Method for preparing metal sealed intermetallic compound base lamination composite amour

A technology of intermetallic compounds and metal encapsulation, which is applied in the field of preparing metal-encapsulated intermetallic compound-based laminated composite armor, which can solve problems such as layer spacing, layer thickness ratio is not easy to control, oxides are generated at the interface, and the performance of composite materials is affected. Achieve the effect of high penetration resistance, low production cost and unique process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

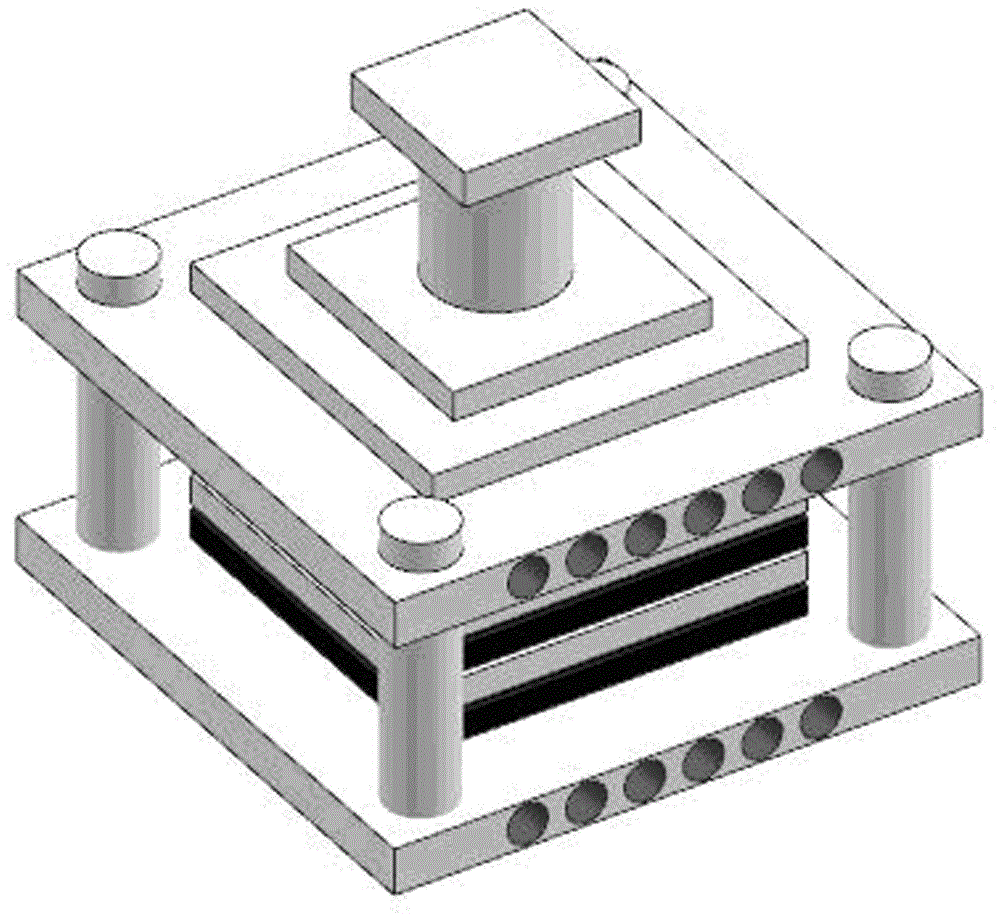

[0047] Preparation of titanium alloy package Ti-Al 3 Ti intermetallic compound-based laminated composite armor: Note that when choosing a metal foil, the length and width of the Ti foil is 10mm larger than that of the Al foil;

[0048] The length, width and thickness of TC4 foil are 300mm, 300mm and 0.027mm respectively;

[0049] The length, width and thickness of Al foil are 290mm, 290mm and 0.027mm respectively;

[0050] (1) Surface treatment of sandpaper polishing and acetone ultrasonic cleaning: the 0.027mm thick metal Ti foil was cut into 300×300mm, and the 0.027mm thick metal Al foil was cut into 290×290 mm, and the number of Ti foil cut was 11 layers , Al foil is 10 layers; then the cut metal foil material is evenly polished with 800 mesh and 1500 mesh sandpaper in turn until a metallic luster appears, and the polished metal foil materials are classified and placed; the glass beaker is pre-cleaned with acetone solution , put the polished metal Ti foil and metal Al foi...

Embodiment 2

[0056] Preparation of aluminum alloy package Al-Al 3 Ti intermetallic compound-based laminated composite armor: Note that when selecting metal foils, Al foils are 10mm larger in length and width than Ti foils;

[0057] The length, width and thickness of TC4 foil are 290mm, 290mm and 0.02mm respectively;

[0058] The length, width and thickness of Al foil are 300mm, 300mm and 0.08mm respectively;

[0059] (1) Surface treatment of sandpaper polishing and acetone ultrasonic cleaning: 0.08 mm thick metal Al foil is cut to 300×300 mm, 0.02 mm thick metal Ti foil is cut to 290×290 mm, and the number of Al foil cutting is 11 layers , Ti foil is 10 layers; then the cut metal foil material is evenly polished with 800 mesh and 1500 mesh sandpaper in turn until it appears metallic luster, and the polished metal foil materials are classified and placed; the glass beaker is pre-cleaned with acetone solution , Put the polished metal Al foil and metal Ti foil into cleaned glass beakers res...

Embodiment 3

[0065] Preparation of Titanium Alloy Encapsulation Ti-Al 3 Ti-Al intermetallic compound-based laminated composite armor: Note that when selecting metal foils, Ti foils are 10mm larger in length and width than Al foils;

[0066] The length, width and thickness of TC4 foil are 300mm, 300mm and 0.027mm respectively;

[0067] The length, width and thickness of Al foil are 295mm, 295mm and 0.054mm respectively;

[0068] (1) Surface treatment of sandpaper polishing and acetone ultrasonic cleaning: cut the 0.027mm thick metal Ti foil to 300×300mm, and the 0.054mm thick metal Al foil to 290×290 mm, and the number of Ti foil cutting is 11 layers , Al foil is 10 layers; then the cut metal foil material is evenly polished with 800 mesh and 1500 mesh sandpaper in turn until a metallic luster appears, and the polished metal foil materials are classified and placed; the glass beaker is pre-cleaned with acetone solution , put the polished metal Ti foil and metal Al foil into cleaned glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com