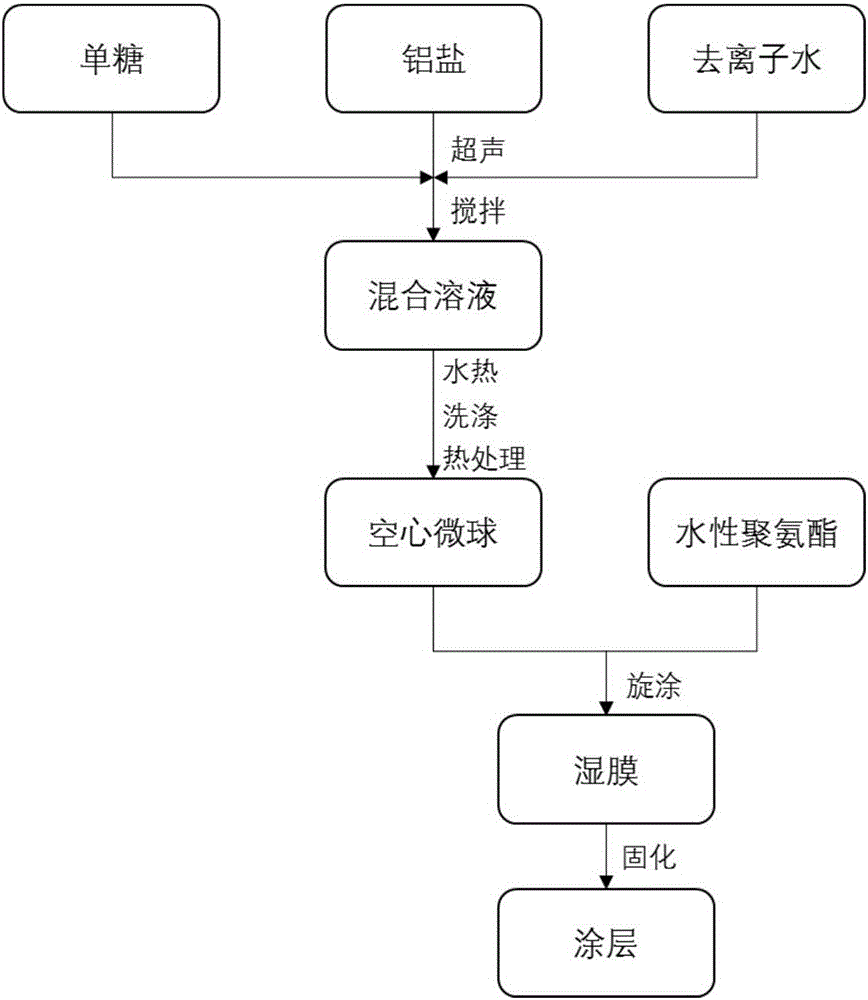

Preparation method of hollow aluminum oxide ceramic microsphere modified polyurethane coating

A hollow alumina, polyurethane coating technology, used in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of mechanical performance failure of coatings, environmental pollution, poor water resistance, etc. The effect of simple process and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] Weigh 2gAl(NO 3 ) 3 9H 2 0. 5g of glucose was added to 70ml of deionized water, ultrasonicated for 10min, magnetically stirred for 10min, placed in a 100ml polytetrafluoroethylene reactor, and kept at 160°C for 24h; the resulting brown gelatinous liquid was washed with deionized water until The pH value of the solution is about 7, vacuum-dried at 80°C for 24 hours after vacuum filtration; put the obtained product into a high-temperature tube furnace, and sinter at 1200°C for 2 hours to obtain hollow alumina ceramic microspheres.

[0025] Take 0.01 g of hollow alumina ceramic microspheres and add them to 3.3 g of water-based polyurethane coating (solid content: 30%), high-speed dispersion at 6000 rpm for 1.5 h, and ultrasonic dispersion for 0.5 h. The resulting dispersion was coated with a spin coater at a low speed of 600r / min for 30s and a high speed of 1800r / min for 20s; the obtained wet film was placed in a va...

Embodiment 2

[0027] This embodiment includes the following steps:

[0028] Weigh 1gAl(NO 3 ) 3 9H 2 0. Mix 3 g of fructose, add to 70 ml of deionized water, ultrasonicate for 20 min, magnetically stir for 20 min, place in a 100 ml polytetrafluoroethylene reaction kettle, keep warm at 180°C for 22 h; wash the obtained brown gelatinous liquid with deionized water When the pH of the solution is about 7, vacuum-dry at 80°C for 24 hours after vacuum filtration; put the obtained product in a high-temperature tube furnace and sinter at 1300°C for 5 hours to obtain hollow alumina ceramic microspheres.

[0029] 0.1 g of hollow alumina ceramic microspheres were added to 3.3 g of water-based polyurethane coating (solid content: 30%), dispersed at a high speed of 3000 rpm for 1.5 h, and ultrasonically dispersed for 0.1 h. The resulting dispersion was coated with a spin coater at a low speed of 500r / min for 30s, and at a high speed of 2000r / min for 20s; the obtained wet film was placed in a vacuum d...

Embodiment 3

[0031] This embodiment includes the following steps:

[0032] (1) Weigh 4gAl(NO 3 ) 3 9H 2 O. Mix 10 g of fructose, add to 70 ml of deionized water, ultrasonicate for 60 min, magnetically stir for 60 min, place in a 100 ml polytetrafluoroethylene reaction kettle, keep warm at 220°C for 2 h; wash the obtained brown gelatinous liquid with deionized water When the pH value of the solution is about 7, vacuum-dry at 80°C for 24 hours after vacuum filtration; put the obtained product into a high-temperature tube furnace and sinter at 1500°C for 1 hour to obtain hollow alumina ceramic microspheres.

[0033] (2) Add 0.5 g of hollow alumina ceramic microspheres to 3.3 g of water-based polyurethane coating (solid content 30%), disperse at high speed at 6000 rpm for 1 h, and disperse with ultrasonic for 1 h. The resulting dispersion was coated with a spin coater at a low speed of 800r / min for 20s, and at a high speed of 2000r / min for 5s; the obtained wet film was placed in a vacuum dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com