Fluorine-containing polyimide composite film material with low infrared emissivity and preparation method thereof

A technology of fluorine-containing polyimide and polyimide film, applied in the field of fluorine-containing polyimide infrared low emissivity composite film material and its preparation, can solve the problems of low emissivity and inability to implement infrared stealth , to achieve the effect of excellent film-forming performance, excellent compatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

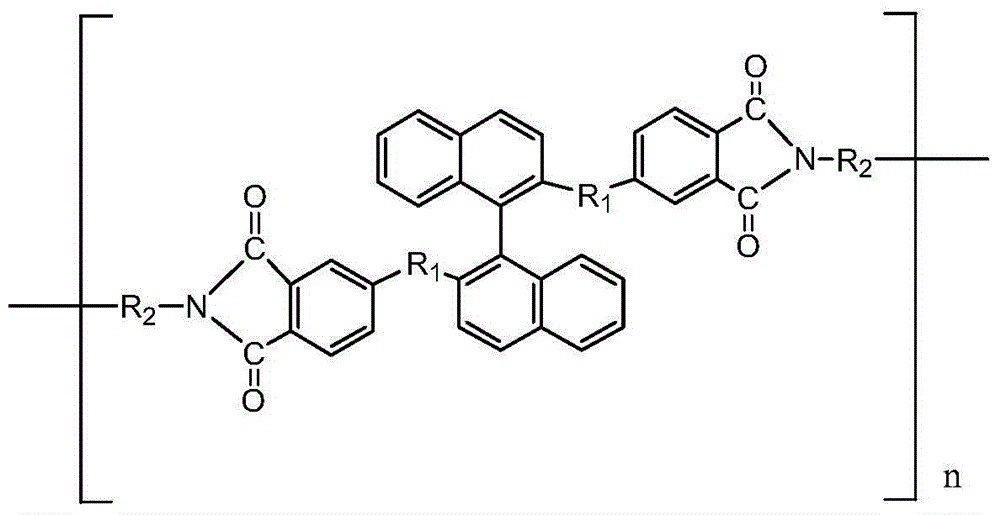

[0051] In this embodiment, the infrared low-emission composite film is composed of a fluorine-containing polyimide film and ITO, wherein the structural formula of the fluorine-containing polyimide is exactly the same as that of the fluorine-containing polyimide film in Comparative Example 1, That is:

[0052]

[0053] ITO is dispersed in fluorine-containing polyimide film-forming resin as crystal phase powder to form a multi-phase solid film; the mass ratio of fluorine-containing polyimide to ITO is 9.5:0.5.

[0054] The preparation method of above-mentioned composite film is as follows:

[0055] (1) Utilizing the preparation method in Comparative Example 1 to prepare a fluorine-containing polyimide film;

[0056] (2) Take 8g of fluorine-containing polyimide film and dissolve it in 150mL of DMAc organic solvent, add ITO to the obtained clear liquid, in which the mass ratio of fluorine-containing polyimide to ITO is 9.5:0.5, and ultrasonically vibrate for 20 minutes to make...

Embodiment 2

[0059] In this embodiment, the infrared low-emission composite film is composed of a fluorine-containing polyimide film and ITO, wherein the structural formula of the fluorine-containing polyimide film is exactly the same as that of the fluorine-containing polyimide film in Example 1. ITO is dispersed in fluorine-containing polyimide film-forming resin as crystal phase powder to form a multi-phase solid film; the mass ratio of fluorine-containing polyimide to ITO is 9:1.

[0060] The preparation method of above-mentioned composite film is as follows:

[0061] (1) Using the preparation method in Example 1 to prepare a fluorine-containing polyimide film;

[0062] (2) Take 8 g of fluorine-containing polyimide film and dissolve it in 150 mL of DMAc organic solvent, add ITO to the obtained clear solution, wherein the mass ratio of fluorine-containing polyimide to ITO is 9:1, and ultrasonically vibrate for 20 minutes to make a suspension turbid solution; then, cast the suspension o...

Embodiment 3

[0065] In this embodiment, the infrared low-emission composite film is composed of a fluorine-containing polyimide film and ITO, wherein the structural formula of the fluorine-containing polyimide is exactly the same as that of the fluorine-containing polyimide film in Example 1, and the ITO The crystal phase powder is dispersed in the fluorine-containing polyimide film-forming resin to form a multi-phase solid film; the mass ratio of fluorine-containing polyimide to ITO is 9.9:0.1.

[0066] The preparation method of above-mentioned composite film is as follows:

[0067] (1) Using the preparation method in Example 1 to prepare a fluorine-containing polyimide film;

[0068] (2) Dissolve 8g of fluorine-containing polyimide in 150mL of DMAc organic solvent, add ITO to the obtained clear liquid, in which the mass ratio of fluorine-containing polyimide to ITO is 9.9:0.1, and oscillate ultrasonically for 20 minutes to make a suspension liquid; then, cast the suspension on a glass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com