Method for continuously synthesizing single-wall carbon nano tube by high temperature chemical vapor deposition method

A technology of single-wall carbon nanotubes and vapor deposition method, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of inability to prepare and synthesize single-wall carbon nanotubes, and achieve the goal of improving structural defects and saving carrier gas The effect of using and simplifying process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

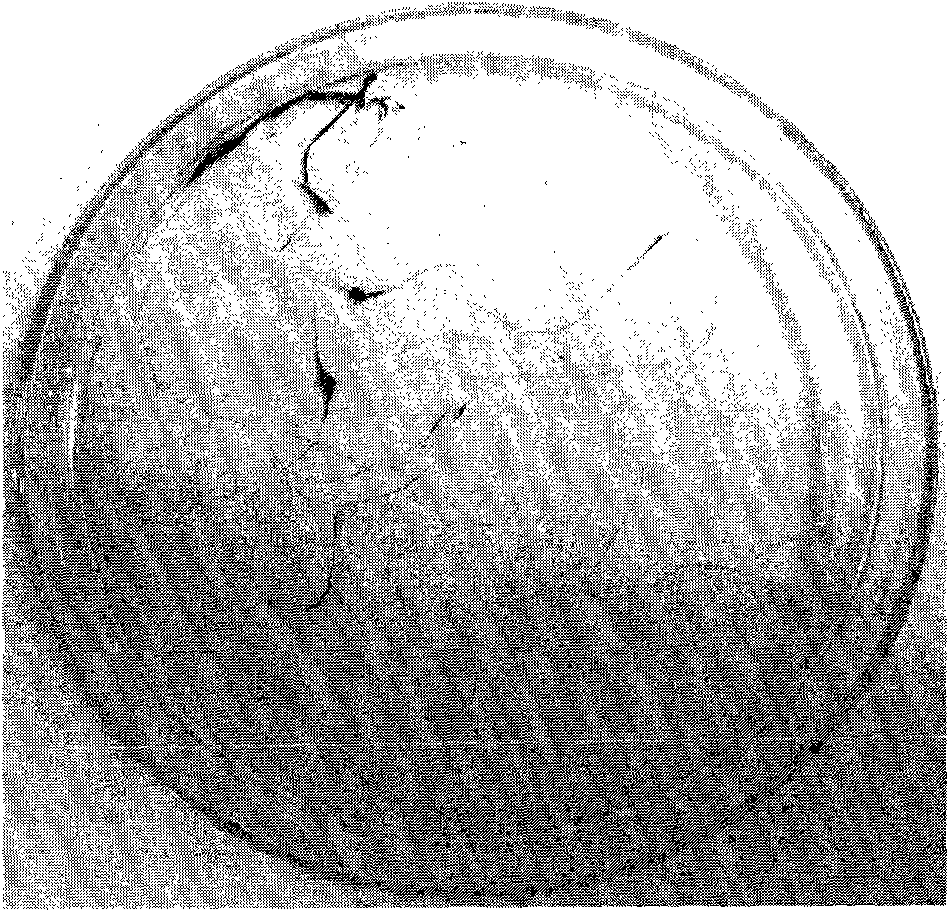

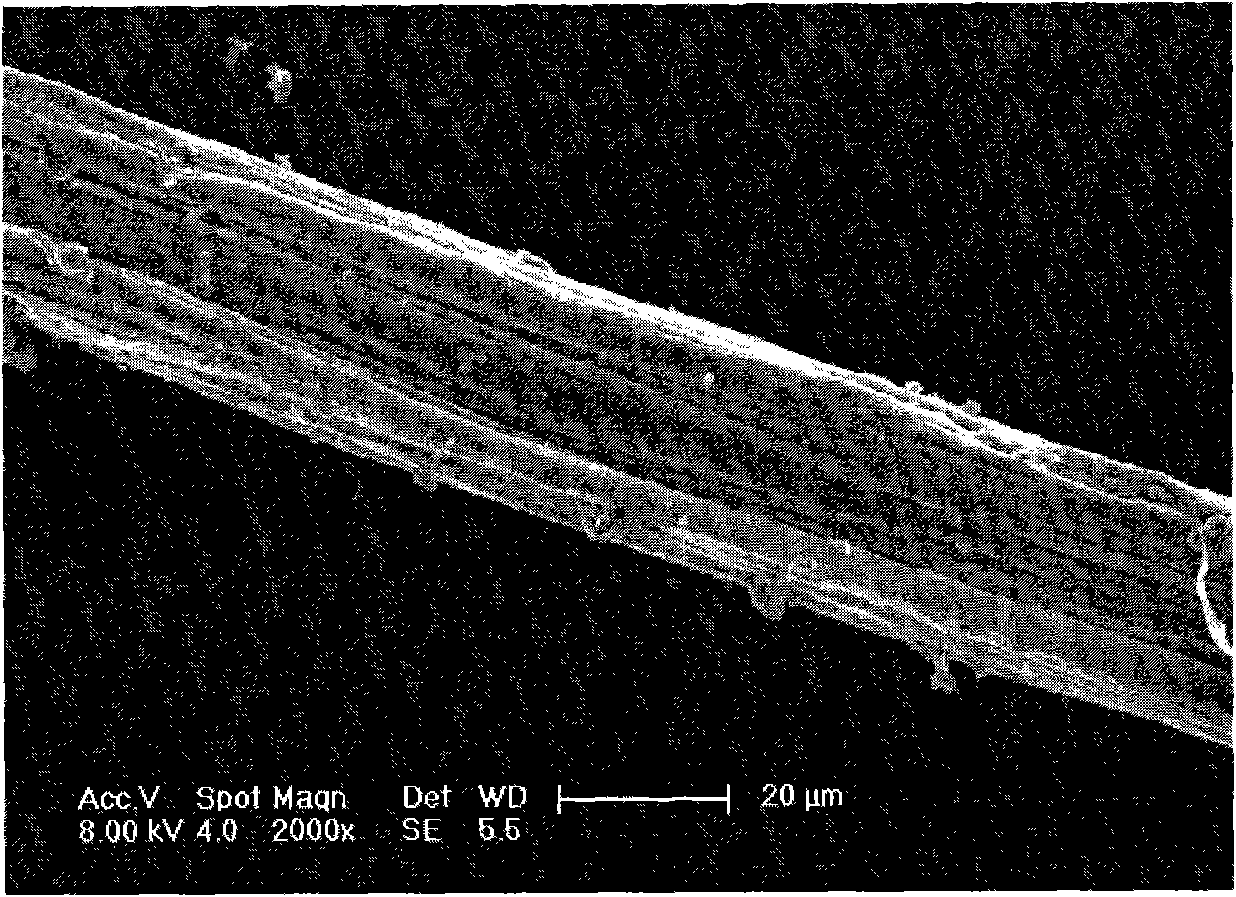

[0030] The synthesis is carried out in a horizontal corundum tube reactor. Under the protection of nitrogen gas, the temperature is raised to 1500°C at a heating rate of 10°C / min, and then ethanol / methanol dissolved in ferrocene is fed by an electronic peristaltic pump. Mix solution (volume ratio 9:1), concentration is 0.1g / 100ml, thiophene concentration is 0.1ml / 100ml, feed rate is 0.5ml / min, the flow rate of regulating argon is 20l / h, and reaction time continues 3 hours. The product is collected at the outlet, and the surface of the product is sprayed with ethanol solution to obtain a fibrous single-walled carbon nanotube product, such as figure 1 shown. The obtained product is a single-wall carbon nanotube bundle, and the size of a single single-wall carbon nanotube is about 1 nm. Single-walled carbon nanotubes are relatively pure, with a small amount of metal iron particles adsorbed on the surface. The field emission scanning electron microscope picture is as follows: f...

Embodiment 2

[0033] The synthesis is carried out in a horizontal corundum tube reactor. Under the protection of argon, the temperature is raised to 1500 °C at a heating rate of 10 °C / min, and then the ethanol / Methanol mixed solution (volume ratio 9: 1), concentration is 0.1g / 100ml, thiophene concentration is 0.5%, feed rate is 0.5ml / min, the flow rate of regulating argon is 20l / h, and reaction time continues 3 hours. The product is collected at the outlet, and the obtained product is a single-wall carbon nanotube bundle, and the size of a single single-wall carbon nanotube is about 2 nm. Single-walled carbon nanotubes are relatively pure, with a small amount of metal iron particles adsorbed on the surface.

[0034] The single-walled carbon nanotubes synthesized by the above method were laid flat on a corundum boat, and the corundum boat was placed in a corundum tube reaction tube for heat treatment. The furnace temperature was raised to 400°C at a rate of 10°C / min and kept for 1 hour. Af...

