Preparation method of infrared stealth textile coating fabric

A fabric and coating technology, applied in the field of infrared stealth fabric coating fabrics, can solve the problems of poor comprehensive performance of infrared stealth fabrics, low infrared emissivity mechanical properties, etc., achieve strong tear resistance, good stealth effect, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing an infrared stealth fabric coated fabric, characterized in that: a printing layer, a surface layer, a heat insulation layer, an adhesive layer and a base cloth layer are bonded together, and the specific steps are as follows:

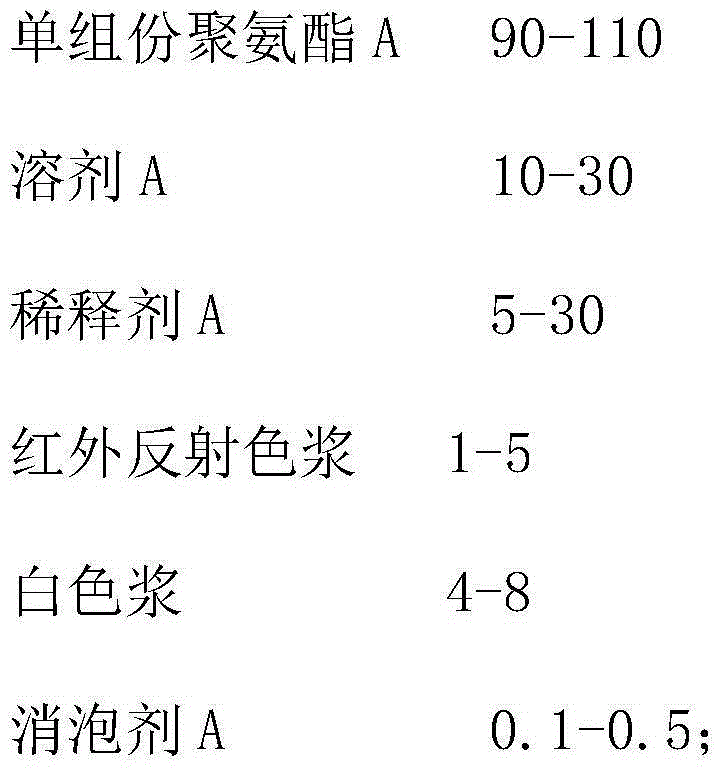

[0047] Step 1. Use the scraper of the coating machine to scrape the surface layer on the release paper, the distance between the scraper and the release paper is 0.15-0.3mm, dry in an oven, and the drying temperature is 80- 140°C, after drying, cool to below 50°C; the surface layer is composed of the following components in parts by weight:

[0048]

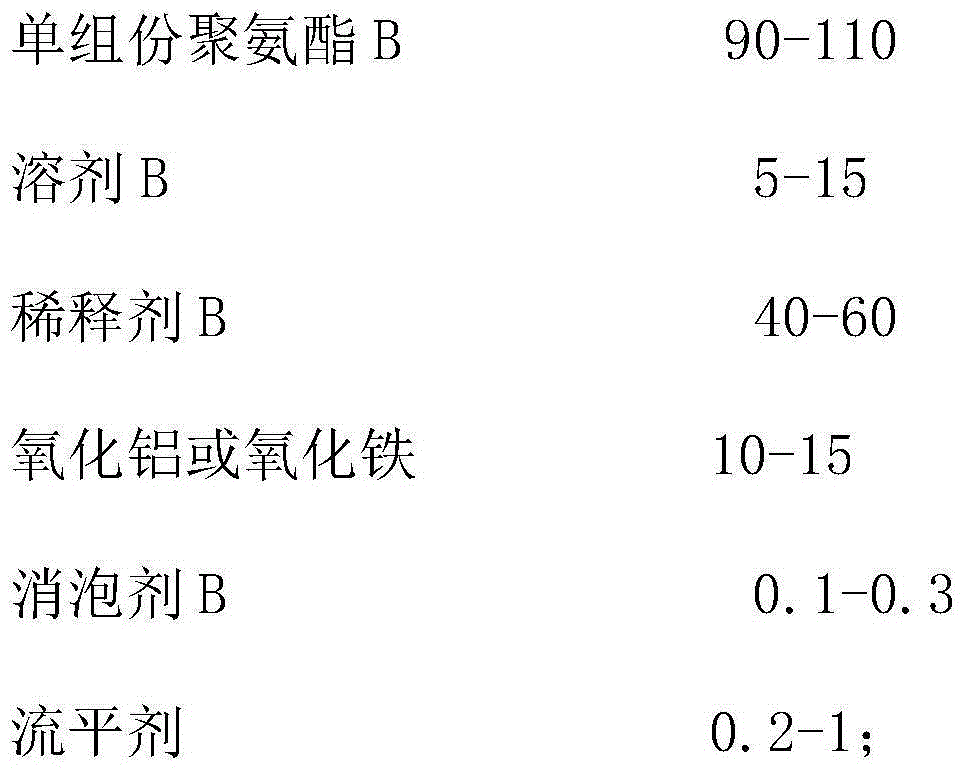

[0049]

[0050] Wherein, the 100% modulus of the one-component polyurethane B is 55-60kg / cm 2 , the viscosity at 30°C is 30,000-150,000CPS, the molecular weight is 100,000-300,000, the solid content is 30%-35%, and the alumina is flake-shaped with a particle size of 5-50um.

