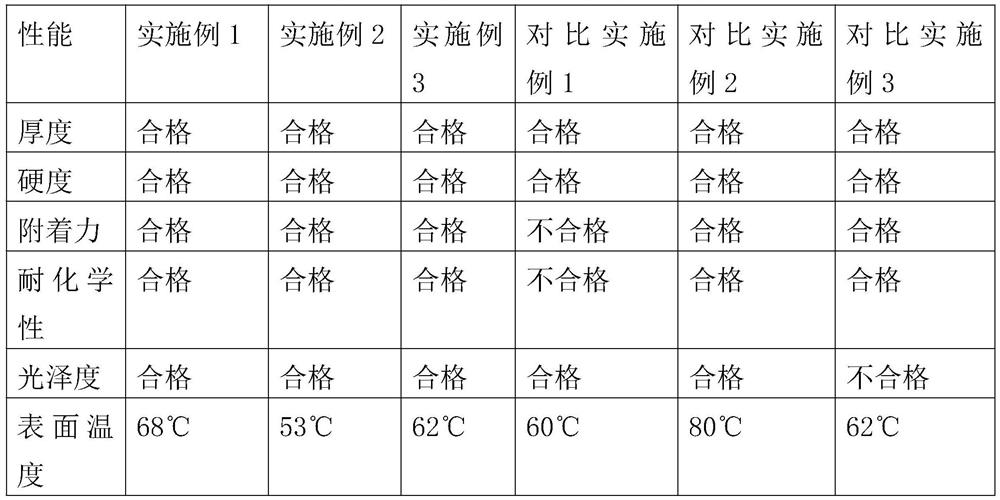

Examples

preparation example Construction

[0049] Correspondingly, the present invention also provides the preparation method of above-mentioned high heat dissipation ink, comprises the following steps:

[0050] Step S1, stirring the solvent for 15-20 minutes, the speed is 800-1200 rpm, the temperature is 50-80°C, and the pressure is normal pressure to obtain the stirred solvent;

[0051] Step S2. Slowly add filler, dispersant, and catalyst to the stirred solvent, stir for 5-15 minutes at a speed of 800-1200 rpm, a temperature of 50-80°C, and a pressure of normal pressure to obtain a mixed solution A;

[0052]Step S3, after adding the modified epoxy glue into the mixed liquid A, then add the defoamer, and stir for 5-10 minutes, the speed is 700-1000 rpm, the temperature is 40-70°C, and the pressure is normal pressure to obtain the mixed Liquid B;

[0053] Wherein, the preparation method of described modified epoxy glue comprises the following steps:

[0054] Step S31, add phthalic anhydride and polyether polyol into ...

Embodiment 1

[0063] This embodiment provides a high heat dissipation ink, and its preparation raw materials include: 30 parts of modified epoxy glue, 15 parts of solvent, 10 parts of curing agent, 10 parts of filler, 0.5 part of catalyst, 0.5 part of dispersant, and 2 parts of defoamer and 0.1 parts of carbon nanotubes;

[0064] Wherein, the modified epoxy glue comprises epoxy resin and B glue, and the volume of the epoxy resin accounts for 20% of the volume of the modified epoxy glue;

[0065] The acid value of the B glue is 113mgKOH / g, and its preparation raw materials include 25 parts of phthalic anhydride, 65 parts of polyether polyols and 15 parts of propylene glycol methyl ether acetate;

[0066] The solvent is propylene glycol methyl ether acetate; the curing agent is polyether polyol;

[0067] The filler includes nano barium sulfate and nano silicon dioxide, and the weight of the nano barium sulfate is 50% of the total weight of the filler.

[0068] The catalyst is toluenesulfoni...

Embodiment 2

[0079] This embodiment provides a high heat dissipation ink, its preparation raw materials include: 50 parts of modified epoxy glue, 25 parts of solvent, 20 parts of curing agent, 20 parts of filler, 3 parts of catalyst, 1 part of dispersant, 7 parts of defoamer and 2 carbon nanotubes;

[0080] Wherein, described modified epoxy glue comprises epoxy resin and B glue, and the volume of described epoxy resin accounts for 50% of the volume of described modified epoxy glue;

[0081] The acid value of the B glue is 110mgKOH / g, and its preparation raw materials include 35 parts of phthalic anhydride, 75 parts of polyether polyols and 35 parts of propylene glycol methyl ether acetate;

[0082] The solvent is propylene glycol methyl ether acetate; the curing agent is polyether polyol;

[0083] The filler includes nano-barium sulfate and nano-silicon dioxide, and the weight of the nano-barium sulfate is 60% of the total weight of the filler.

[0084] The catalyst is toluenesulfonic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com