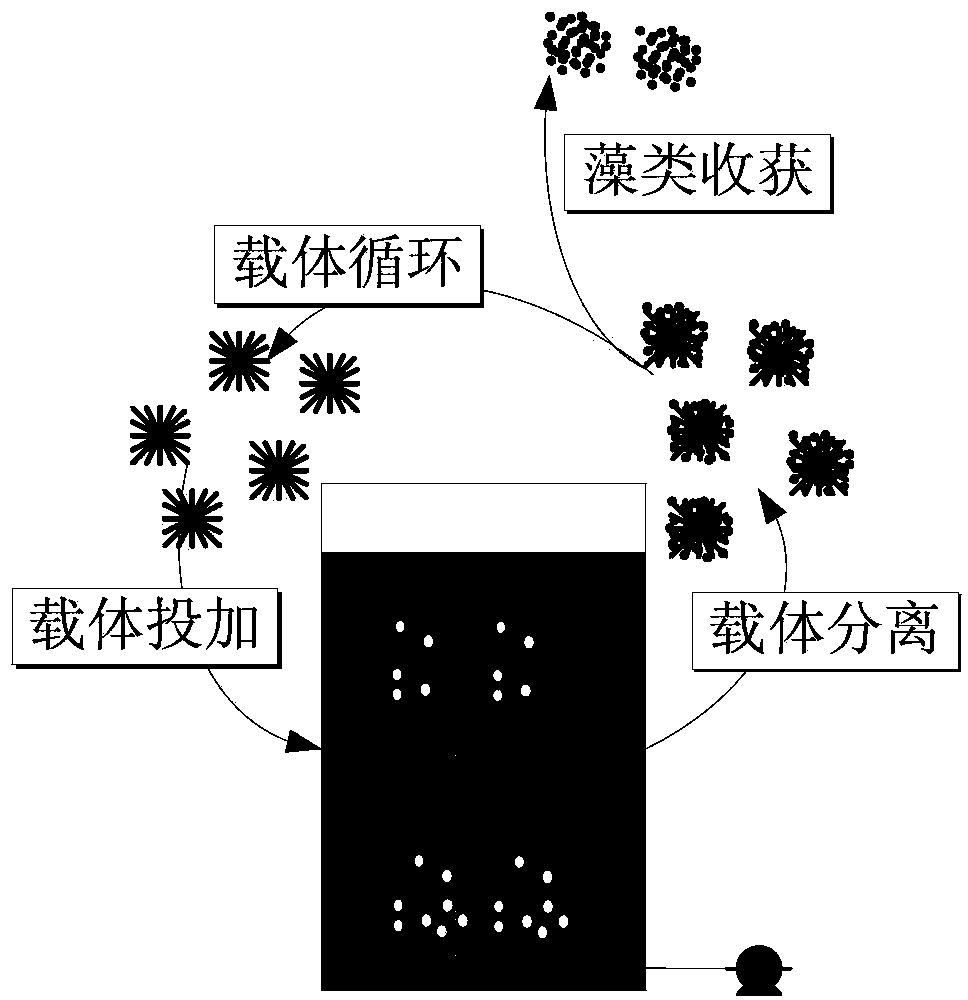

Microalgae suspension-adhesion mixed culture and separated harvesting method based on suspended carrier

A technology of mixed culture and harvesting method, which is applied in the field of production and harvesting of microalgae and related products, can solve the problems of complex operation, uneconomical chemicals, unstable fixation of longitudinal algae film, and restrictions on large-scale application, so as to improve the resistance The effect of environmental interference ability, saving the cost of using medicine, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