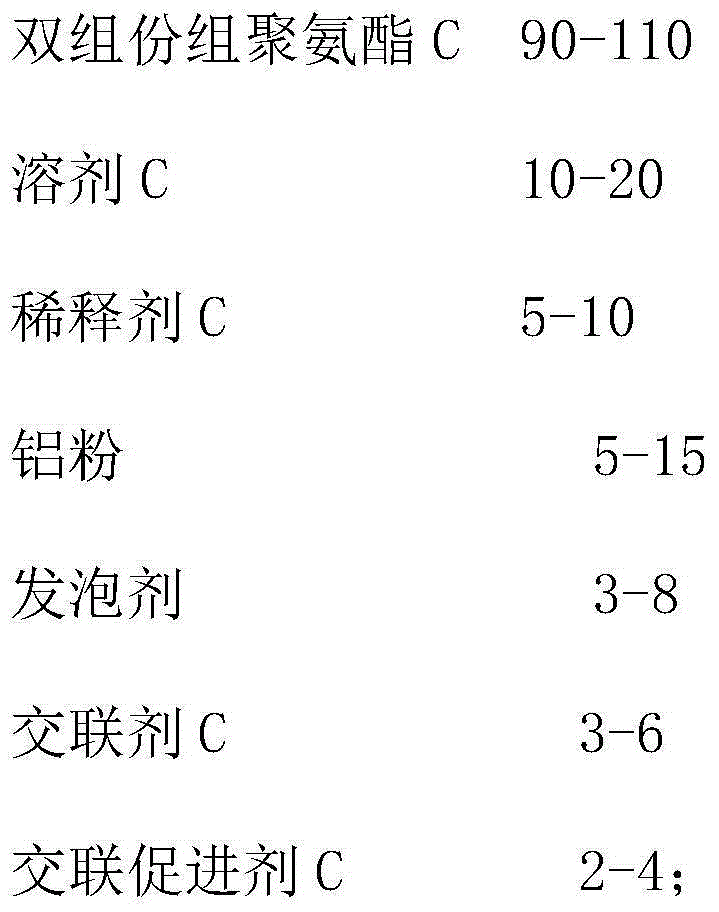

[0051] Step 2. Use the scraper of the coating machine to scrape the heat insulation layer on th...

Embodiment 2

[0064] A method for preparing an infrared stealth fabric coated fabric, comprising bonding a printing layer, a surface layer, a heat insulation layer, an adhesive layer and a base cloth layer together, and the specific steps are as follows:

[0065] Step 1. Use the scraper of the coating machine to scrape the surface layer on the release paper, the distance between the scraper and the release paper is 0.15-0.3mm, dry in an oven, and the drying temperature is 80- 140°C, after drying, cool to below 50°C; the surface layer is composed of the following components in parts by weight:

[0066]

[0067] Wherein, the 100% modulus of the one-component polyurethane B is 65-70kg / cm 2 , the viscosity at 30°C is 30000-150000CPS, the molecular weight is 100000-300000, the solid content is 25%-35%, the iron oxide is flake-shaped, and the particle size is 25-30um.

[0068] Step 2. Use the scraper of the coating machine to scrape the heat insulation layer on the surface layer, the distance...

Embodiment 3

[0080] A method for preparing an infrared stealth fabric coated fabric, comprising bonding a printing layer, a surface layer, a heat insulation layer, an adhesive layer and a base cloth layer together, and the specific steps are as follows:

[0081] Step 1. Use the scraper of the coating machine to scrape the surface layer on the release paper, the distance between the scraper and the release paper is 0.15-0.3mm, dry in an oven, and the drying temperature is 80- 140°C, after drying, cool to below 50°C; the surface layer is composed of the following components in parts by weight:

[0082]

[0083] Wherein, the 100% modulus of the one-component polyurethane B is 55-60kg / cm 2 , the viscosity at 30°C is 80000-150000CPS, the molecular weight is 200000-300000, the solid content is 45%-50%, and the aluminum oxide is flake-shaped with a particle size of 35-45um.

[0084] Step 2. Use the scraper of the coating machine to scrape the heat insulation layer on the surface layer, the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| 100% modulus | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com