Antistatic artificial lawn and preparation method thereof

An artificial turf and antistatic technology, applied in the manufacture of conductive/antistatic filaments, one-component polyolefin artificial filaments, one-component polyamide artificial filaments, etc., can solve the problems affecting the movement and comfort of artificial turf , Restricting the promotion and use of artificial turf, unable to maintain the antistatic effect, etc., to achieve a huge specific surface area, good weather resistance, and long-lasting excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

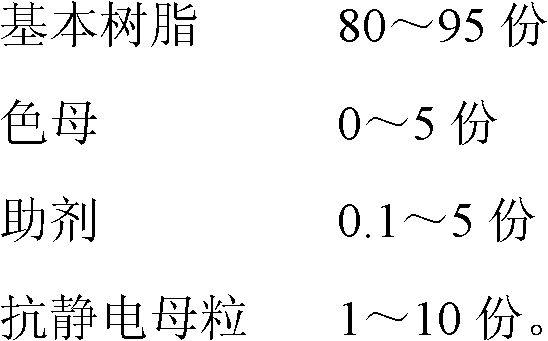

Method used

Image

Examples

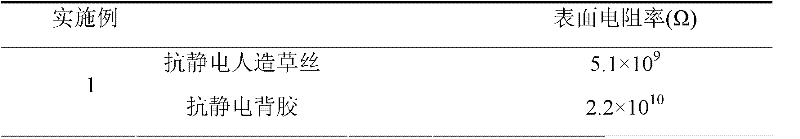

Embodiment 1

[0032] Preparation of antistatic masterbatch:

[0033] Mix 5kg of polyethylene, 2kg of ATO, 2kg of antistatic agent, and 1kg of auxiliary agent (including 0.3kg of ultraviolet light stabilizer, 0.3kg of antioxidant, 0.2kg of anti-blocking agent, and 0.2kg of dispersant), and mix them uniformly on a twin-screw extruder. Granulation, the temperature is controlled at 165°C; preparation of antistatic artificial turf:

[0034] Polyethylene 90kg, color masterbatch 4kg, auxiliary agent 1kg (wherein ultraviolet light stabilizer 0.2kg, antioxidant 0.2kg, opening agent 0.3kg, dispersant 0.3kg), antistatic masterbatch 5kg blending extrusion molding, prepare antistatic Electrostatic straw, the extrusion molding temperature is 200kg, the total draw ratio is 5.2, and the oven temperature is 95°C;

[0035] Preparation of antistatic adhesive:

[0036] Stir and mix 50kg of styrene-butadiene latex, 50kg of calcium carbonate, 1kg of carbon nanotubes, and 1kg of superconducting carbon black;

...

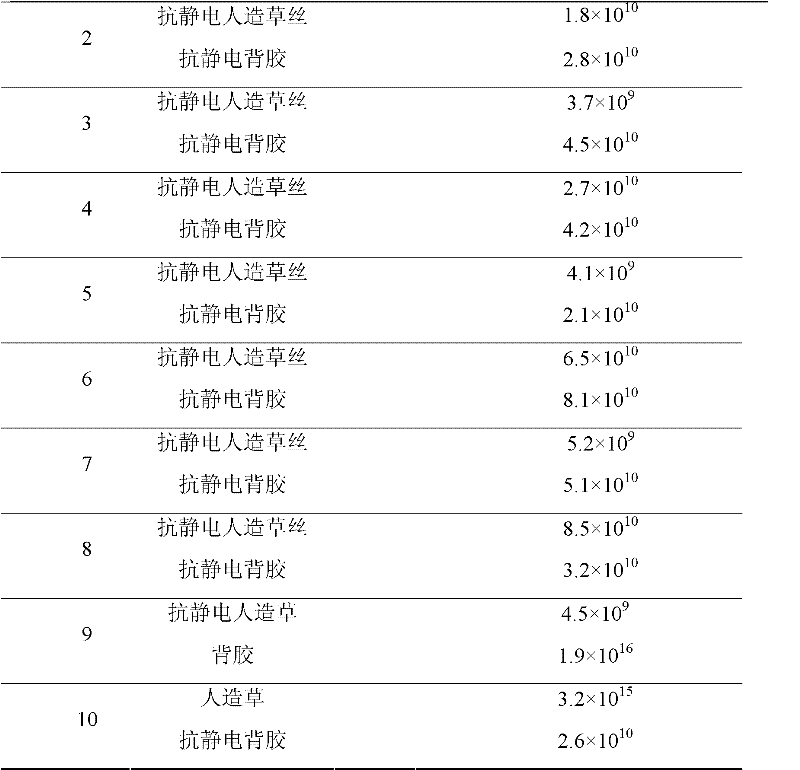

Embodiment 2

[0039] Preparation of antistatic masterbatch:

[0040] 5kg of polyethylene, 2kg of nano-conductive mica, 2kg of antistatic agent, and 1kg of auxiliary agent (including 0.2kg of ultraviolet light stabilizer, 0.2kg of antioxidant, 0.3kg of anti-blocking agent, and 0.3kg of dispersant) were mixed evenly, and then extruded in a twin-screw Granulate on the machine, the temperature is controlled at 165°C;

[0041] Antistatic artificial turf preparation:

[0042] Polyethylene 90kg, color masterbatch 4kg, auxiliary agent 1kg (wherein ultraviolet light stabilizer 0.2kg, antioxidant 0.2kg, opening agent 0.3kg, dispersant 0.3kg), antistatic masterbatch 5kg blending extrusion molding, prepare antistatic Electrostatic grass silk, the extrusion molding temperature is 210kg, the total draw ratio is 5.1, and the oven temperature is 95°C;

[0043] Preparation of antistatic adhesive:

[0044] Stir and mix 50kg of styrene-butadiene latex, 50kg of calcium carbonate, 0.5kg of conductive carbon ...

Embodiment 3

[0047] Preparation of antistatic masterbatch:

[0048] Mix polyethylene 5kg, ATO 1kg, nano conductive mica 1kg, antistatic agent 2kg, auxiliary agent 1kg (wherein UV light stabilizer 0.2kg, antioxidant 0.2kg, blocking agent 0.3kg, dispersant 0.3kg) mix uniformly, in Granulate on a twin-screw extruder, the temperature is controlled at 165°C;

[0049] Antistatic artificial turf preparation:

[0050] Polyethylene 90kg, color masterbatch 4kg, auxiliary agent 1kg (wherein ultraviolet light stabilizer 0.3kg, antioxidant 0.2kg, opening agent 0.2kg, dispersant 0.3kg), antistatic masterbatch 5kg blending extrusion molding, prepare antistatic Electrostatic grass silk, the extrusion molding temperature is 210kg, the total draw ratio is 5.1, and the oven temperature is 95°C;

[0051] Preparation of antistatic adhesive:

[0052] Stir and mix 50kg of styrene-butadiene latex, 50kg of calcium carbonate, 0.5kg of carbon nanotubes, and 1.5kg of conductive carbon fiber; tuft grass silk, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com