Pesticide packaging bottle and preparation method thereof

A technology for packaging bottles and pesticides, applied in the field of pesticide packaging containers, can solve problems such as unsatisfactory heat resistance, thermal expansion of pesticide bottles, and detachment of the bottom of the bottle, and achieve the effects of good heat insulation capability, improved adhesion, and prevention of thermal expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

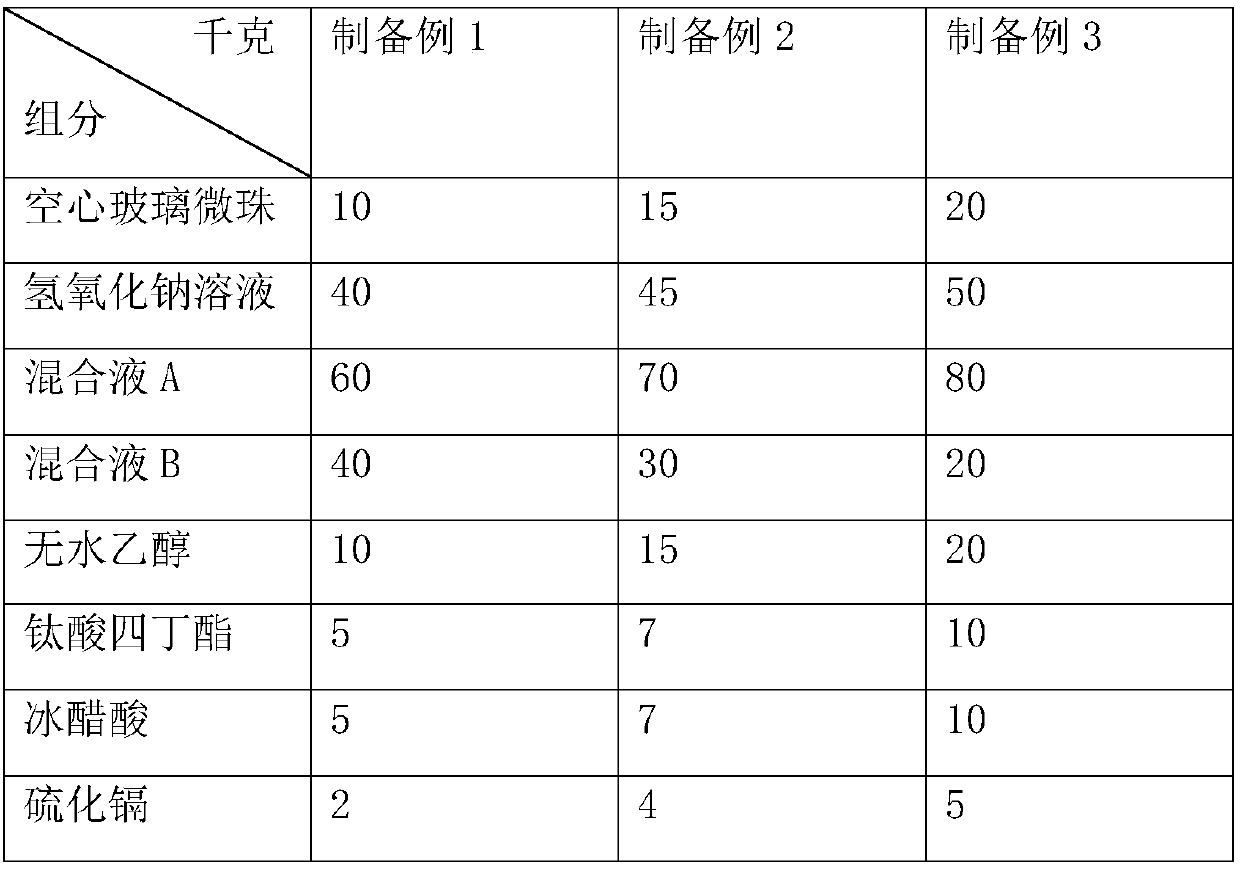

[0044] Preparation Example 1: (1) According to the proportioning in Table 1, put 10 kg of hollow glass microspheres with a particle size of 10 μm into 40 kg of 8% sodium hydroxide solution and stir for 10 h, then wash and dry;

[0045] (2) preparation mass fraction is the mixed solution A of zinc nitrate and isopropanol of 1.12%, mass fraction is the mixed solution B of 0.45% sodium hydroxide and isopropanol, gets 60 kilograms of mixed solution A and 40 kilograms of mixed solution B. Mix evenly to form a mixed solution C. Put the hollow glass microspheres treated in step (1) into the mixed solution C, stir at 40°C for 20 minutes, filter with suction, dry, calcinate at 420°C for 10 minutes, and then cool to room temperature;

[0046] (3) getting 10 kilograms of mass fraction is 2.5% dehydrated alcohol, 5 kg of mass fraction is 1.1% tetrabutyl titanate and 5 kg of mass fraction is 1.4% glacial acetic acid, 2 kg of mass fraction is 1.2% vulcanization Put cadmium in the reactor, ...

preparation example 2

[0047] Preparation Example 2: (1) According to the proportioning in Table 1, 15 kg of hollow glass microspheres with a particle size of 15 μm were put into 45 kg of 9% sodium hydroxide solution and stirred for 11 h, washed and dried;

[0048] (2) preparation mass fraction is the mixed solution A of zinc nitrate and isopropanol of 1.18%, mass fraction is the mixed solution B of 0.48% sodium hydroxide and isopropanol, gets 70 kilograms of mixed solution A and 30 kilograms of mixed solution B. Mix evenly to form a mixed solution C. Put the hollow glass microspheres treated in step (1) into the mixed solution C, stir at 45°C for 25 minutes, filter with suction, dry, calcinate at 440°C for 13 minutes, and then cool to room temperature;

[0049] (3) getting 15 kilograms of mass fraction is 2.9% dehydrated alcohol, 7 kg of mass fraction is 1.3% tetrabutyl titanate and 7 kg of mass fraction is 1.6% glacial acetic acid, 4 kg of mass fraction is 1.3% vulcanization Put cadmium in the re...

preparation example 3

[0050] Preparation Example 3: (1) According to the proportioning in Table 1, put 20 kg of hollow glass microspheres with a particle size of 20 μm into 50 kg of 10% sodium hydroxide solution and stir for 12 hours, then wash and dry;

[0051] (2) preparation mass fraction is the mixed solution A of zinc nitrate and isopropanol of 1.25%, mass fraction is the mixed solution B of 0.5% sodium hydroxide and isopropanol, gets 80 kilograms of mixed solution A and 20 kilograms of mixed solution B. Mix evenly to form a mixed solution C. Put the hollow glass microspheres treated in step (1) into the mixed solution C, stir at 50°C for 30 minutes, filter with suction, dry, calcinate at 450°C for 15 minutes, and then cool to room temperature;

[0052] (3) 20 kilograms of mass fraction is 3.2% dehydrated alcohol, 10 kg of mass fraction is 1.4% tetrabutyl titanate and 10 kg of mass fraction is 1.8% glacial acetic acid, 5 kg of mass fraction is 1.5% vulcanization Put cadmium in the reactor, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com