A hydraulic system of a scallion combine harvester and a scallion combine harvester

A combine harvester and hydraulic control system technology, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of easy failure, poor reliability and stability, etc., so as to improve operating efficiency and save system Resources, the effect of improving operational efficiency and automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

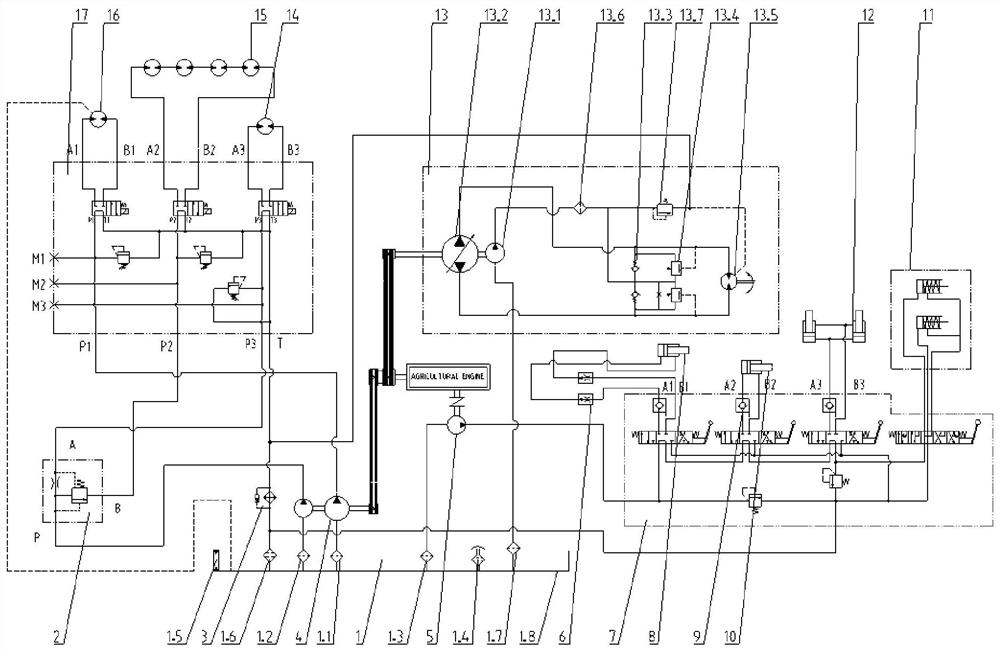

[0035] In a typical embodiment of the present invention, such as figure 1 As shown, a hydraulic control system of a scallion combine harvester includes three parts: a travel control system, an operation control system and an auxiliary manipulation control system;

[0036] Among them, the walking control system adopts HST hydraulic transmission technology, including hydraulic oil tank 1, charge pump 13.1, two-way variable plunger pump 13.2, one-way valve 13.3, work safety pressure limiting valve 13.4, quantitative plunger motor 13.5, pressure oil Oil filter 13.6, oil charge overflow valve 13.7 and cooler 3, the specific connection relationship is that one end of oil charge pump 13.1 is connected to hydraulic oil tank 1 through a pipeline, and the pipeline connecting oil charge pump 13.1 to the travel control system is sequentially provided with pressure oil filter oil The pipeline between the pressure oil filter 13.6 and the oil relief valve 13.7 is connected to the circulation...

Embodiment 2

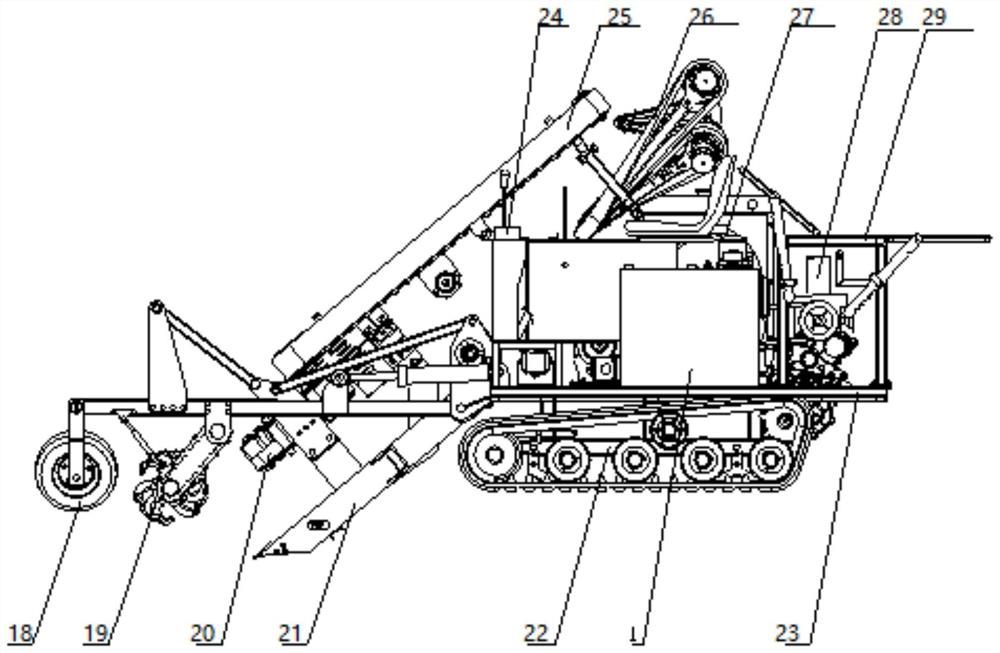

[0046] In a typical embodiment of the present invention, such as figure 2 Shown, a kind of scallion combine harvester comprises a kind of scallion combine harvester hydraulic control system and the scallion combine harvester main body as described in embodiment 1.

[0047] The onion combine harvester main body includes a depth-limiting wheel 18, a ripper 19, a primary clamping device 20, a loose soil-bottom conveying device 21, a walking device 22, a frame 23, a console 24, a clamping conveying device 25, Smoothing device 26, engine 27, HST transmission device 28 and finishing platform 29, its specific connection relationship is, depth-limiting wheel 18 and scarifier 19 connect depth-limiting loosening mechanism lifting oil cylinder 12, loosening-bottom conveying device 21 connects loosening Soil-bottom conveying and soil-removing motor 16, traveling device 22 connected to quantitative plunger motor 13.5, clamping conveying device 25 connected to terminal conveying motor 14. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com