Preparation method for nitrogen-doped porous carbon supported non-noble metal electrocatalyst and electrocatalyst application

A nitrogen-doped porous carbon, non-precious metal technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the gap in electrochemical activity, and achieve the effect of enhancing oxygen reduction activity, simple operation, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Preparation of nitrogen-doped porous carbon materials

[0036] Mix 2.8g of magnesium oxide, 1.2g of phenanthroline and 0.9g of adipic acid in 60mL of ethanol, ultrasonically disperse for 30min, and spin-evaporate at 25°C to obtain a white mixture, then roast at 900°C for 2h under argon , at 25°C, wash with 2M hydrochloric acid for 24 hours to remove the hard template, wash with water until neutral, and dry in a vacuum oven to obtain a nitrogen-doped porous carbon support;

[0037] 2) Loading transition metal macrocyclic compounds

[0038] Disperse 300mg of hemin in 25mL of ethanol, mix it with 700mg of the carbon material prepared in 1), ultrasonicate for 30min, at 50°C, after rotary evaporation, roast at 900°C for 2h under argon, at 80°C, 0.5 Wash with M sulfuric acid for 6 hours to remove impurities, wash with water until neutral, and dry overnight to obtain a supported non-precious metal electrocatalyst.

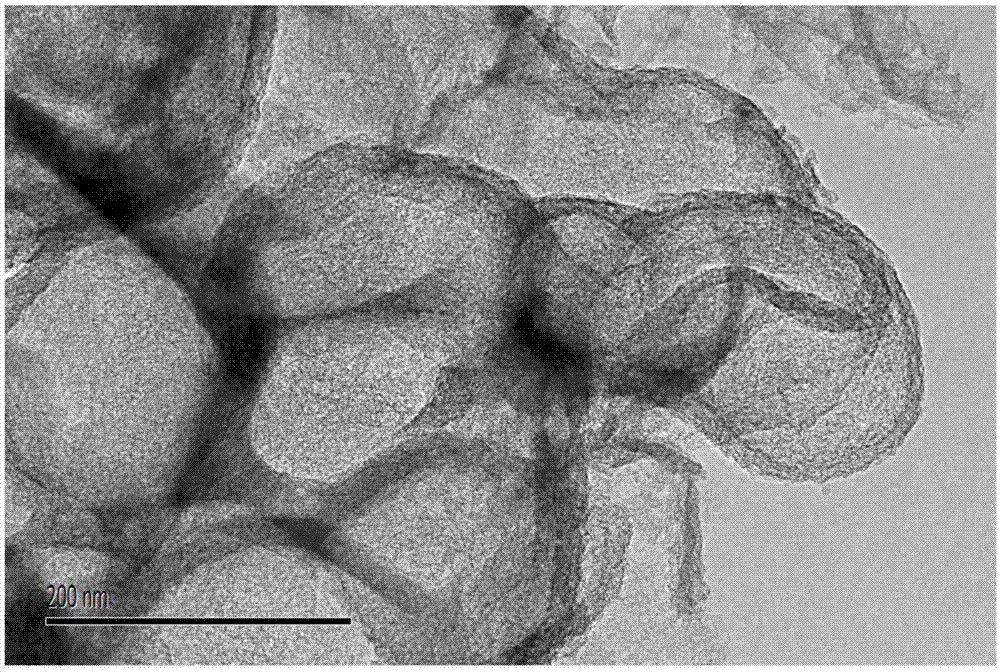

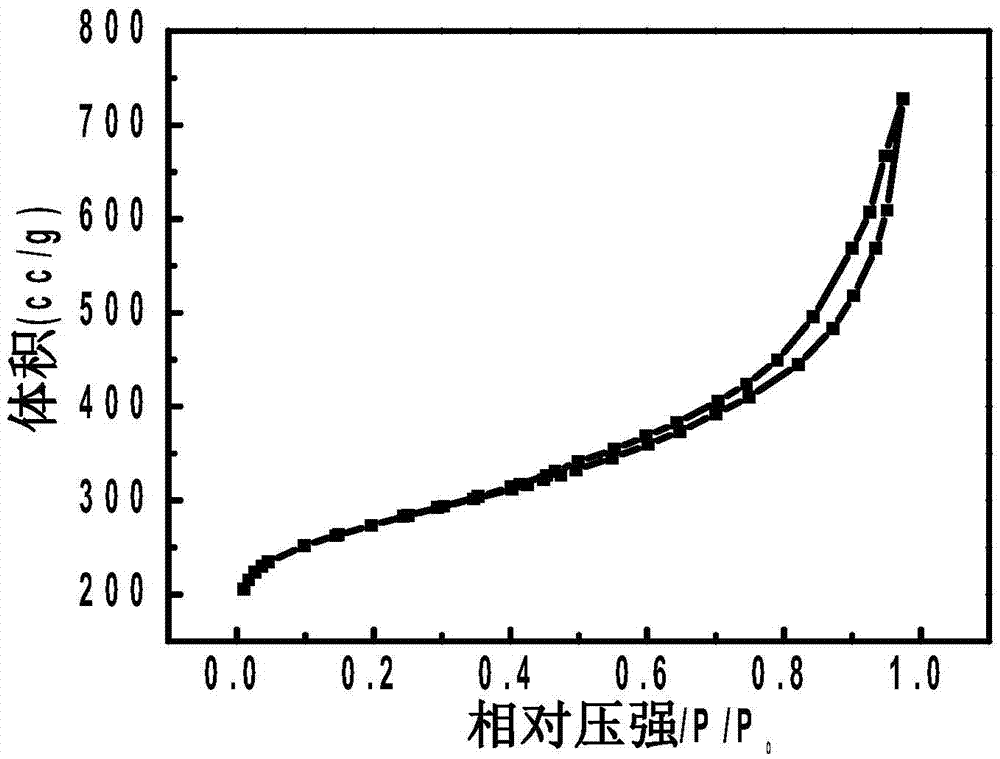

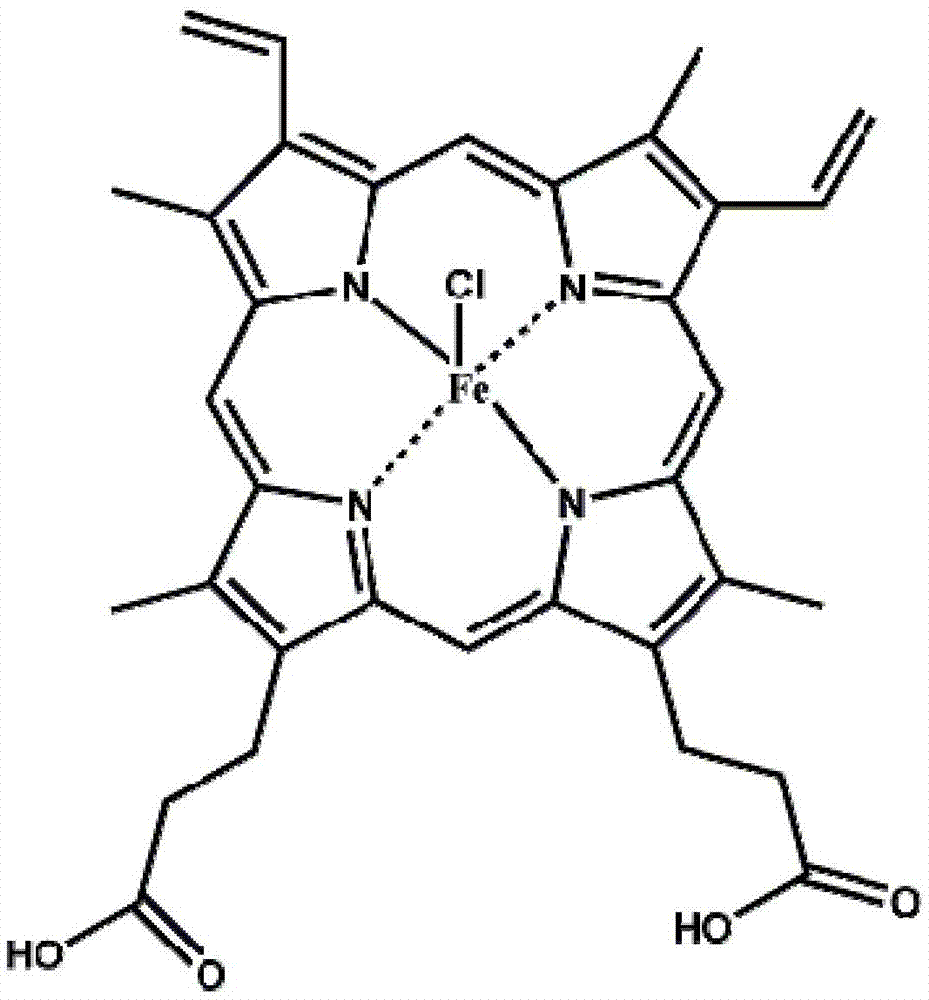

[0039] Such as figure 1 , the transmission electron mic...

Embodiment 2

[0044] 1) Preparation of nitrogen-doped porous carbon materials

[0045] Grind and mix 2.8g magnesium oxide, 1.2g o-phenanthroline and 0.9g adipic acid, then bake at 800°C for 2h under argon, wash with 2M hydrochloric acid for 24h at 25°C to remove the hard template, wash with water until neutral , to obtain a nitrogen-doped porous carbon carrier after drying in a vacuum oven;

