Patents

Literature

31 results about "Continuous harvest" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In agriculture, continuous harvest is the availability of a crop over an extended period during the growing season. Each crop has a harvest window during which it is ready for picking. Some are harvested by removing the whole plant, for example, cutting a head of lettuce. Others can be picked over varying periods: peas and corn may have a window of two weeks, cucumbers six or eight, tomatoes produce until the end of the season.

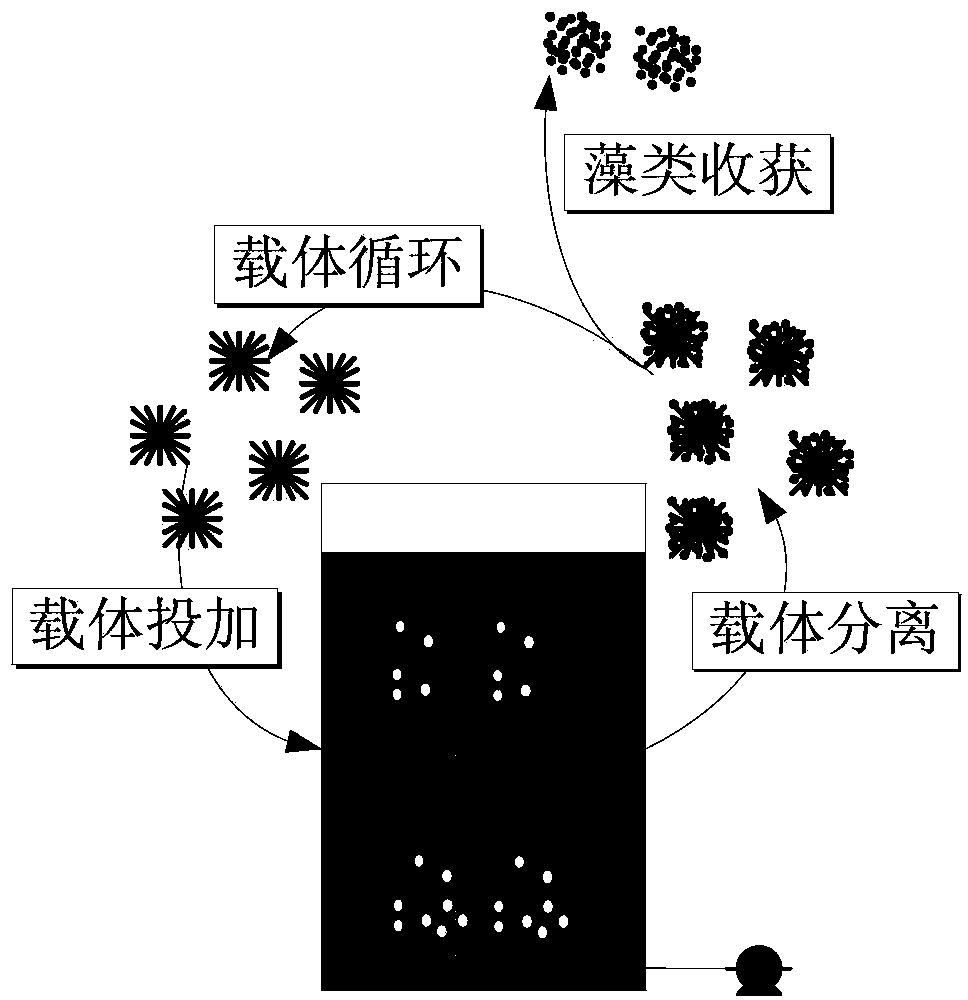

Microalgae suspension-adhesion mixed culture and separated harvesting method based on suspended carrier

InactiveCN103409321ALow costAchieve separationUnicellular algaeMicroorganism based processesMixed cultureCentrifugation

A microalgae suspension-adhesion mixed culture and separated harvesting method based on a suspended carrier comprises the following steps: on the basis of original microalgae suspension culture, a predetermined amount of solid carrier is added into a culture solution and enabled to suspend in the liquid phase in an aerating or mechanical stirring manner; during cultivation, the microalgae is enabled to attach to a solid carrier to form an algae membrane; the solid carrier is separated to harvest algae cells; the solid carrier from which the algae cells are harvested is recovered for recycling and re-injected into the microalgae culture solution; serving as seeds, the liquid-phase algae cells are re-attached to the solid carrier to grow, so that continuous culture and harvest of the algae cells are realized. Compared with the air floatation, precipitation, centrifugation, filtering and other harvest methods, the microalgae suspension-adhesion mixed culture and separated harvesting method is simple to operate, dispenses with agents, is low in energy consumption, and can realize large-scale and mechanical continuous harvesting, thereby effectively saving the cost in harvesting the algae cells.

Owner:TSINGHUA UNIV

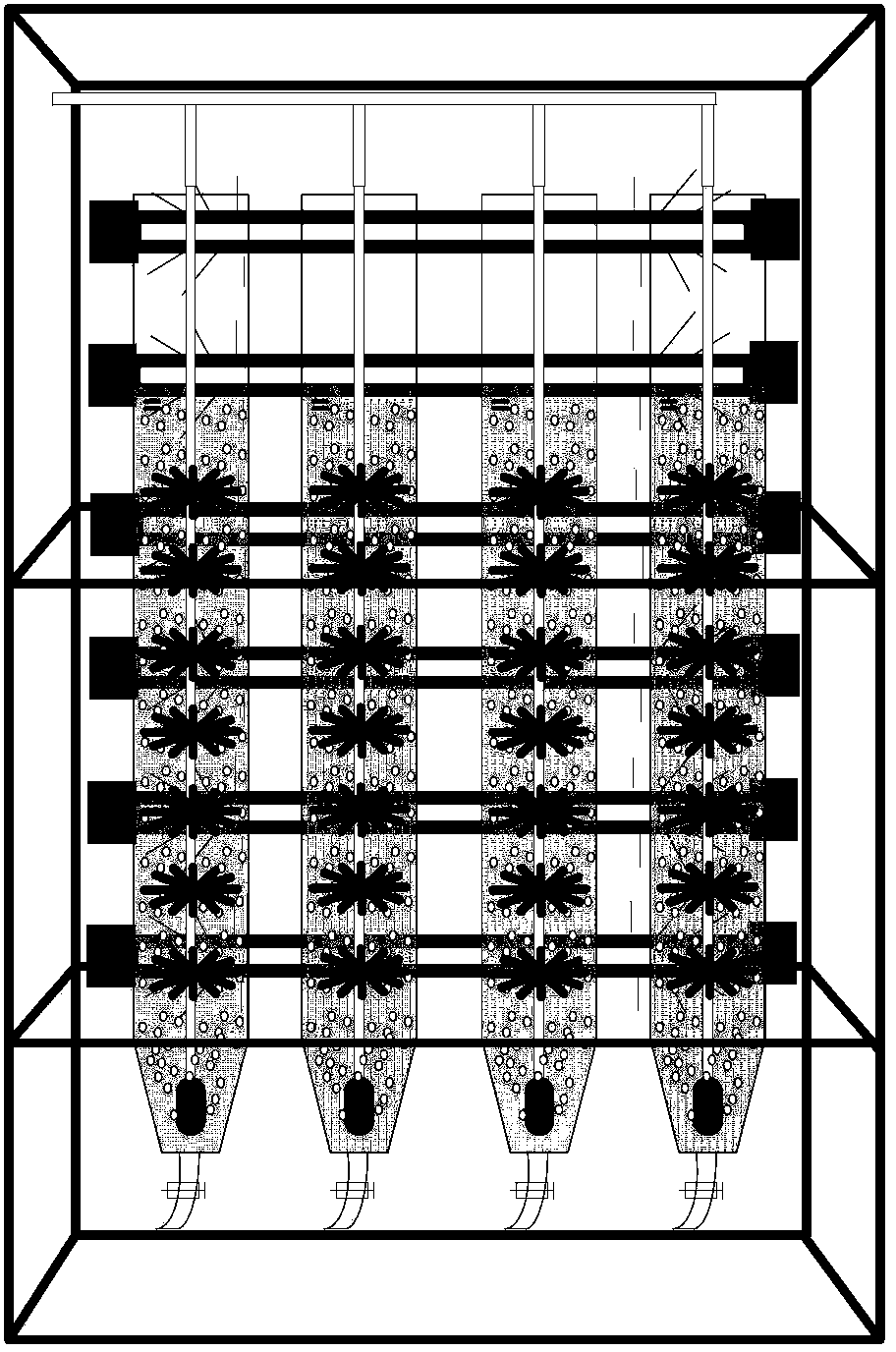

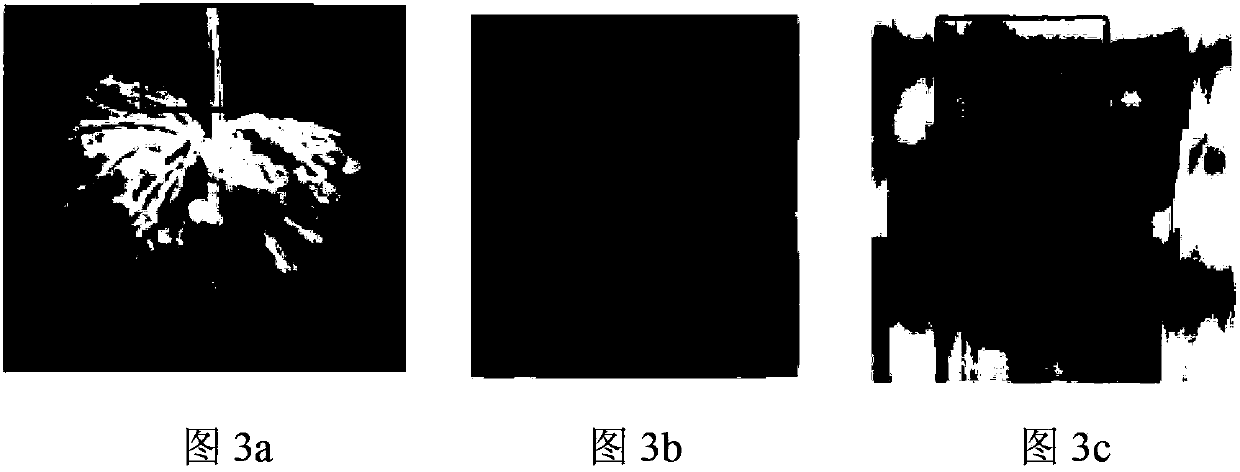

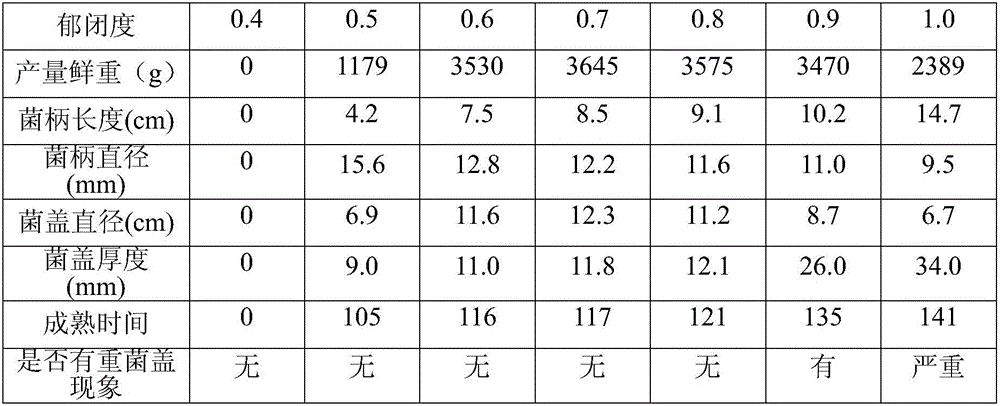

Ganoderma undergrowth bionics wild cultivation method

InactiveCN106613324AIncrease productionImprove qualityCultivating equipmentsMushroom cultivationThermal insulationSoil texture

The invention discloses a ganoderma undergrowth bionics wild cultivation method. The method comprises the steps of A, choosing a wild ganoderma variety in the South China area and separating a mother culture; B, choosing a cut-log; C, cutting the cut-log into wood sections with the length of 20-30 cm; D, putting the cut-log into fungus bags; E, putting the bagged fungus material into a sterilization room; F, putting strains on an inoculation shelf and conducting space sterilization; G, when inoculation is conducted, pinching the strains into small blocks of 2-4 cm<3> with hands; H, choosing a room with good thermal insulation performance as a cultivation room, wherein the room temperature is at 25-28 DEG C; I, choosing a Chinese fir forest, a weed tree forest or a bamboo forest with the canopy density of 0.6-0.8, good ventilation and drainage performance and loose and fertile soil texture as a ganoderma cultivation plot; J, choosing Spring Festival to the end of the second month in lunar calendar as cultivation time; K, removing the bags and burying fungus sticks, wherein the burying density is 1500-3000 sticks / mu (a Chinese area unit and is equal to 666.67 m<3>). The ganoderma undergrowth bionics wild cultivation method mainly aims at undergrowth planting of ganoderma fungus sticks in the South China area, according to the method, no facilities and manual watering are needed, continuous harvest for many years can be achieved, and the ganoderma is high in yield and good in quality.

