A kind of intelligent wave absorbing material and preparation method thereof

A wave-absorbing material and intelligent technology, applied in chemical instruments and methods, other chemical processes, electrical components, etc., can solve the problems of large material thickness, which are not mentioned in detail, and achieve high molding efficiency, low manufacturing cost, and good quality. Effects of oxidation resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

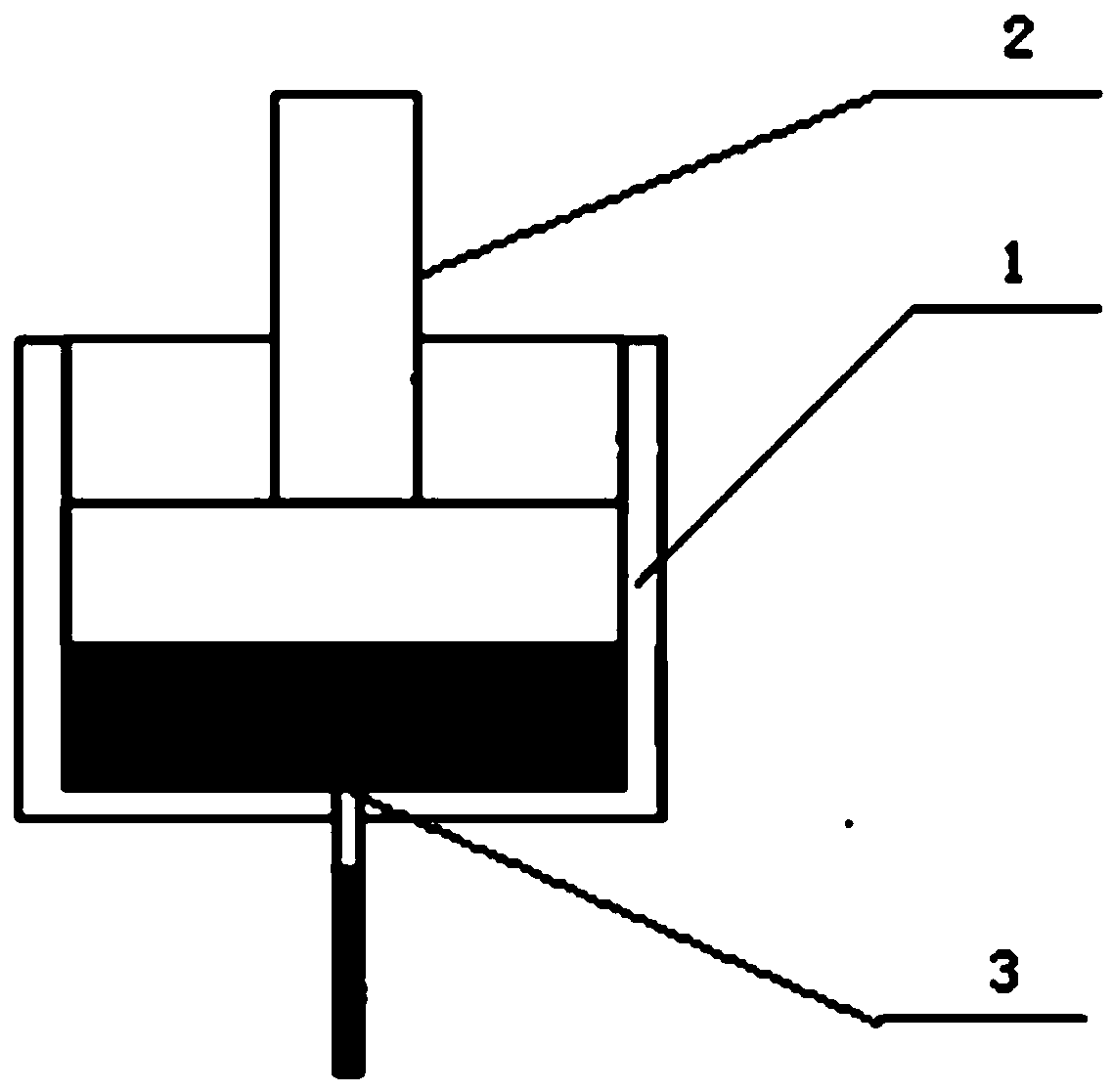

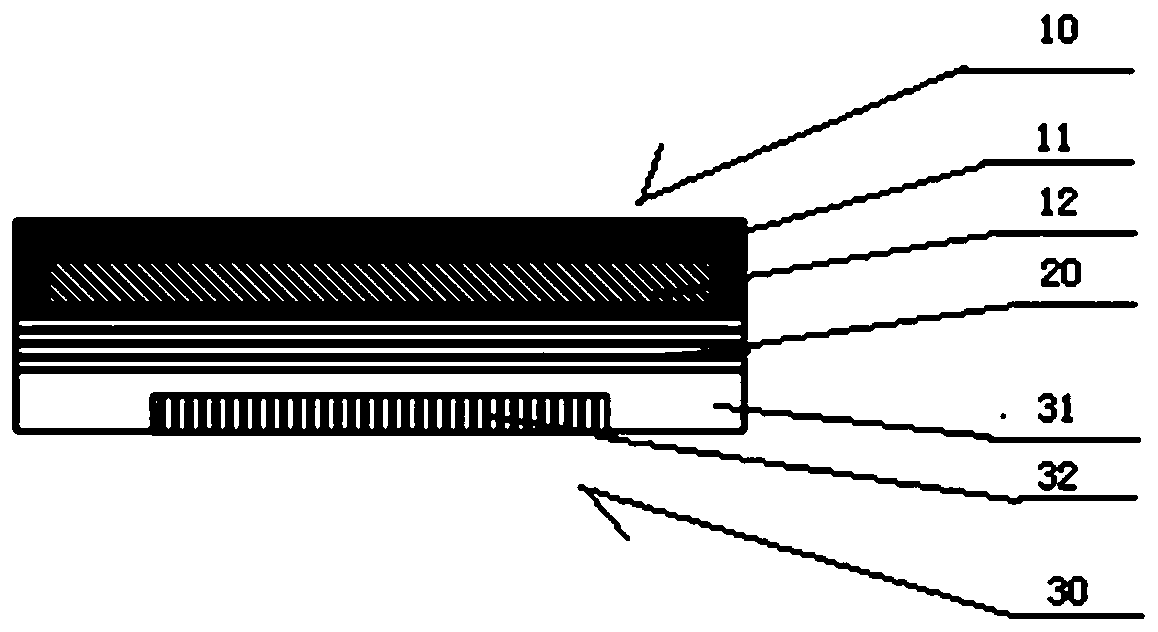

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

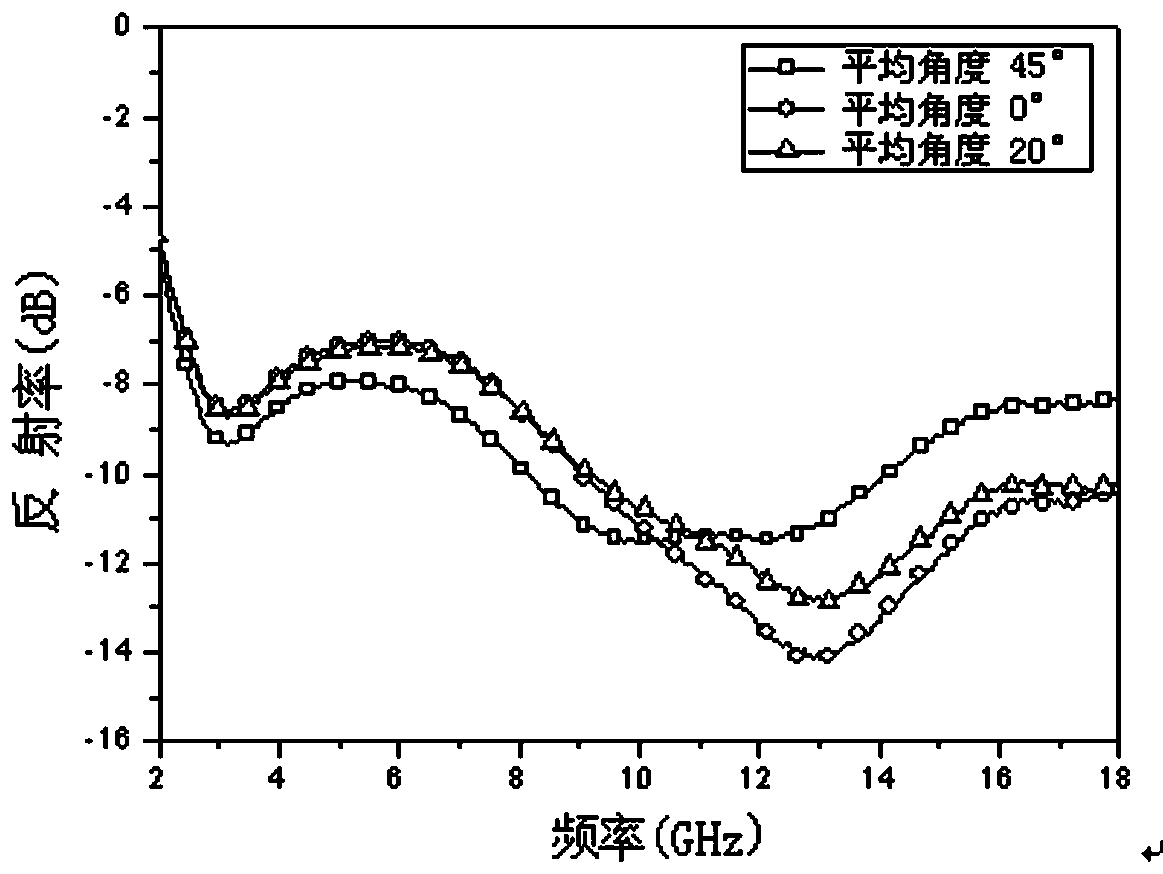

[0040] The intelligent wave-absorbing material provided by the present invention adjusts the wave-absorbing characteristics of the wave-absorbing material by integrating the characteristics of various wave-absorbing materials through the principle of electromagnetic matching design.

[0041] The invention proposes a wave-absorbing material design method combining frequency-divided design and manufacturing, and conducts preliminary design of the wave-absorbing material in a wide frequency band, and the actual manufacturing structure follows the principle of approximation. Then, aiming at the preparation process of the absorbing materials in the two frequency bands, a low-frequency band rubber rolling curing molding is proposed, while a high-frequency band cavity absorbing structure 3D molding process is combined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com