Foam concentration and harvest device for microalgae

A foam and microalgae technology, applied in the field of microalgae harvesting, can solve the problems of the micro-bubble technology that needs to be improved, the performance of the flocculant is not ideal, and has not appeared, and achieves the effects of simple structure, reduced labor cost, and improved utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

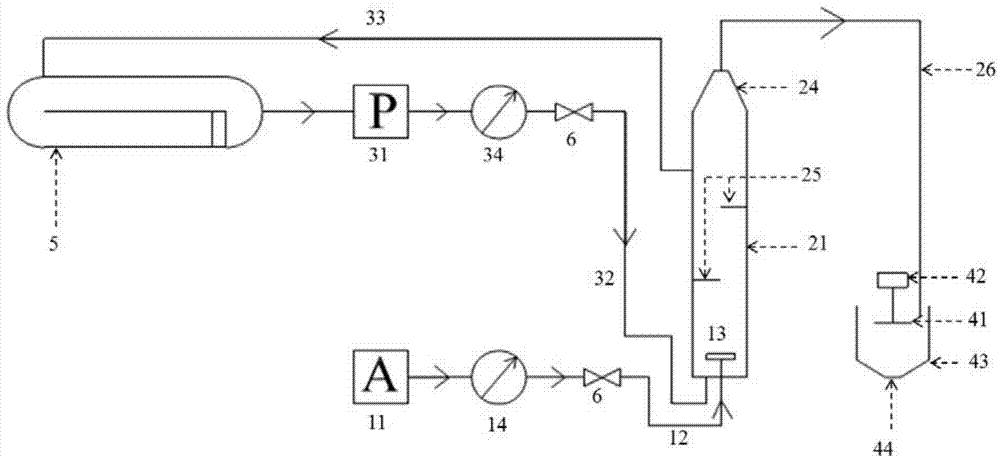

[0070] Embodiment one is used for the concentrated collection of self-produced foam microalgae

[0071] On the basis of following the patent principle of the present invention, a small-scale foam concentration and recovery equipment with a concentration tower volume of 36L is designed and used in the recovery of a self-produced foam microalgae. Please refer to Figure 1-3 As shown, the optical density (OD 700 ) is 2.0, after being concentrated by the recovery device, the optical density (OD 700) is 40.0, the concentration ratio can reach 20, and the concentrated algae liquid can be directly used in the development of bait products. If the concentrated algae liquid is harvested through the centrifuge again, the harvesting cost can be saved by at least 10 times.

Embodiment 2

[0072] Embodiment two is used for the concentrated collection of non-self-produced foam microalgae

[0073] The device of the present invention can not only be used for harvesting self-produced foam microalgae, but also can be used for harvesting non-self-produced foam microalgae. By adding an appropriate concentration, non-toxic, and low-cost foaming agent and foam stabilizer to the algae liquid to be concentrated, more types of microalgae in nature can be concentrated and harvested.