Owner:GUANGXI FORESTRY RES INST

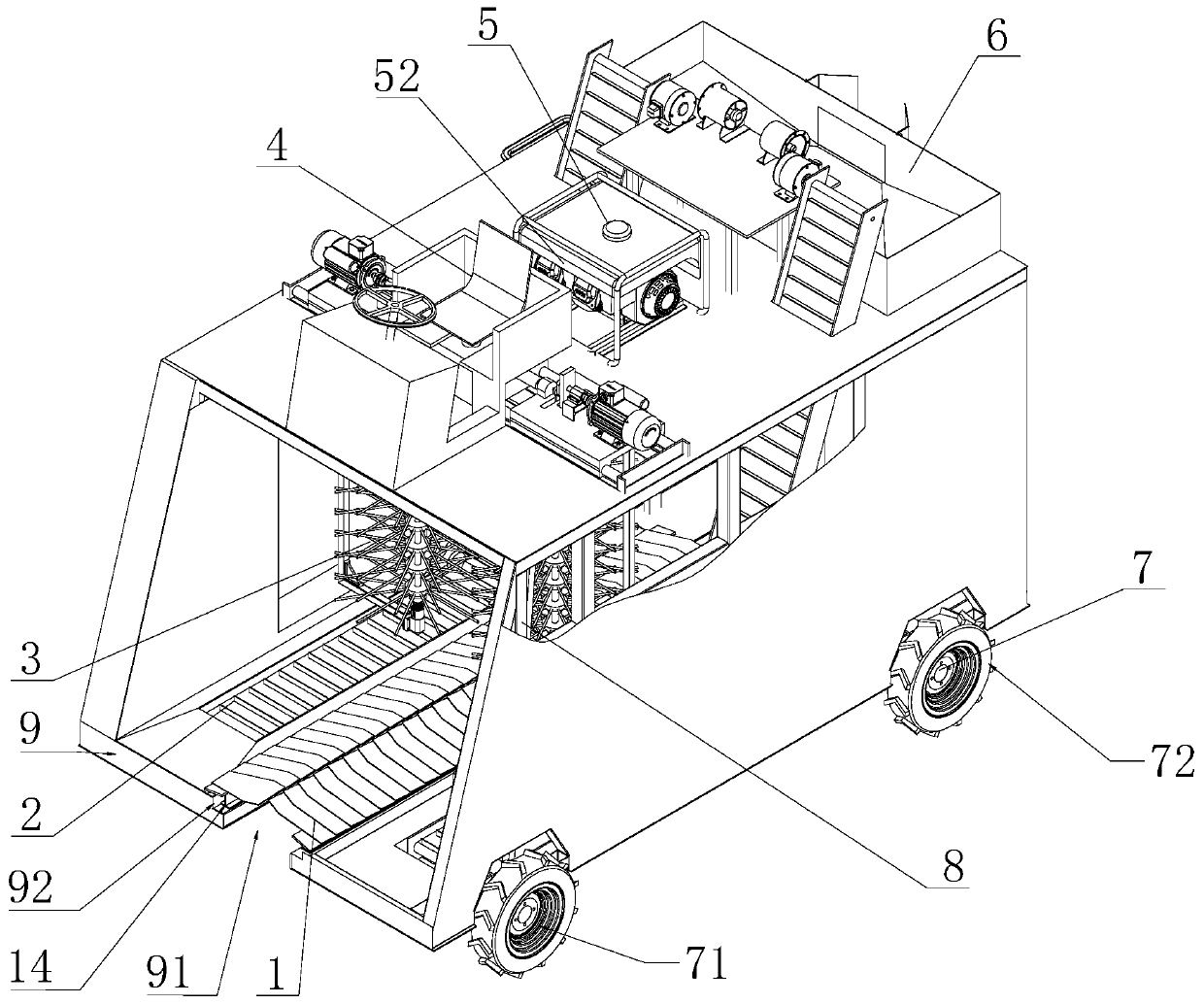

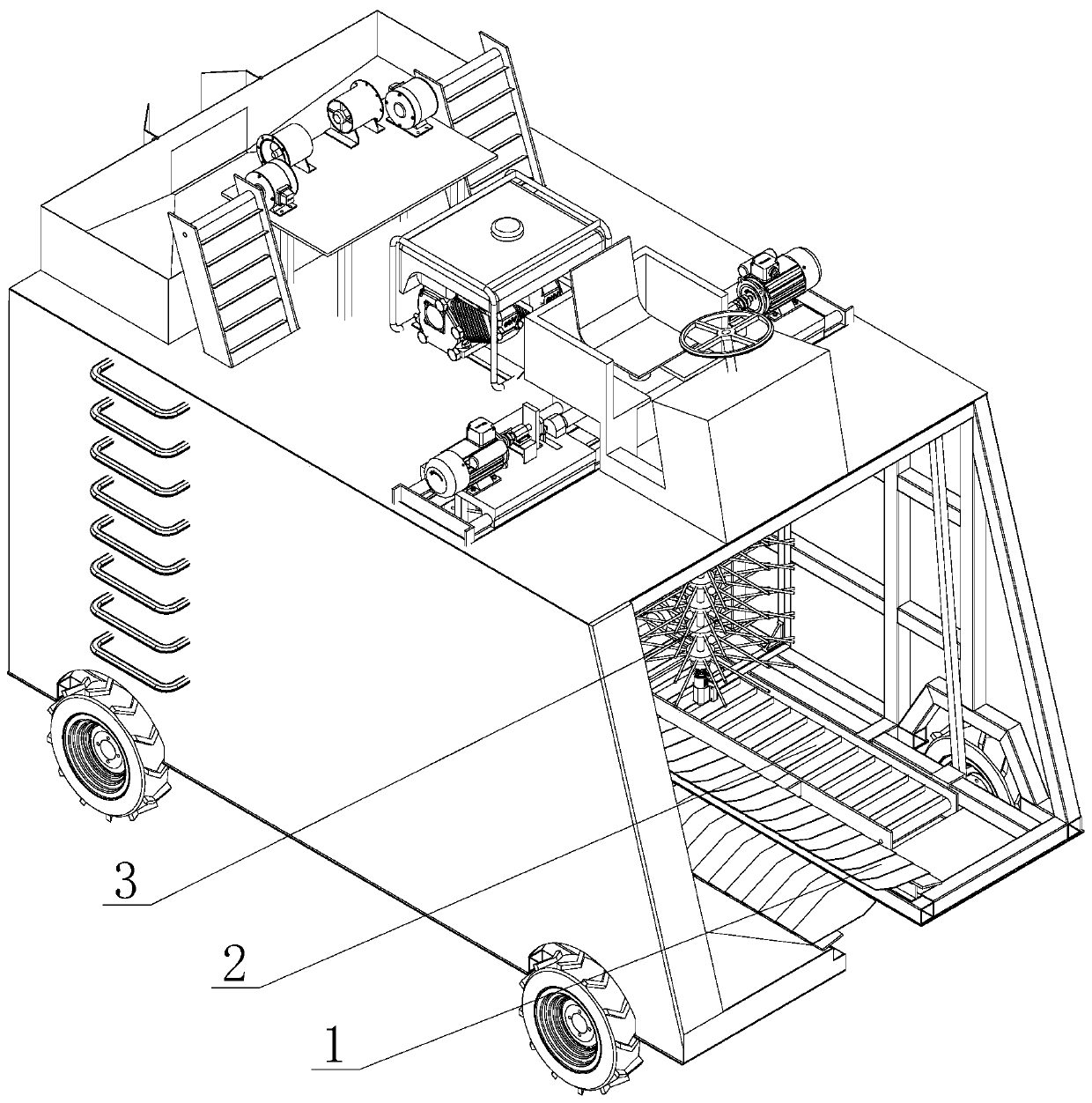

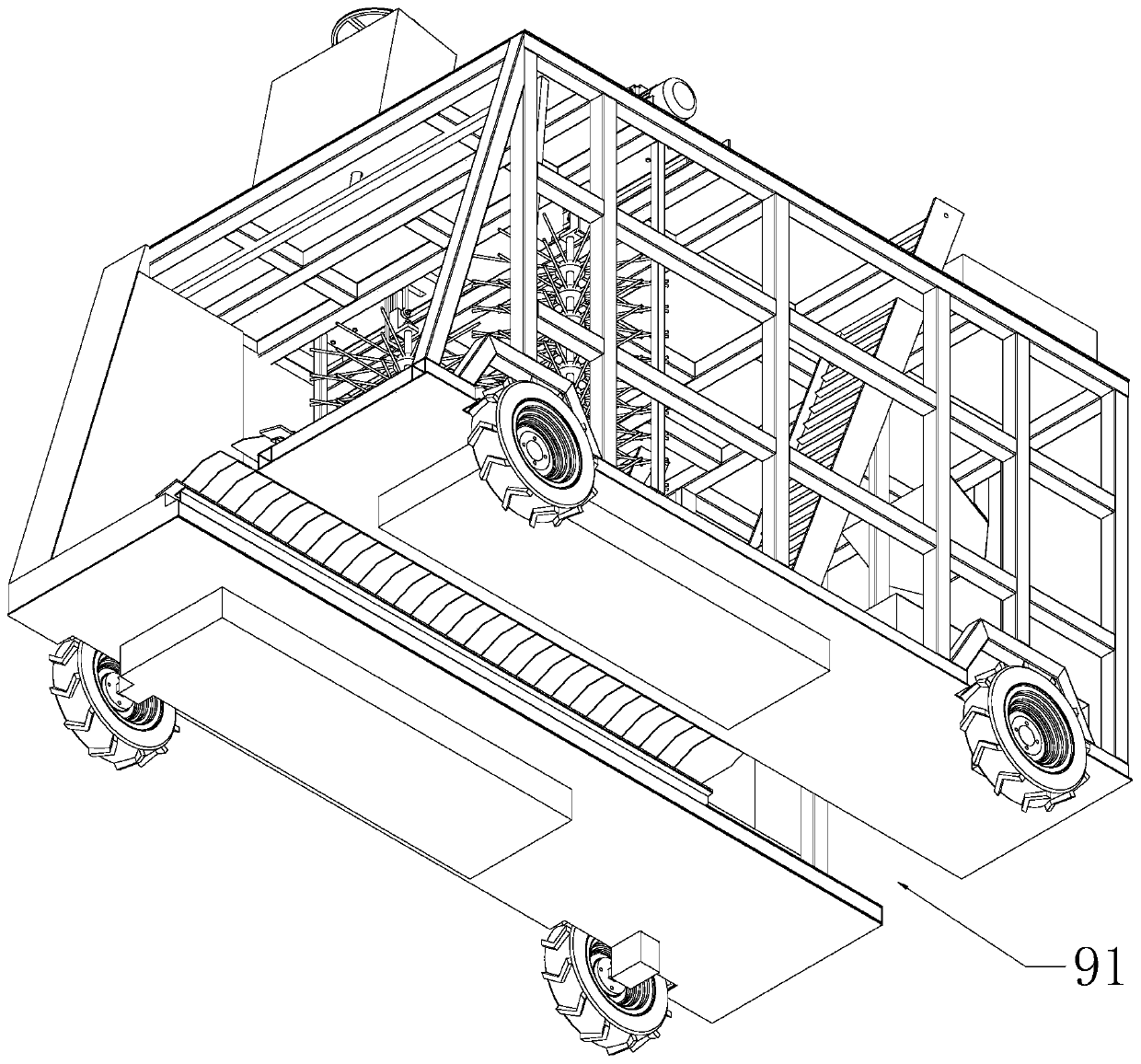

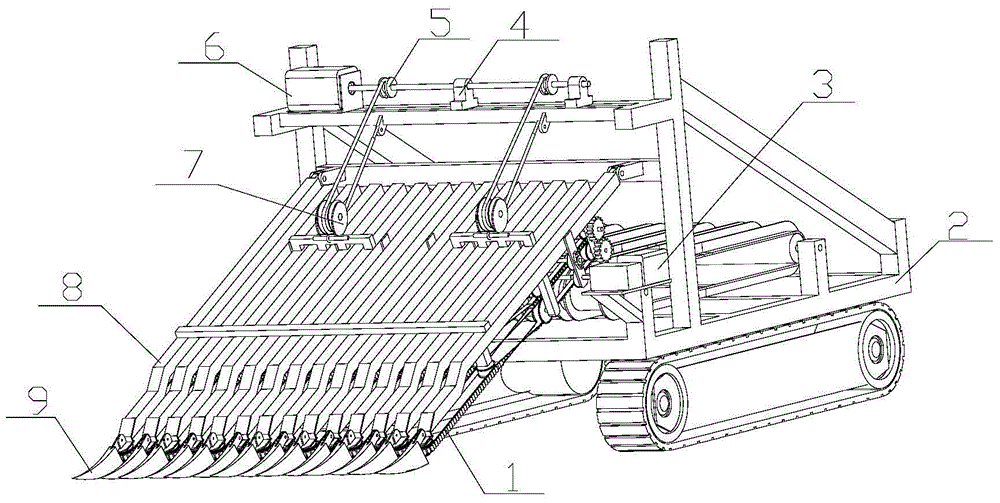

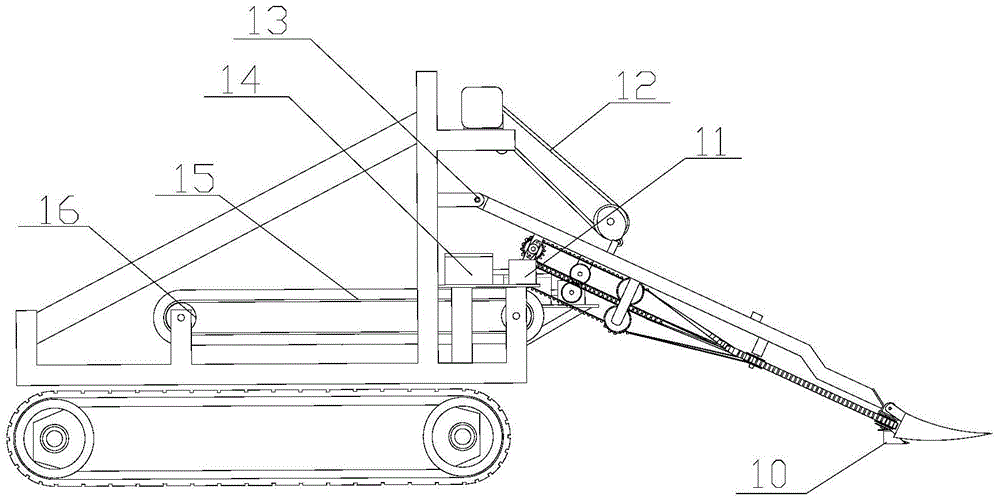

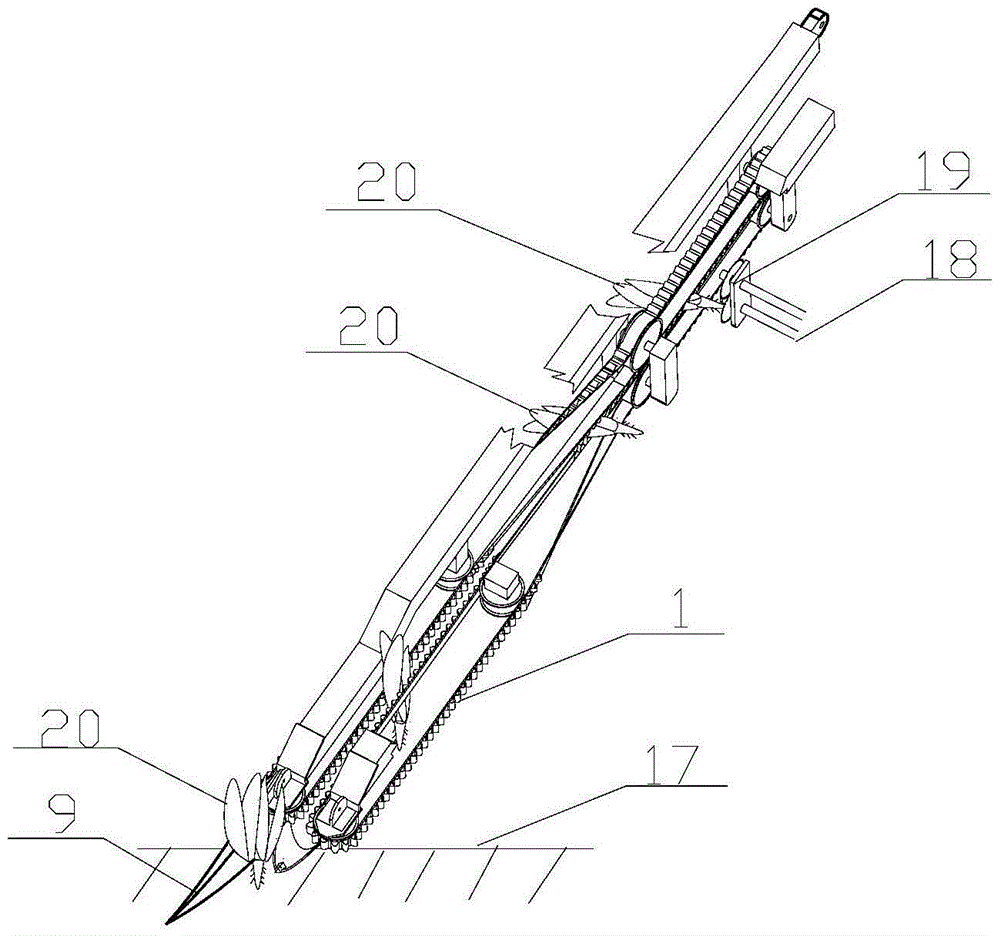

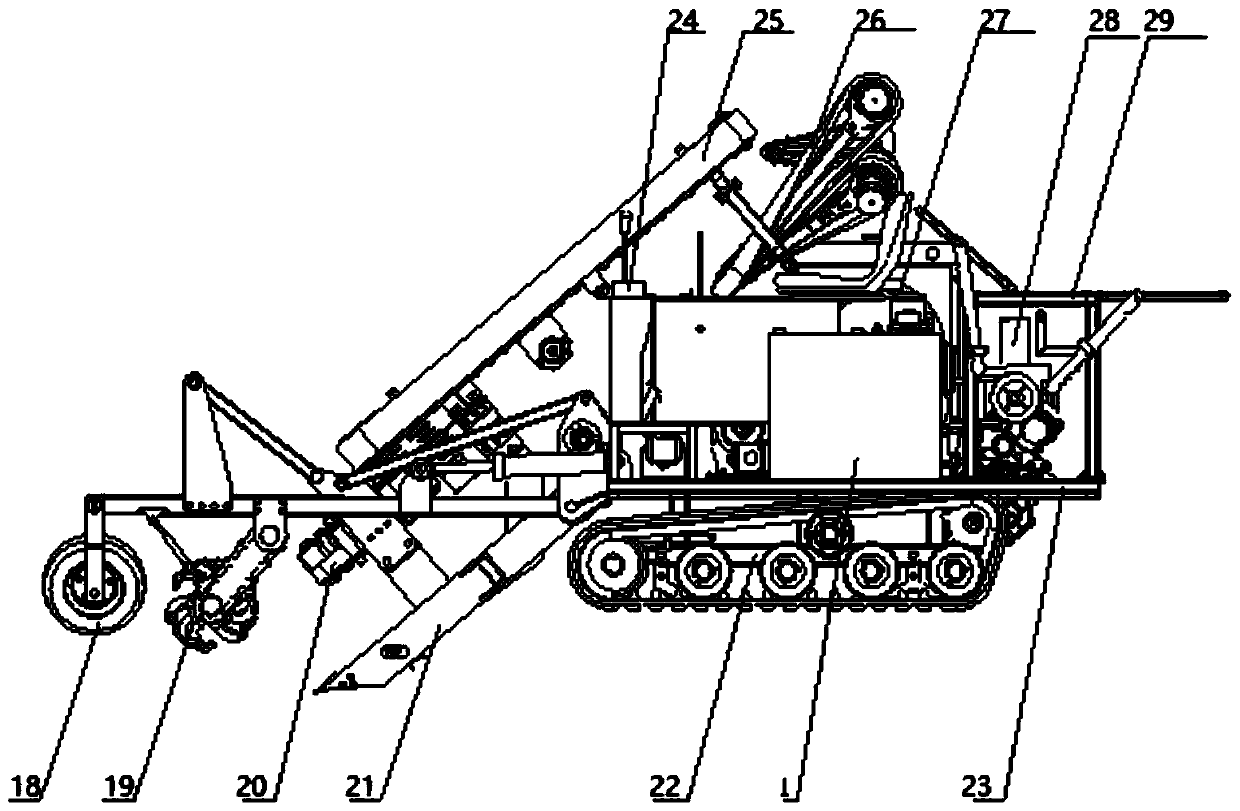

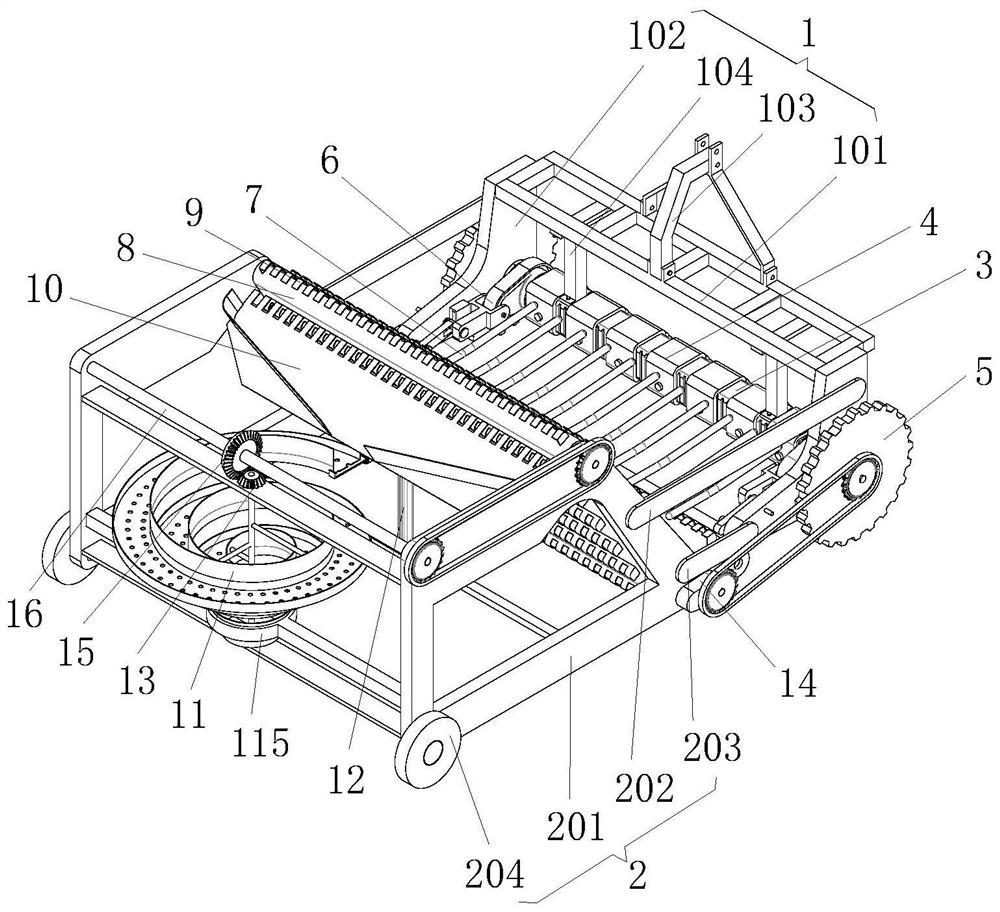

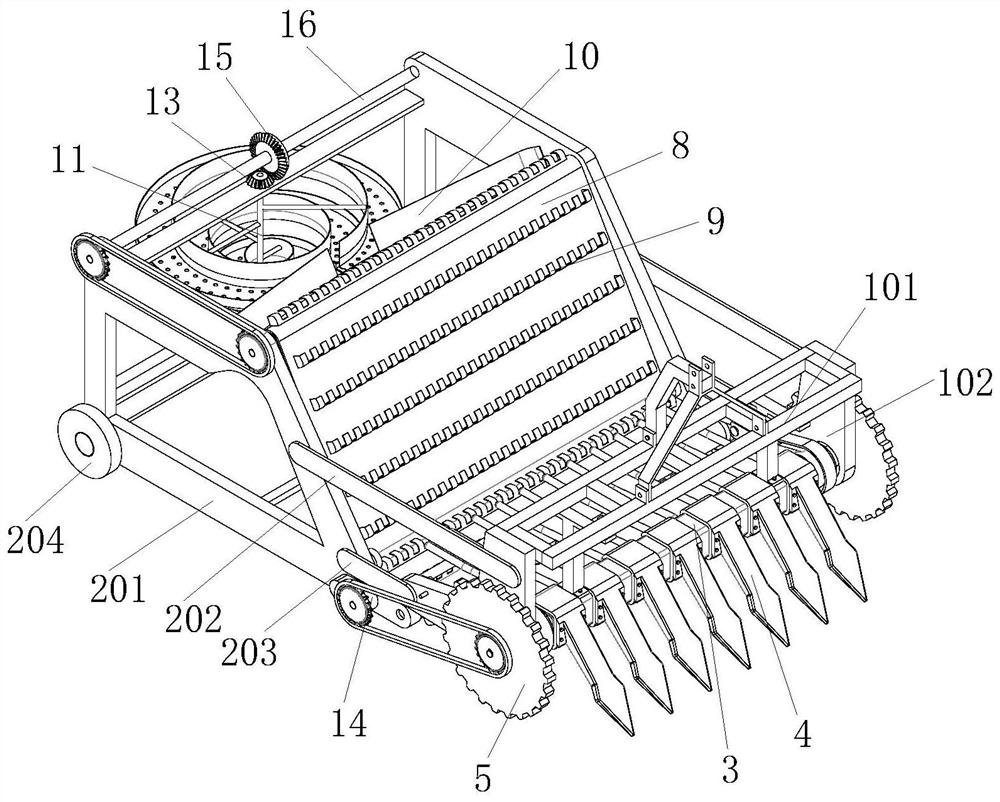

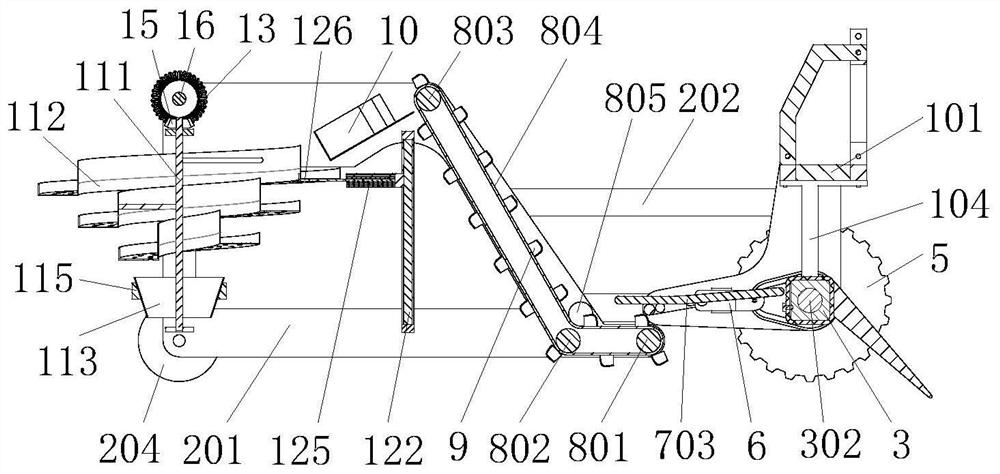

Comb brush shock excitation type red date harvesting machine

The invention relates to the technical field of agricultural and forestry machinery, and provides a comb brush shock excitation type red date harvesting machine. The comb brush shock excitation type red date harvesting machine is mainly used for mechanical continuous harvest of red dates of a date garden in a dwarfing close-planting mode, and can effectively prevent the red dates from falling. Thecomb brush shock excitation type red date harvesting machine comprises a chassis, a walking device, a machine frame, a collecting device, a pair of fruit receiving devices, a pair of conveying devices and a pair of shock excitation devices, wherein the chassis is provided with a passing groove in the longitudinal direction; the walking device is arranged under the chassis; the machine frame is fixedly connected onto the chassis; the front end of the machine frame is open; the back end of the machine frame is provided with an opening; the collecting device is arranged on the machine frame andis used for gathering, storing and unloading the red dates; the pair of fruit receiving devices is arranged on the chassis; the pair of conveying devices is arranged on the chassis, is positioned at two sides of the fruit receiving devices and is used for conveying the red dates to the collecting device; the pair of shock excitation devices is arranged in the machine frame, is positioned above thefruit receiving devices and is used for exerting shock excitation effect on red date plants.

Owner:NANJING FORESTRY UNIV

Method for preparing anti-cropping ecological fungicide for repairing panax notoginseng continuous cropping soil

InactiveCN103045582ALow costShorten the fermentation cycleAgriculture tools and machinesMicroorganism based processesContinuous croppingRoot growth

The invention discloses a method for preparing a probiotic fungicide for preventing panax notoginseng continuous cropping diseases, belonging to the field of microbial fermentation. The method comprises the steps of fermenting, namely respectively culturing individual production strains of the probiotic fungicide into a primary seed solution, inoculating to a culture medium which takes corn flour-potato-bean pulp as a principle component for performing aerobic mixed fermentation and enlarged cultivation, wherein the production strains are selected from seven bacteria-fungi such as bacillus subtilis; and adsorbing and immobilizing the fermentation end products to turf charcoal so as to prepare a solid fungicide. The continuous cropping diseases which are ubiquitous in the conventional panax notoginseng plantation technology are solved, and continuous cropping and continuous harvest can be realized in the panax notoginseng planting fields after the panax notoginseng is planted for 2-3 years. The preparation method has the outstanding characteristics of low production cost, short fermentation period and high flora density. According to the fungicide, dead seedlings, yellow seedlings, wither, dried leaves, root rot and other ecological soil symptoms in the panax notoginseng planting process can be prevented; and meanwhile, according to the method, root growth can be promoted, the soil is loosened, strong seedlings are cultivated, and pesticide and fertilizer residues are removed and the obvious function of ecologically repairing the soil is achieved.

Owner:NANKAI UNIV +2

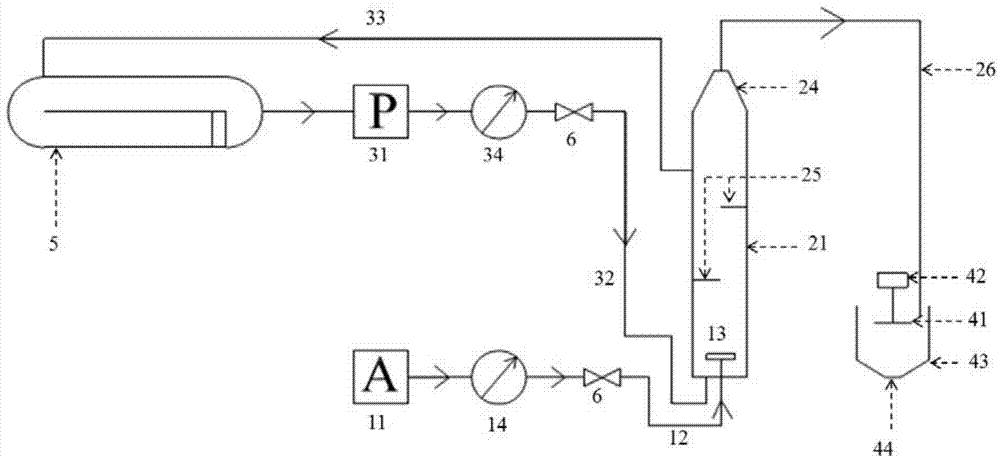

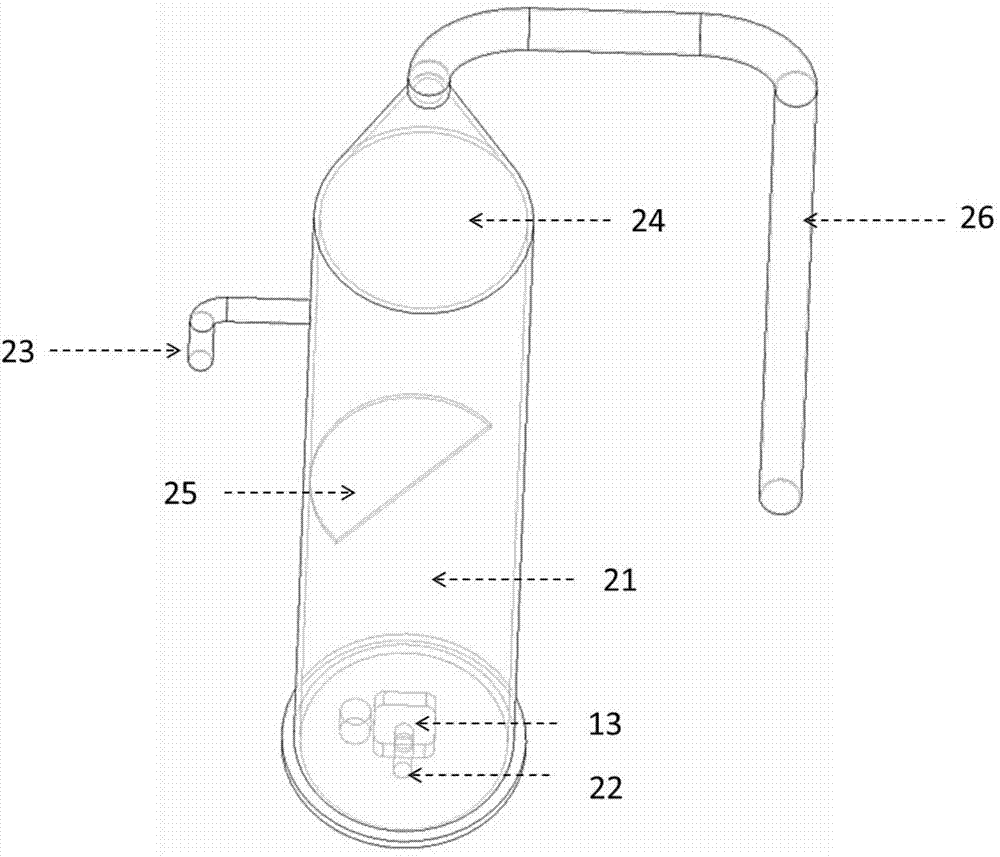

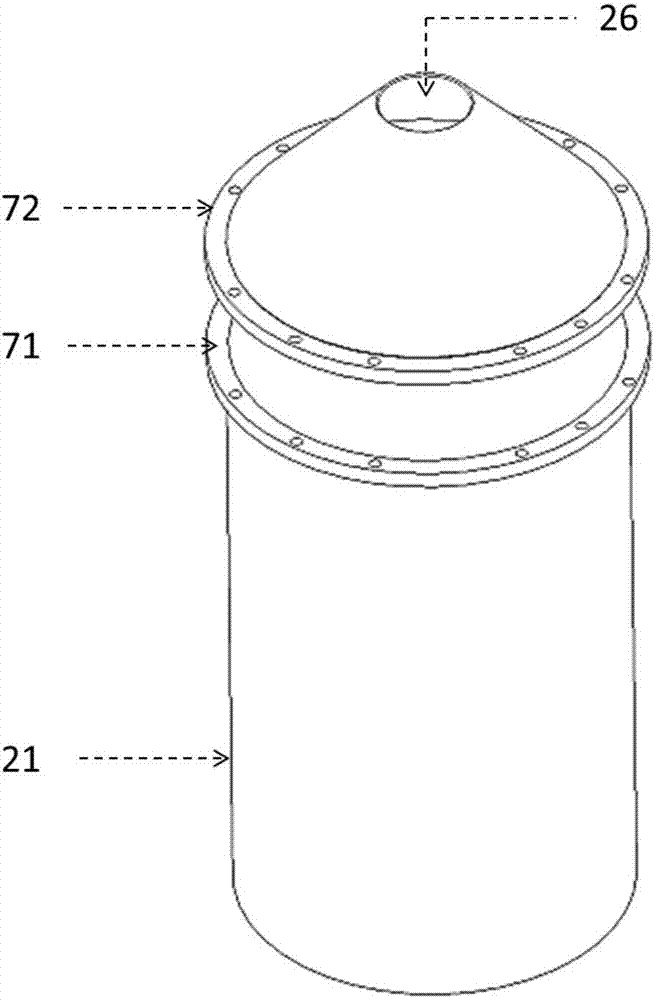

Foam concentration and harvest device for microalgae

InactiveCN103756893AEasy to processLow costMicroorganism based processesBiomass after-treatmentRefluxEngineering

The invention discloses a foam concentration and harvest device for microalgae. The foam concentration and harvest device comprises an air bubble generating unit, a concentration and separation tower, a liquid flow circulating unit and a foam collecting unit, wherein the air bubble generating unit comprises a gas source for generating gas, a gas distributor for dispersing the gas into fine air bubbles, and a gas conveying pipeline for connecting the gas source and the gas distributor; the concentration and separation tower comprises a concentration tower main body, a gas path interface, a liquid flow interface, a foam flow diverter and a foam diversion pipe; the liquid flow circulating unit comprises a conveying pump, a liquid conveying pipeline and a liquid reflux pipeline; the foam collecting unit comprises an antifoaming paddle, an antifoaming motor, a collecting pond and a concentrated solution outlet. The microalgae are harvested through a foam concentration and separation structure, so that continuous harvest, serial amplification, multi-stage concentration and easiness in processing are realized during concentration and harvest of microalgae, professional technical personnel is not needed, and the labor cost is reduced.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

