Radar and infrared compatible stealthy material and preparation method thereof

A stealth material, radar technology, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of adverse effects of radar wave absorption performance, difficult to control dielectric properties, high infrared emissivity, and easy to scale Production and application, solve the effect of poor compatibility and mature preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

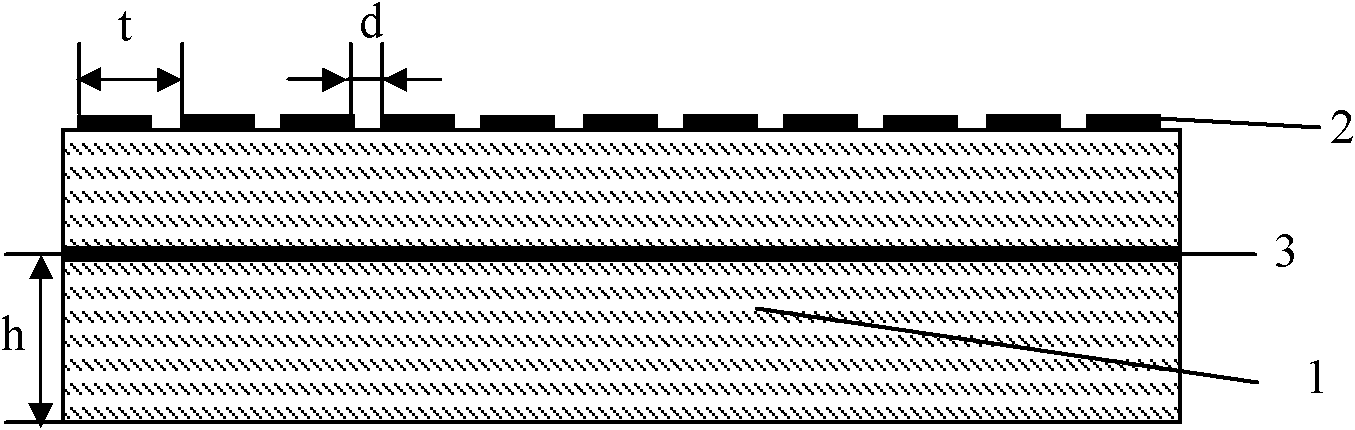

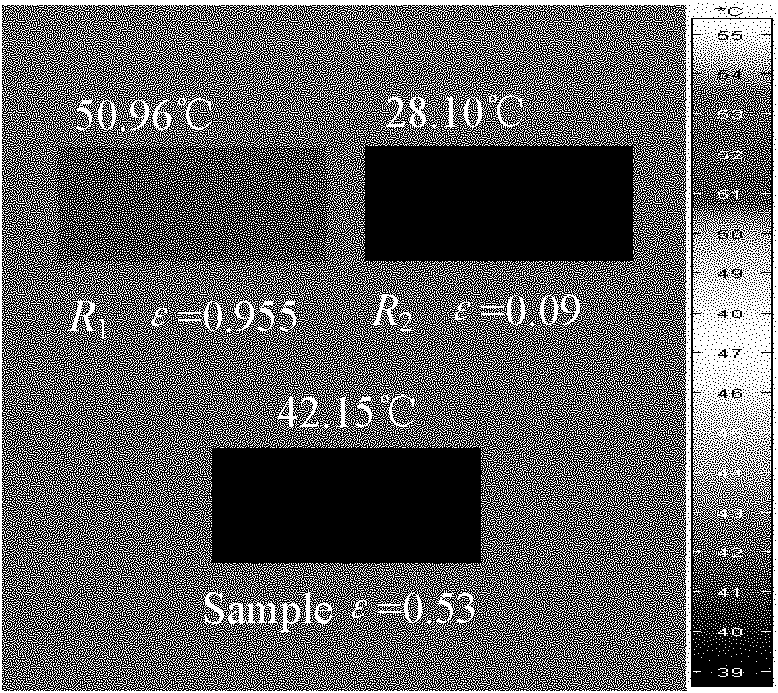

[0024] a kind of like figure 1 The radar and infrared compatible stealth material of the present invention shown is mainly composed of a radar absorbing structure layer 1 and an infrared stealth function layer 2. The radar absorbing structure layer 1 is made of glass fiber-reinforced FRP composite material. to make. The middle part of the radar absorbing structure layer 1 is provided with a layer of resistive sheet 3, and the square resistance of the resistive sheet 3 is 120Ω / □, and the dielectric constant of the radar absorbing structural layer 1 thus formed is 4; The thickness is 5 mm, and the distance h between the resistor sheet 3 and the bottom layer of the radar absorbing structure layer 1 is 2.75 mm. The infrared stealth function layer 2 is a capacitive frequency selective surface. The corresponding unit period t of the capacitive frequency selective surface is 0.36 mm, the gap width d is 0.08 mm, and the infrared emissivity of the capacitive frequency selective surfa...

Embodiment 2

[0035] a kind of like figure 1 The radar and infrared compatible stealth material of the present invention shown is mainly composed of a radar absorbing structure layer 1 and an infrared stealth function layer 2. The radar absorbing structure layer 1 is made of glass fiber-reinforced FRP composite material. to make. The middle part of the radar absorbing structure layer 1 is provided with a layer of resistive sheet 3, the square resistance of the resistive sheet 3 is 130Ω / □, the dielectric constant of the radar absorbing structure layer 1 thus formed is 4.5; The thickness is 5.5 mm, and the distance h between the resistor sheet 3 and the bottom layer of the radar absorbing structure layer 1 is 3.3 mm. The infrared stealth function layer 2 is a capacitive frequency selective surface. The corresponding unit period t of the capacitive frequency selective surface is 0.8 mm, the gap width d is 0.08 mm, and the infrared emissivity of the capacitive frequency selective surface is 0...

Embodiment 3

[0041] a kind of like figure 1The radar and infrared compatible stealth material of the present invention shown is mainly composed of a radar absorbing structure layer 1 and an infrared stealth function layer 2. The radar absorbing structure layer 1 is made of glass fiber-reinforced FRP composite material. to make. The middle part of the radar absorbing structure layer 1 is provided with a layer of resistive sheet 3, the square resistance of the resistive sheet 3 is 125Ω / □, the dielectric constant of the radar absorbing structure layer 1 thus formed is 5; The thickness is 4.5 mm, and the distance h between the resistor sheet 3 and the bottom layer of the radar absorbing structure layer 1 is 2.25 mm. The infrared stealth function layer 2 is a capacitive frequency selective surface. The corresponding unit period t of the capacitive frequency selective surface is 0.8 mm, the gap width d is 0.12 mm, and the infrared emissivity of the capacitive frequency selective surface is 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com