Temperature controlled focal plane detector mechanism

A technology of detectors and temperature focal surfaces, applied in the direction of instruments, temperature control, non-electric variable control, etc., can solve problems such as unsatisfactory, achieve the effects of reducing pollution, high reliability, and reducing heat conduction and heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

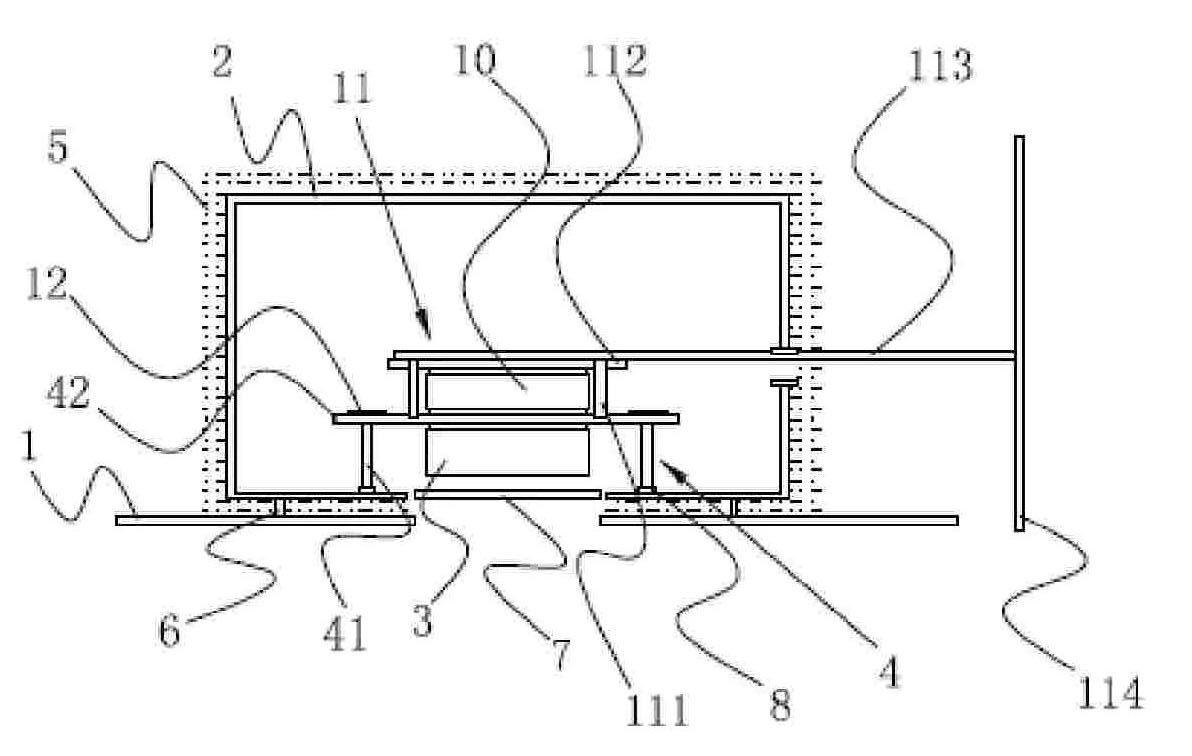

[0024] The present invention is described in detail below in conjunction with accompanying drawing, as figure 1 Shown:

[0025] The temperature-controllable focal plane detector mechanism includes a housing 1, a chassis 2, a detector 3 and a detector mounting seat 4. The inner surface of the housing 1 can be gold-plated or aluminum-plated, which can reduce radiation heat leakage and Infrared emissivity;

[0026] The outer shell 1 is provided with a heat insulating material 5, which is a multi-layer heat insulating material or a foam heat insulating material, which reduces the impact on the surrounding environment; the chassis 2 is fixed in the shell 1, and the 1. It is fixedly connected through the heat insulation pad 6; the light inlet of the chassis is provided with a transparent observation window 7 corresponding to the observation position of the detector, so that the surface of the detector is affected by frost, fog and pollution when it is cooled, so that the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com