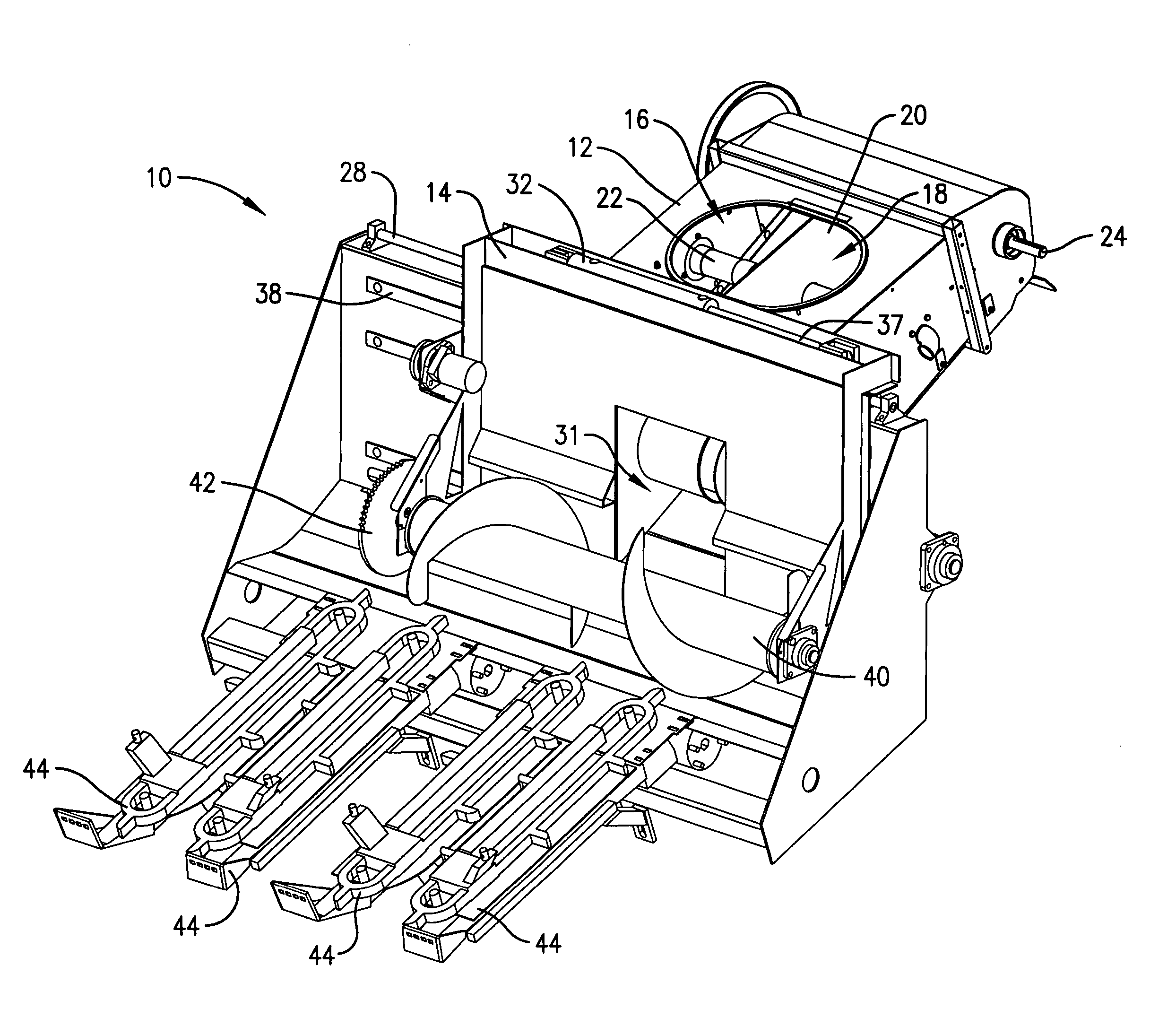

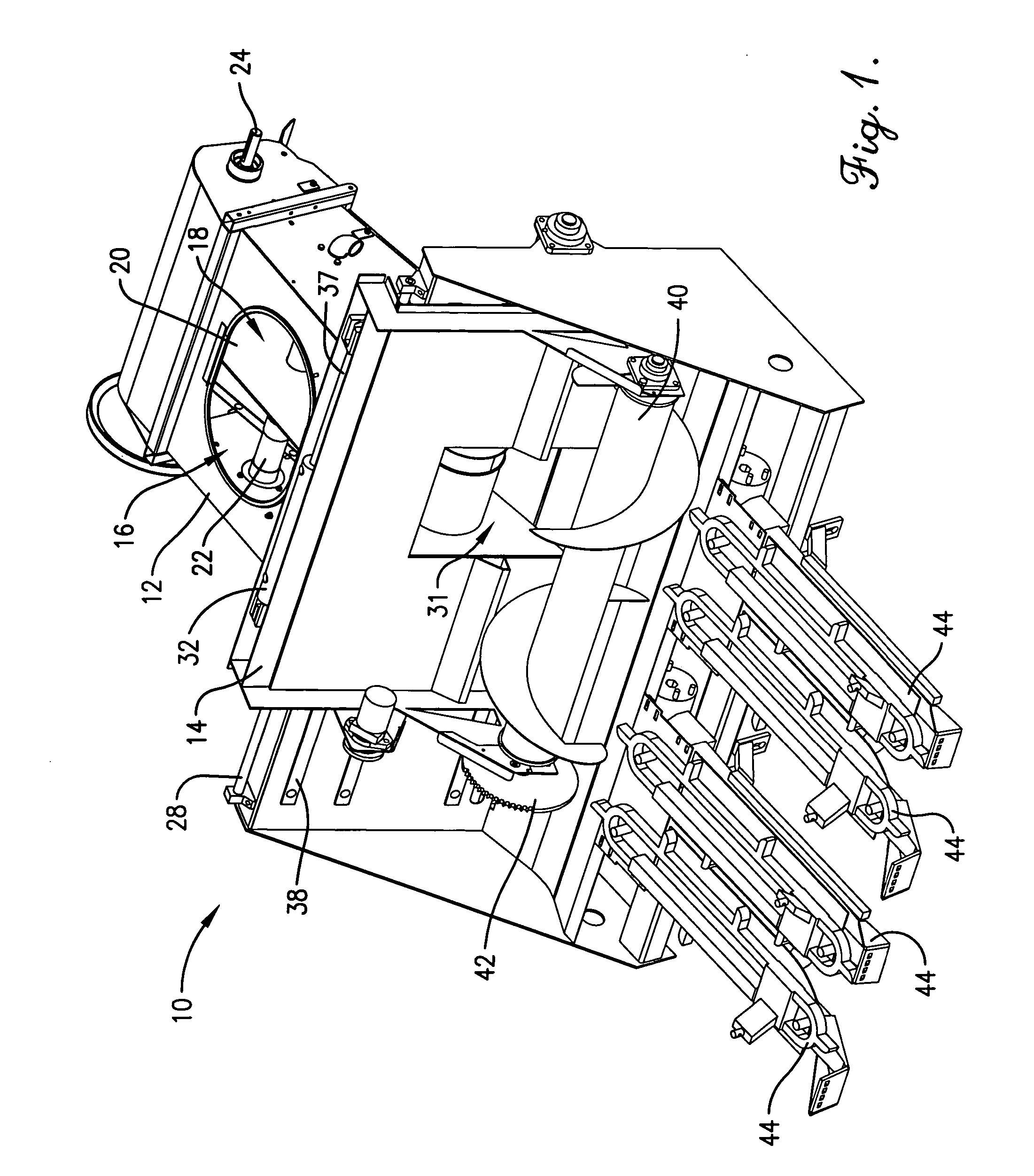

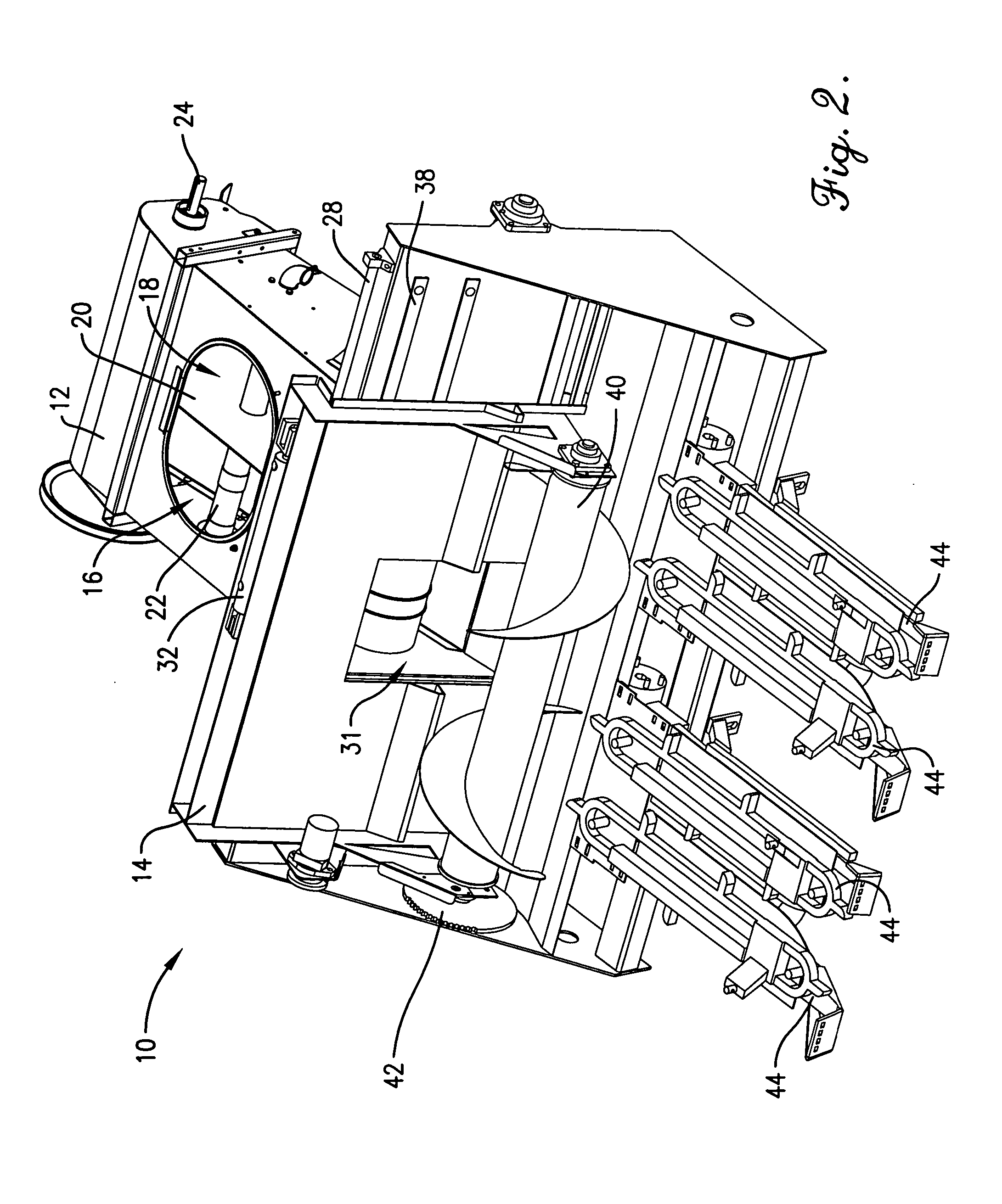

Shuttle auger for continuous harvesting of multi-crop research plots

InactiveUS7318310B2Harvesting multi-crop research plots efficientlyEfficient HarvestingMowersEngineeringCombine harvester

Owner:KINCAID EQUIP MFG

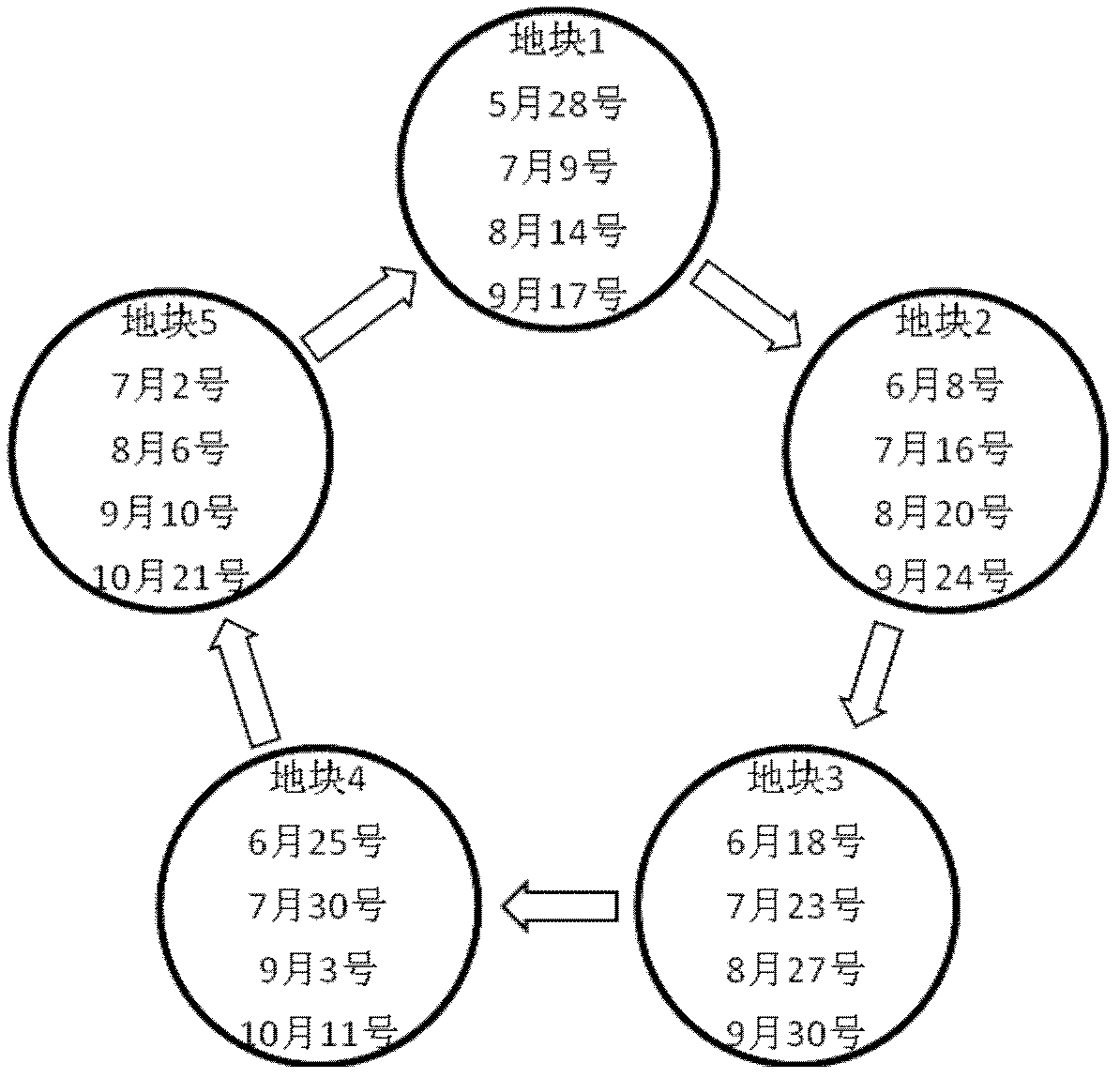

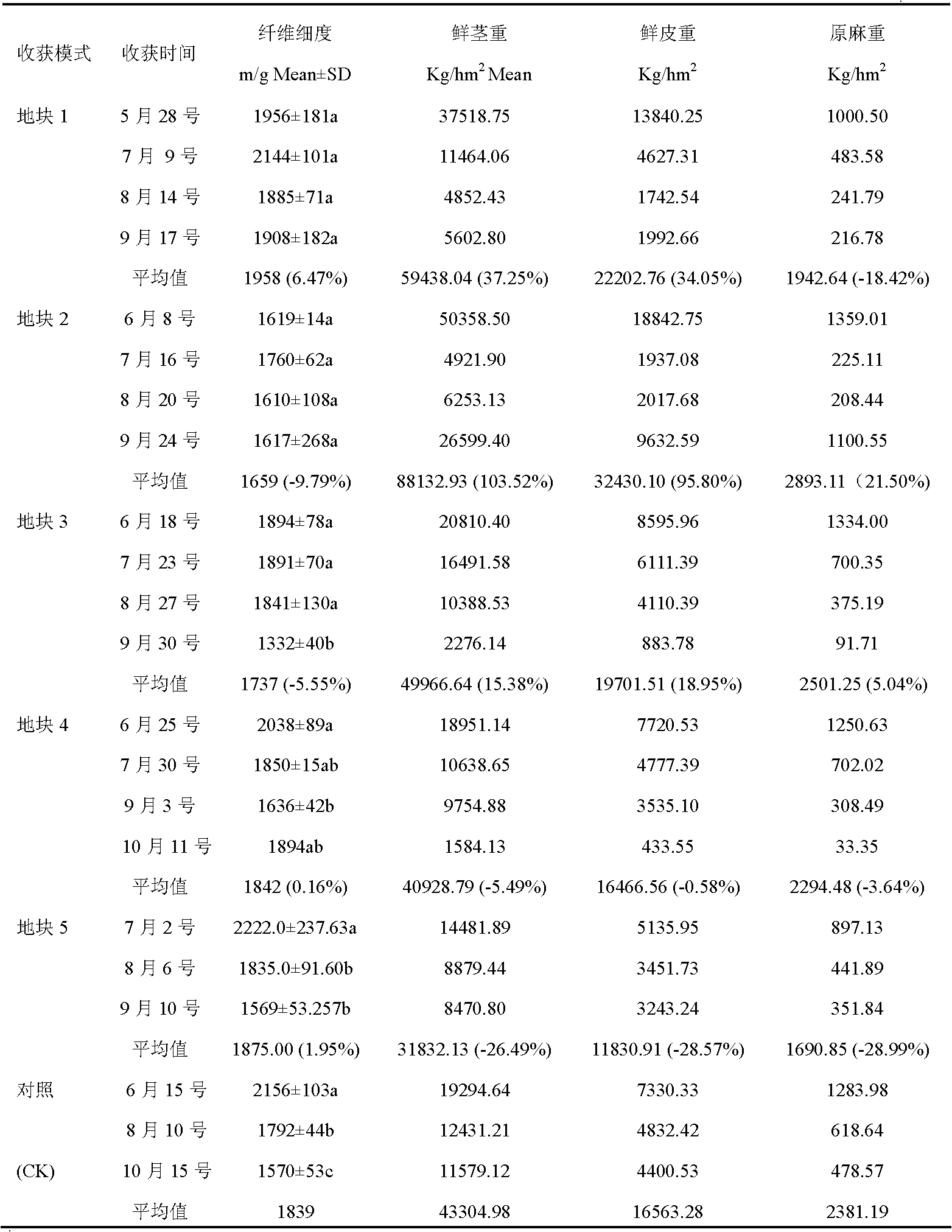

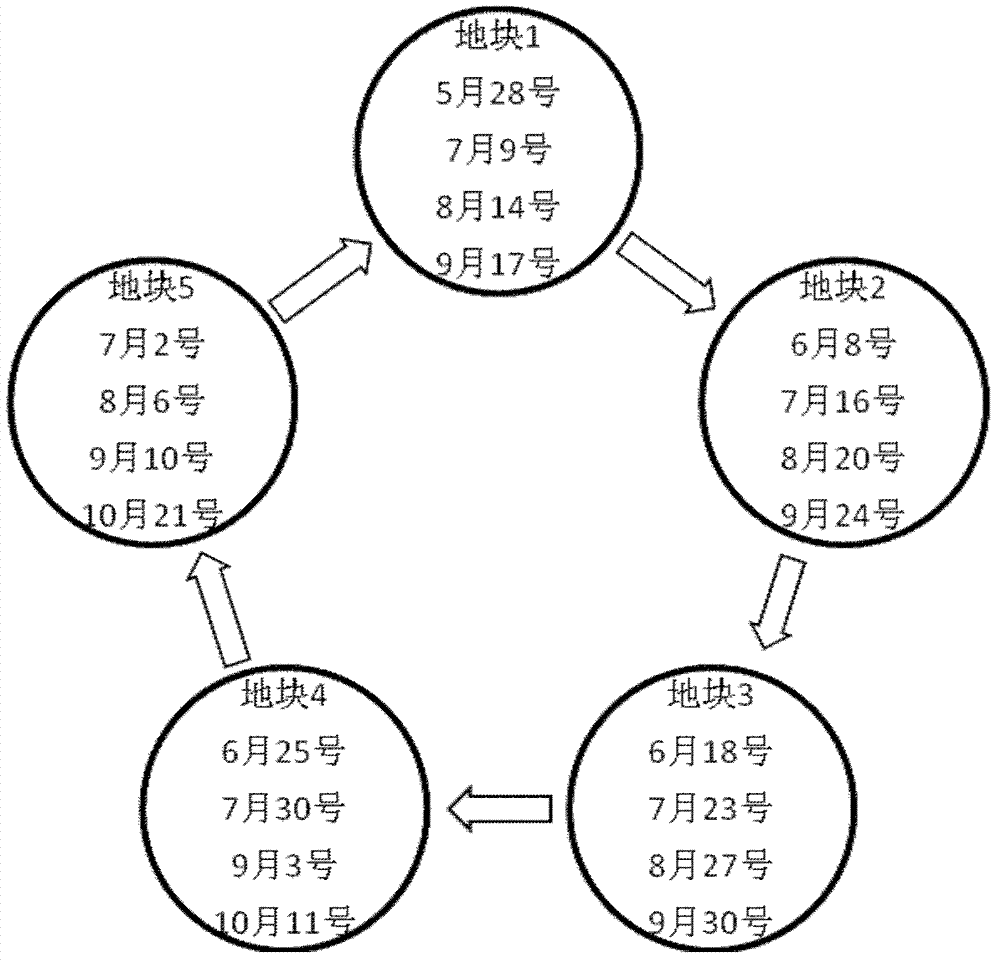

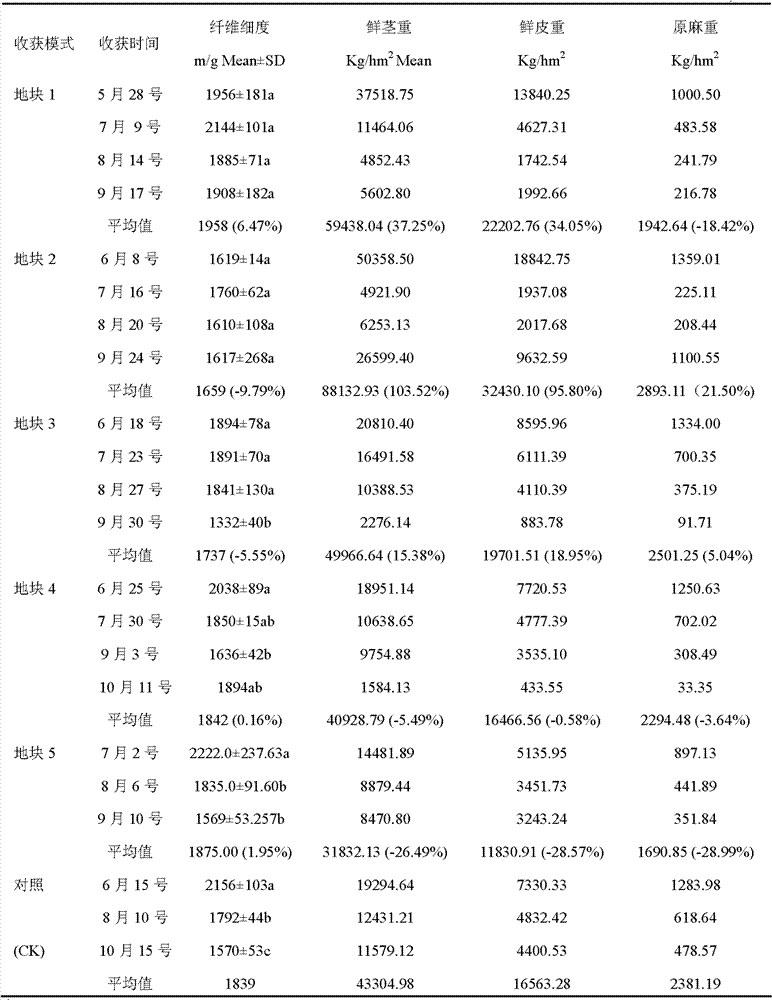

Method for continuously harvesting ramie fibers

The invention discloses a method for continuously harvesting ramie fibers, which comprises the following steps of: A. ramie plantation segmentation: the planted ramie is harvested in different areas in different time periods, the area of a ramie plantation is divided into blocks according to the standard of harvesting 1-10 days / block, and by utilizing the natural condition with sufficient rainfall and sunlight in June-September, the continuous harvest in May-October in each year can be realized; B. early harvesting: the time is five-twenty days earlier than the normal harvesting time; C. additionally fertilizing: after the ramie fibers are harvested, a nitrogenous fertilizer is applied according to a N60-80kg / hm2 standard; and D. culturing and managing in winter: the culture and the management are strengthened in winter, and a cake fertilizer (1,000-1,500kg / hm2) and NPK compound-fertilizers (600-80kg / hm2) are applied again.

