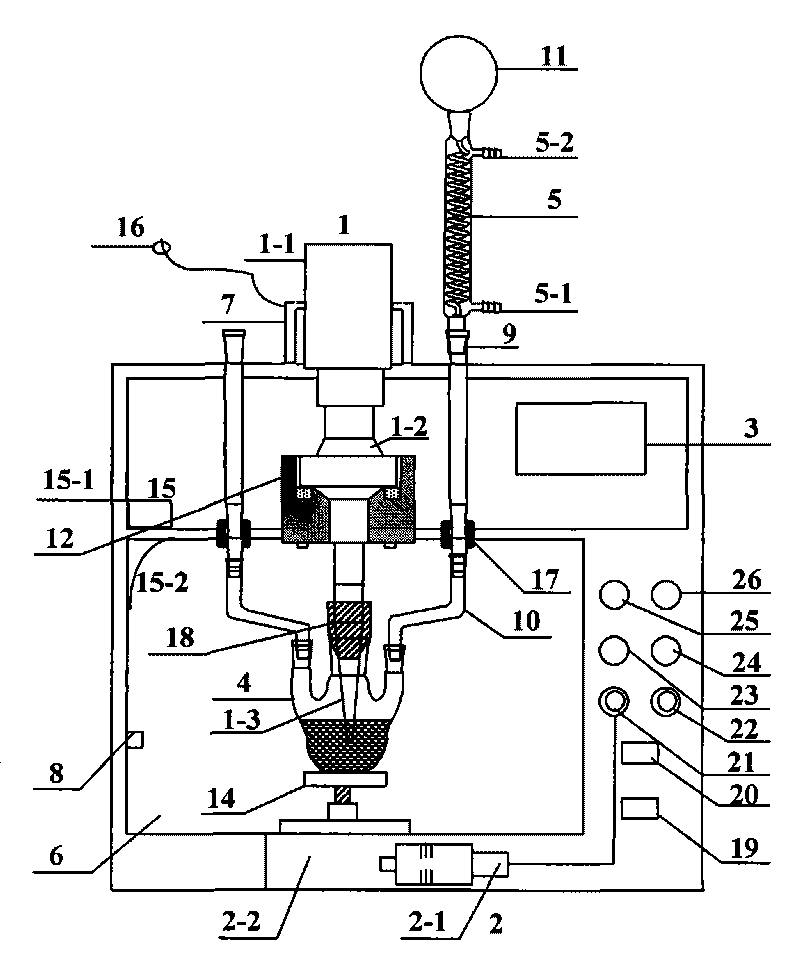

Multifunctional ultrasonic microwave collaborative chemical reactor and method for preparing nano semiconductor chalcogenide by using same

A technology of ultrasonic microwave synergy and chemical reactor, applied in the preparation of sulfide/polysulfide, chemical/physical/physicochemical process of energy application, binary selenium/tellurium compound, etc., can solve discharge phenomenon, high frequency Short circuit and other problems, to overcome overheating carbonization, reduce bonding force, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

