Method for coating infrared stealth coating on object surface coated with radar absorbing coating

A wave-absorbing coating and object surface technology, applied in coatings, polyester coatings, epoxy resin coatings, etc., can solve problems such as radar compatibility effects, high radar wave reflectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

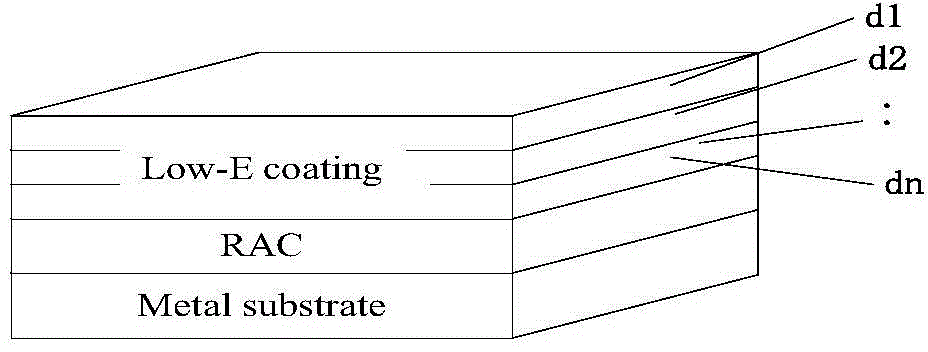

Method used

Image

Examples

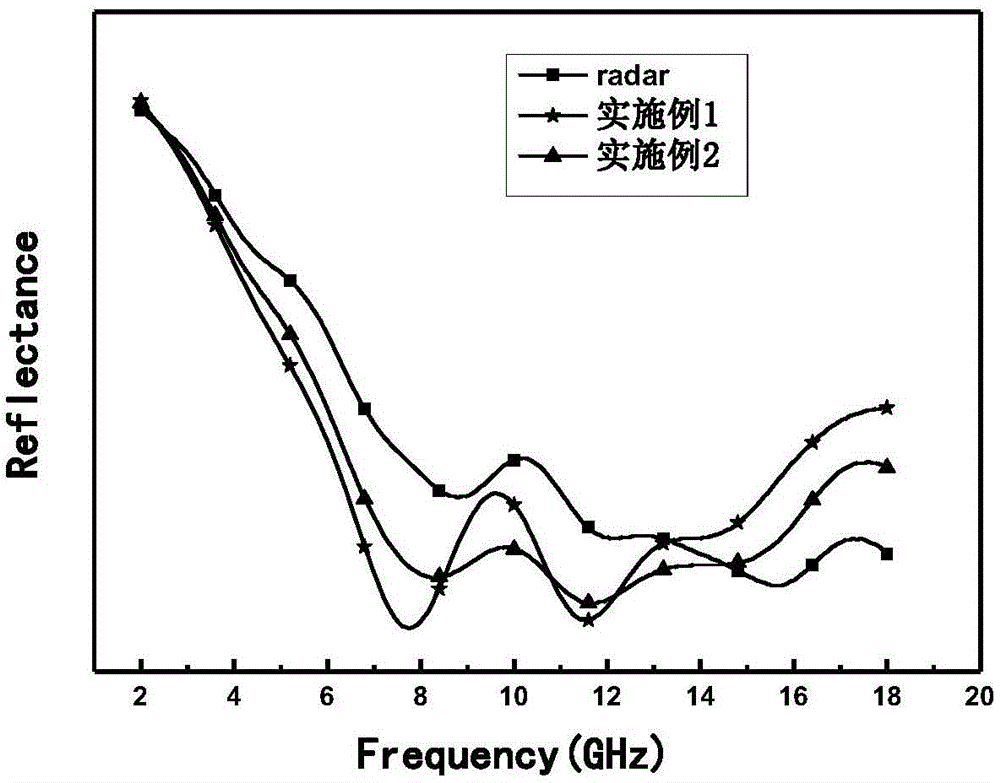

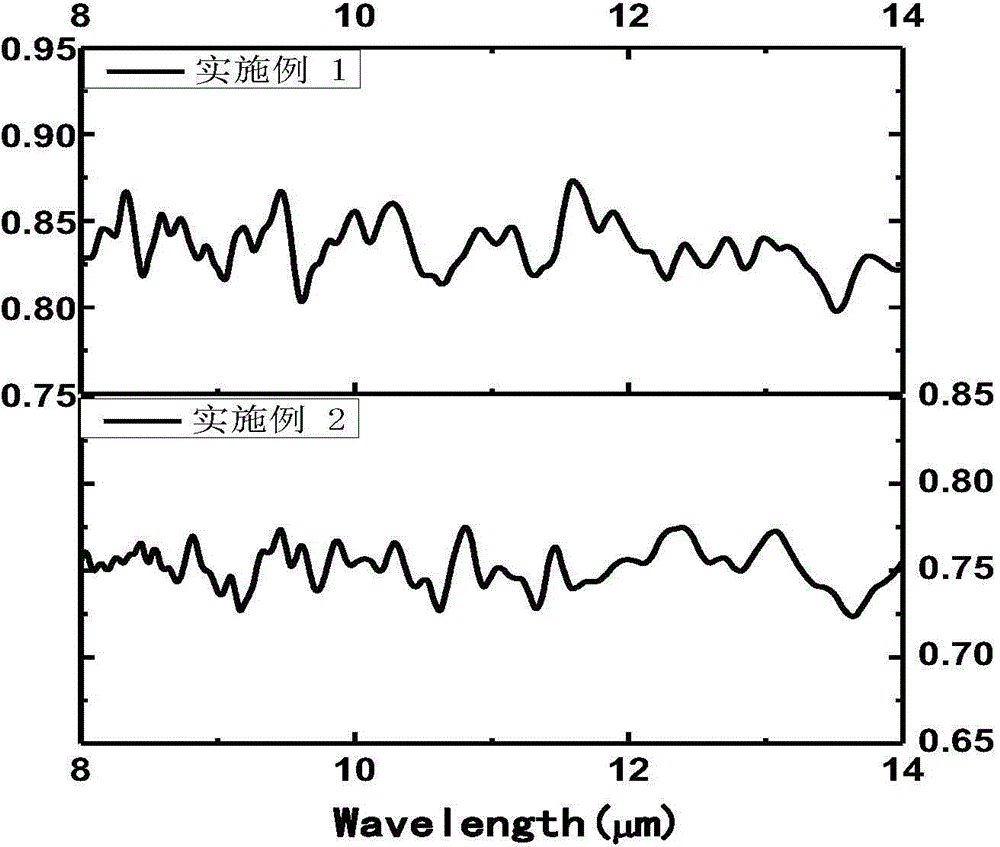

Embodiment 1

[0029] In this embodiment, the sample size of the radar absorbing coating is 3m*5m, the average diameter of the flake aluminum powder used is about 25 microns, the total metal pigment content of the control coating is 100%, and the metal with three-layer structure is selected. The powder content is respectively 50%, 100%, and 150% of the infrared coating from the inner layer to the outer layer, and the thickness of each layer is 18 μm, 18 μm, and 18 μm.

[0030] First prepare the coating: take 5kg of polyurethane resin and 6kg of ethyl acetate, mix and stir evenly to prepare the carrier, weigh 4.4kg, 4kg, and 3.5kg of the carrier from the inner layer to the outer layer of the paint for use; Weigh 1kg, 1.8kg, and 2.4kg of flake aluminum powder to the outer coating for use; weigh 2kg, 1.8kg, and 1.6kg of curing agent for the inner to outer coating respectively. Then paint spraying: first clean the surface of the model, starting from the inner layer, mix and stir the weighed carr...

Embodiment 2

[0033] In this embodiment, the sample size of the radar absorbing coating is 3m*5m, the average diameter of the flake aluminum powder used is about 8 microns, the total metal pigment content of the control coating is 95%, and the metal with four-layer structure is selected. The powder content is 50%, 75%, 100%, and 125% of the infrared coating from the inner layer to the outer layer, and the thickness of each layer is 10 μm, 10 μm, 10 μm, and 20 μm.

[0034] First prepare the coating: take 5kg of polyurethane resin and 6kg of ethyl acetate, mix and stir evenly to obtain a carrier, and weigh 2.64kg, 2.42kg, 1.98kg, and 3.87kg of carriers for the coating from the inner layer to the outer layer for use; Weigh 0.6kg, 0.83kg, 0.9kg, and 2.2kg of flake aluminum powder for use from the inner layer to the outer layer of the coating; weigh 1.2kg, 1.1kg, 0.9kg, and 1.76kg of curing agent is ready for use. Then paint spraying: first clean the surface of the model, starting from the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com