Owner:HUAZHONG AGRI UNIV

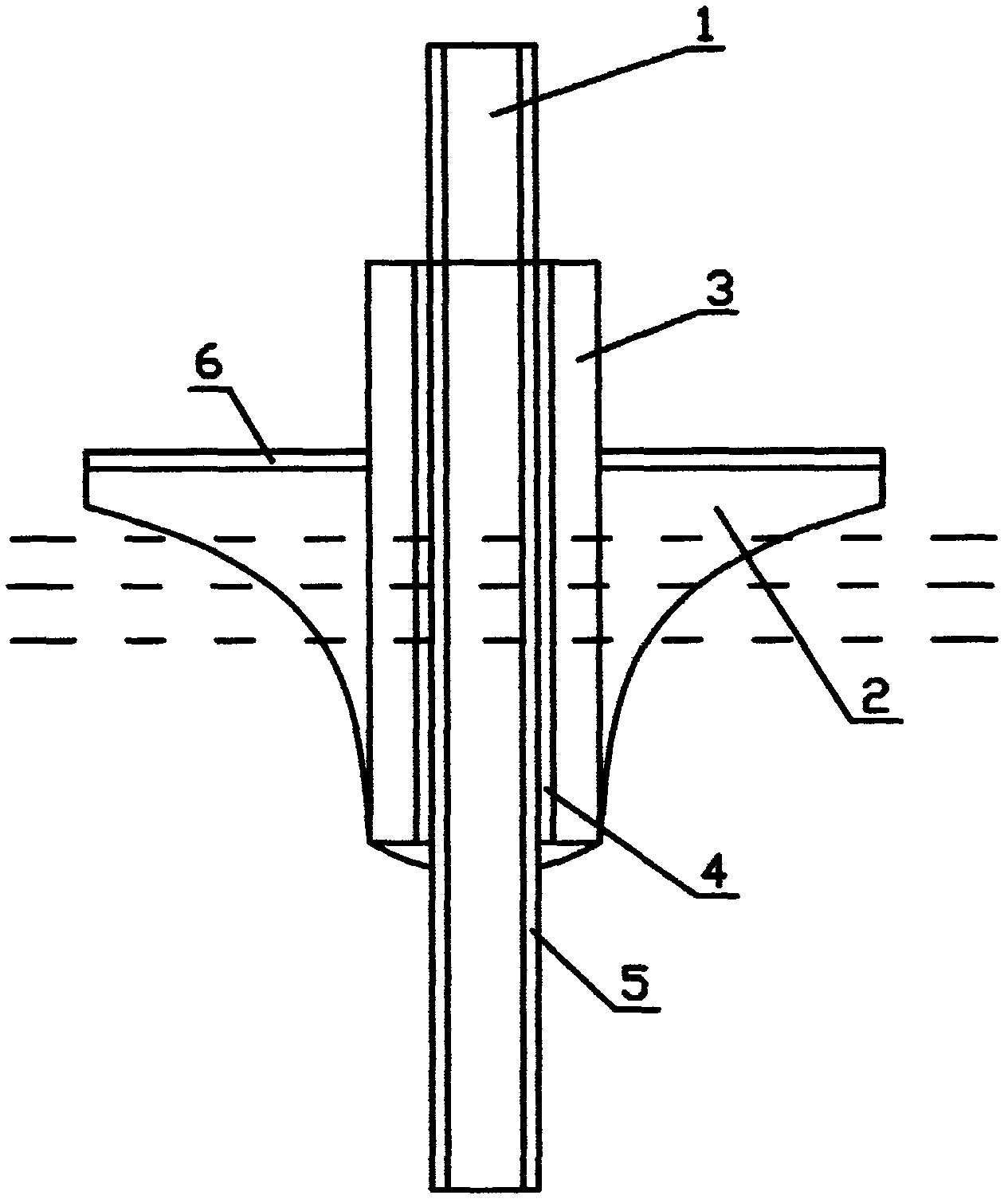

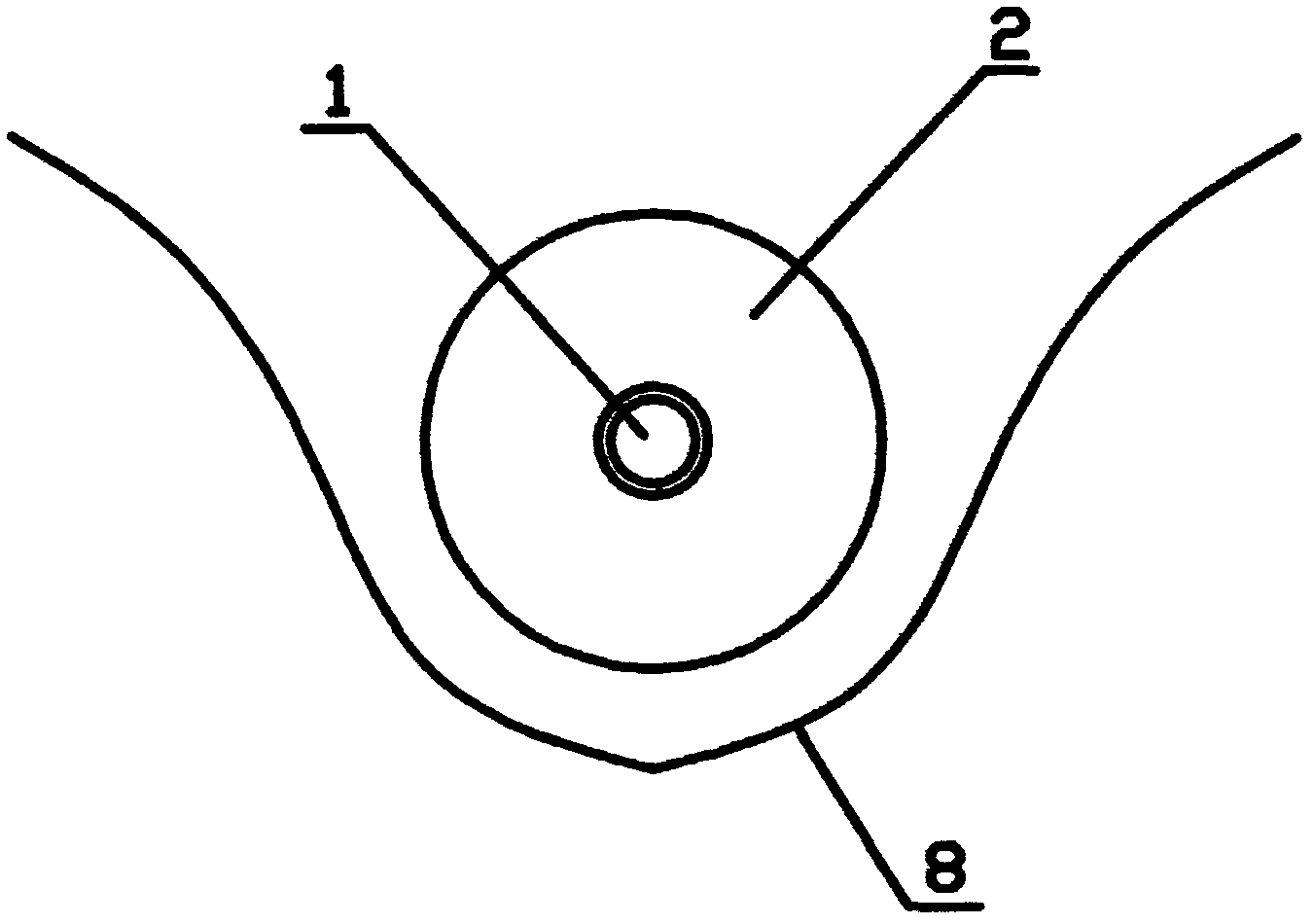

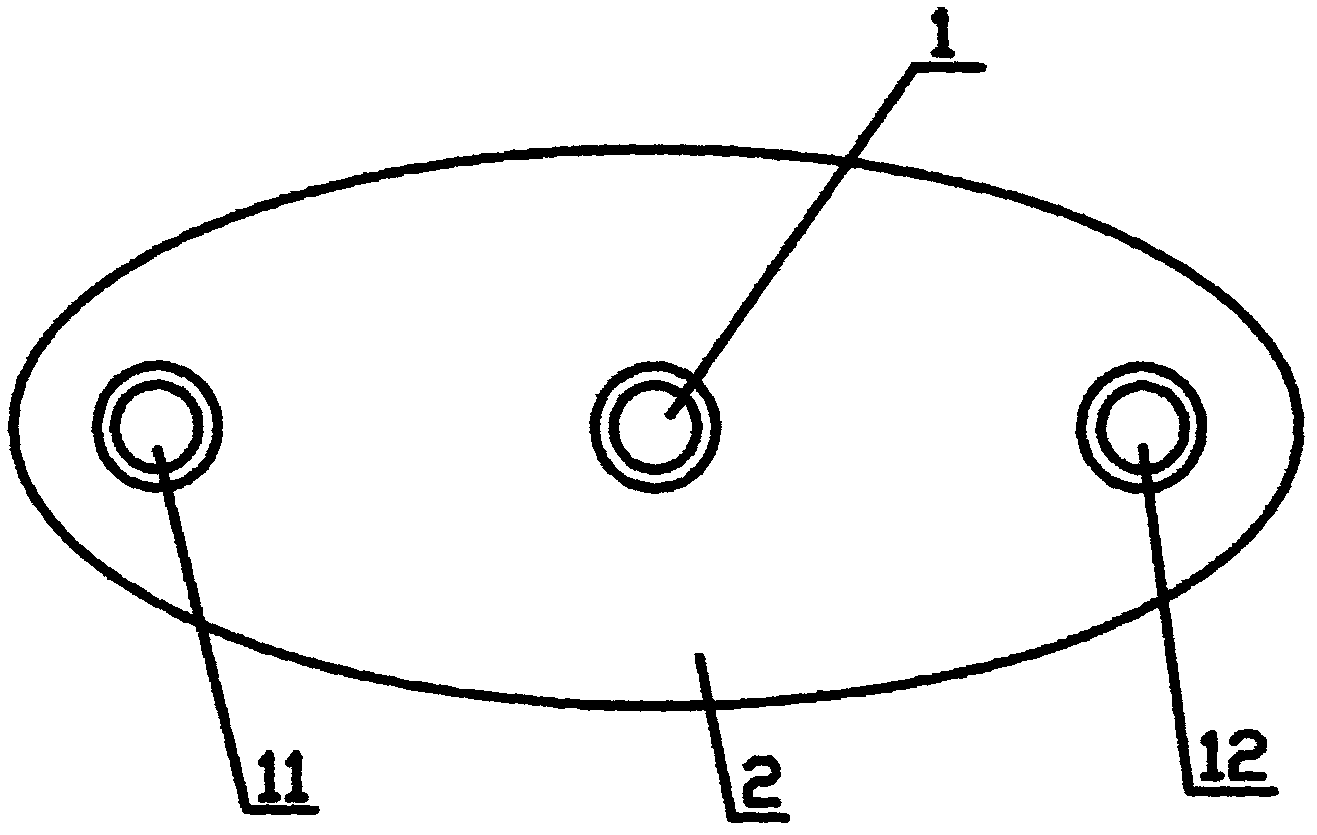

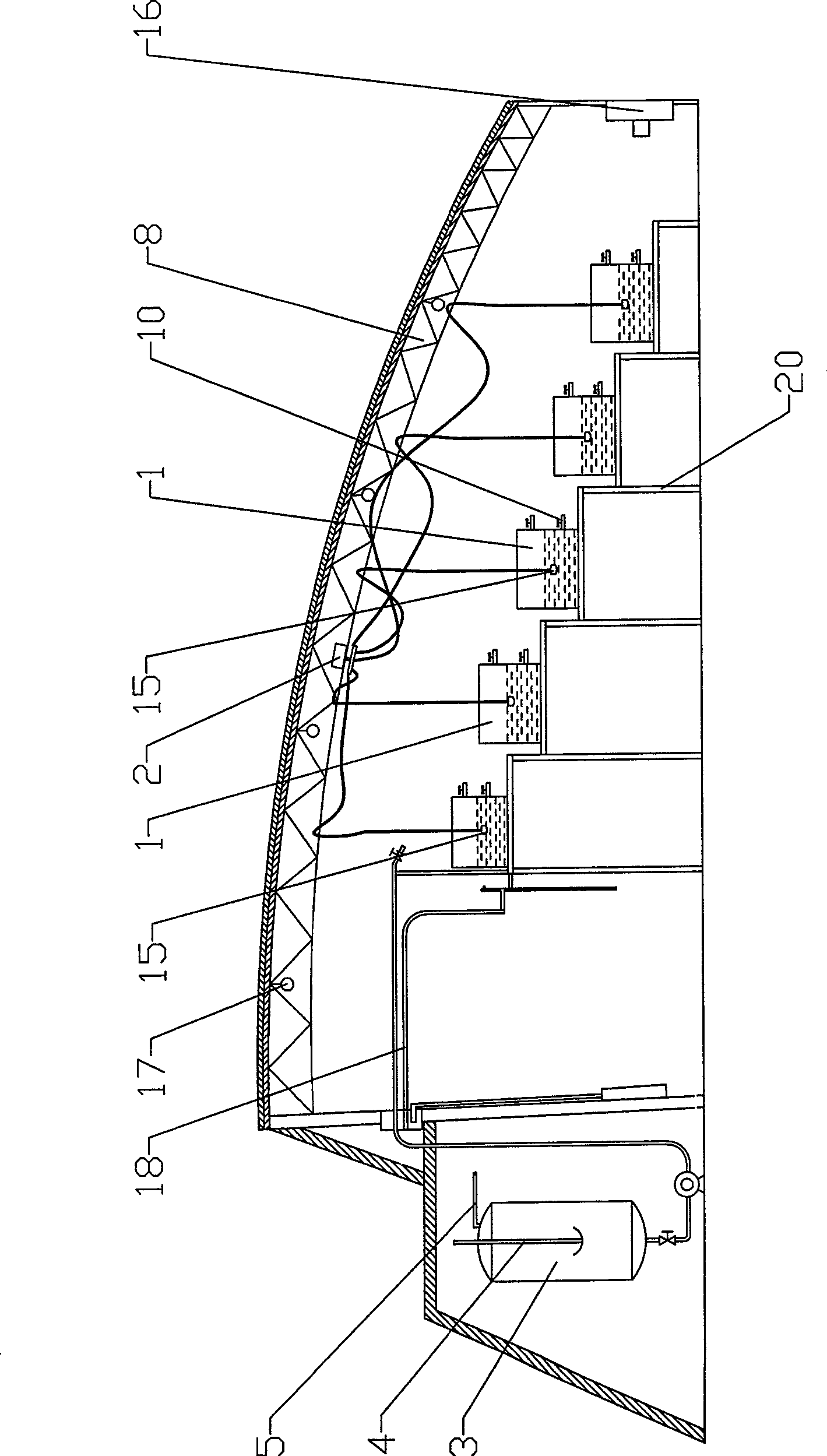

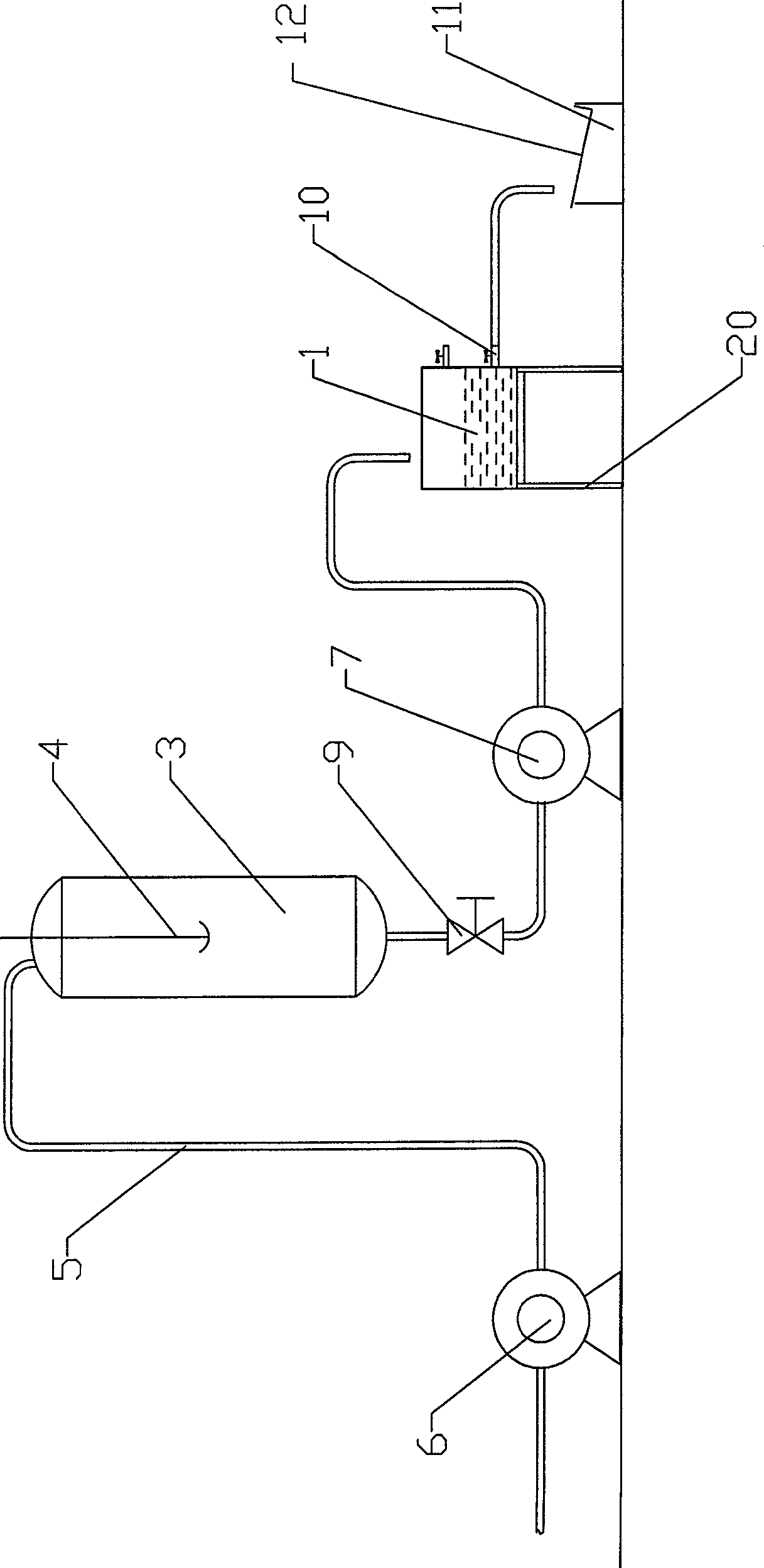

Wind-solar hybrid wave power station

ActiveCN102297069AEasy to installEasy maintenanceMachines/enginesEngine componentsEngineeringTurbine

The invention relates to a wind-solar hybrid wave power station, comprising a pillar and a floating body, the pillar is fixed on the seabed, the floating body is provided with a pillar hole, and a pillar is sleeved in each pillar hole, the floating body is movably connected with the pillar and can reciprocate up and down relative to the pillar; A linear generator is arranged between the floating body and the pillar, the mover of the generator is arranged on the floating body, and the stator is arranged on the pillar. The wave power station consists of a number of independent floating bodies and pillars. There is a linear generator between each pillar and the floating body. All generators are connected by wires to form a power supply network; Battery. The present invention arranges a number of floating bodies and pillars equipped with generators in the forward direction of the waves, connects them through wires to form a power supply network, continuously collects the energy of wave fluctuations in a large range, and gathers the electricity generated by each generator through the power supply network. To realize continuous power supply, the invention has a simple structure and is relatively convenient for installation and maintenance.

Owner:江苏纳泉弘远新能源科技有限公司

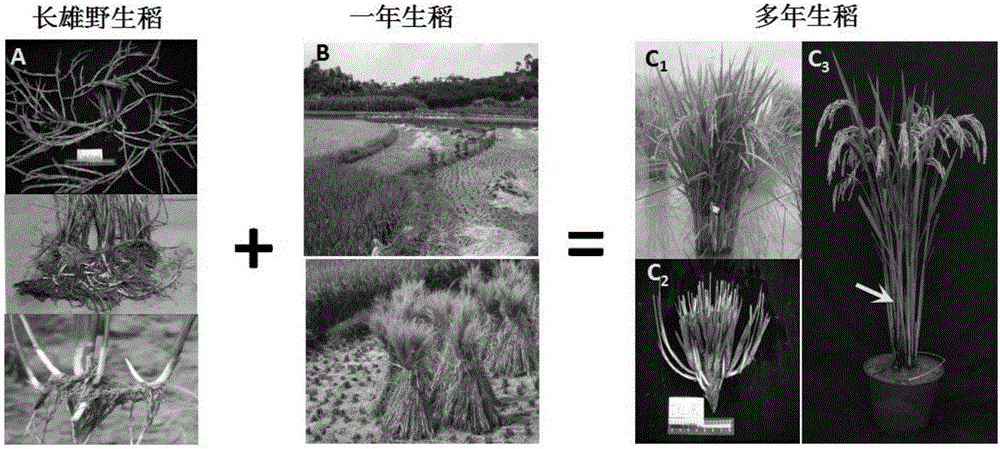

Breeding method of perennial rice and application

InactiveCN106342679AAvoid churnProtect environmentPlant genotype modificationOryzaMarker-assisted selection

The invention relates to a breeding method of rice with a perennial property in rice breeding and belongs to the field of rice genetics breeding. The method is a breeding method which takes oryza longistaminata as a male parent and O.sativa as a female parent to hybridize and transfers the perennial property of the oryza longistaminata to the O.sativa to breed a perennial rice (PR) variety through hybridization and back-crossing by utilizing marker assisted selection (MAS). With the adoption of the perennial rice breeding method provided by the invention, the perennial rice variety is bred, and the aim of planting the rice for one time and continuously harvesting for a plurality of years (times) can be realized.

Owner:YUNNAN UNIV +1

Artificial cultivating technology for barrenwort

InactiveCN101084712AIncrease productionGuaranteed outputHorticulture methodsFarmyard manureContinuous harvest

The invention discloses an artificial cultivated method of Herba Epimedii. The method comprises preparing conventional asexually seedling through vegetative propagation, deep ploughing the porous soil over 20cm, applying well-rotted farmyard manure, thorough harrowing, dragging, making furrows, permanent planting at the beginning of year, harvesting thrice respectively at May, August and November, completely cutting aerial part every time, and dressing nitrogen-phosphonium-kalium compound fertilizer. The invention can harvest in continuous triennium for one permanent planting with 3 harvests annually, and restart at the fourth year. The invention has the advantages of easy operation, low cost, and improved Herba Epimedii output.

Owner:GUIZHOU BOTANICAL GARDEN (GUIZHOU INST OF HORTICULTURAL SCI GUIZHOU INST OF BOTANY)

