Titanium alloy surface composite coating and preparation method and application thereof

A surface compounding and titanium alloy technology, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems that cannot meet the composite functions of flame retardancy, heat insulation and infrared stealth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

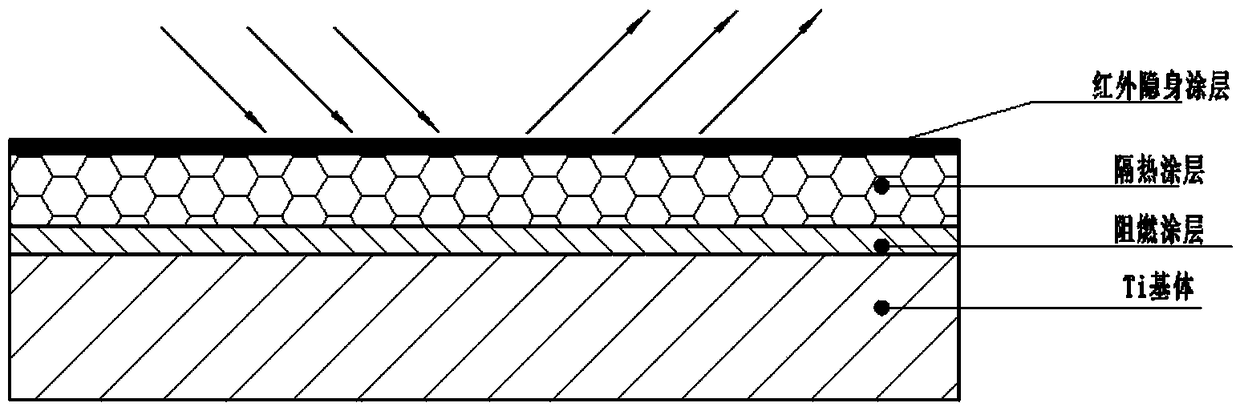

[0036] The present invention also provides a preparation method of the titanium alloy surface composite coating, comprising the following steps:

[0037]Depositing Ti on the Surface of Titanium Alloy Substrate by Electrospark Deposition 40 Zr 25 Ni 3 Cu 12 be 20 , forming a flame retardant coating;

[0038] Adopt plasma spraying method to spray ZrO on the surface of the flame retardant coating 2 -Y 2 o 3 , forming a thermal insulation coating;

[0039] A diamond-like DLC coating is prepared on the surface of the heat-shielding coating by a plasma-enhanced chemical vapor deposition method, and used as an infrared stealth coating to obtain a titanium alloy surface composite coating.

[0040] The present invention adopts electric spark deposition method to deposit Ti on the surface of titanium alloy matrix 40 Zr 25 Ni 3 Cu 12 be 20 , forming a flame retardant coating. In the present invention, it is preferable to use alcohol to clean the surface of the titanium allo...

Embodiment 1

[0067] Clean the titanium alloy surface with alcohol in an ultrasonic cleaning pool, wash for 5 minutes and then blow dry;

[0068] Deposition of Ti on Titanium Alloy Surface by Electrospark Deposition 40 Zr 25 Ni 3 Cu 12 be 20 , forming a flame-retardant coating with a thickness of 0.15mm, the deposition process is carried out in an argon atmosphere, the flow rate of argon is 20L / min, and the voltage is set to 60V, the frequency is 2KHz, and the discharge capacitance is from 40μF, 80μF, 120μF increases step by step, and then decreases step by step, the deposition time is 5min / cm 2 ;

[0069] Obtain a flame-retardant coating and sandblast the flame-retardant coating to obtain a coating with a surface roughness of 6-8 μm, and spray Ni-22wt%Cr-6wt% with a thickness of 0.08mm by supersonic flame spraying Al-2wt%Y transition coating; in the process of supersonic flame spraying, the base material is Ni-22wt%Cr-6wt%Al-2wt%Y; the fuel is kerosene, the flow rate of kerosene is c...

Embodiment 2

[0082] Clean the titanium alloy surface with alcohol in an ultrasonic cleaning pool, wash for 5 minutes and then blow dry;

[0083] Deposition of Ti on Titanium Alloy Surface by Electrospark Deposition 40 Zr 25 Ni 3 Cu 12 be 20 , forming a flame-retardant coating with a thickness of 0.1mm, the deposition process is carried out in an argon atmosphere, the flow rate of argon is 20L / min, and the voltage is set to 60V, the frequency is 2KHz, and the discharge capacitance is from 40μF to 80μF , 120μF increases step by step, and then decreases to 40μF step by step, the specific deposition time is 5min / cm 2 ;

[0084] Obtain a flame-retardant coating and sandblast the flame-retardant coating to obtain a coating with a surface roughness of 6-8 μm, and spray Ni-22wt%Cr-6wt% Ni-22wt%Cr-6wt% with a thickness of 0.10mm by a supersonic flame spraying method Al-2wt%Y transition coating; in the supersonic flame spraying process, the matrix material is Ni-22wt%Cr-6wt%Al-2wt%Y; the fuel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com