Surface processing technology for dental implant

A dental implant and surface treatment technology, which is applied to dentures, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of complex process, poor biological activity, long production cycle, etc., and achieve high bonding strength. Residue and contamination, effect of good surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the steps of processing the cylindrical threaded pure titanium dental implant are:

[0027] A. After the pure titanium dental implant is finely ground, it is ultrasonically cleaned twice with acetone, absolute ethanol, and purified water in sequence, each time for five minutes, in order to clean and degrease, and then dry.

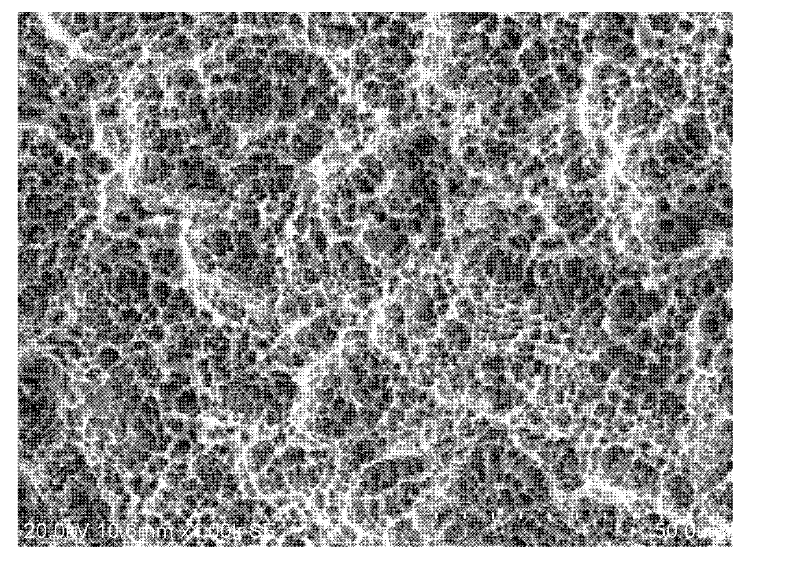

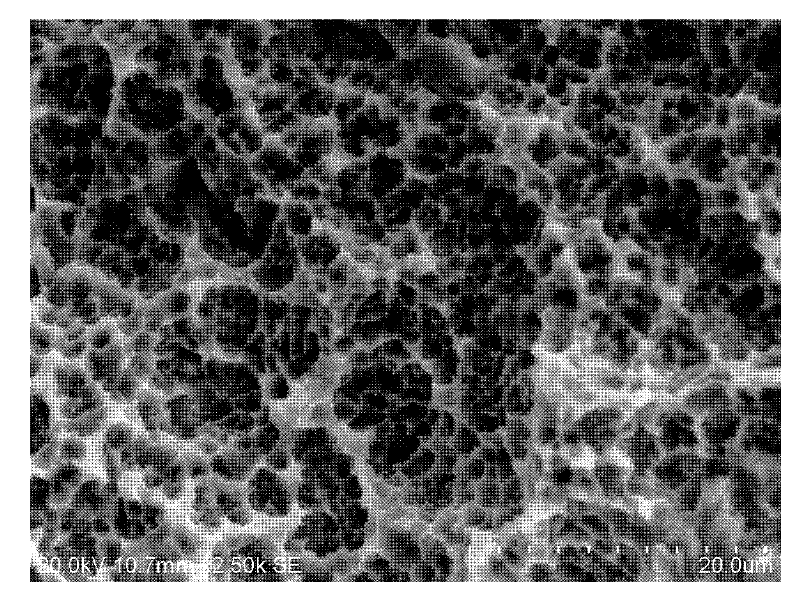

[0028] B. Use 24-40 mesh white corundum particles to sandblast the surface of the dental implant for 8 seconds. During the sandblasting process, the spray gun and the implant axis are at 45°, the sandblasting pressure is 0.5MPa, and the spray distance is 10cm, until the surface forms a uniform Gray, three-dimensional porous structure formed on the surface of the dental implant, the roughness Ra is about 3 μm, and the pit diameter of the porous structure is between 10 and 50 μm. Ultrasonic cleaning with purified water and drying.

[0029] C. Place blasted dental implants in 63wt% H 2 SO 4 In a mixed acid with 10wt% HCl, heat tr...

Embodiment 2

[0032] In this embodiment, the steps of processing the cylindrical threaded pure titanium dental implant are:

[0033] A. After the pure titanium dental implant is finely ground, it is ultrasonically cleaned twice with acetone, absolute ethanol, and purified water in sequence, each time for 7 minutes, so as to clean and degrease, and then dry.

[0034] B. Sandblast the surface of the dental implant with 24-40 mesh white corundum particles for 8 seconds. During the sandblasting process, the spray gun and the implant axis are 60°, the sandblasting pressure is 0.4MPa, and the spray distance is 8cm, until the surface forms a uniform Gray, the three-dimensional porous structure formed on the surface of the dental implant, the roughness Ra is about 4 μm, and the pit diameter of the porous structure is between 10 and 50 μm. Ultrasonic cleaning with purified water and drying.

[0035] C. Place the blasted dental implant in 55wt% H 2 SO 4 In a mixed acid with 18wt% HCl, heat treatme...

Embodiment 3

[0038] In this embodiment, the steps of processing the cylindrical threaded pure titanium dental implant are:

[0039] A. After the pure titanium dental implant is finely ground, use acetone, absolute ethanol, and purified water to ultrasonically clean it twice, each time for 8 minutes, so as to clean and remove oil, and then dry it.

[0040] B. Use 24-40 mesh white corundum particles to sandblast the surface of the dental implant for 8 seconds. During the sandblasting process, the spray gun and the implant axis are 60°, the sandblasting pressure is 0.3MPa, and the spray distance is 8cm, until the surface forms a uniform Gray, the three-dimensional porous structure formed on the surface of the dental implant, the roughness Ra is about 4 μm, and the pit diameter of the porous structure is between 10 and 50 μm. Ultrasonic cleaning with purified water and drying.

[0041] C. Place the blasted dental implant in 56 wt% H 2 SO 4In a mixed acid with 12wt% HCl, heat treatment in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com