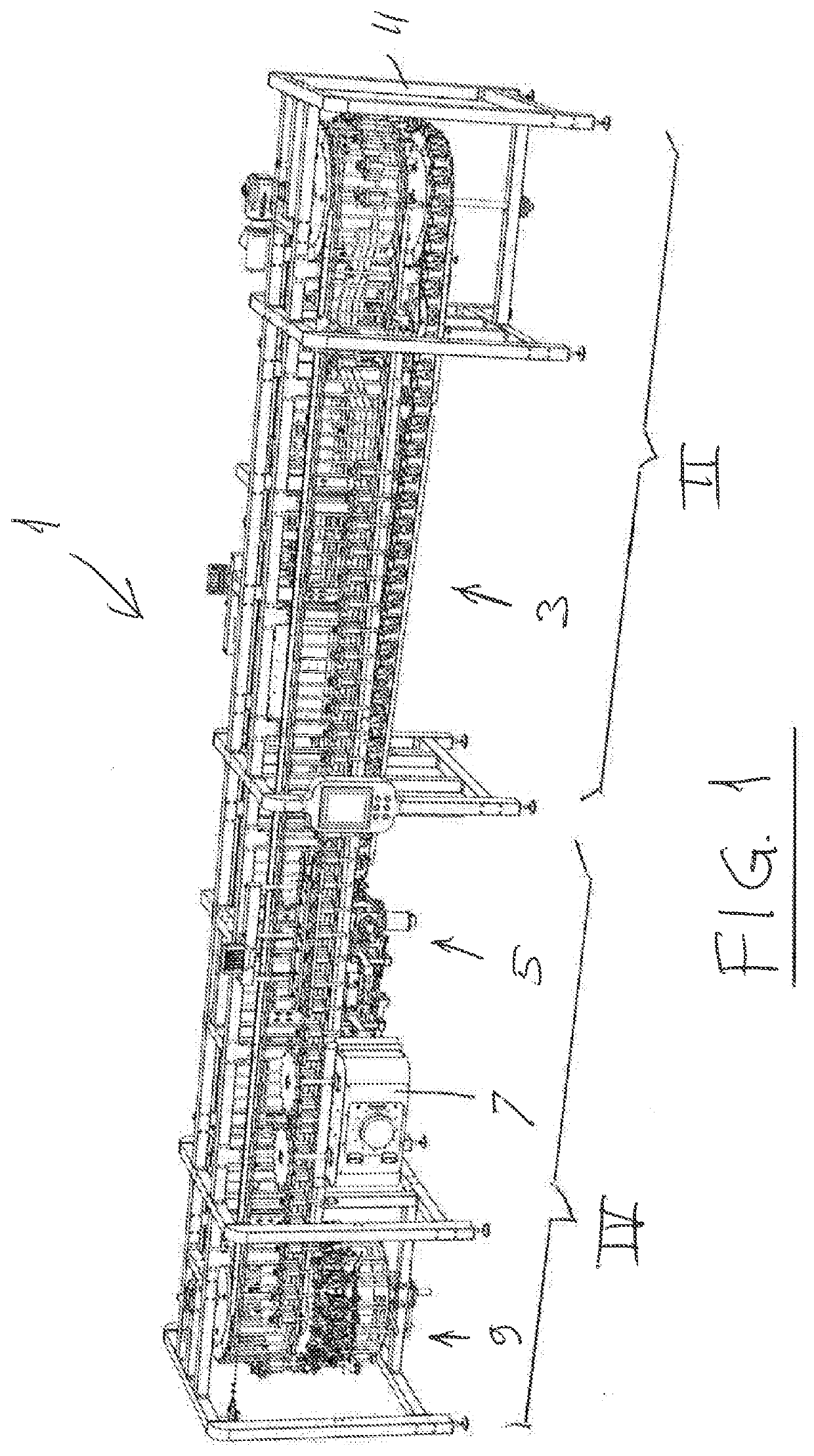

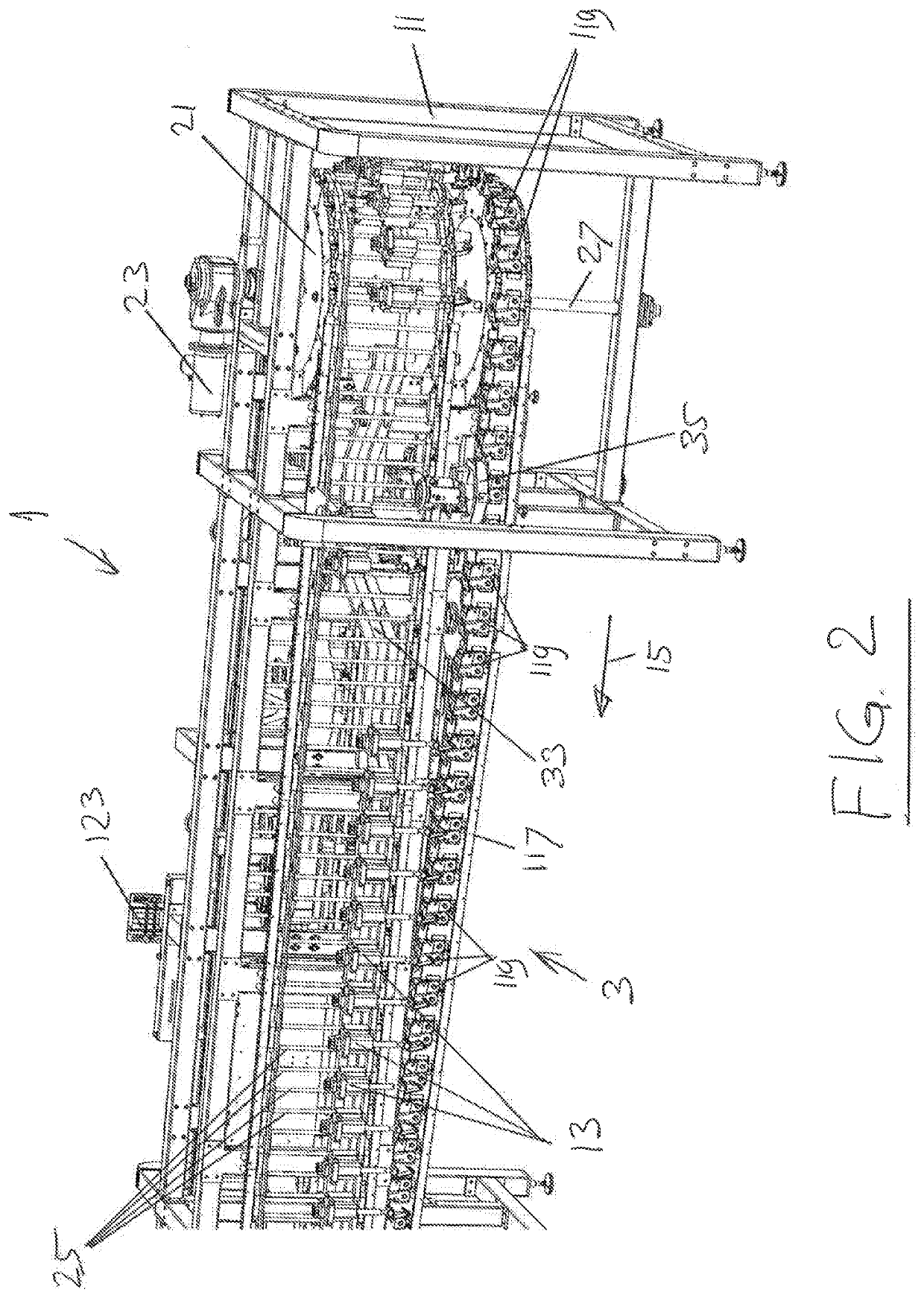

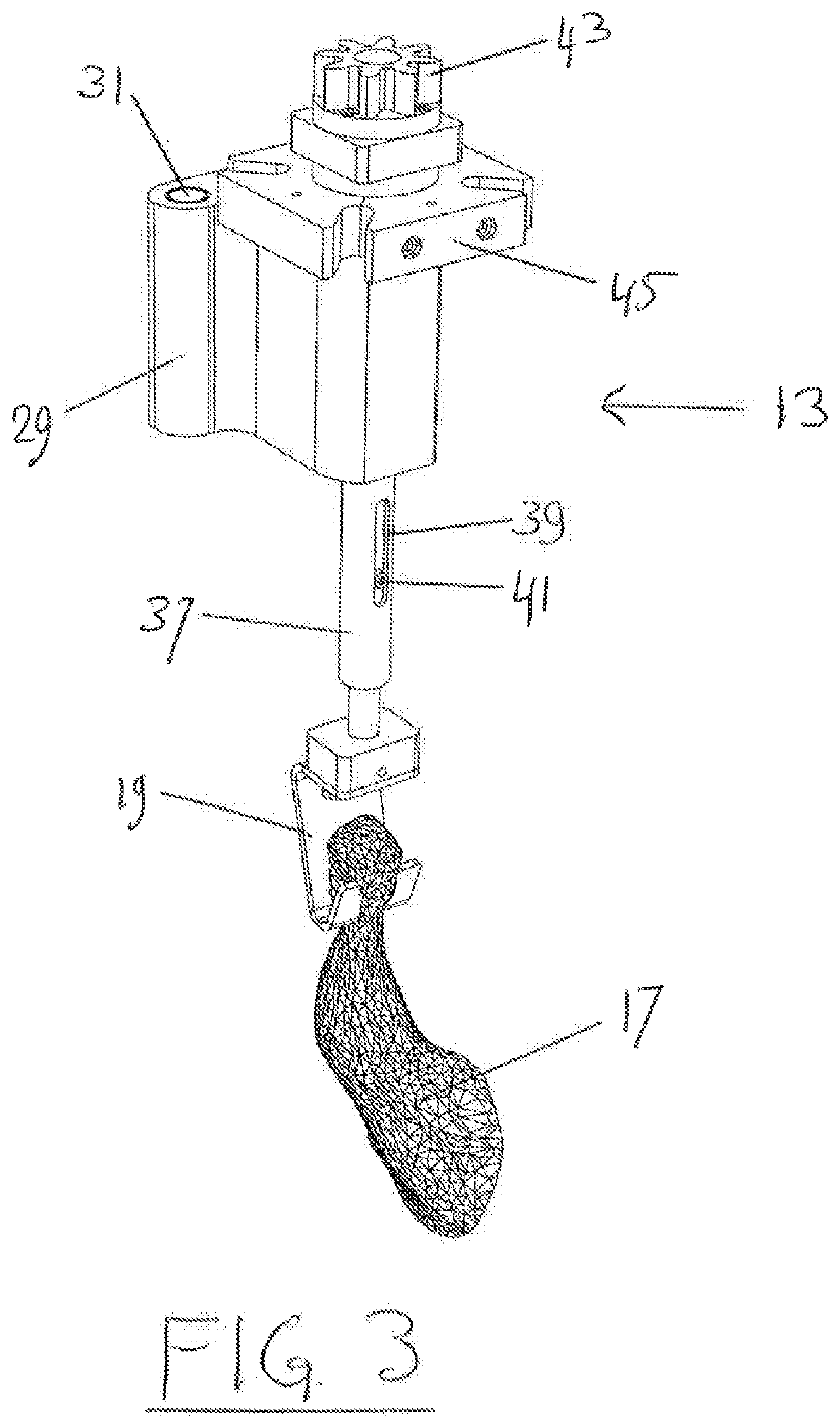

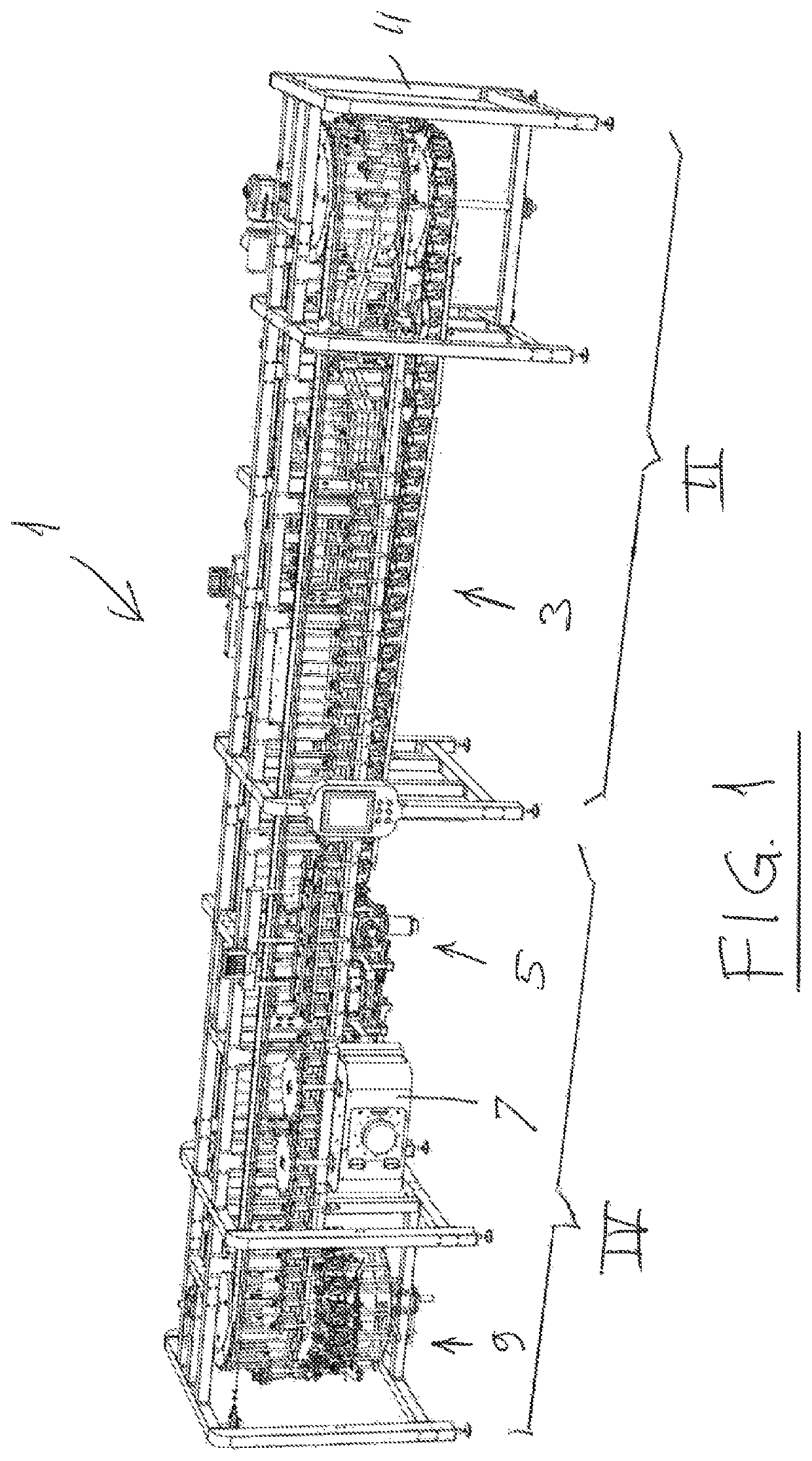

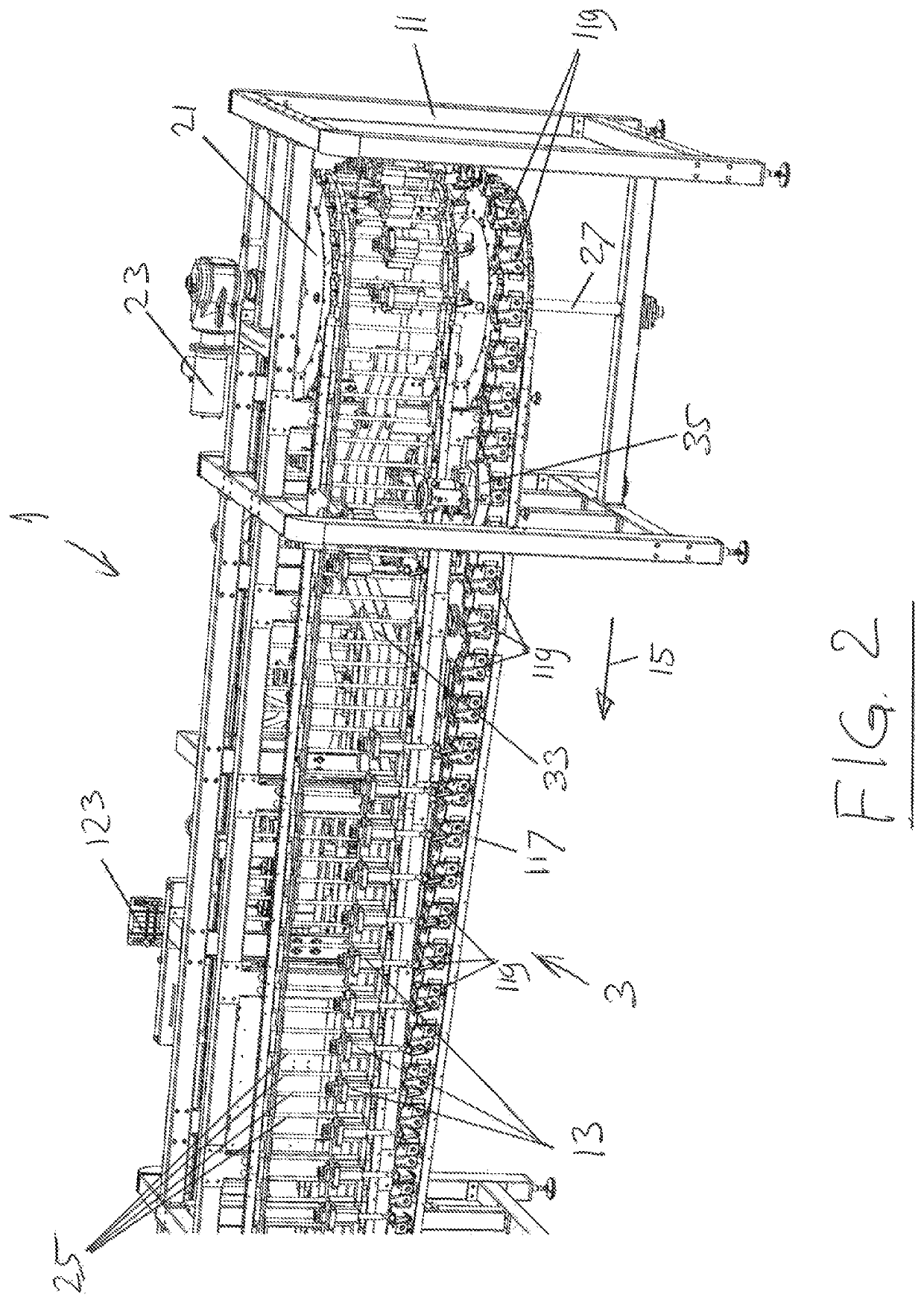

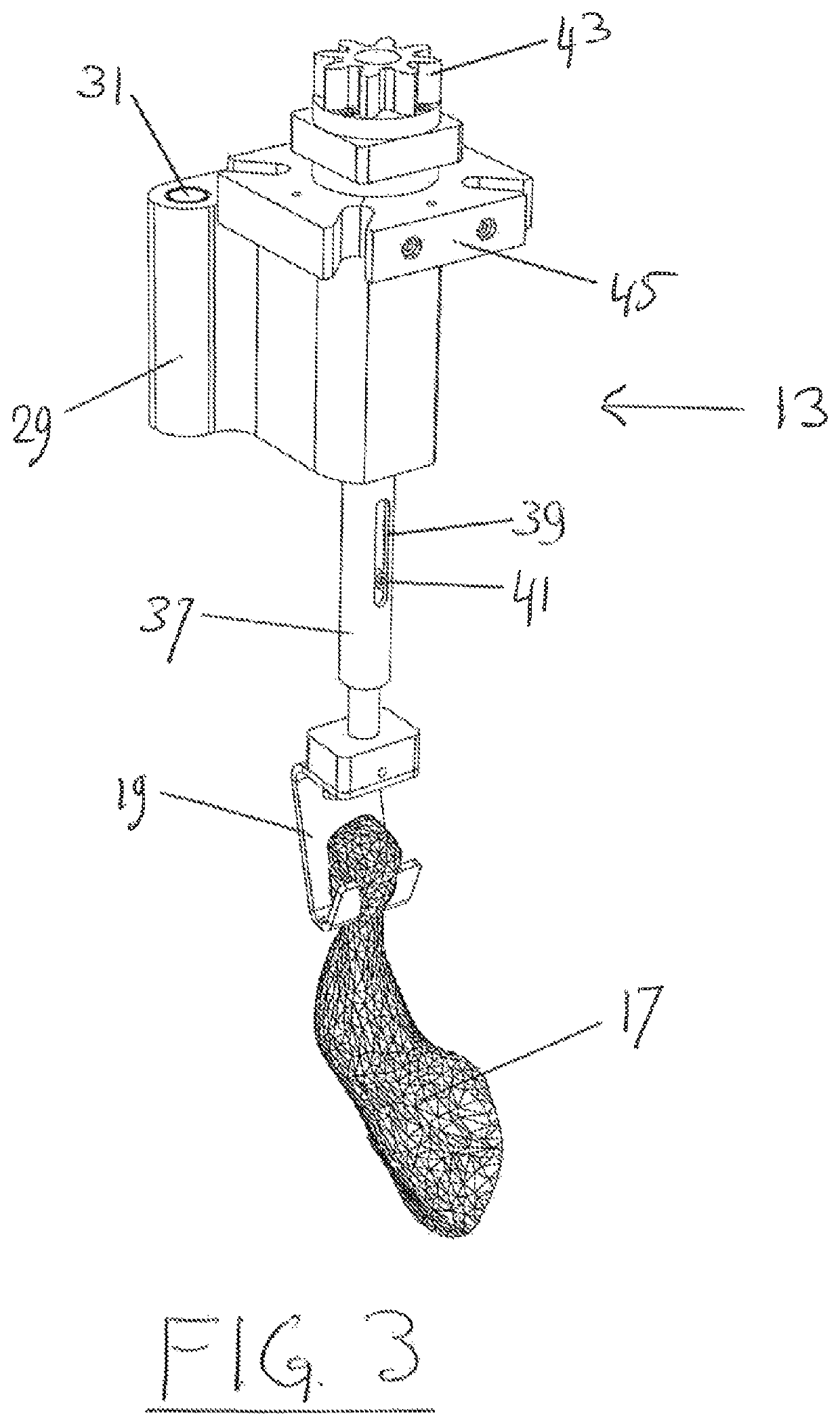

Method and apparatus for continuously harvesting surrounding meat from a successive plurality animal legs

ActiveUS20190387757A1Less cumbersome in assemblyCumbersome operationPoultry deboningPoultry shacklesEngineeringSacroiliac joint

A method of, and an apparatus (1) for, continuously harvesting surrounding meat from a successive plurality animal legs having articulated first and second animal bones and an intermediate joint. The method continuously conveys the animal legs through a path of conveyance, and determines a location of the intermediate joint. Based on the determined location of the intermediate joint, adjusting a position of the intermediate joint and a cutting implement relative to one another, and performing cutting of tissue at a location commensurate with the location of the intermediate joint. The step of determining the location of the intermediate joint is performed contactless, and without interrupting continuous conveyance of the animal legs.

Owner:FOODMATE

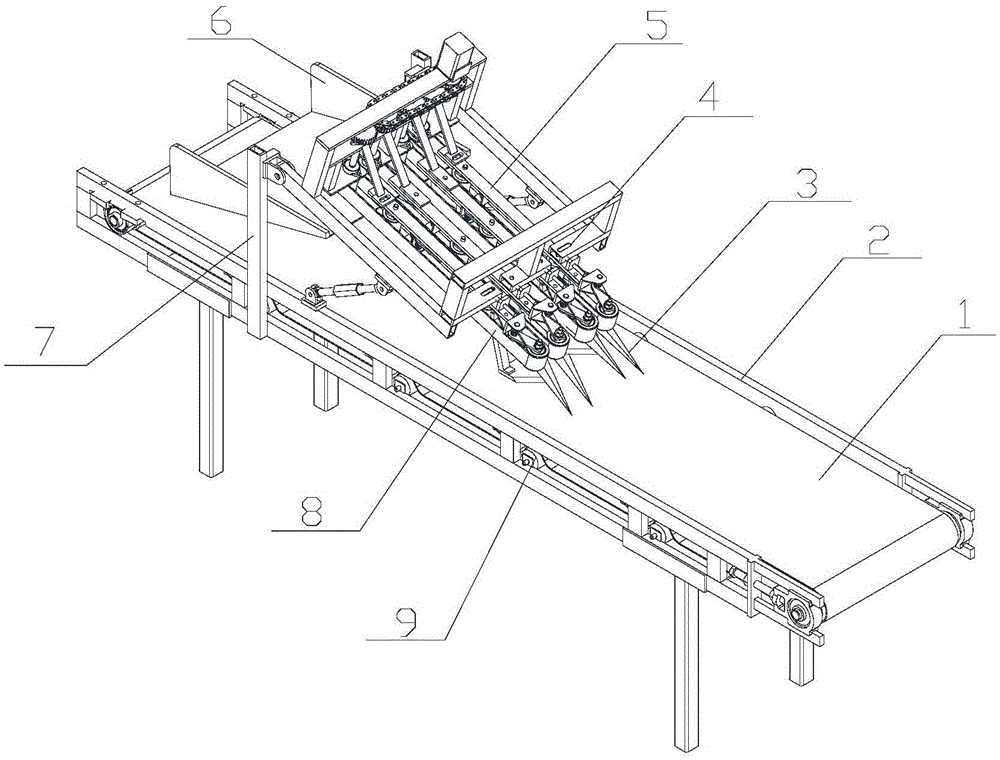

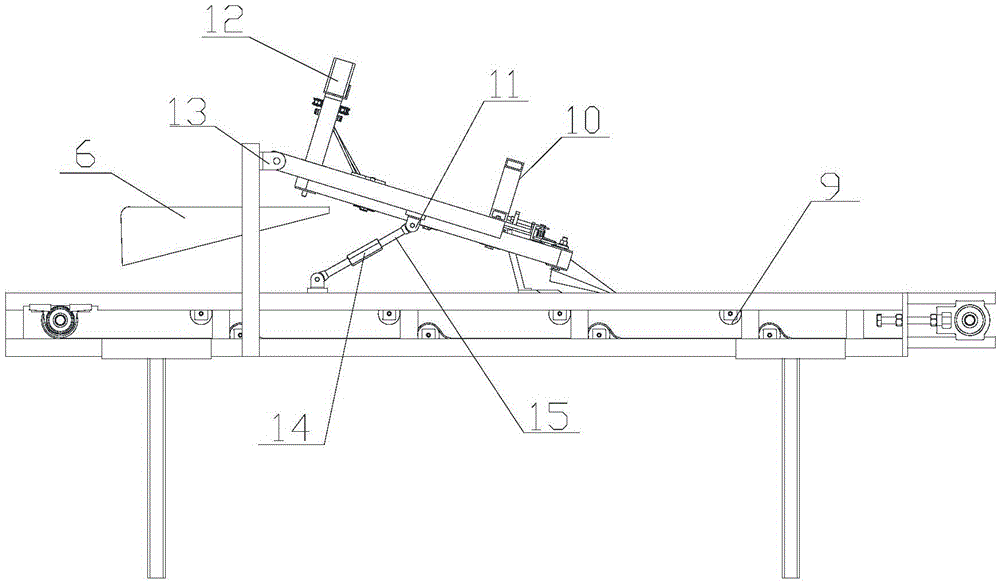

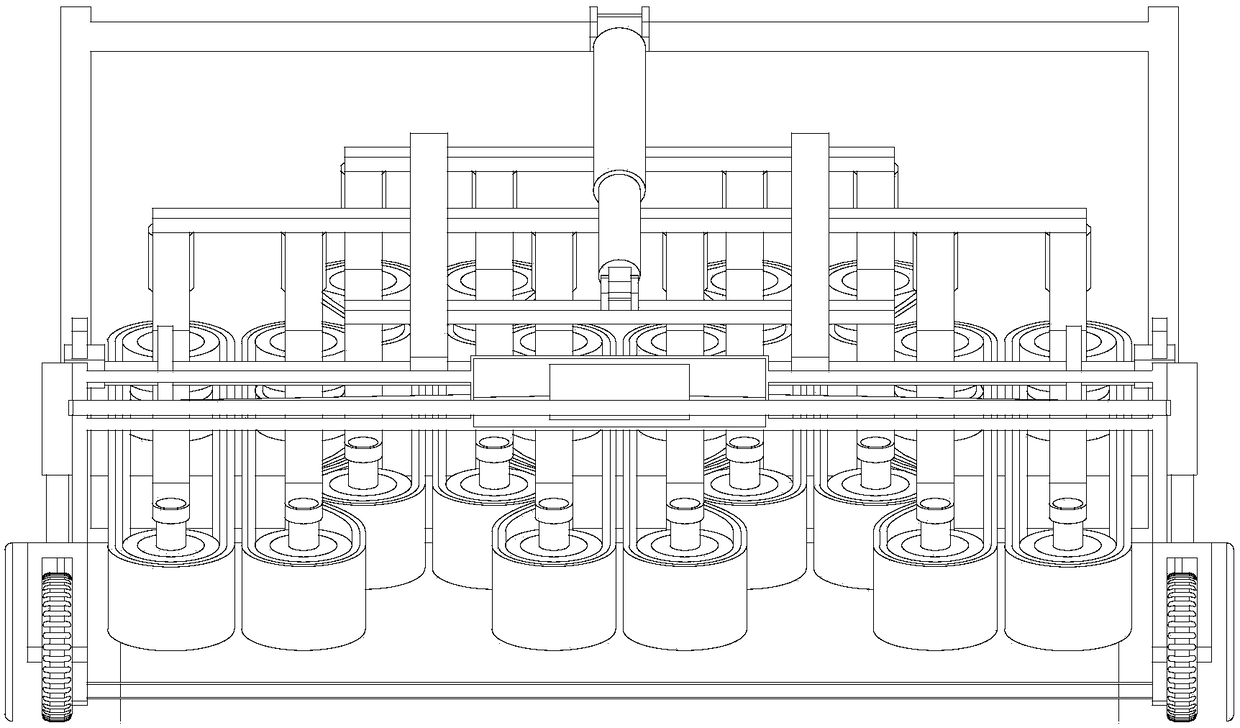

Intelligent control test device and test method for continuous harvesting of whole green-leaf vegetables

InactiveCN105425677AImplementing Multiple Combination TestsImprove developmentProgramme controlComputer controlEngineeringIntelligent control

The invention relates to an intelligent control test device for continuous harvesting of whole green-leaf vegetables. The intelligent control test device comprises a conveying device, a root soil cutting device, a plant clamping device, a lifting device, an intelligent control detection module and planting boxes. The conveying device is used for conveying the planting boxes for cultivating green-leaf vegetables at different speeds; the root soil cutting device is used for cutting or loosening the roots of the green-leaf vegetables in the planting boxes; the plant clamping device is used for clamping the root-cut green-leaf vegetables and drawing out the whole green-leaf vegetables; the lifting device is used for adjusting the cutting soil-entering angle of the root soil cutting device and the clamping angle of the plant clamping device; and the intelligent control detection module is used for controlling working parameters of components and monitoring working parameters of harvesting links under different working conditions. The device can be used for adjusting each working component and testing multiple processes of cutting, drawing-out and root cutting, thus obtaining influencing factors of mechanical harvesting low damage more accurately.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

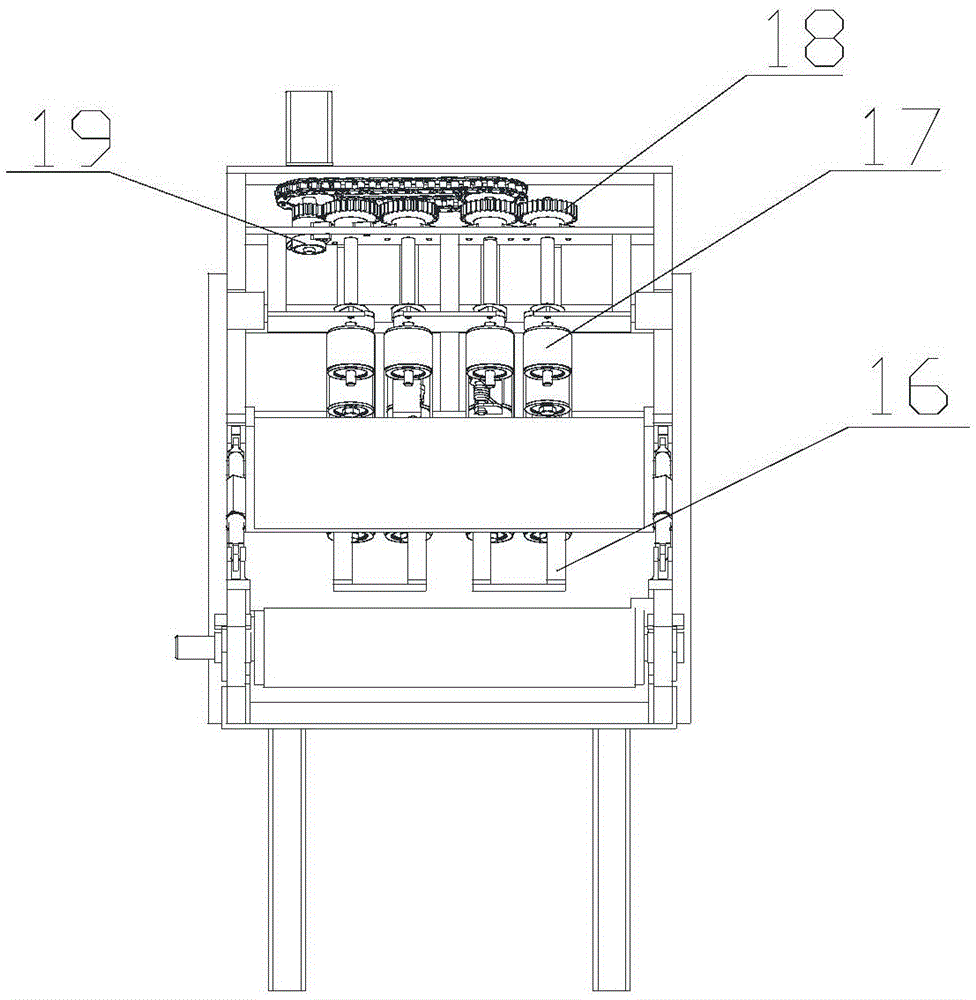

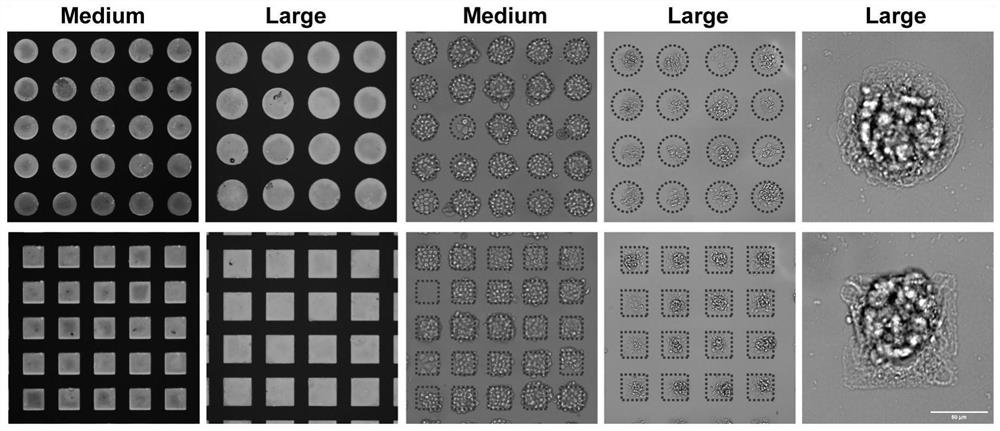

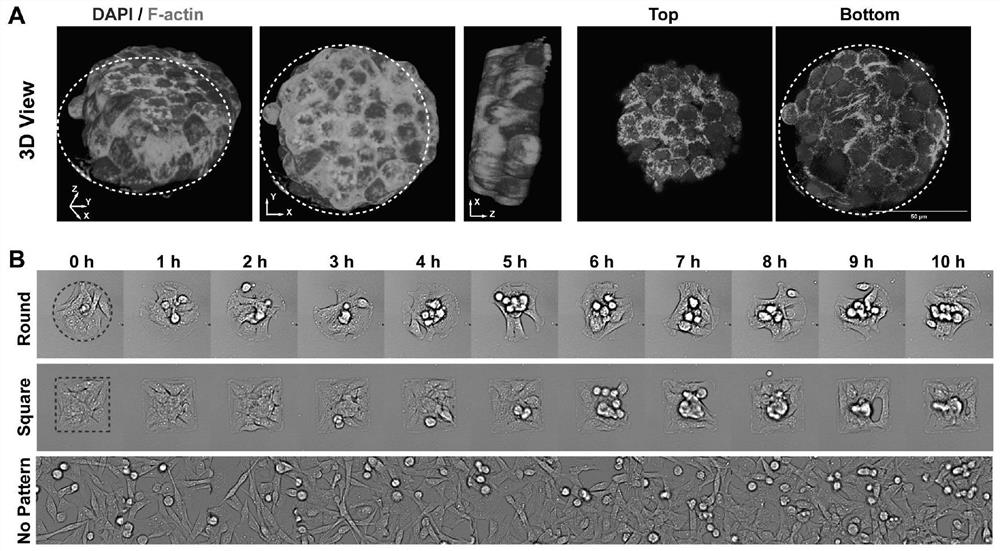

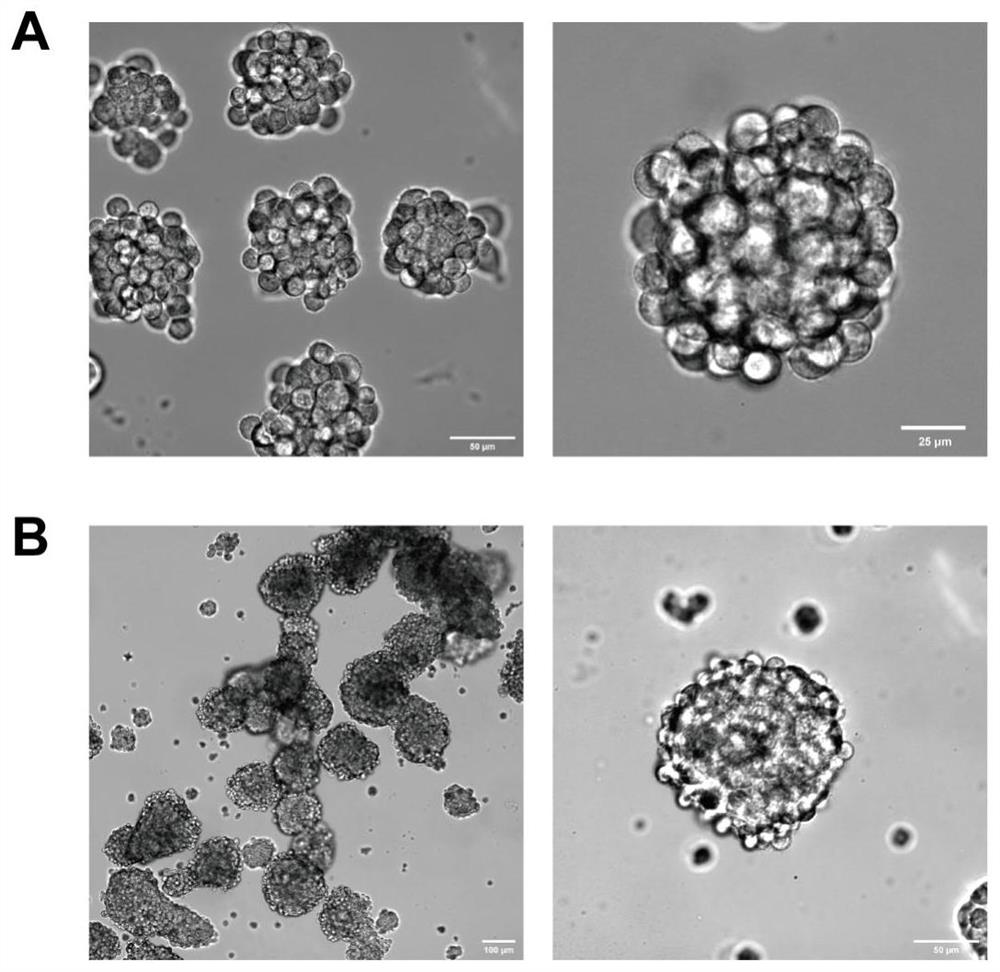

2D and 3D cell co-culture system capable of implementing continuous harvesting without enzyme digestion and construction method and application thereof