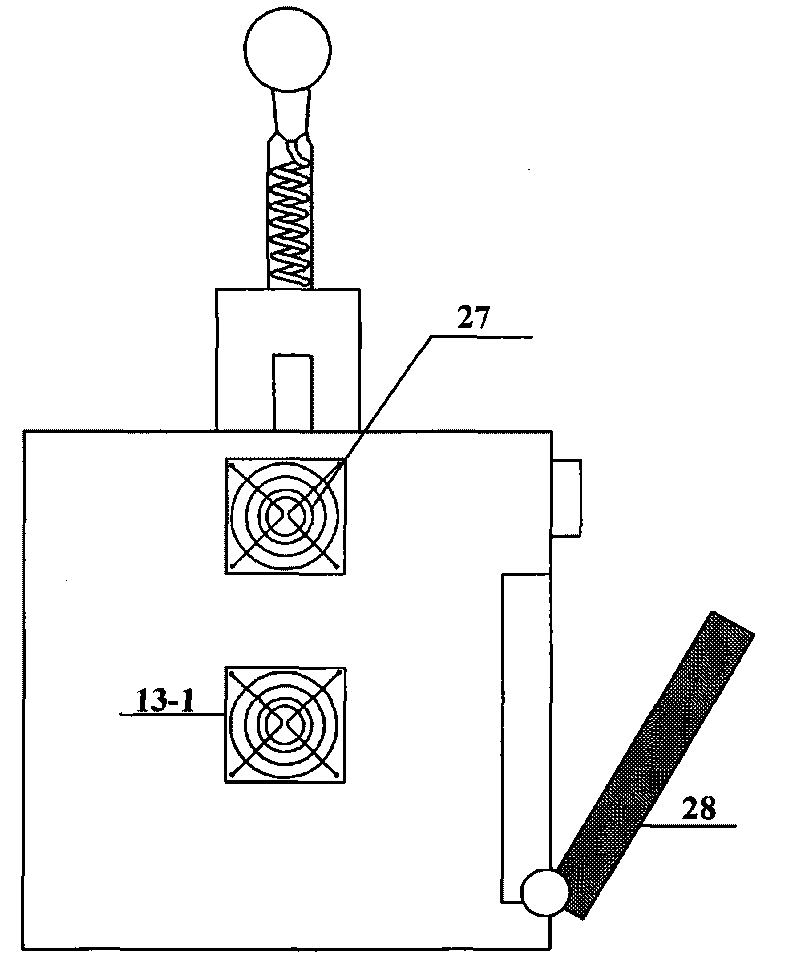

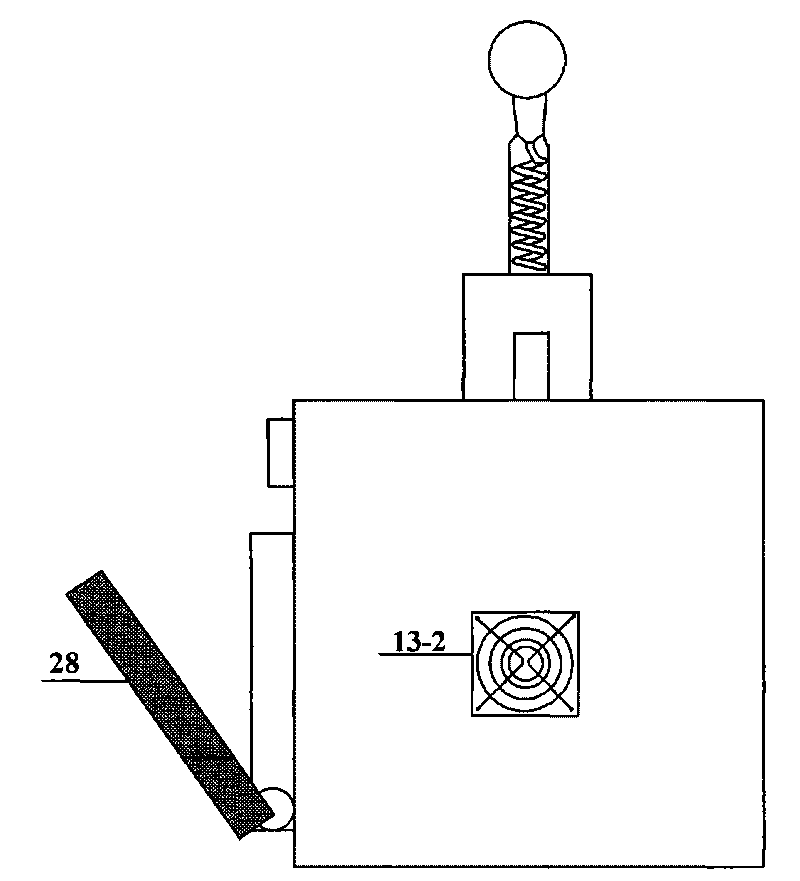

Method used

Image

Examples

Embodiment 1

[0050] Synthesis of Nano PbTe

[0051] Raw materials: analytically pure Pb(NO 3 ) 2 , Na 2 TeO 3 , ethylene glycol, ethylenediamine.

