Method for preparing biodiesel by ultrasonic and microwave combination

A biodiesel and ultrasonic technology, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures, etc., can solve the problems of low reaction conversion rate, inability to be widely used, and long reaction time, and achieve novel production technology and production cost. Low, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

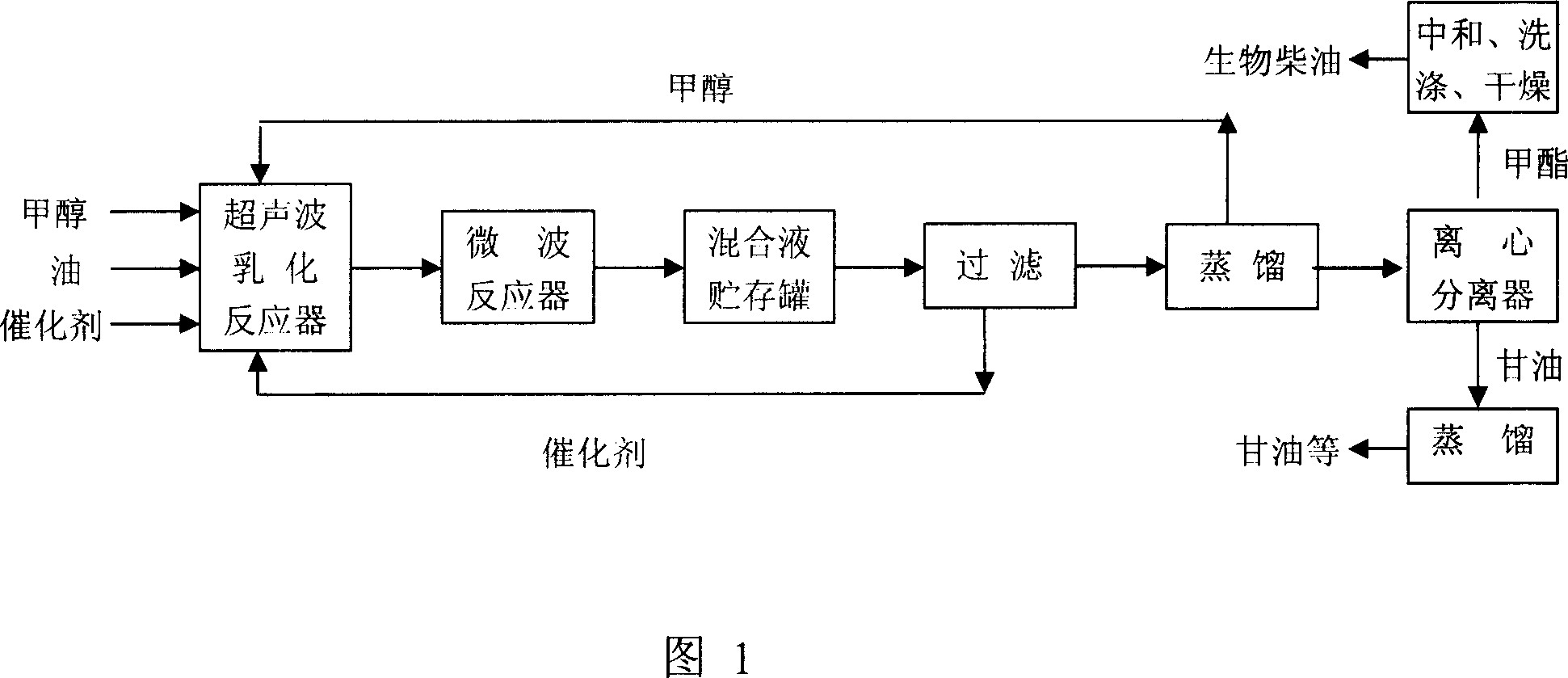

Image

Examples

Embodiment 1

[0020] Add 1 mol of deacidified and dehydrated soybean oil, 6 mol of methanol, and 2% of calcium oxide catalyst into a 1.5-liter flask, and emulsify in an ultrasonic reactor at 35°C and 50 kHz for 2 minutes. After the emulsification reaction, transfer the mixture into a microwave reactor for transesterification reaction, control the reaction temperature at 45°C, heat and reflux for 3 minutes, filter the mixed solution while hot after the reaction, and recycle the obtained solid catalyst after activation treatment. The liquid is distilled to recover excess methanol.

[0021] Then adopt the method of centrifugation to separate crude biodiesel and glycerin. The crude biodiesel is neutralized, washed with water, dried, and continuously distilled under reduced pressure at 220-250°C to obtain high-purity biodiesel. The fatty acid methyl ester content of biodiesel is 98.3% through chromatographic detection.

Embodiment 2

[0023] Add 1 mol of deacidified and dehydrated rapeseed oil, 8 mol of methanol, and 3% barium oxide catalyst into a 1.5-liter flask, and emulsify in an ultrasonic reactor at 40°C and 100 kHz for 3 minutes. After the emulsification reaction, the mixture was transferred to a microwave reactor for transesterification reaction, the reaction temperature was controlled at 65°C, and heated to reflux for 7 minutes. After the reaction was completed, the mixed solution was filtered while it was hot, and the obtained solid catalyst was activated and then recycled. The liquid is distilled to recover excess methanol.

[0024] Then adopt the method of centrifugation to separate crude biodiesel and glycerin. The crude biodiesel is neutralized, washed with water, dried, and continuously distilled under reduced pressure at 220-250°C to obtain high-purity biodiesel. The fatty acid methyl ester content of biodiesel is 97.3% through chromatographic detection.

Embodiment 3

[0026] Add 1 mol of recovered waste oil, 12 mol of methanol and 2.5% catalyst zinc oxide into a 1.5-liter flask, and emulsify in an ultrasonic reactor at 45°C and 150kHz for 2 minutes. After the emulsification reaction, the mixture was transferred to a microwave reactor for transesterification reaction, the reaction temperature was controlled at 65°C, and heated to reflux for 8 minutes. After the reaction was completed, the mixed solution was filtered while it was hot, and the obtained solid catalyst was activated and then recycled. The liquid is distilled to recover excess methanol.

[0027] Then adopt the method of centrifugation to separate crude biodiesel and glycerin. The crude biodiesel is neutralized, washed with water, dried, and continuously distilled under reduced pressure at 220-250°C to obtain high-purity biodiesel. The fatty acid methyl ester content of biodiesel is 95.3% through chromatographic detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com