PendingCN112210536ACoexistence 2DCoexistenceCompound screeningApoptosis detectionBiotechnologyEnzyme digestion

The invention discloses a 2D and 3D cell co-culture system capable of implementing continuous harvesting without enzyme digestion and a construction method and application thereof. The construction method of the 2D and 3D cell co-culture system comprises: (1) preparing a seal with a microarray pattern; (2) preparing a culture substrate with a microarray pattern; (3) co-culturing 2D and 3D cells onthe micro-pattern culture substrate; and (4) obtaining a 3D cell microsphere and 2D cell co-culture system. According to the cell 2D and 3D co-culture system capable of implementing continuous harvesting without enzyme digestion, which is provided by the invention, 2D and 3D coexsiting co-culture of the cells can be implemented in the same environment, and if 3D cell microspheres need to be obtained, the 3D cell microspheres can be harvested by simple blowing and beating through a simple suction pipe without enzyme digestion; In addition, the substrate cells can still continue to generate the3D cell microspheres just like that continuous harvesting can be implemented by planting plants, meanwhile, collagen, sodium alginate and other materials do not need to be added in the formation of the 3D cell microspheres, so as to reduce the influence of exogenous extracellular matrixes in research.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

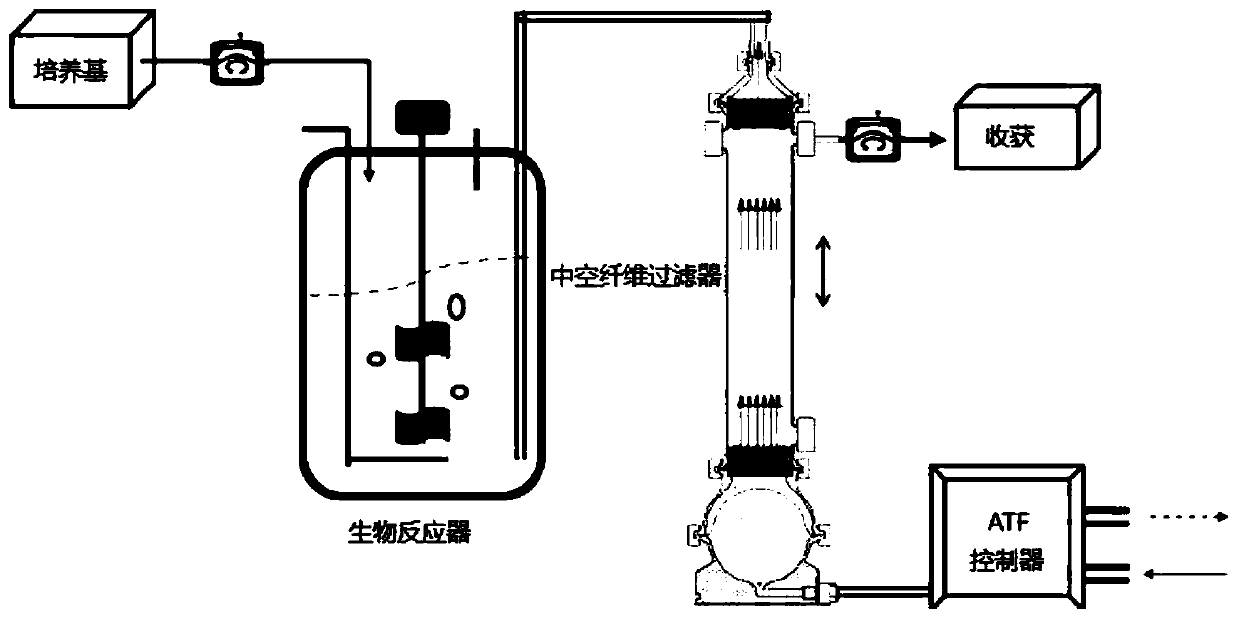

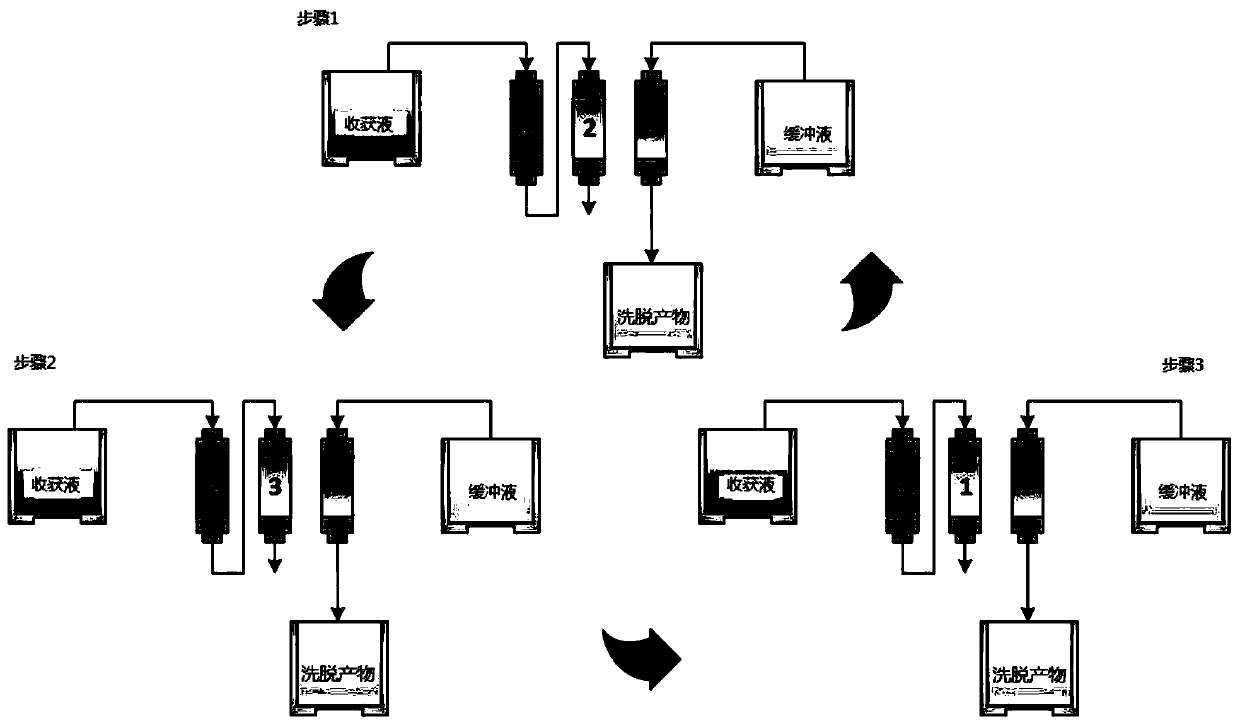

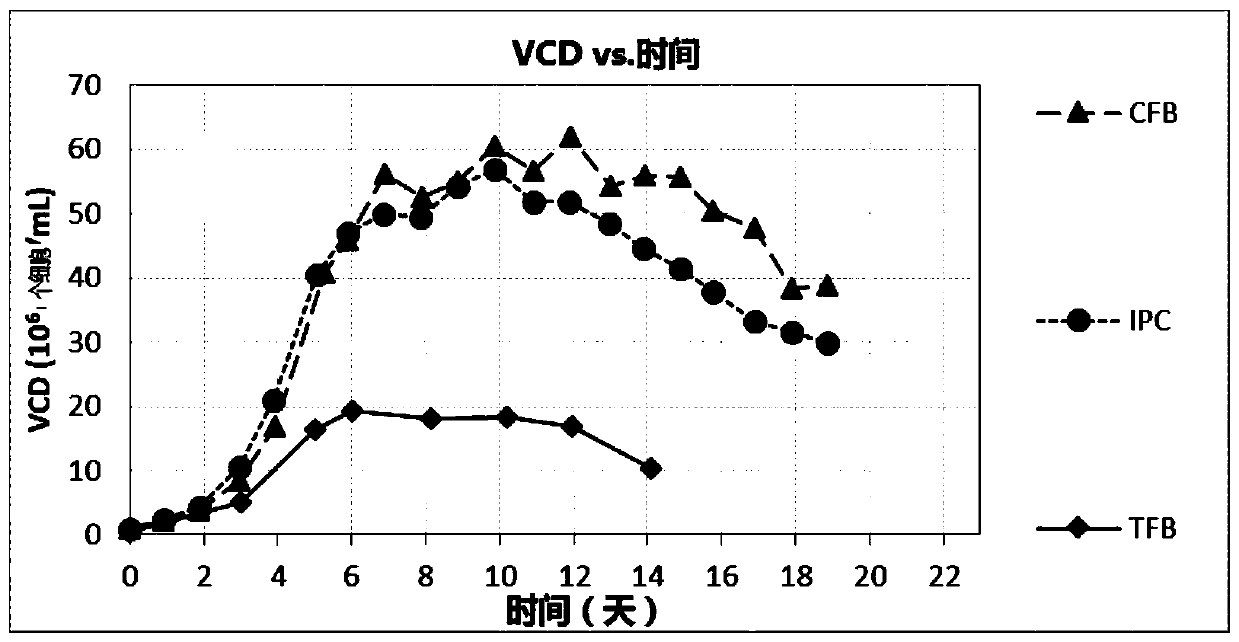

Cell culture process by intensified perfusion with continuous harvest and without cell bleeding

PendingCN111406105ABioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyCell free

Provided are a method and a system for culturing cells and harvesting biologics. More particularly process for cell culture by intensified perfusion with continuous harvest and without cell bleeding is provided.

Owner:SHANGHAI WUXI BIOLOGIC TECH CO LTD

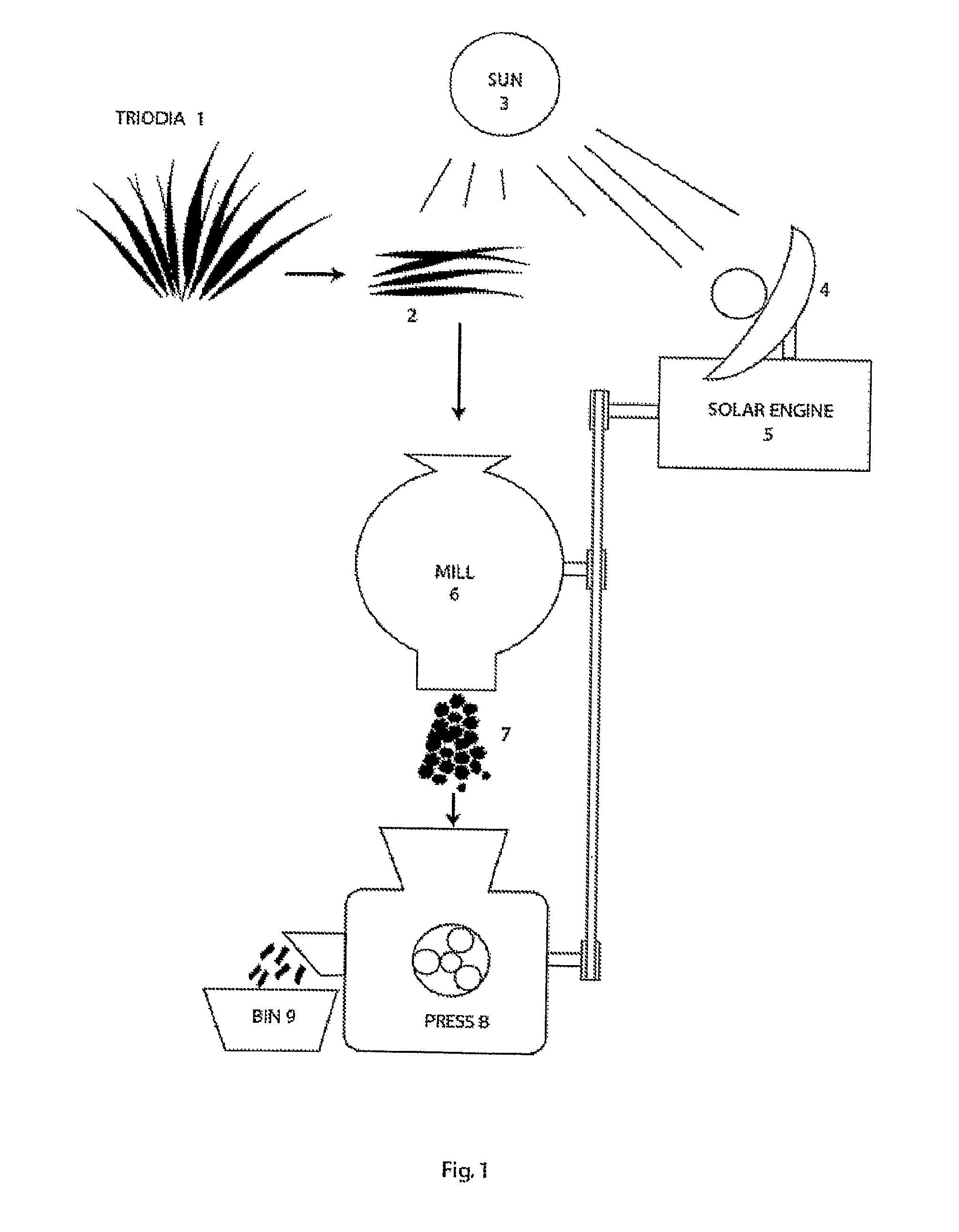

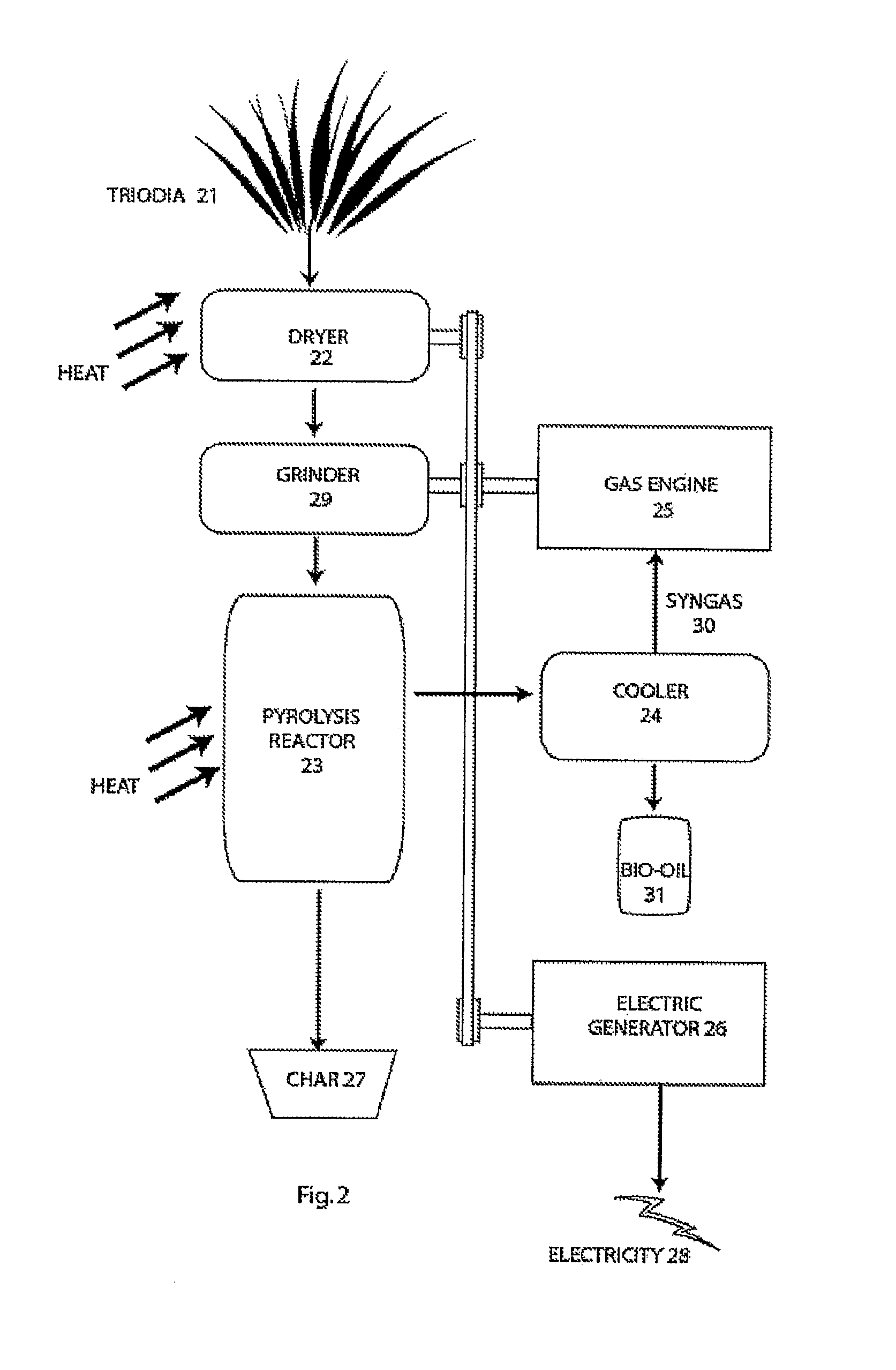

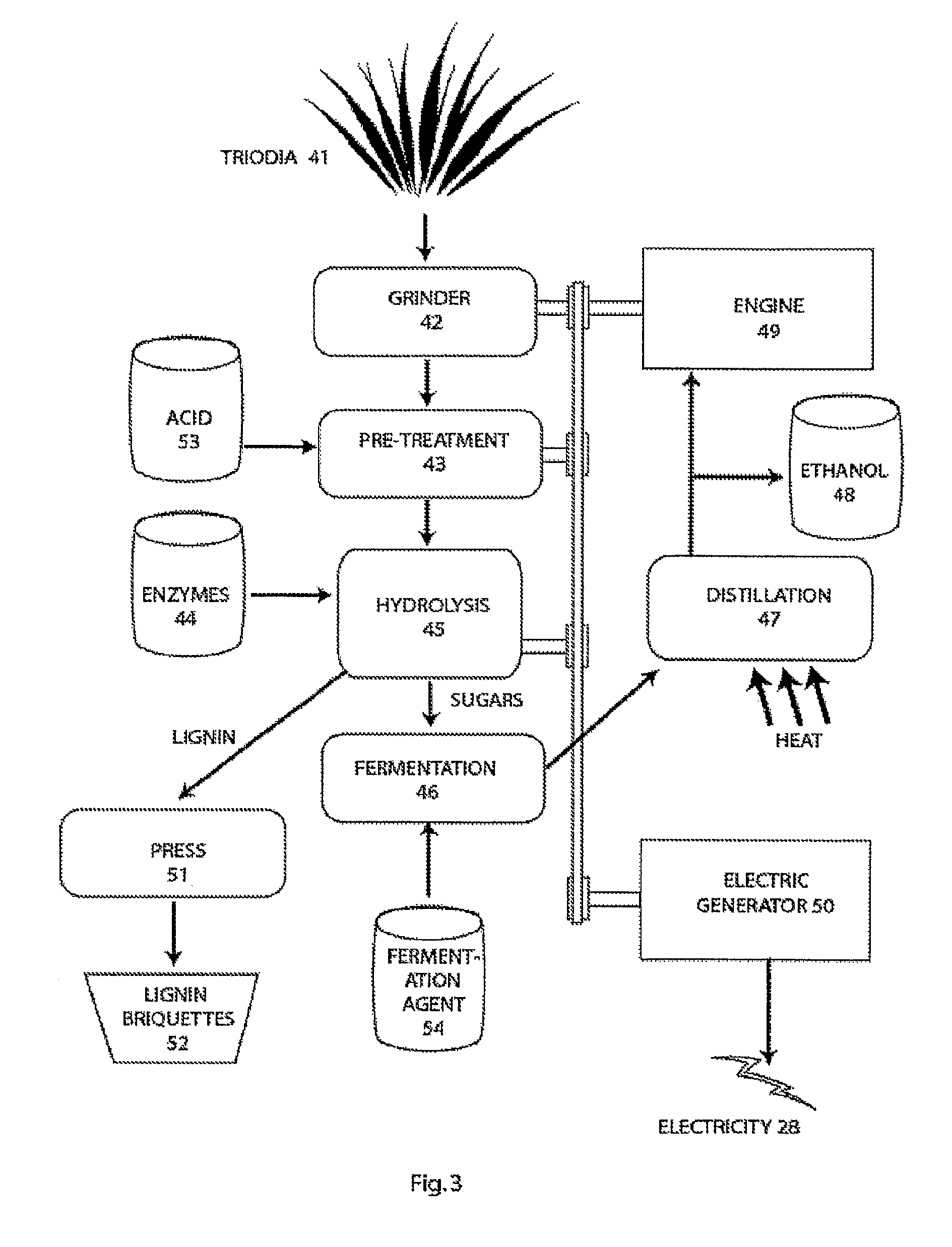

Methods and products using grass of the genus Triodia

ActiveUS8557307B2High resin contentAmount of resin is minimisedAntibacterial agentsBioreactor/fermenter combinationsBiotechnologyBiofuel feedstock

Owner:ARCHER MICHAEL

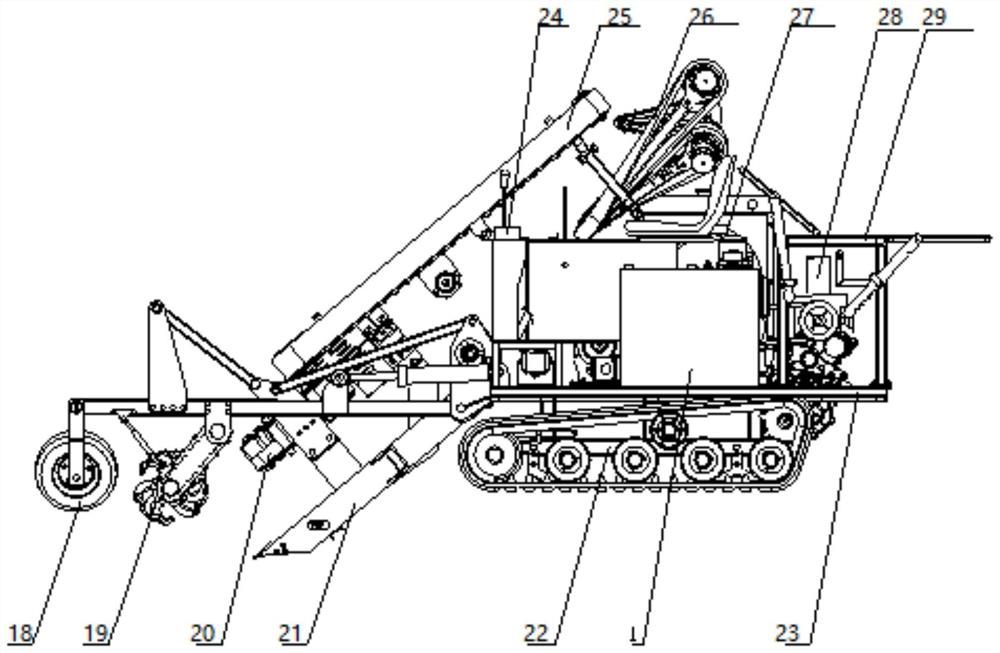

Device and method for continuous harvesting of whole green leafy vegetables

InactiveCN105409437BIncrease effective yieldReduced Harvest CostsHarvestersEngineeringParallel processing

The present invention relates to a reaping apparatus and a reaping method for continuously reaping whole plants of green vegetables. The reaping apparatus comprises a machine frame, a crop divider, a ripper, a clamping, pulling and reversing apparatus, a root cutting apparatus, a transport apparatus, a lifting apparatus, and a walking apparatus. The crop divider is used for dividing and lifting green vegetables in a harvest area; the ripper is used for ripping a soil at roots of the green vegetables that are gathered together by the crop divider; the clamping, pulling and reversing apparatus is used for clamping and pulling the green vegetables that are gathered together, and reversing the green vegetables during a clamping and conveying process; the root cutting apparatus is used for stably and regularly cutting roots of the green vegetables during a clamping and delivering process; the transport apparatus is used for transporting the green vegetables that are pulled out; the lifting apparatus is used for supporting the clamping, pulling and reversing apparatus, and adjusting a height of the clamping, pulling and reversing apparatus from the ground; and the walking apparatus is used for driving the machine frame to walk in the harvest area. According to the reaping apparatus and reaping method provided by the present invention, a pulling method with flexible belts parallel processing is adopted to continuously reap the whole plants of green vegetables; a flexible material is adopted to avoid damage to stems or leaves; and adaptability to vegetable harvest is good.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

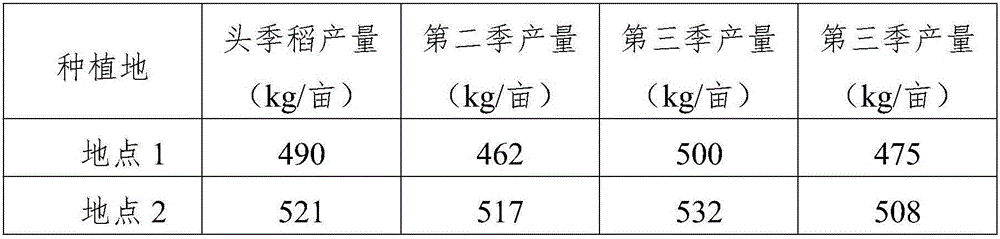

Perennial-root culturing technique for early season rice

The present invention discloses a perennial cultivation technology of early season rice. The is is characterized by that on the ridgeless flatland or land on the slopes under the condition of droughtthe land is prepared and sown, and the water content can be obtained by rain, after harvest the rice head is remained, to be used as next growing seed seedling, and a proper management method is adopted, so that after sowing once, it can continuously harvest for above 9 times.