[0052] Experimental steps:

[0053] (1) Pb(NO 3 ) 2 Soluble in the mixed solution of ethylene glycol and ethylenediamine (V 乙二胺 :V 乙二醇 =0~1∶5), it is formulated into 0.01~0.1M Pb(NO 3 ) 2 solution, the Na 2 TeO 3 Soluble in the mixed solution of ethylene glycol and ethylenediamine (V 乙二胺 :V 乙二醇 =0~1:5), it is also formulated to be 0.01~0.1M Na 2 TeO 3 The solution.

[0054] (2) the above Pb (NO 3 ) 2 solution and Na 2 TeO 3 Take 20 mL of each solution (the molar ratio of the two is 1:1) and pour it into a reaction vessel, add 20 mL of ethylene glycol, and stir magnetically for 30-120 min to make it clear.

[0055] (3) The mixed solution in (2) was then placed in a microwave resonant cavity, the power of the microwave resonant cavity was set to 400W, the temperature was 140°C, the ultrasonic power was 400W, reacted for 30min...

Embodiment 2

[0059] Synthesis of Nano-Sb by Ultrasonic-Microwave Synergistic Chemical Method 2 Te 3

[0060] Raw materials: analytically pure Sb(CH 3 COO) 3 , Na 2 TeO 3 , ethylene glycol, ethylenediamine.

[0061] Experimental steps:

[0062] (1) Sb(CH 3 COO) 3 Soluble in the mixed solution of ethylene glycol and ethylenediamine (V 乙二胺 :V 乙二醇 =0~1:5), it is formulated to be 0.01~0.1M Sb(CH 3 COO) 3 solution, the Na 2 TeO 3 Soluble in the mixed solution of ethylene glycol and ethylenediamine (V 乙二胺 :V 乙二醇 =0~1:5), it is also formulated to be 0.01~0.1M Na 2 TeO 3 The solution.

[0063] (2) the above Sb (CH 3 COO) 3 solution and Na 2 TeO 3 Take 20 mL of each solution (the molar ratio of the two is 2:3) and pour it into a reaction vessel, add 20 mL of ethylene glycol, and stir magnetically for 30-120 min to make it clear.

[0064] (3) The mixed solution in (2) was then placed in a microwave resonant cavity. The power of the microwave resonant cavity was set to 400W, the...

Embodiment 3

[0068] Synthetic Nano Bi 2 Te 3

[0069] Raw materials: analytically pure Bi(NO 3 ) 3 , Na 2 TeO 3 , ethylene glycol, ethylenediamine.

[0070] (1) Bi(NO 3 ) 3 Dissolved in ethylene glycol to make 0.01~0.1M Bi(NO 3 ) 3 solution, the Na 2 TeO 3 Soluble in the mixed solution of ethylene glycol and ethylenediamine (V 乙二胺 :V 乙二醇 =0~1:5) to make 0.01~0.1M Na 2 TeO 3 The solution.

[0071] (2) the above Bi(NO 3 ) 3 solution and Na 2 TeO 3 Take 20 mL of each solution (the molar ratio of the two is 2:3) and pour it into a reaction vessel, then add 20 mL of ethylene glycol, and stir magnetically for 30-120 min to make it clear.

[0072] (3) The mixed solution in (2) was then placed in a microwave resonant cavity, the power of the microwave resonant cavity was set to 400W, the temperature was 140°C, the ultrasonic power was 400W, reacted for 30min, and allowed to cool naturally to room temperature.

[0073] (4) The above black deposit was repeatedly washed with abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com