Embodiment 3

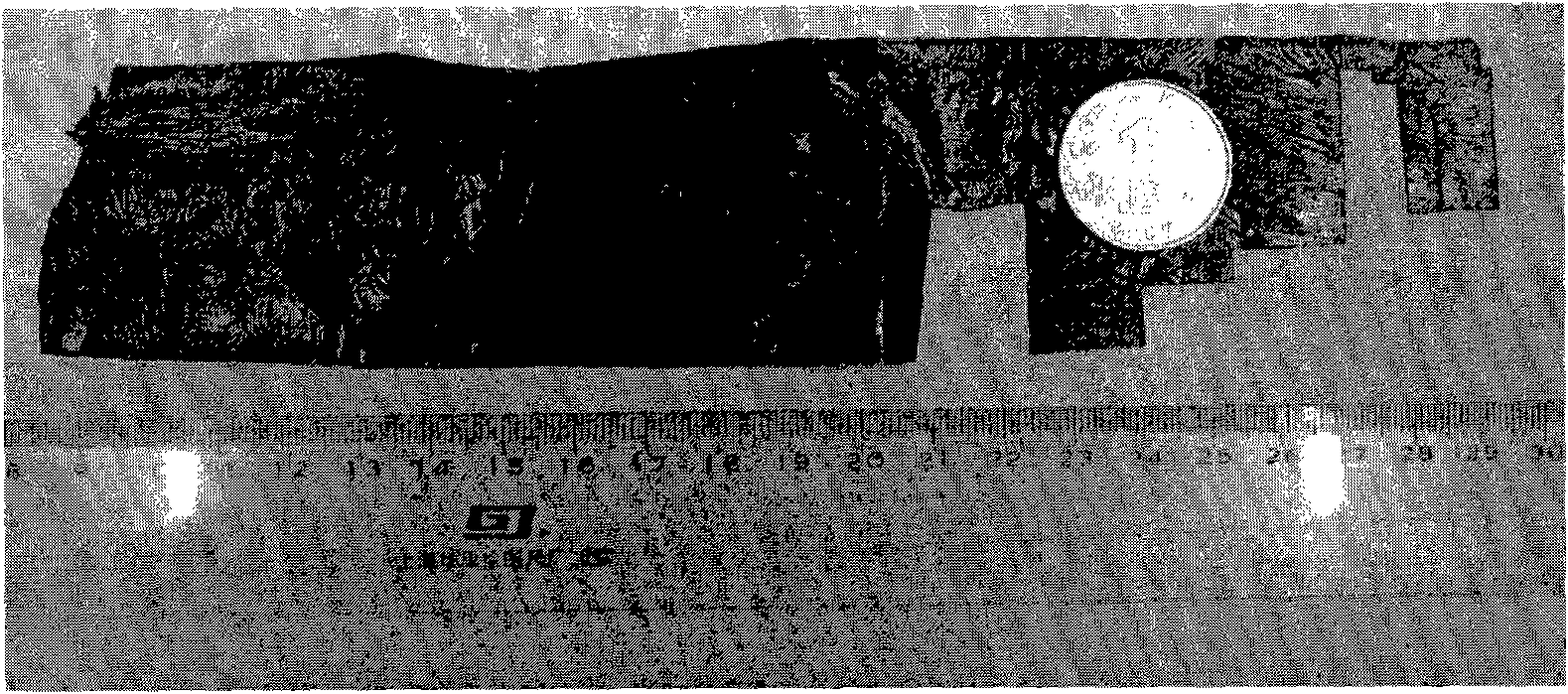

[0036] The synthesis is carried out in a horizontal corundum tube reactor. Under the protection of nitrogen gas, the temperature is raised to 1500°C at a heating rate of 10°C / min, and then ethanol / methanol dissolved in ferrocene is fed by an electronic peristaltic pump. Mix solution (volume ratio 7: 3), concentration is 0.1g / 100ml, thiophene concentration is 1%, feed rate is 0.5ml / min, the flow rate of regulating argon is 20l / h, and reaction time continues 3 hours. The product is collected at the outlet, and the product is attached to a glass substrate to obtain a film-like product such as image 3 shown. The obtained product is a single-wall carbon nanotube, and the size of a single single-wall carbon nanotube is about 4 nm. Single-walled carbon nanotubes are relatively pure, and there are more metal iron particles adsorbed on the surface. Scanning electron microscope pictures of the original single-walled carbon nanotube samples obtained are as follows: Figure 4 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com