Owner:福建农大菌草技术开发公司

Outdoor large-area cultivating method for Isochrysis galbana H29 containing rich DHA

InactiveCN100473719CReduce consumptionEffective defenseUnicellular algaeClimate change adaptationIsochrysis galbanaCulture fluid

Owner:TIANJIN UNIV OF SCI & TECH

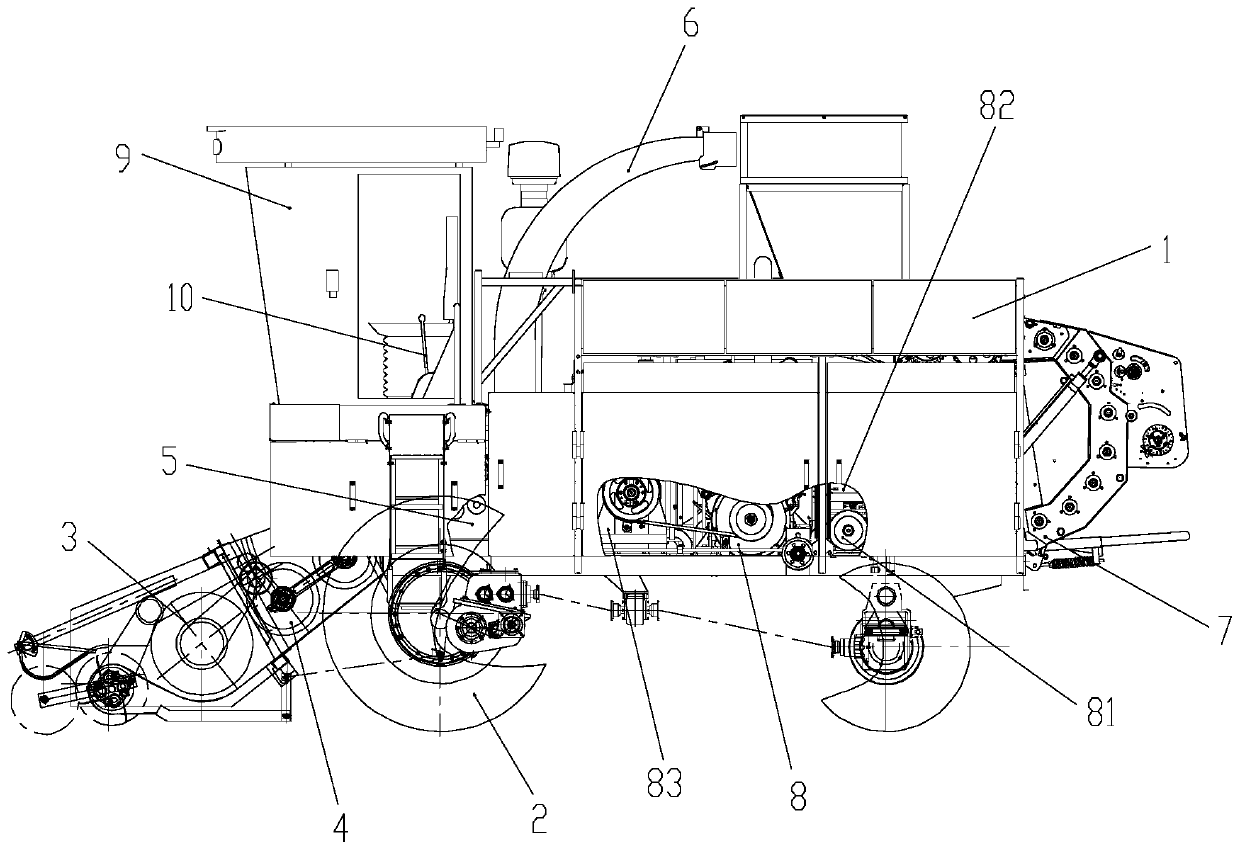

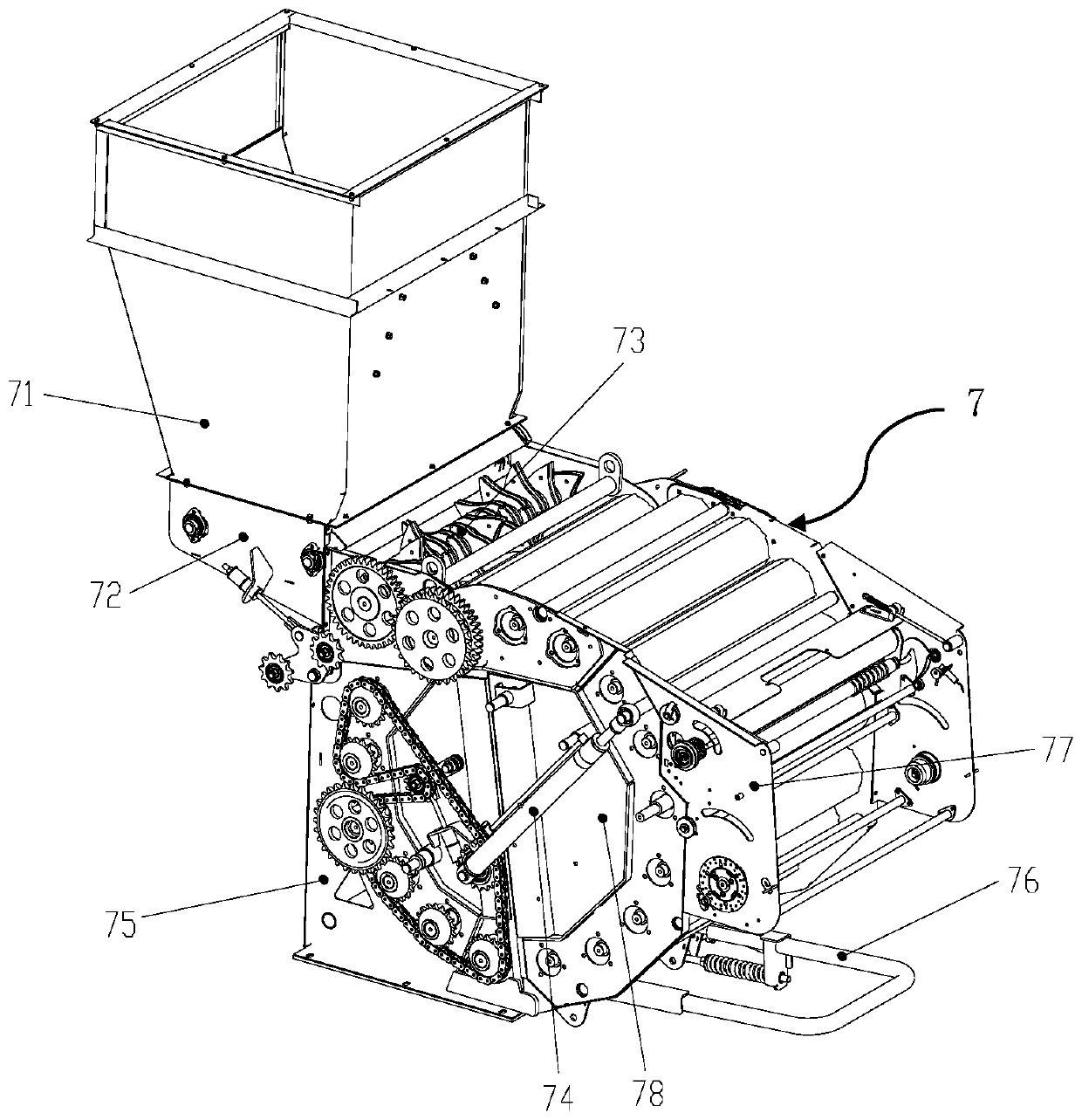

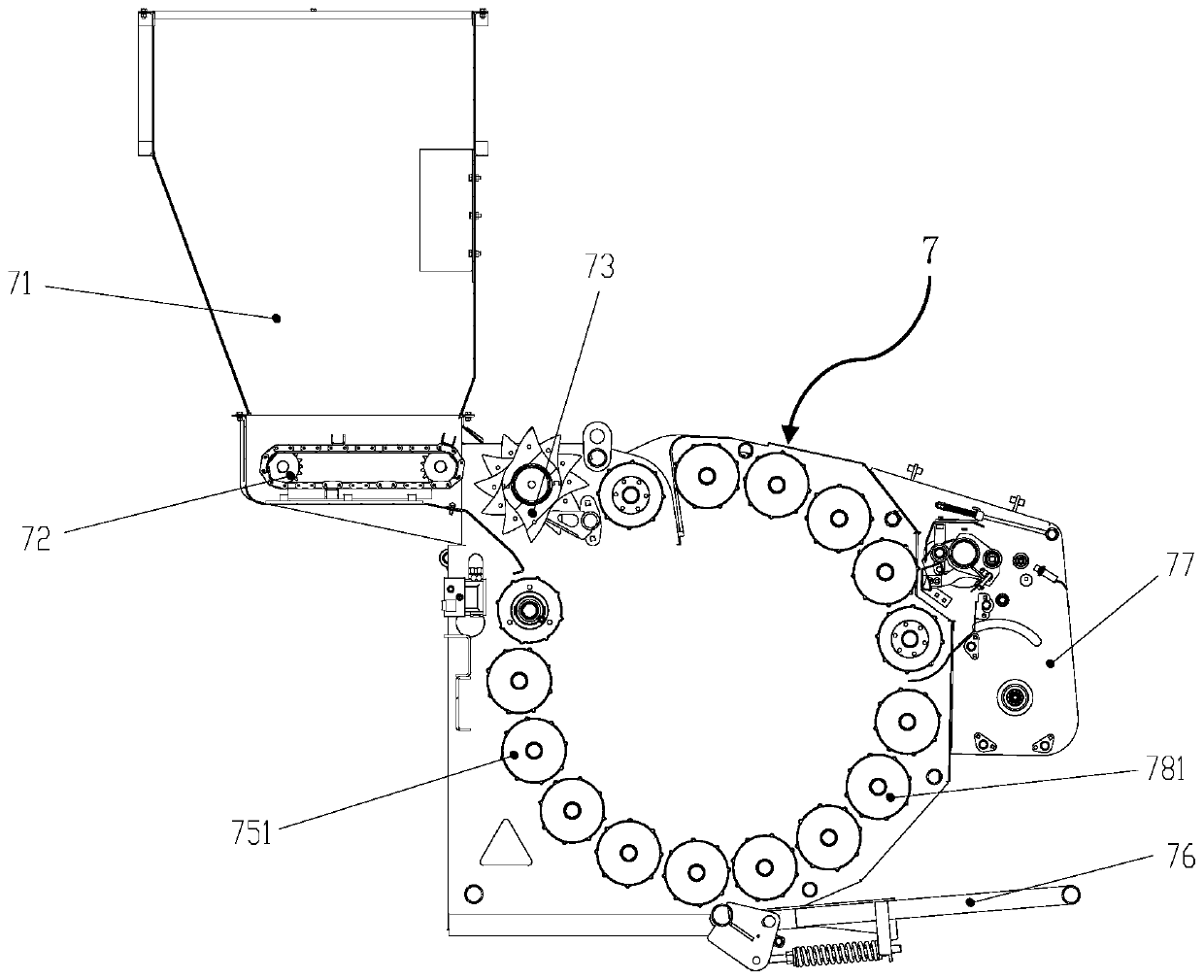

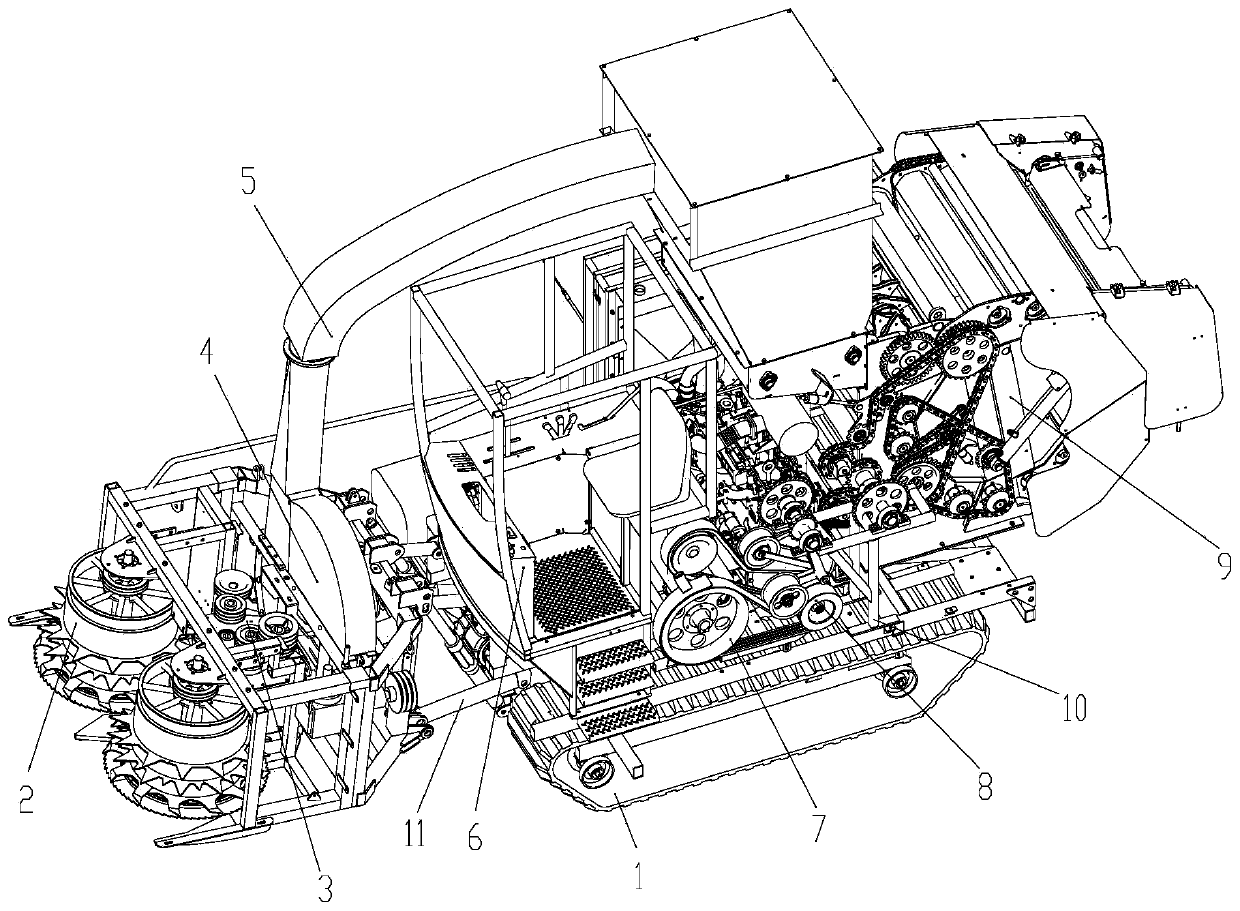

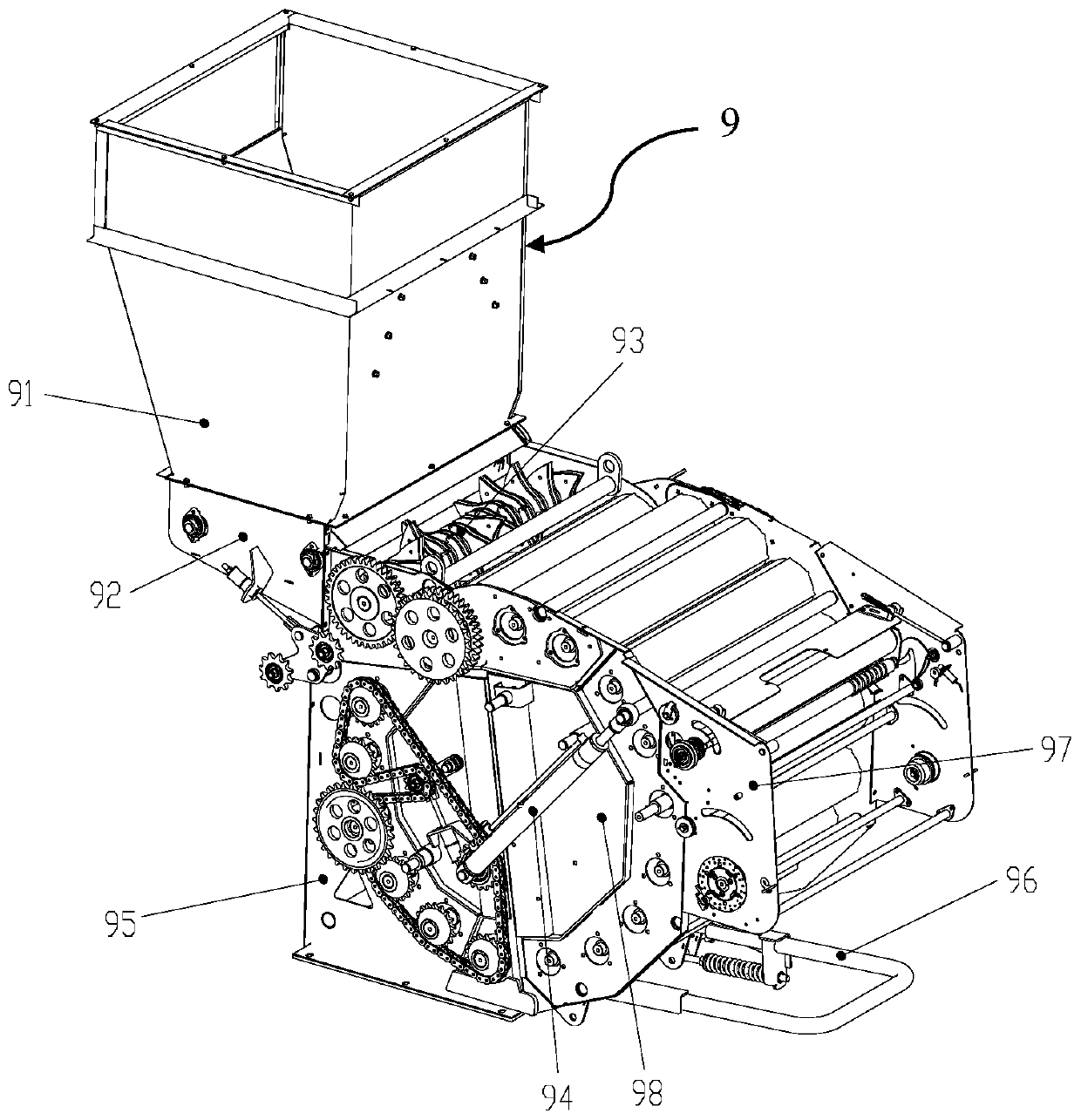

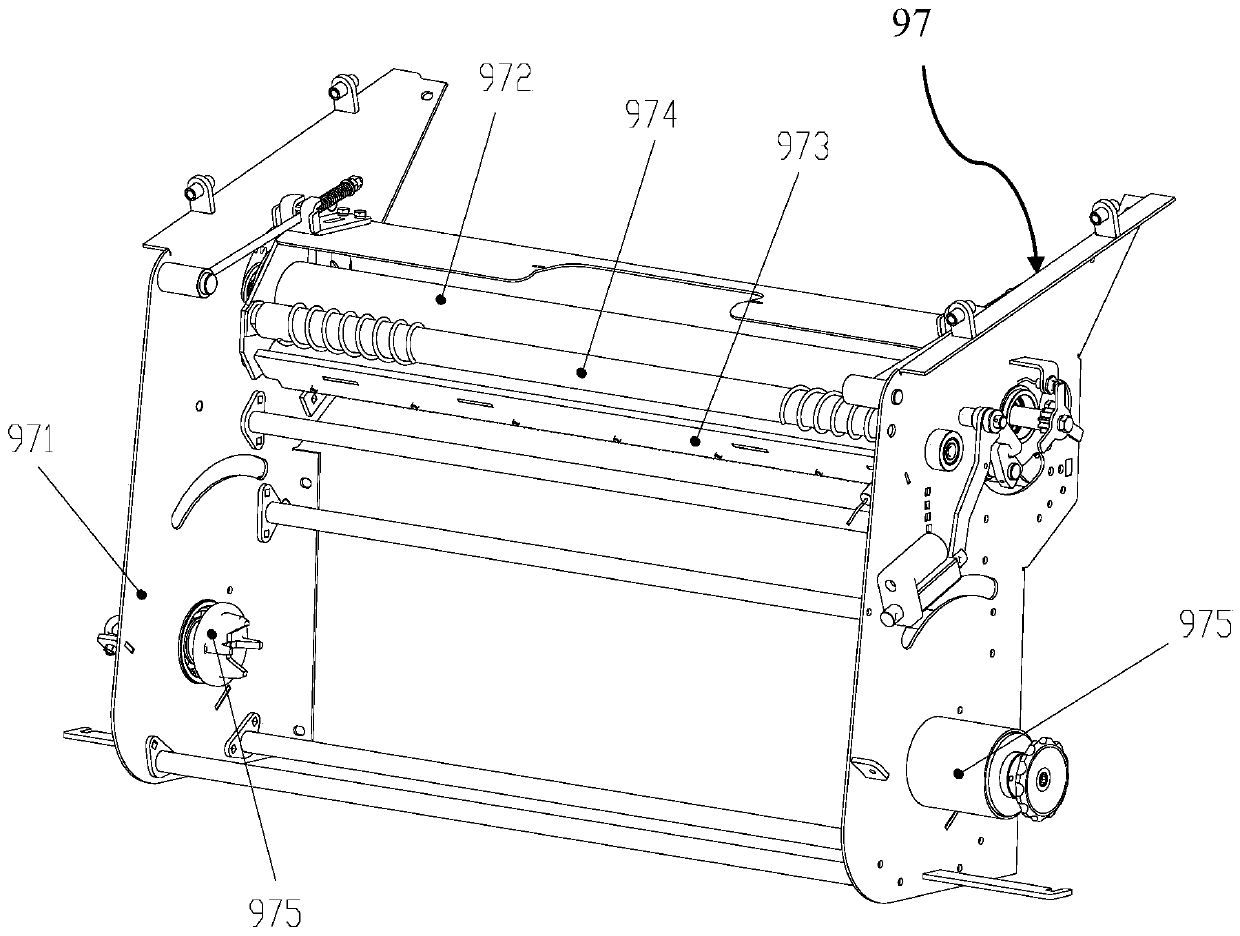

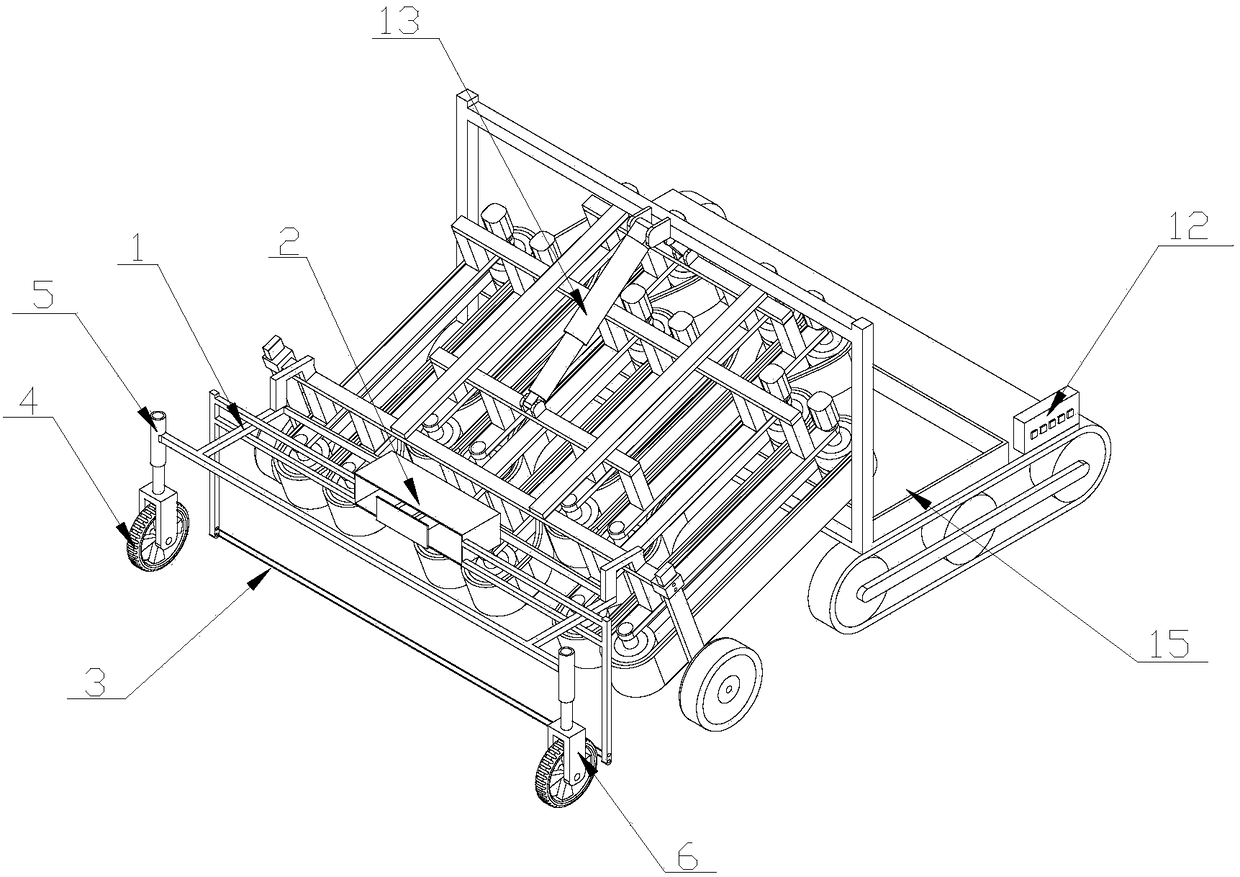

Self-propelled bundling machine

PendingCN111418359ARealize self-propelled operationPrevent overloadingLoadersBalingAgricultural engineeringMachine