Embodiment 3

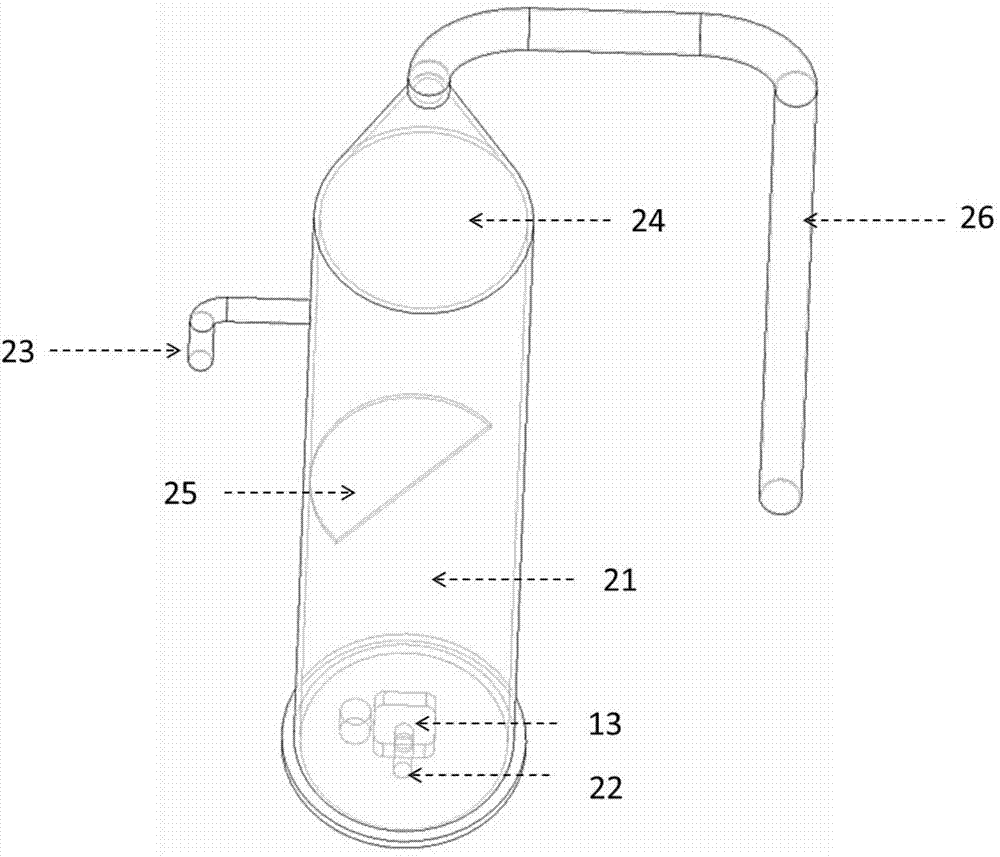

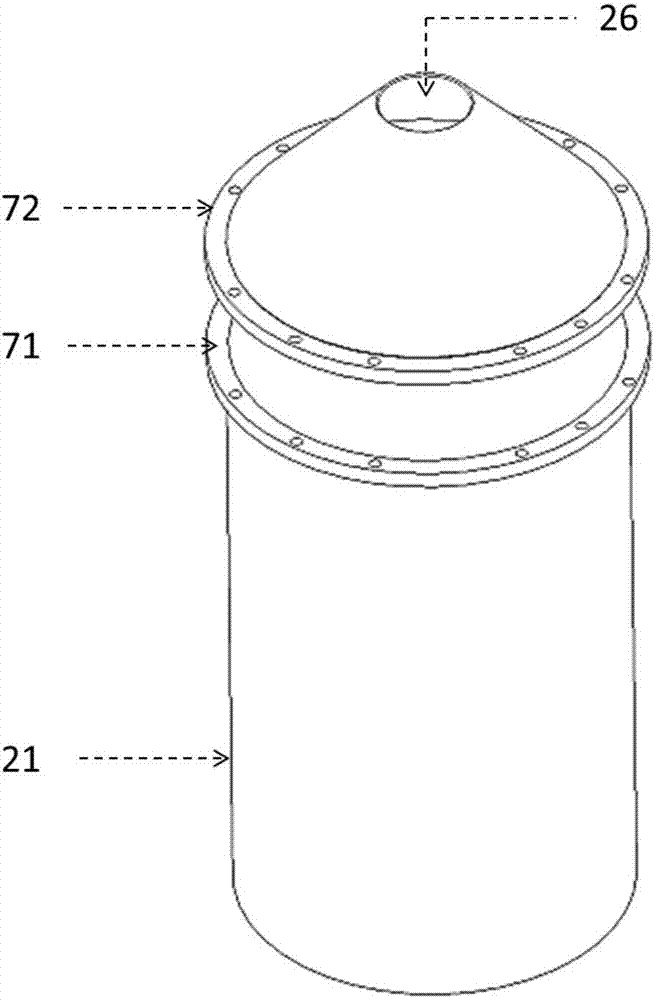

[0074] Example 3 A small-scale concentrated recovery device for the study of recovery mechanism and condition optimization

[0075] On the basis of following the principles of the patent of the present invention, a small concentration and recovery device is designed for laboratory basic theoretical research and condition optimization, see Figure 4 , is a preferred embodiment for this purpose. It integrates the bubble generating unit and the liquid flow circulation unit, through the bubble generating unit and the liquid flow circulation unit, the control of parameters such as the size of the bubble, the flow rate of the bubble, and the flow rate of the algae liquid can be easily realized, and at the same time, the type and quantity of the gas distributor can be controlled. optimization research.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com