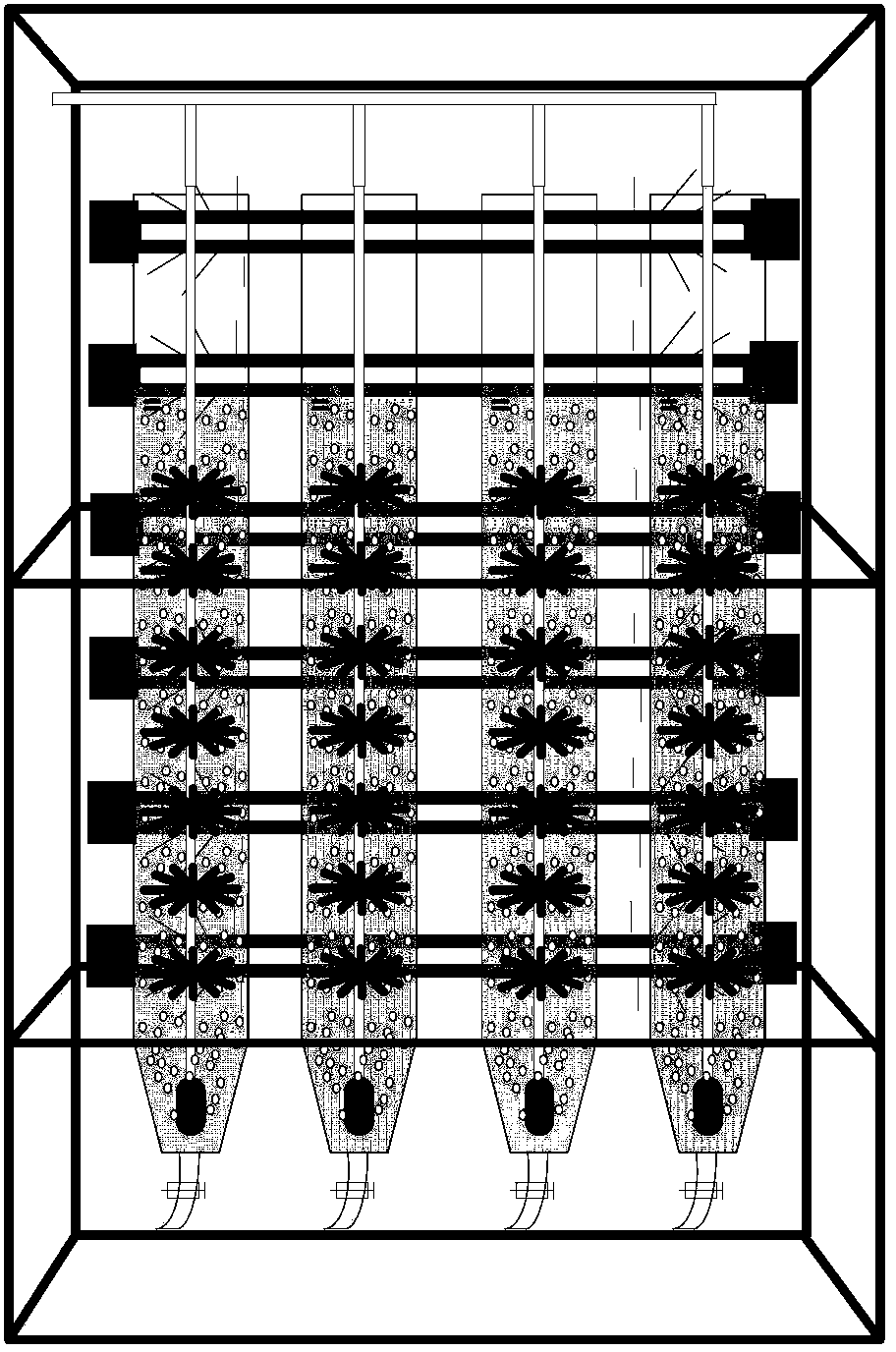

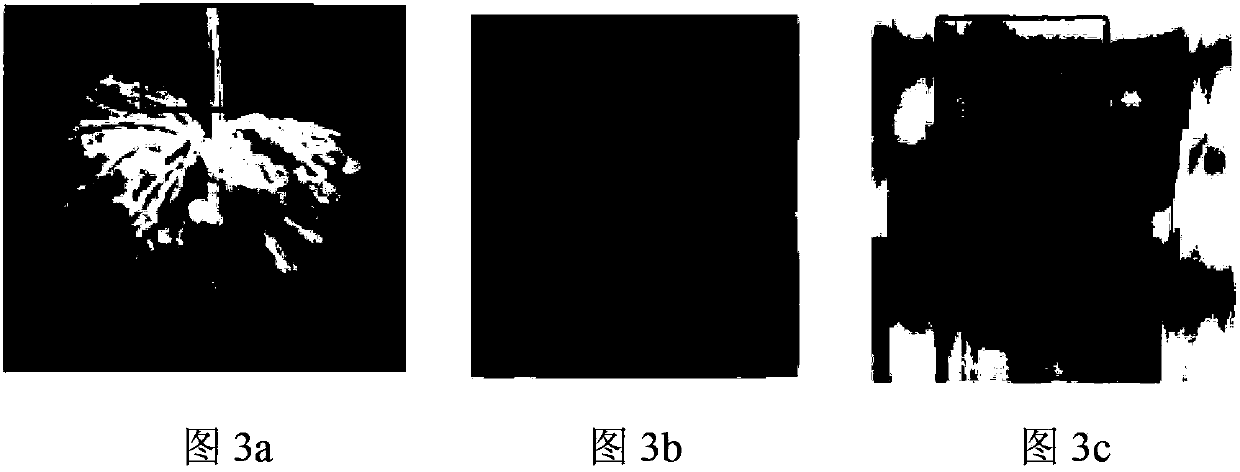

[0031] Such as figure 2 As shown, the microalgae are cultivated in a cylindrical suspended carrier photobioreactor, and the suspended carrier and the algae cells have a certain relative movement by aeration at the bottom. Inoculate Scenedesmus S.LX1 into the prepared mBG11, the initial concentration is about 1×10 4 pcs / ml, with a total volume of 4L, add 6 suspension carriers (each suspension carrier is bundled by 100×15cm fiber materials) and place them in a photobiological reaction column for aerated culture, where the light-dark ratio is 14:10, and the light Strong 800~1300Lux, temperature is room temperature. The algal cell attachment on the carrier changes as image 3 As shown, after 2 days of culture, the solid phase algae film first appeared, about 2.0×10 5 pcs / cm carrier. After 10 days of culture, the algae density in the liquid phase can reach 3.4×10 6 cells / mL, the solid-phase algae cell density can reach 4.2×10 6 pcs / cm carrier.

Embodiment 2

[0033] Such as Figure 4 As shown, microalgae are cultivated in a cuboid fully aerated suspension-type carrier photobioreactor, and the volume of the liquid phase in the reactor is about 8L. In this embodiment, the bottom side aeration method (air or carbon dioxide-containing air) is adopted to make the suspended microalgae and the carrier flow in the reactor. Microalgae are attached to the surface of the carrier, and with the circulation of the fluid, they are periodically exposed to sunlight for photosynthesis. During the aeration process, the motility of algal cells is increased, that is, the probability of algal cells being captured and attached to the carrier is increased. The algal cells on the carrier can use the carbon dioxide supplemented during the aeration process to achieve regrowth after attachment, making the carrier The thickness of the algae film on the surface increases, which is convenient for harvesting. Formed algae film under the optical microscope metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com