Preparation method of hydrogenation catalyst for nitrobenzene and derivatives thereof

A hydrogenation catalyst and nitrobenzene technology, which is applied in the direction of amino compound preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the complicated preparation process, large particle size, and easy agglomeration Problems such as growth, to achieve the effect of low equipment requirements, improved load capacity, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

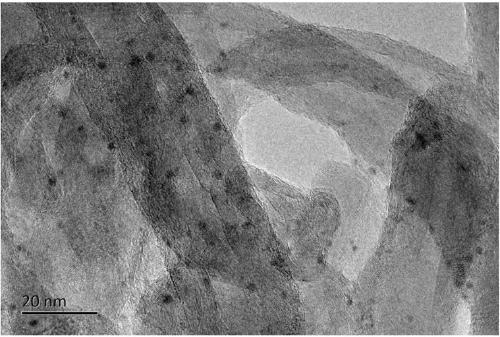

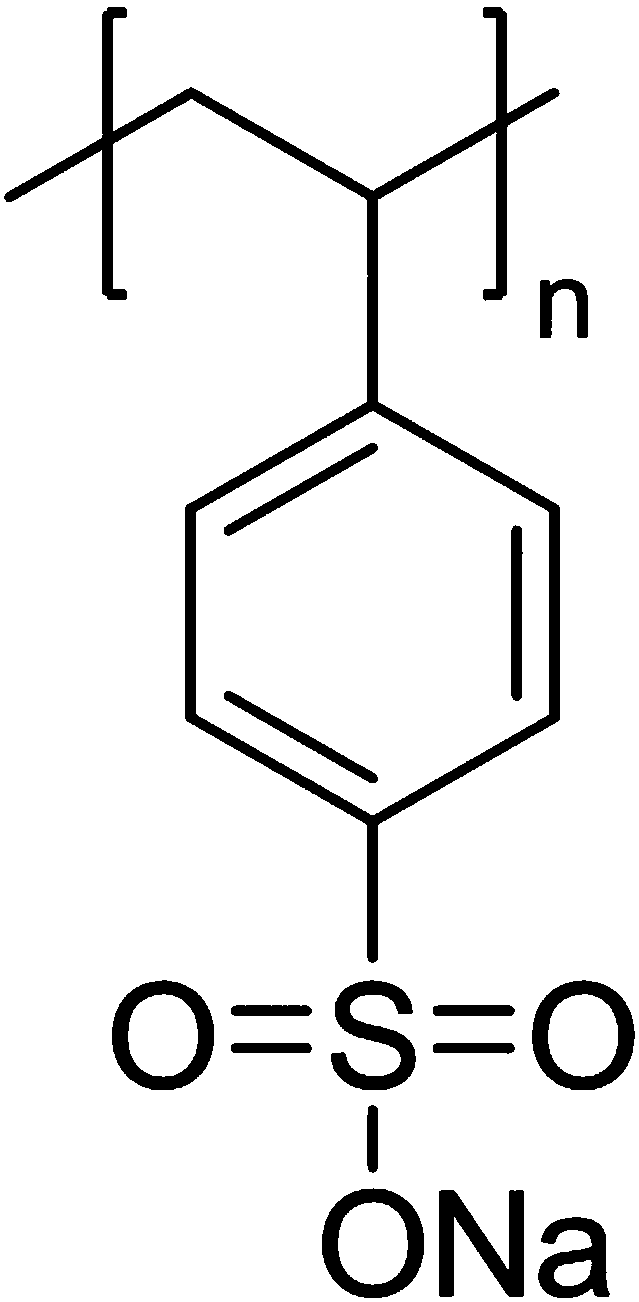

[0029] 1) Preparation of functional carbon materials

[0030] Disperse 100 mg of sodium polystyrene sulfonate in a sodium chloride solution with a volume of 500 ml and a mass fraction of 1 wt%, and sonicate for 10 minutes; disperse 100 mg of carbon nanotubes in the above solution and sonicate for 2 hours at 30 ℃; filter and dry Obtain functionalized carbon materials;

[0031] 2) Preparation of precious metal nanoparticles

[0032] Add 10ml of an aqueous solution containing 20.60mg of chloroauric acid to 41.2mg of polyvinylpyrrolidone with a molecular weight of 8000, mix and stir for 1 hour at a stirring speed of 1000rpm, then add 103.0mg of sodium borohydride to reduce for 2 hours to obtain nano-Au particle catalyst;

[0033] 3) Support precious metal nanoparticles

[0034] Disperse 49mg of functionalized carbon material in 10ml of ethanol solution, sonicate for 0.5h, then drop 5ml of ethanol solution containing 1mg of nano Au particles, mix and stir for 6h, functionalized carbon mater...

Embodiment 2

[0037] 1) Preparation of functional carbon materials

[0038] Disperse 50 mg of polydiallyl dimethyl ammonium chloride in a sodium chloride solution with a volume of 500 ml and a mass fraction of 5 wt%, and sonicate for 10 minutes; disperse 100 mg of carbon nanotubes in the above solution and perform ultrasonic treatment at 30°C 2h; suction filtration and drying to obtain functionalized carbon material;

[0039] 2) Preparation of precious metal nanoparticles

[0040] Add 10ml of an aqueous solution containing 20.60mg of chloroauric acid to 20.6mg of polyvinylpyrrolidone with a molecular weight of 10000, mix and stir for 1 hour at a stirring speed of 1000rpm, and then add 164.8mg of sodium borohydride to reduce for 4 hours to obtain nano-Au particle catalyst;

[0041] 3) Support precious metal nanoparticles

[0042] Disperse 95mg of functionalized carbon material in 20ml of ethanol solution, sonicate for 0.5h, drop 10ml of ethanol solution containing 5mg nano Au particles, mix and stir ...

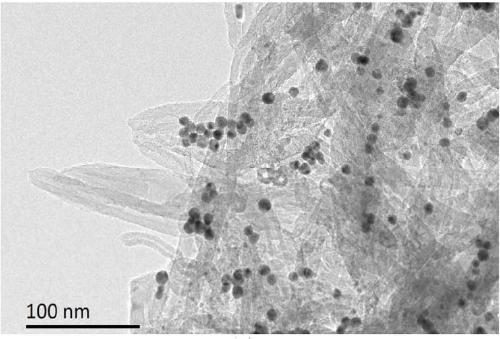

Embodiment 3

[0045] 1) Preparation of functional carbon materials

[0046] Disperse 100 mg of sodium polystyrene sulfonate in a sodium chloride solution with a volume of 500 ml and a mass fraction of 2 wt%, and sonicate for 10 minutes; disperse 50 mg of carbon nanotubes in the above solution and sonicate for 2 hours at 50°C; filter and dry Obtain functionalized carbon materials;

[0047] 2) Preparation of precious metal nanoparticles

[0048] Add 10ml of an aqueous solution containing 20.60mg of chloroauric acid to 41.2mg of polyvinylpyrrolidone with a molecular weight of 8000 and mix and stir for 1h at a stirring speed of 1000rpm, then add 103.0mg of ascorbic acid to reduce for 2h to obtain nano-Au particle catalyst;

[0049] 3) Support precious metal nanoparticles

[0050] Disperse 92mg functionalized carbon material in 10ml ethanol solution, sonicate for 0.5h, drop 10ml ethanol solution containing 8mg nano Au particles, mix and stir for 10h, functionalized carbon material supports precious metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com