An infrared-radar compatible stealth material and its preparation method

A stealth material and compatible technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve problems such as narrow radar absorption frequency band, high infrared emission rate, and weak interlayer bonding force. Achieve the effects of low maintenance and maintenance costs, excellent infrared stealth performance, and good radar stealth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

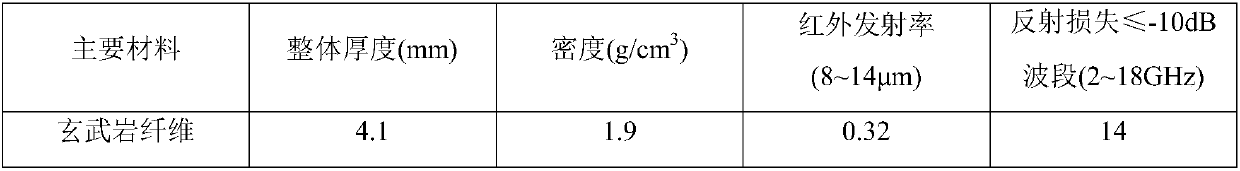

Embodiment 1

[0029] Low infrared emissivity layer: take inorganic phosphate binder, add 10% aluminum powder and mix well, prepare low infrared emissivity layer with 2 layers of basalt fiber checkered cloth as reinforcing material; control the low infrared emissivity layer The mass percentage of the reinforcing material is 45%~60%;

[0030] Radar wave-transmitting layer: use epoxy resin as the matrix material and two-layer basalt fiber checkered cloth as the reinforcing material to prepare the radar wave-transmitting layer prepreg; control the mass percentage of the reinforcing material of this layer to 50%~70%;

[0031] Radar absorbing layer: The basalt fiber roving is washed with acetone to remove the sizing agent on the surface, dried and activated by reaction with nitrile-based resin, and then magnetic nano Fe is added 3 O 4 The powder reaction makes the surface of the basalt fiber graft a large amount of absorbing functional materials to obtain a radar absorbing layer; control the mass perce...

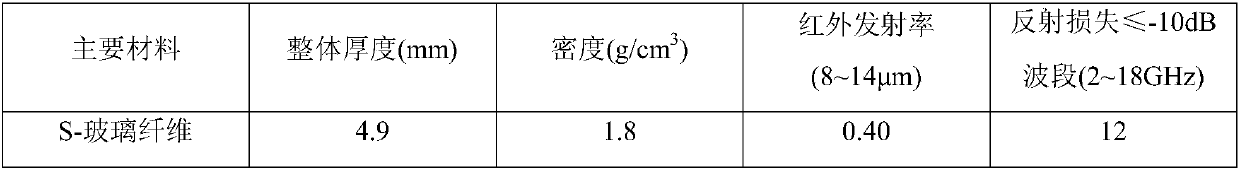

Embodiment 2

[0038] Low infrared emissivity layer: take inorganic phosphate binder, add 15% silver powder and mix well, prepare low infrared emissivity layer with 2 layers of S-glass fiber cloth as reinforcing material; control the low infrared emissivity layer The mass percentage of reinforcing material is 45%~60%;

[0039] Radar wave-transmitting layer: take epoxy resin as the matrix material and use 3 layers of S-glass fiber cloth as the reinforcement material to prepare the radar wave-transmitting layer prepreg; control the mass percentage of the reinforcement material of this layer to 50%~70%;

[0040] Radar absorbing layer: the basalt fiber roving is washed with ethanol to remove the sizing agent on the surface, dried and activated by reaction with nitrile-based resin, and then magnetic nano Fe is added 3 O 4 The powder reaction makes the surface of the basalt fiber graft a large amount of absorbing functional materials to obtain a radar absorbing layer; control the mass percentage of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com