Precise thermal control mechanism of focal plane detector

A detector and thermal control technology, which is applied in the direction of instruments, temperature control, non-electric variable control, etc., can solve the problems that the thermal control mechanism of the focal plane detector cannot meet the temperature, switch rapidly, and cannot meet the work requirements, etc., and achieve the speed of action Fast, precise temperature control, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

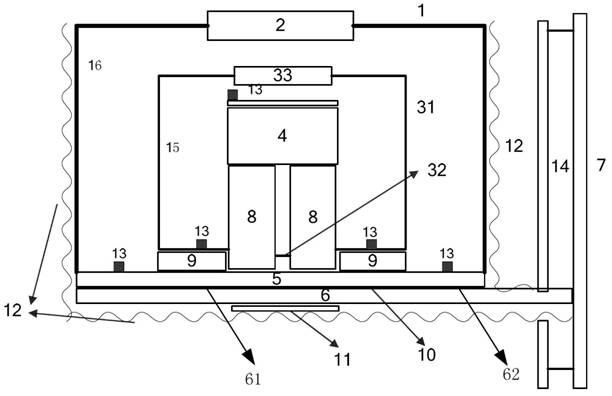

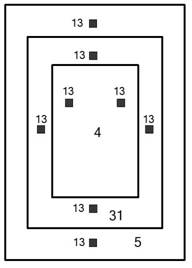

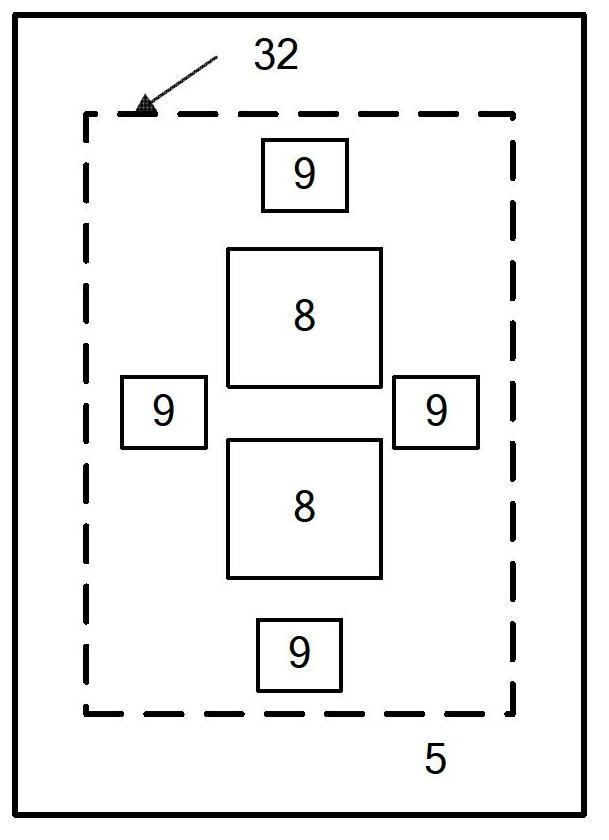

[0037] A focal plane detector precision thermal control mechanism, including a vacuum box 1, a vacuum window glass 2, a cold shield assembly 3 (including a cold shield cover 31, a cold shield bottom plate 32 and a window glass 33), a detector, and a refrigerator substrate 5 , heat pipe assembly 6, heat dissipation plate 7, detector cooler 8, cold screen cooler 9, substrate film heater 10, heat pipe film heater 11, multi-layer insulation material 12, temperature sensor 13, environment boundary 14 where the mechanism is located ,

[0038] The outside of the vacuum box 1 is provided with a heat insulating layer 12, the heat insulating material is a multi-layer heat insulating material or a foam heat insulating material, the vacuum housing 1 is fixedly connected with the refrigerator substrate 6 to form a closed cavity, and the detection assembly and The cooling assembly is set in a closed cavity,

[0039] Vacuumizing is implemented in the airtight cavity; a sealed heat insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com