High-performance multilayer composite solar selective absorption coating and preparation method thereof

A multi-layer composite, absorbing coating technology, applied in coatings, solar thermal devices, solar thermal power generation, etc., can solve the problems of low heat absorption efficiency and poor weather resistance, and achieve improved bonding force, improved heat absorption performance, and improved The effect of corrosion resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

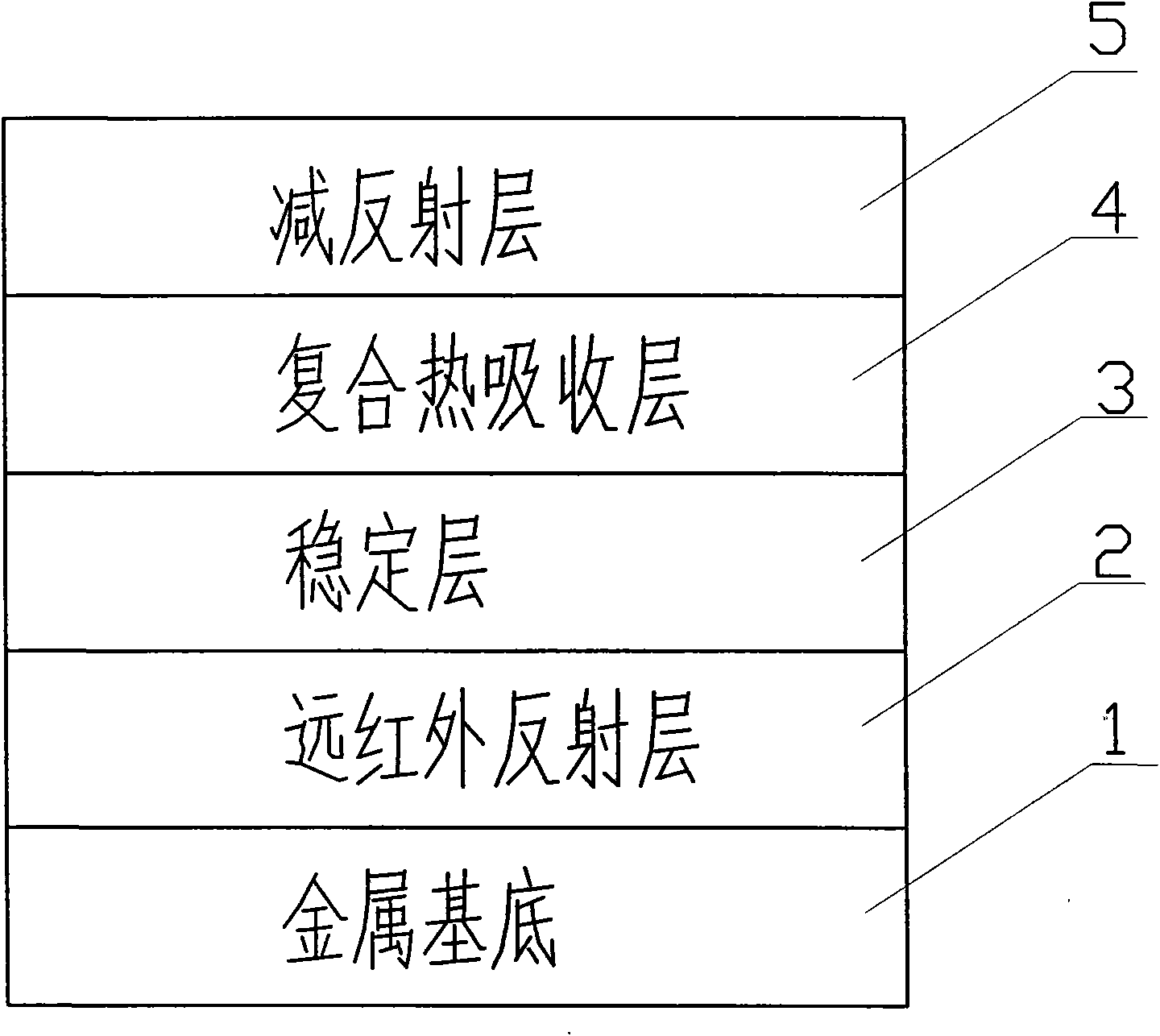

[0028] Embodiment 1: a kind of high-performance multi-layer composite solar selective absorbing coating comprises that far-infrared reflection layer 2, composite heat absorption layer 4 and anti-oxidation and anti-reflection layer 5 are arranged on substrate 1 in sequence, far-infrared reflection Layer 2 is an Al layer deposited on the substrate 1 by sputtering; the composite heat absorbing layer 4 is a TiNOx layer deposited on the far-infrared reflective layer 2 by sputtering, and the anti-oxidation and anti-reflection layer 5 is deposited on the composite heat absorbing layer by sputtering SiO on 4 2 layer. The substrate 1 is phosphorus deoxidized copper strip or oxygen-free copper strip or aluminum strip. The thickness of the far-infrared reflective layer 2 is 100-120 nm. The thickness of the composite thermal coefficient layer 4 is 100-120 nm. The thickness of the anti-oxidation and anti-reflection layer 5 is 60-70 nm.

Embodiment 2

[0029] Embodiment 2: A kind of high-performance multi-layer composite solar selective absorbing coating comprises that far-infrared reflection layer 2, composite heat absorption layer 4 and anti-oxidation and anti-reflection layer 5 are arranged on substrate 1 in sequence, far-infrared reflection Layer 2 is an Al layer deposited on the substrate 1 by sputtering; the composite heat absorbing layer 4 is a TiNOx layer deposited on the far-infrared reflective layer 2 by sputtering, and the anti-oxidation and anti-reflection layer 5 is deposited on the composite heat absorbing layer by sputtering SiO on 4 2layer. The substrate 1 is phosphorus deoxidized copper strip or oxygen-free copper strip or aluminum strip. The thickness of the far-infrared reflective layer 2 is 120-170 nm. The thickness of the composite thermal coefficient layer 4 is 120-170 nm. The thickness of the anti-oxidation and anti-reflection layer 5 is 70-90 nm.

Embodiment 3

[0030] Embodiment 3: a kind of high-performance multi-layer composite solar selective absorbing coating, comprises and is provided with far-infrared reflecting layer 2, composite heat-absorbing layer 4 and anti-oxidation and anti-reflection layer 5 in sequence on substrate 1, far-infrared reflecting Layer 2 is an Al layer deposited on the substrate 1 by sputtering; the composite heat absorbing layer 4 is a TiNOx layer deposited on the far-infrared reflective layer 2 by sputtering, and the anti-oxidation and anti-reflection layer 5 is deposited on the composite heat absorbing layer by sputtering SiO on 4 2 layer. The substrate 1 is phosphorus deoxidized copper strip or oxygen-free copper strip or aluminum strip. The thickness of the far-infrared reflective layer 2 is 170-200 nm. The thickness of the composite thermal coefficient layer 4 is 170-200 nm. The thickness of the anti-oxidation and anti-reflection layer 5 is 90-100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com