The invention discloses a self-propelled bundling machine. The self-propelled bundling machine comprises a machine frame, a self-propelled chassis and a power driving device; the self-propelled chassis and the power driving device are mounted on the machine frame; the chassis is located below the machine frame and connected with the power driving device; the bundling machine further comprises a picking and cutting table, a feeding device, a crushing device, a throwing device and a bundling device which are mounted on the machine frame and arranged in sequence; the picking and cutting table ismounted at the front end of the machine frame; the front end of the feeding device corresponds to the picking and cutting table; the crushing device is connected with the feeding device and the throwing device; the outlet end of the throwing device is connected with the bundling device; and the power driving device is connected with the picking and cutting table, the feeding device, the crushing device, the throwing device and the bundling device. The bundling machine is suitable for harvesting various crops such as straws and pasture grass, can complete the operation of picking and collecting, feeding, crushing, throwing, soil and impurity removing, bundling and net winding, net cutting and bundle unloading and the like, realizes self-propelled non-stop continuous harvesting and bundling,and improves the efficiency while ensuring the quality.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

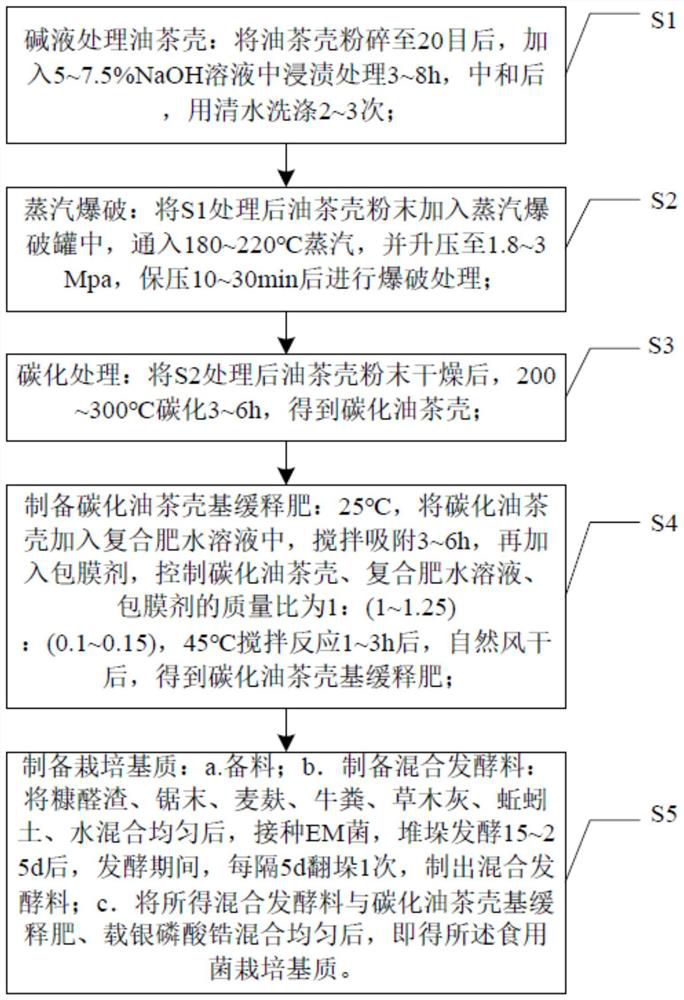

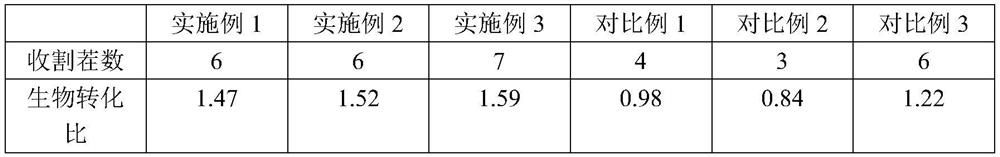

Method for preparing edible fungus culture medium from camellia oleifera shells

InactiveCN111972214AAvoid degradationHigh stability of film formationAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBiotechnologyCamellia oleifera

The invention discloses a method for preparing an edible fungus culture medium from camellia oleifera shells. The method comprises the following steps: S1, treating the camellia oleifera shells with alkali liquor; S2, performing steam explosion; S3, drying the camellia oleifera shell powder treated in S2, and conducting carbonizing at 200-300 DEG C for 3-6 hours to obtain carbonized camellia oleifera shells; S4, adding the carbonized camellia oleifera shells into a compound fertilizer aqueous solution at 25 DEG C, conducting stirring and adsorbing for 3-6 hours, adding a coating agent, conducting stirring and reacting for 1-3 hours at 45 DEG C, and conducting natural air-drying; and S5, a, preparing materials; b, uniformly mixing furfural residues, saw dust, wheat bran, cow dung, plant ash, earthworm soil and water, inoculating the mixture with EM bacteria, conducting stacking and fermenting for 15-25 days, and turning over the stack once every 5 days during fermentation; and c, mixingthe obtained mixed fermentation material with a carbonized camellia oleifera shell-based slow-release fertilizer and silver-loaded zirconium phosphate to obtain the fertilizer. The edible fungus culture medium prepared by the invention has excellent moisture and fertilizer retention performance and dual purposes of medicines and fertilizers, has antibacterial and insecticidal effects, effectivelyimproves the yield of edible fungi, realizes six-crop continuous harvest, and reduces resource waste.

Owner:ANHUI YUMIN ECOLOGICAL AGRI

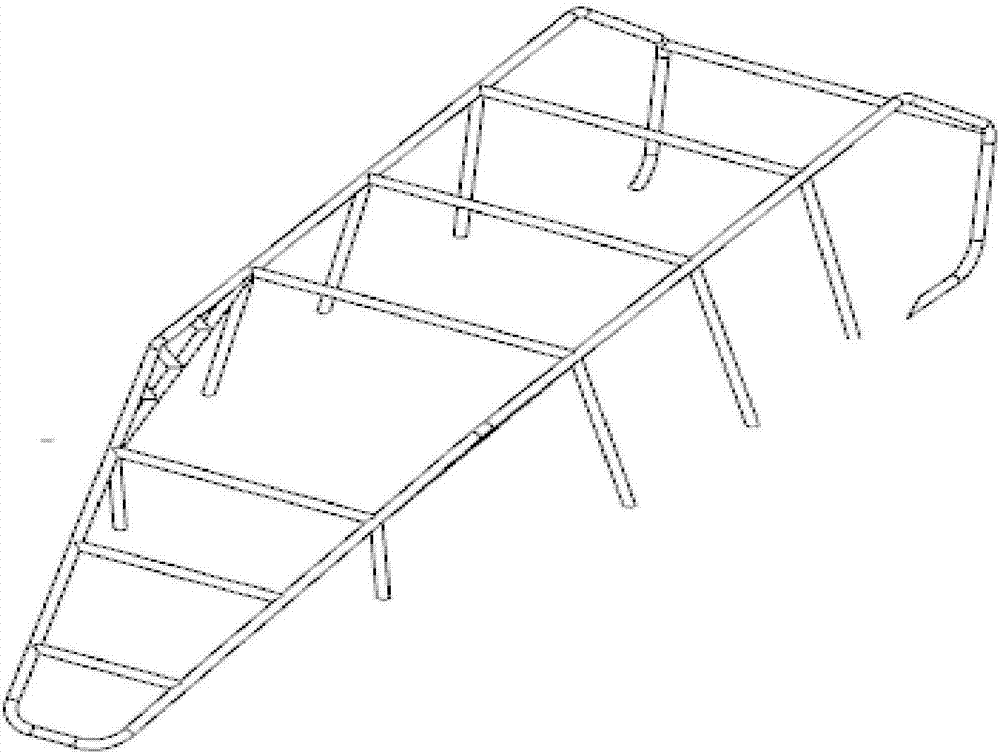

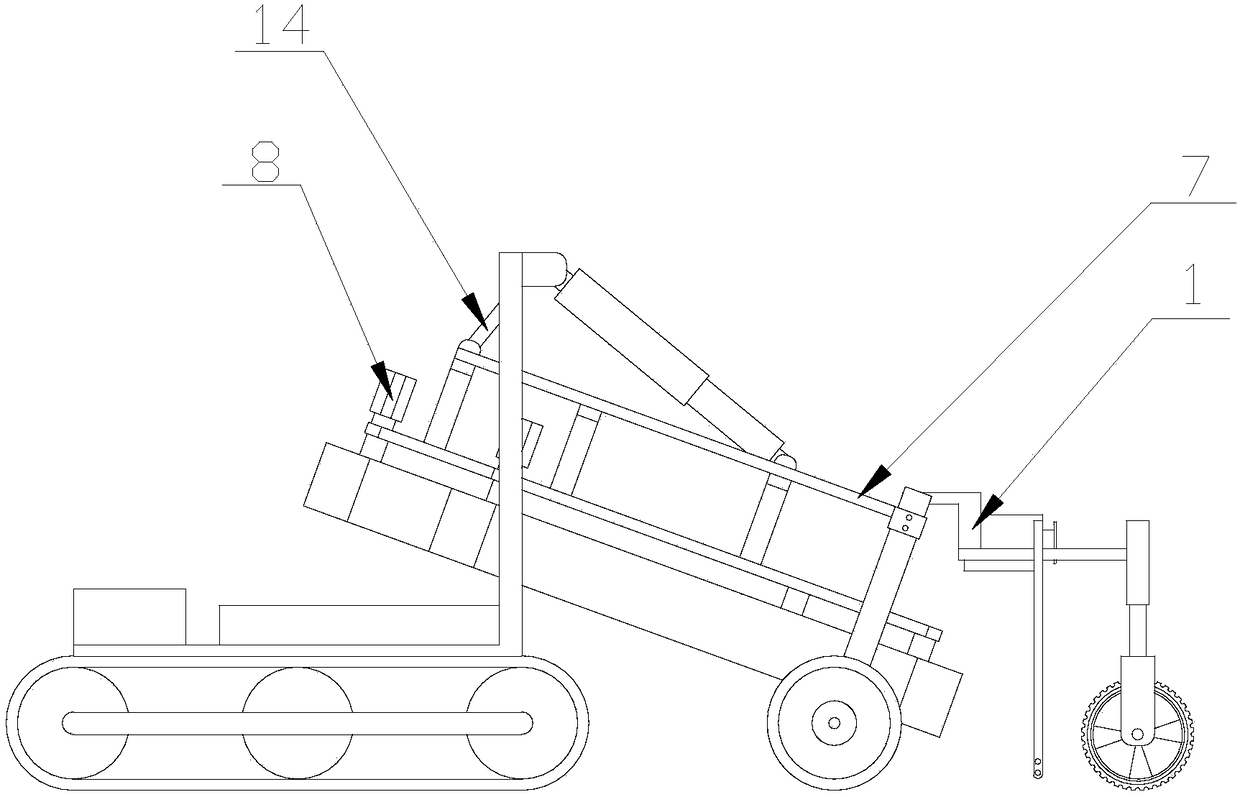

Crawler harvesting and bundling integrated machine for broussonetia papyrifera

The invention relates to a crawler harvesting and bundling integrated machine for broussonetia papyrifera. The integrated machine comprises a frame, a crawler chassis, an engine, headers, a feeding device, a crushing device and a bundling machine, wherein the crawler chassis, the engine, the headers, the feeding device, the crushing device and the bundling machine are installed on the frame; the headers are located at the front end of the frame; the bundling machine is located above the rear part of the crawler chassis and realizes non-stop continuous harvesting and bundling operations in a manner that materials are fed from the upper end of a bundling front bin and a bin body of a net wrapping mechanism is arranged at the rear part; the feeding device and the crushing device are sequentially arranged behind the headers; an exit of the crushing device is provided with a material throwing tube; an exit end of the material throwing tube is connected with an entrance end of the bundling machine; and the engine transmits power to the crawler chassis, the headers and the bundling machine through a drive intermediate shaft. The integrated machine can realize high-efficiency harvesting operation and high-density and high-efficiency bundling operation of broussonetia papyrifera feed, and can realize non-stop continuous harvesting and bundling operations.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

Soilless cultivation method

InactiveCN107969331AOvercome obstacles to continuous croppingTake advantage ofAgriculture gas emission reductionCultivating equipmentsContinuous croppingPlant roots

The invention relates to a soilless cultivation method. The method is divided into three types according to different types: hydroponic cultivation, mist cultivation and substrate cultivation, whereinthe hydroponic cultivation is a cultivation method that a plant root system is directly contacted with a nutrient solution without using a substrate, and has the distinctive feature that the hydroponic cultivation can stably supply sufficient nutrients to the plant root system; the mist cultivation utilizes a mist spraying device to atomize the nutrient solution to make the plant root system in aclosed dark root box and suspended in an atomized nutrient solution environment; and the substrate cultivation is that the plant root system grows in a solid substrate, and the nutrient solution is conveyed through a drip irrigation system for absorption of the root system. The soilless cultivation provided by the invention is a cultivation (vegetable) method with the modern high technology, andhas the advantages that the yield is high, water and nutrients are saved, labor and work are saved, the method is easy to manage, continuous cropping obstacles of soil are avoided, the space is fullyutilized, and the method is clean and hygienic, and the product obtained by the soilless cultivation is listed on the market earlier than that of soil cultivation, thereby having a long continuous harvest period.

Owner:ENPING LANHAI AGRI TECH

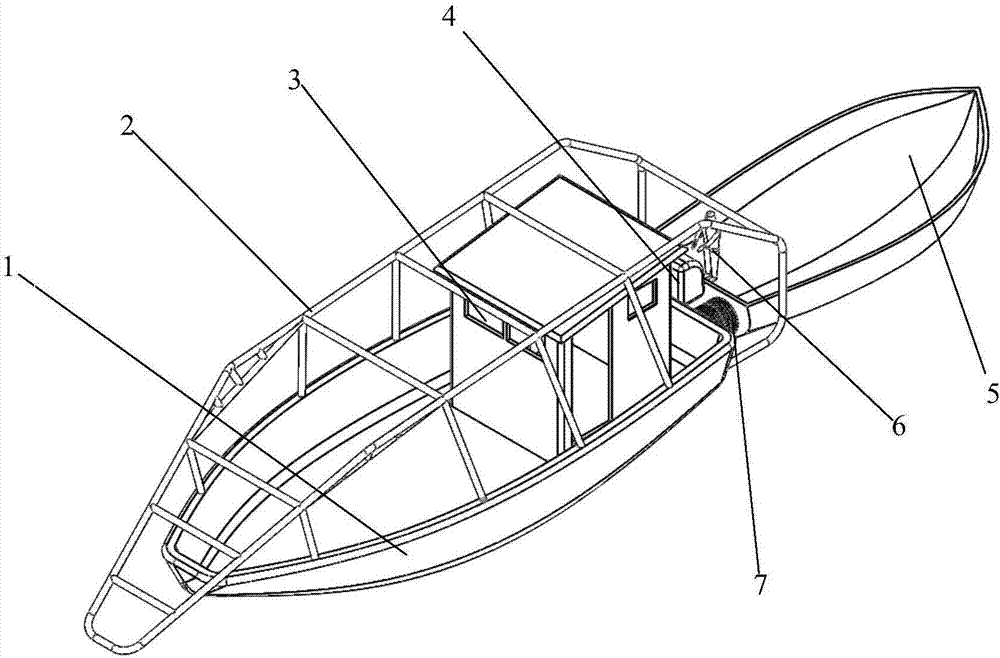

One-drag-one type laminaria japonica harvesting device

InactiveCN107409612ASimple structureImprove harvesting efficiencyTowing/pushing equipmentHarvestersLaminaria japonicaFishery

The invention relates to a one-drag-one type laminaria japonica harvesting device which can achieve continuous harvesting and does not need a special hull. The laminaria japonica harvesting device is integrally designed in a one-drag-one mode, and a transport ship and a laminaria japonica harvesting ship are connected through a mooring rope in a stern-to-stern mode. The transport ship serves as a laminaria japonica harvesting cabin, the transport ship can be replaced so that the situation that the laminaria japonica harvesting ship conducts loading and unloading back and forth can be avoided, and the work efficiency is improved. The laminaria japonica harvesting ship is provided with a detachable laminaria japonica harvesting frame. A laminaria japonica stem rope is lifted by means of the portion, extending into the sea, of the laminaria japonica harvesting frame, and a driving cab provides power for the harvesting ship to move forwards, so that laminaria japonica is conveyed backwards, and workers on the transport ship can disassemble buckles and harvest the laminaria japonica onto the transport ship. After the transport ship is fully loaded, the transport ship is disconnected with the harvesting ship and driven back to the shore, and the standby transport ship can continue to be connected with the harvesting ship for work.

Owner:OCEAN UNIV OF CHINA

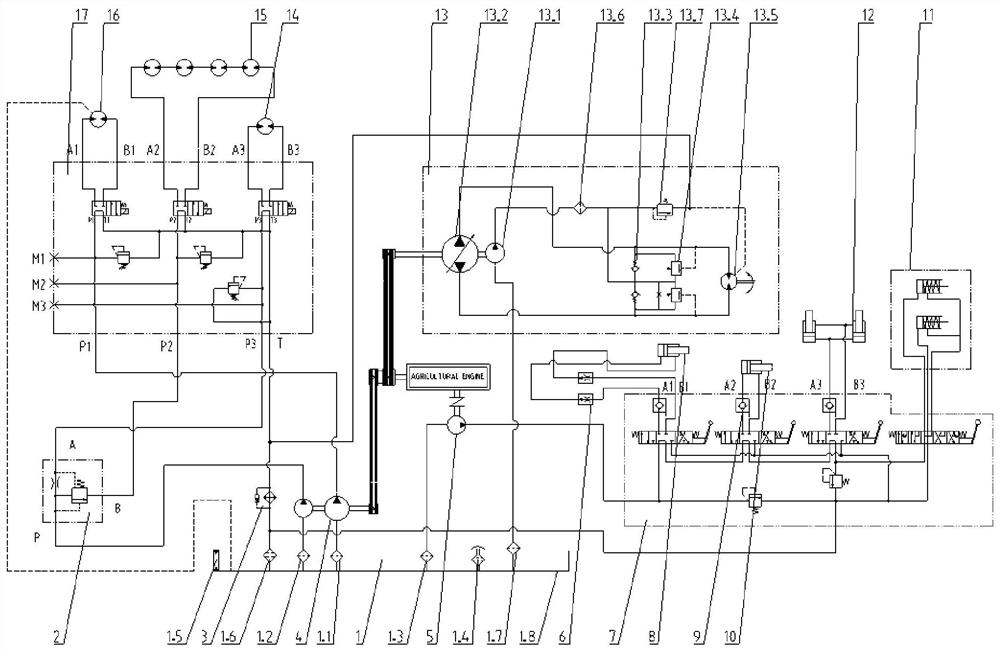

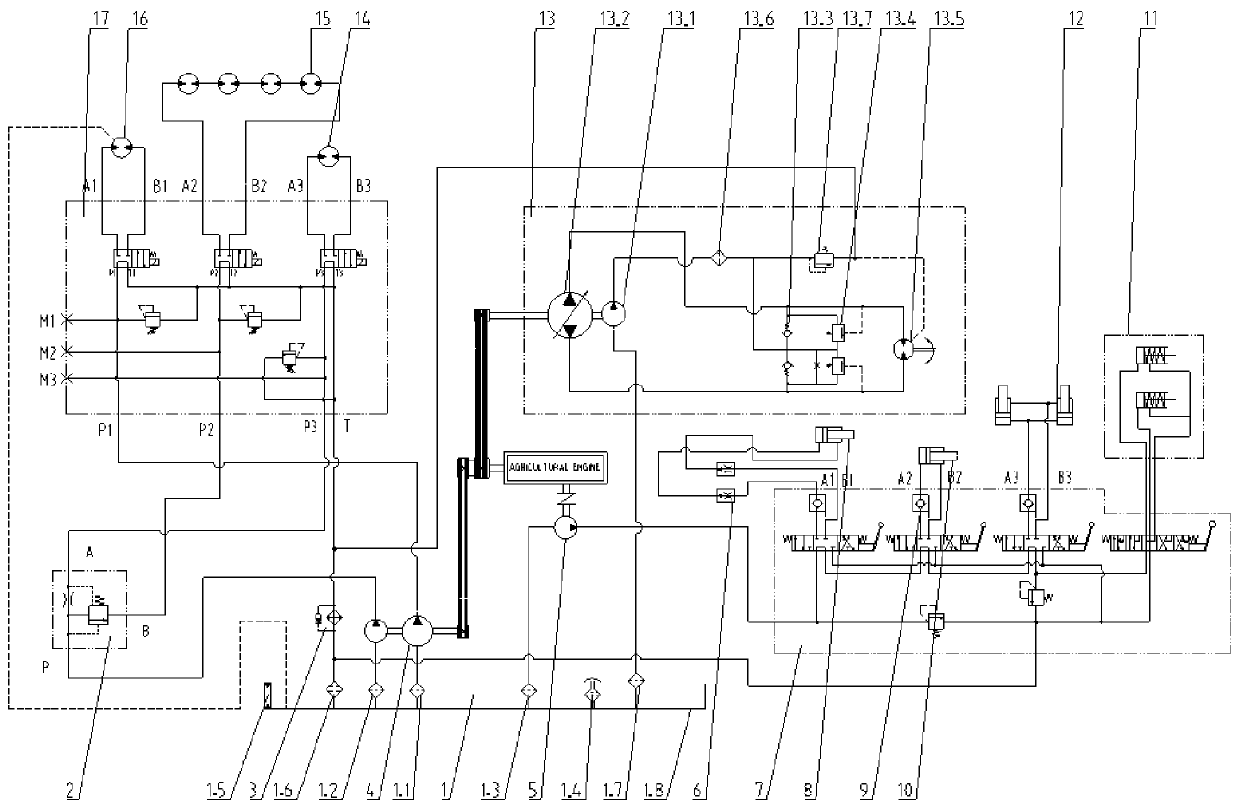

A hydraulic system of a scallion combine harvester and a scallion combine harvester

ActiveCN111357464BRealize automatic continuous harvestingPromote the development of mechanizationDiggersHydraulic motorAgricultural science

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES +1

Hydraulic system of combined harvester of scallions and combined harvester of scallions

ActiveCN111357464ARealize automatic continuous harvestingPromote the development of mechanizationDiggersAgricultural scienceAgricultural engineering

The invention discloses a hydraulic control system of a combined harvester of scallions and relates to the field of agricultural machinery. The hydraulic control system comprises a hydraulic oil tank,a walking control system, an operation control system and an auxiliary operation control system, wherein the walking control system is a closed system, the walking control system, the operation control system and the auxiliary operation control system all communicate with the hydraulic oil tank, and the operation control system and the auxiliary operation control system are open systems; and theoperation control system comprises an electromagnetic reversing valve set and a plurality of hydraulic motor units, and the hydraulic motor units are in parallel connection and are all connected withthe electromagnetic reversing valve set. According to the hydraulic control system, automatic continuous harvesting of the scallions from links such as limited-depth soil loosening, digging conveying,soil removing, gripping and leveling and terminal collecting can be achieved, and the operating efficiency and automation level are increased.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES +1

Method and apparatus for continuously harvesting surrounding meat from a successive plurality animal legs

ActiveUS10952445B2Cumbersome to assembleCumbersome operationPoultry deboningPoultry shacklesAnimal scienceEngineering

Owner:FOODMATE

Method for continuously harvesting ramie fibers

Owner:HUAZHONG AGRI UNIV

Method for cultivating spirulina

The invention discloses a method for cultivating spirulina, which includes constructing the cultivating environment of the spirulina, liquid preparation, nursing during the cultivating process, collecting and harvesting the spirulina, and preserving, first constructing the cultivating environment of the spirulina, and then preparing the culture solution : The composition and weight ratio of the culture medium are: NaHCO310~15Kg, KH2PO40.1~0.9Kg, trace elements 1~8Kg, 1 ton of pure raw water; culture conditions: keep the water temperature at 25°C~35°C, and keep the humidity at 40° ~60°, 24-hour oxygenation and 12 hours of light per day; Harvesting: Rinse the filtered spirulina and test it with pH test paper. It is qualified when it shows neutrality; Supplementary nutrients: After continuous harvesting, proportional The dosage will flow various nutrients into the culture tank to ensure that the algae get sufficient nutrients. When the pH value of the culture solution rises to 11, NaHCO3 is added to keep the pH value of the culture solution within 8-11. Continuous cultivation and harvesting , to keep the spirulina at a certain density, add NaHCO3 to stabilize the pH value of the culture medium, and promote the rapid growth and reproduction of algae in the culture medium.

Owner:SHOUGUANG FUKANG PHARMA

Potato harvester

The invention discloses a potato harvester. The potato harvester comprises a first machine frame and a second machine frame, a bottom beam is fixedly arranged on the inner side of the bottom of the first machine frame, a plurality of plough shovel assemblies with the adjustable positions sleeve the bottom beam, machine wheels are rotationally installed on the two sides of the first machine frame, and vibration transmission assemblies are fixedly installed at the two ends of the bottom beam; vibration separation assemblies are movably connected with the power output ends of the vibration transmission assemblies; a conveying device is arranged on the side, close to the first machine frame, of the second machine frame, a plurality of evenly-distributed strip-shaped material grooves are formed in the conveying device, an obliquely-arranged material gathering groove is formed in the lower part of the side, away from the first machine frame, of the top end of the conveying device, and a spiral material screening assembly which is rotationally installed on the second machine frame and is in transmission connection with the conveying device is arranged below the discharging end of the material gathering groove. The potato harvester is simple in structure, a grading type separation mode is adopted, potato mechanical continuous harvesting is achieved, meanwhile, soil smashing and ploughing can be achieved, and potato picking and later crop planting are facilitated.

Owner:青海省农牧机械推广总站

Leaf vegetable whole-plant continuous harvester suitable for ridging type planting and harvesting method

The invention relates to a leaf vegetable whole-plant continuous harvester suitable for ridging type planting. The continuous harvester comprises a rack, a vibrating root cutting device, a staggered clamping and conveying device, a profiling damping device and a walking device. The rack is used for supporting and fixing other devices. The vibrating root cutting device is used for generating vibration and cutting off roots of leaf vegetable; the staggered clamping and conveying device is used for clamping and conveying the leaf vegetables; the profiling damping device is used for keeping the conveying device to run stably, and the walking device is used for providing power for the whole machine. By means of clamping conveying belt sets arranged in a staggered mode, the requirement for seeding can be greatly reduced, and effective low-loss harvesting can be achieved for the leaf vegetables which do not align to each other.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com