Intelligent control test device and test method for continuous harvesting of whole green-leaf vegetables

A technology of intelligent control and test device, applied in the direction of measuring device, program control, computer control, etc., can solve the problems of mechanical damage, lack of monitoring of green leafy harvesting process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

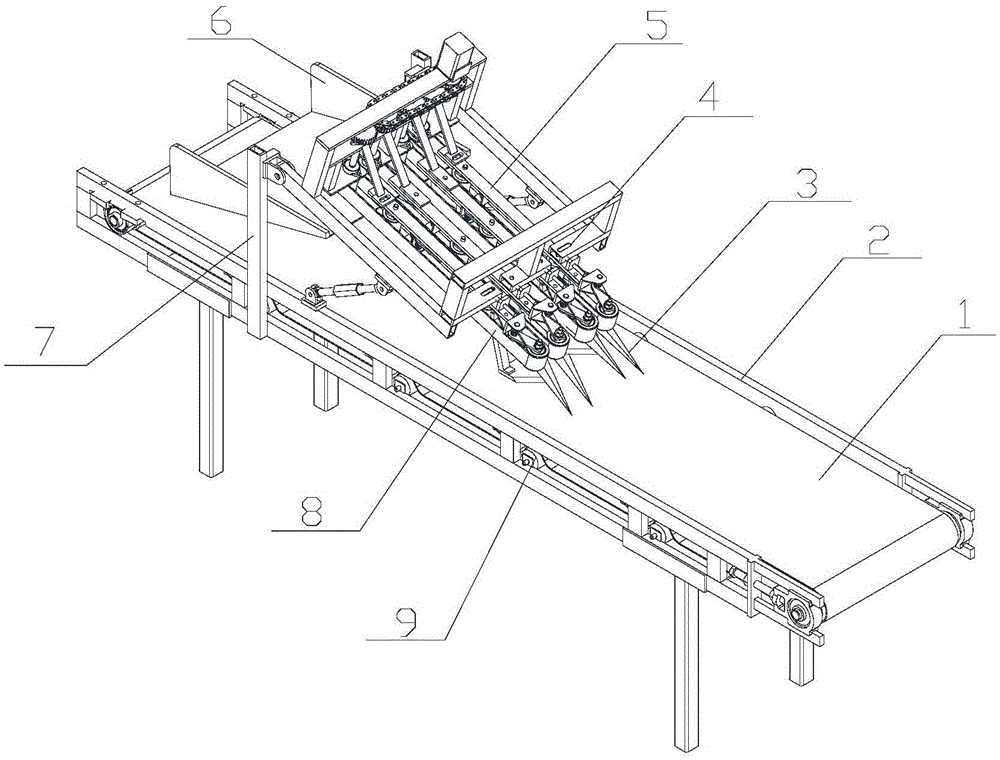

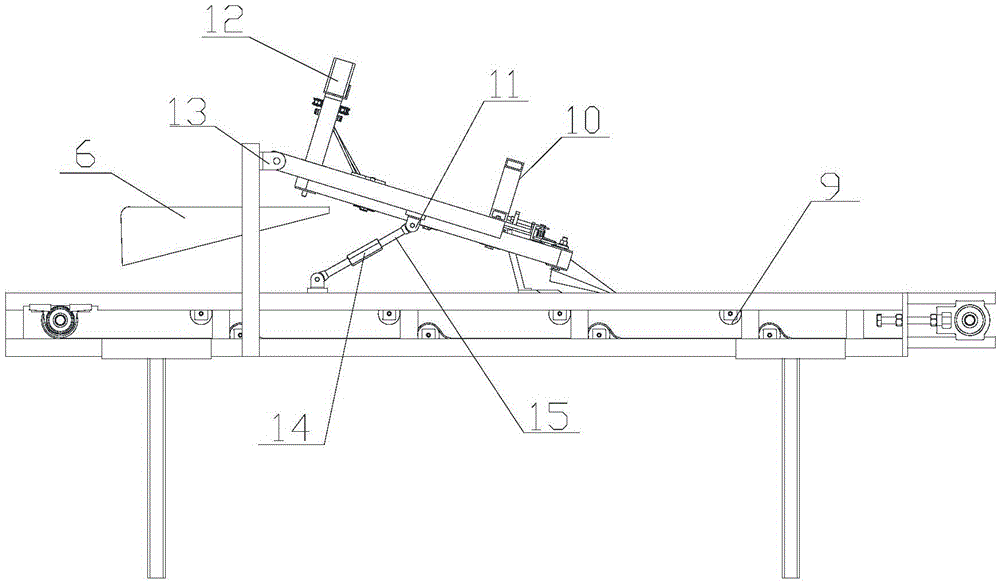

[0029] Below in conjunction with accompanying drawing, the patent of the present invention is further described. like figure 1 As shown, the conveying device includes a conveyor belt (1), a conveying motor, a driving roller, an idler roller (9), a driven roller and a fixed frame (2); the driving