Preparation method and application of phase change-infrared stealth difunctional composite microcapsule

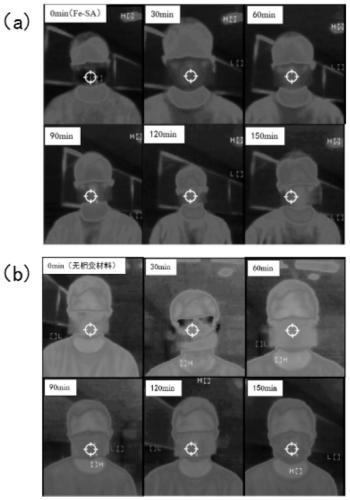

A composite microcapsule, dual-function technology, applied in applications, chemical instruments and methods, special coats, etc., can solve the problems of low emissivity infrared stealth coatings, easy to be oxidized and corroded, and the stealth effect is not strong, and achieve stealth effect. Good, eliminates adverse effects, and has a long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

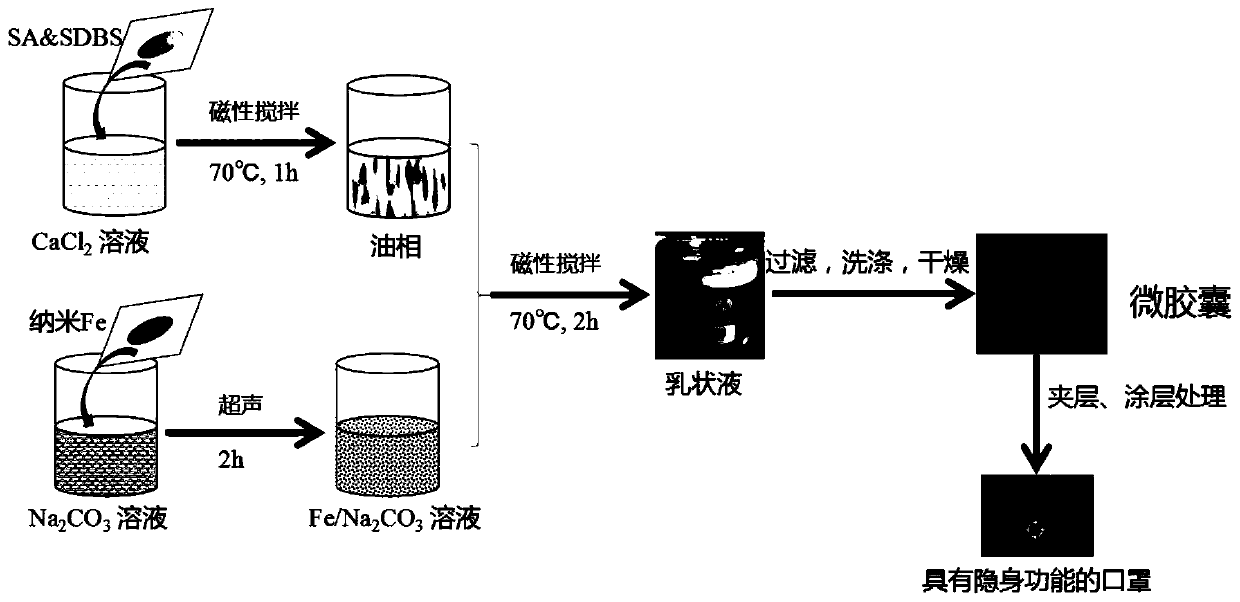

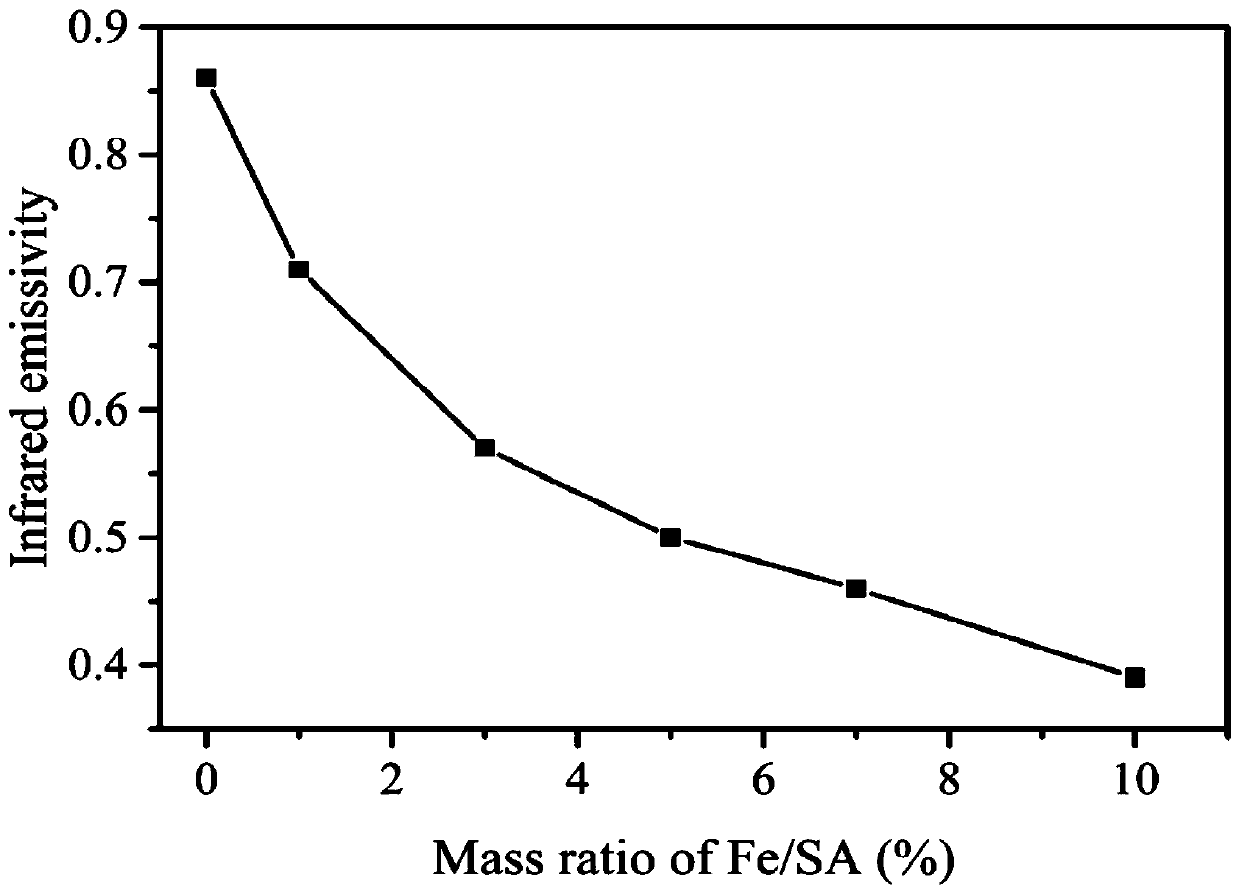

[0032] (1) Dissolve 4.00 g of stearic acid, 0.12 g of sodium dodecylbenzenesulfonate and 1.48 g of calcium chloride in 100 ml of deionized water, and stir at 70° C. with a magnetic stirrer for 60 minutes to obtain component A;

[0033] (2) Dissolve 1.41g of sodium carbonate in 20ml of deionized water, and stir at room temperature for 10min to obtain component B;

[0034] (3) Add 0.04g of nano-iron powder to the component B described in step (2), and use an ultrasonic instrument to ultrasonically disperse for 120min to obtain component C;

[0035] (4) Slowly add component C obtained in step (3) dropwise to component A described in step (1), and stir at 70° C. with a magnetic stirrer for 120 minutes to obtain microcapsule liquid;

[0036] (5) After standing for 12 hours, filter the microcapsule liquid, and wash the filter residue 3 times with absolute ethanol and deionized water respectively, and finally dry at 60°C for 12 hours in a drying oven to obtain a microcapsule powder s...

Embodiment 2

[0038] (1) Dissolve 4.00 g of stearic acid, 0.12 g of sodium dodecylbenzenesulfonate and 1.48 g of calcium chloride in 100 ml of deionized water, and stir at 70° C. with a magnetic stirrer for 60 minutes to obtain component A;