[0046] 2) Loading transition metal macrocyclic compounds

[0047] Disperse 200mg of iron phthalocyanine in 25mL of ethanol, then mix it with 800mg of the carbon material prepared in 1), ultrasonicate for 60min, at 50°C, after rotary evaporation, roast at 800°C for 2h under argon, at 80°C, 0.5M sulfuric acid Wash for 6 hours to remove impurities, wash with water until neutral, and dry overnight to obtain a supported non-precious metal electrocatalyst.

[0048] Such as Figure 5 , The structural representation of the iron phthalocyanine used in the catalyst prepared in Example 2.

[0049] Such as F...

Embodiment 3

[0052]1) Preparation of nitrogen-doped porous carbon materials

[0053] Mix 0.33g of magnesium oxide, 2.1g of phenanthroline and 0.9g of terephthalic acid in 60mL of ethanol at 50°C. Wash with hydrochloric acid for 24 hours to remove the hard template, wash with water until neutral, and dry in a vacuum oven to obtain a nitrogen-doped porous carbon carrier;

[0054] 2) Loading transition metal macrocyclic compounds

[0055] Disperse 700mg of vitamin B12 in 25mL of methanol, then mix it with 300mg of the carbon material prepared in 1), ultrasonicate for 60min, at 50°C, after rotary evaporation, roast at 600°C for 4h under argon, at 25°C, 0.1M hydrochloric acid Impurities were removed for 30 minutes, washed with water until neutral, and dried overnight to obtain a supported non-precious metal electrocatalyst.

[0056] Such as Figure 7 , The structural representation of vitamin B12 used in the catalyst prepared in Example 3.

[0057] The morphology of the catalyst prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com