roller and the driven roller are installed on the fixed frame ( 2) above; the conveying motor provides power, and the driving roller drives the conveyor belt (1) to run; the conveying device is located below the plant clamping device, and the planting boxes transported by the conveying device pass through the plant clamping device at a certain speed.

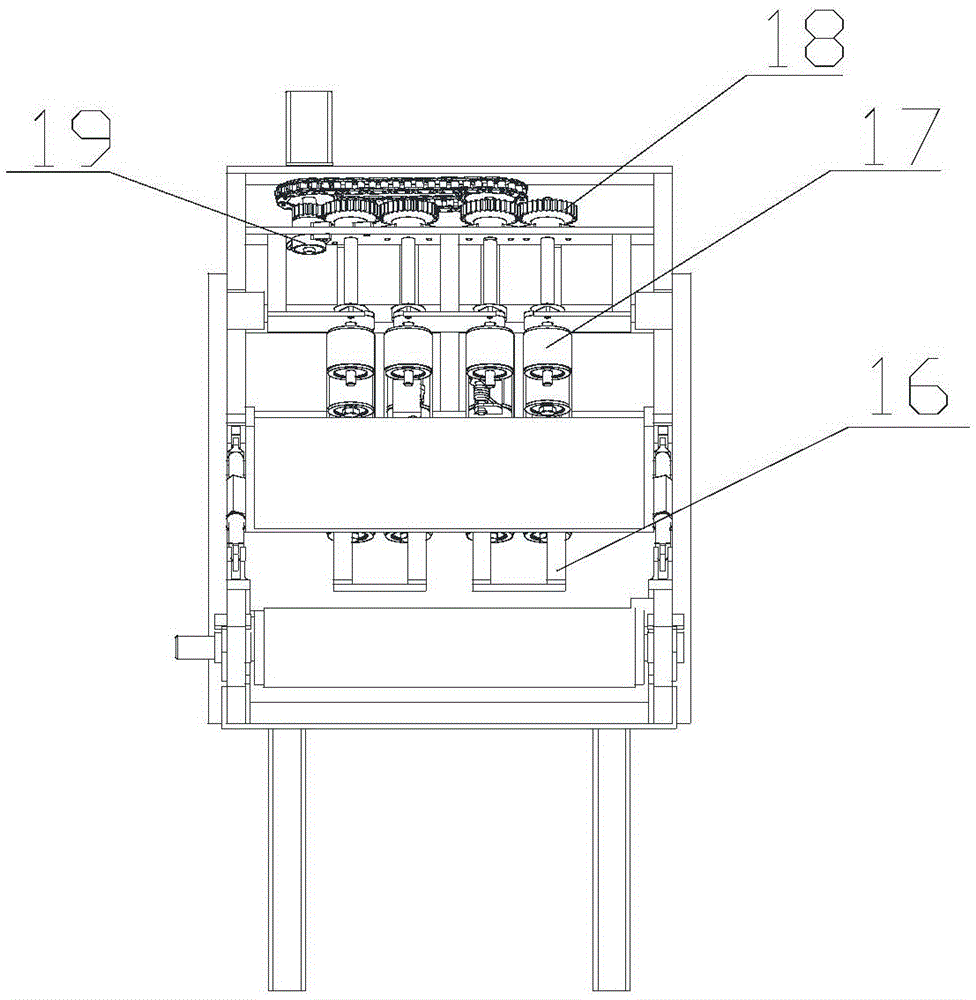

[0030] like figure 1 , 2, 3, 4, and 5, the plant clamping device includes a bracket and a clamping assembly. The support of the plant clamping device is hingedly connected with the vertical rod (7) fixed on the fixed frame of the conveying device; the clamping assembly is a left-right symmetrical structure, wherein the right clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com