Chinese wolfberry milk and preparation method thereof

A technology of wolfberry and milk, which is applied in the field of milk beverage products and its preparation, can solve the problems of flavor and nutrition discount, complexity, short shelf life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

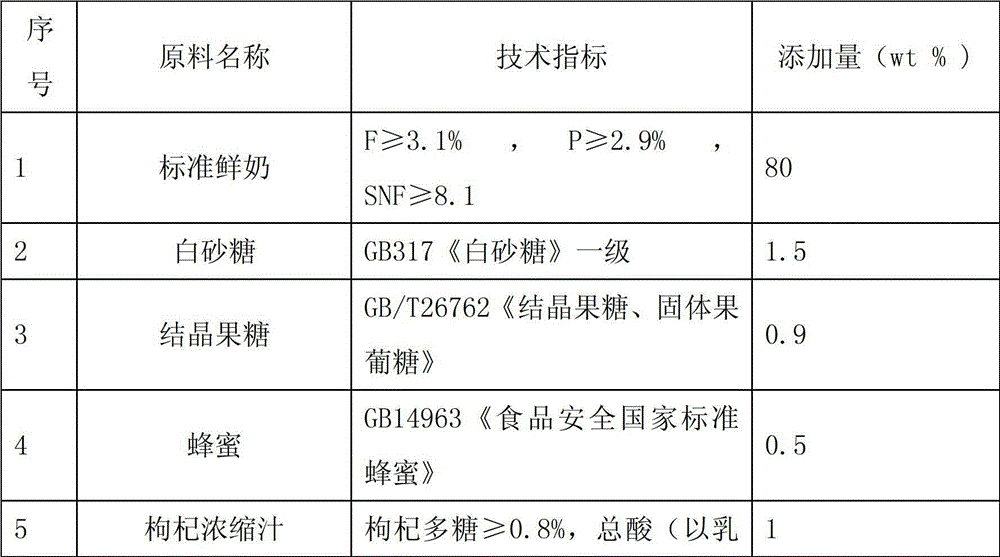

[0052] 1. Raw material formula (see Table 1):

[0053]

[0054]

[0055] Table 1

[0056] Wherein the stabilizer formula is as shown in Table 2, and the percentage wherein is the mass percent equivalent to the total amount of the stabilizer.

[0057] raw material

Amount added (wt / %)

60

10

sodium alginate

10

sodium tripolyphosphate

5

15

total

100

[0058] Table 2

[0059] 2. Preparation method:

[0060] ①Add an appropriate amount of 80°C demineralized water (the amount of water is 50 times the mass of the stabilizer) into the sugar pot, turn on the agitator and the homogenizing pump, and circulate the demineralized water between the pot and the homogenizing pump. Slowly add crystalline fructose and stabilizer into the sugar pot. After feeding, ensure that the temperature of the feed liquid is 80°C, and keep stirring at this temperature fo...

Embodiment 2

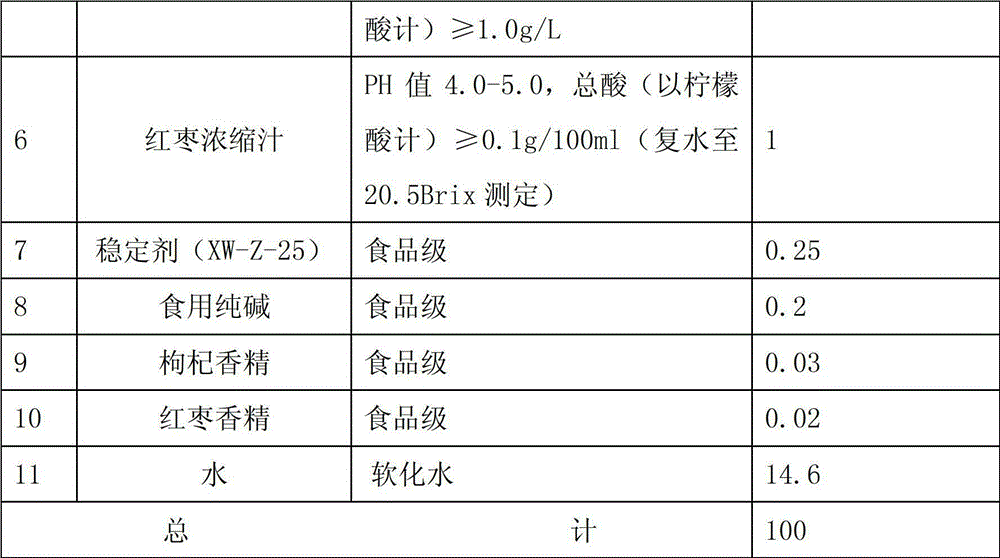

[0070] 1. Raw material formula (see Table 3):

[0071]

[0072]

[0073] table 3

[0074] Wherein the stabilizer formulation is as shown in Table 4, and the percentages therein are mass percents equivalent to the total amount of the stabilizer.

[0075] raw material

Amount added (wt / %)

50

10

sodium alginate

10

sodium tripolyphosphate

15

15

total

100

[0076] Table 4

[0077] 2. Preparation method:

[0078] ①Add an appropriate amount of 80°C demineralized water (40 times the mass of the stabilizer) into the sugar pot, turn on the agitator and the homogenizing pump, and circulate the demineralized water between the pot and the homogenizing pump, mix white sugar, Slowly add crystalline fructose and stabilizer into the sugar pot. After feeding, ensure that the temperature of the feed liquid is 80°C, and keep stirring at this temperature for ...

Embodiment 3

[0088] 1. Raw material formula (see Table 5):

[0089]

[0090] table 5

[0091] Wherein the stabilizer formulation is as shown in Table 6, and the percentages therein are mass percents equivalent to the total amount of the stabilizer.

[0092] raw material

Amount added (wt / %)

[0093] Glyceryl monostearate

55

10

10

sodium tripolyphosphate

10

15

total

100

[0094] Table 6

[0095] 2. Preparation method:

[0096] ①Add an appropriate amount of 80°C demineralized water (the amount of water is 50 times the mass of the stabilizer) into the sugar pot, turn on the agitator and the homogenizing pump, and circulate the demineralized water between the pot and the homogenizing pump. Slowly add crystalline fructose and stabilizer into the sugar pot. After feeding, ensure that the temperature of the feed liquid is 80°C, and keep stirring at this tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com