Method for preparing edible fungus culture medium from camellia oleifera shells

A technology of cultivation substrate and Camellia oleifera shell, applied in the directions of botanical equipment and methods, cultivation, plant cultivation, etc., can solve the problems of limiting the harvesting times of edible fungi, too fast release of fertility, insufficient nutrients, etc., so as to improve slow-release and controlled fertilizer effect, the effect of increasing porosity and specific surface area, and the effect of not producing drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

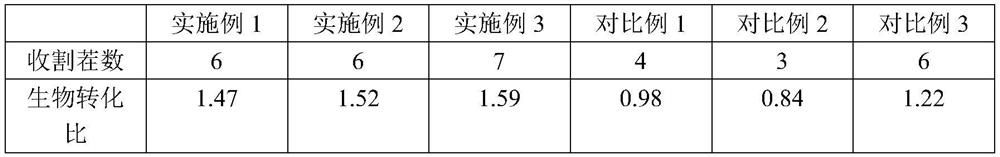

Examples

Embodiment 1

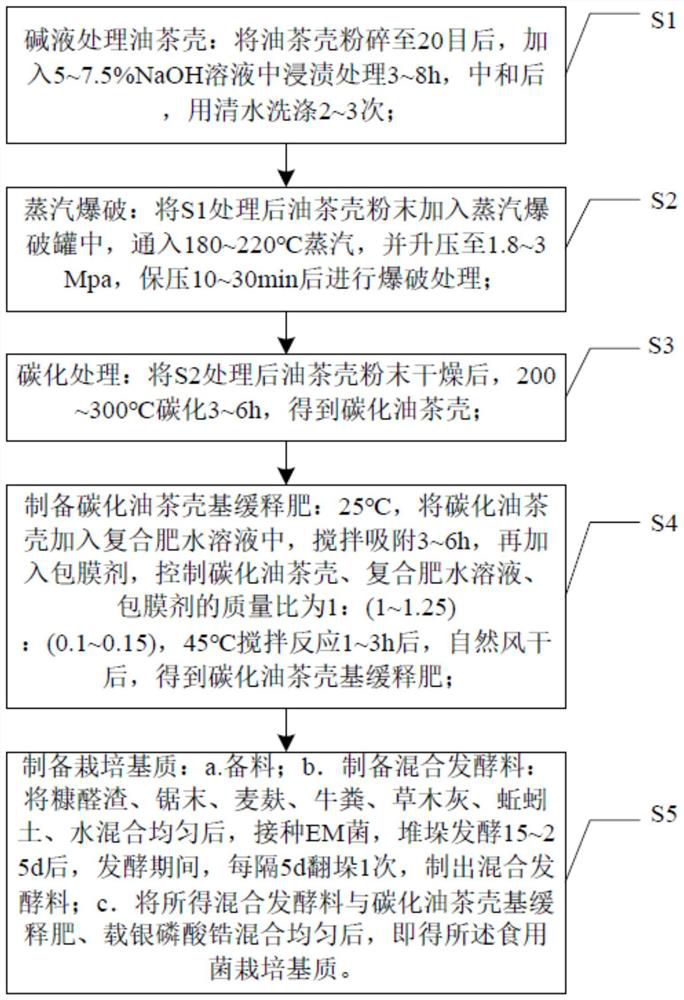

[0026] Camellia oleifera husk prepares edible fungus cultivation substrate method, comprises the following steps:

[0027] S1: Treatment of camellia oleifera shells with lye: crush the camellia oleifera shells to 20 mesh, add 5% NaOH solution for immersion treatment for 3 hours, and wash twice with water after neutralization;

[0028] S2: Steam explosion: put the camellia oleifera husk powder treated in S1 into the steam explosion tank, introduce steam at 180°C, and increase the pressure to 1.8Mpa, hold the pressure for 10 minutes, and then carry out blasting treatment;

[0029] S3: carbonization treatment: dry the camellia oleifera shell powder treated in S2, and carbonize at 200°C for 3 hours to obtain carbonized camellia oleifera shell;

[0030] S4: Preparation of carbonized camellia oleifera shell-based slow-release fertilizer:

[0031] a. Prepare the aqueous solution of compound fertilizer: dissolve urea and ammonium phosphate in water according to the mass ratio of 0.8:...

Embodiment 2

[0039] Camellia oleifera husk prepares edible fungus cultivation substrate method, comprises the following steps:

[0040] S1: Alkaline treatment of camellia oleifera shells: crush the camellia oleifera shells to 20 mesh, add 6% NaOH solution for immersion treatment for 6 hours, and wash 3 times with water after neutralization;

[0041] S2: Steam explosion: put the camellia oleifera husk powder treated in S1 into the steam explosion tank, introduce steam at 200°C, and increase the pressure to 2.4Mpa, hold the pressure for 20 minutes, and then carry out blasting treatment;

[0042] S3: carbonization treatment: dry the camellia oleifera shell powder treated in S2, and carbonize at 250°C for 5 hours to obtain carbonized camellia oleifera shell;

[0043] S4: Preparation of carbonized camellia oleifera shell-based slow-release fertilizer:

[0044] a. Prepare the aqueous solution of compound fertilizer: dissolve urea and ammonium phosphate in water according to the mass ratio of 0....

Embodiment 3

[0052] Camellia oleifera husk prepares edible fungus cultivation substrate method, comprises the following steps:

[0053] S1: Alkaline treatment of camellia oleifera shells: crush the camellia oleifera shells to 20 meshes, add 7.5% NaOH solution for immersion treatment for 8 hours, and wash 3 times with water after neutralization;

[0054] S2: Steam explosion: Put the camellia oleifera husk powder treated in S1 into the steam explosion tank, introduce steam at 220°C, and increase the pressure to 3Mpa, hold the pressure for 30 minutes, and then perform blasting treatment;

[0055] S3: carbonization treatment: dry the camellia oleifera shell powder treated in S2, and carbonize at 300°C for 6 hours to obtain carbonized camellia oleifera shell;

[0056]S4: Preparation of carbonized camellia oleifera shell-based slow-release fertilizer:

[0057] a. Prepare an aqueous solution of compound fertilizer: dissolve urea and ammonium phosphate in water according to a mass ratio of 1:0.25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com