[0039] (2) Dissolve 1.41g of sodium carbonate in 20ml of deionized water, and stir at room temperature for 10min to obtain component B;

[0040] (3) Add 0.12g of nano-iron powder to component B described in step (2), and use an ultrasonic instrument to ultrasonically disperse for 120 minutes to obtain component C;

[0041] (4) Slowly add component C obtained in step (3) dropwise to component A described in step (1), and stir at 70° C. with a magnetic stirrer for 120 minutes to obtain microcapsule liquid;

[0042] (5) After standing for 12 hours, filter the microcapsule liquid, and wash the filter residue 3 times with absolute ethanol and deionized water respectively, and finally dry at 60°C for 12 hours in a drying oven to obtain a microcapsule powder ...

Embodiment 3

[0044] (1) Dissolve 4.00 g of stearic acid, 0.12 g of sodium dodecylbenzenesulfonate and 1.48 g of calcium chloride in 100 ml of deionized water, and stir at 70° C. with a magnetic stirrer for 60 minutes to obtain component A;

[0045] (2) Dissolve 1.41g of sodium carbonate in 20ml of deionized water, and stir at room temperature for 10min to obtain component B;

[0046] (3) Add 0.20 g of nano-iron powder to component B described in step (2), and ultrasonically disperse for 120 minutes with an ultrasonic instrument to obtain component C;

[0047] (4) Slowly add component C obtained in step (3) dropwise to component A described in step (1), and stir at 70° C. with a magnetic stirrer for 120 minutes to obtain microcapsule liquid;

[0048] (5) After standing for 12 hours, filter the microcapsule liquid, and wash the filter residue 3 times with absolute ethanol and deionized water respectively, and finally dry at 60°C for 12 hours in a drying oven to obtain a microcapsule powder s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com